Tea polyphenol-acrylic acid series super absorbent resin and preparation method thereof

A super absorbent resin, acrylic technology, applied in the field of resin materials, can solve problems such as easy breeding of bacteria and lack of antibacterial properties, and achieve the effects of excellent water absorption, less residual monomers, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

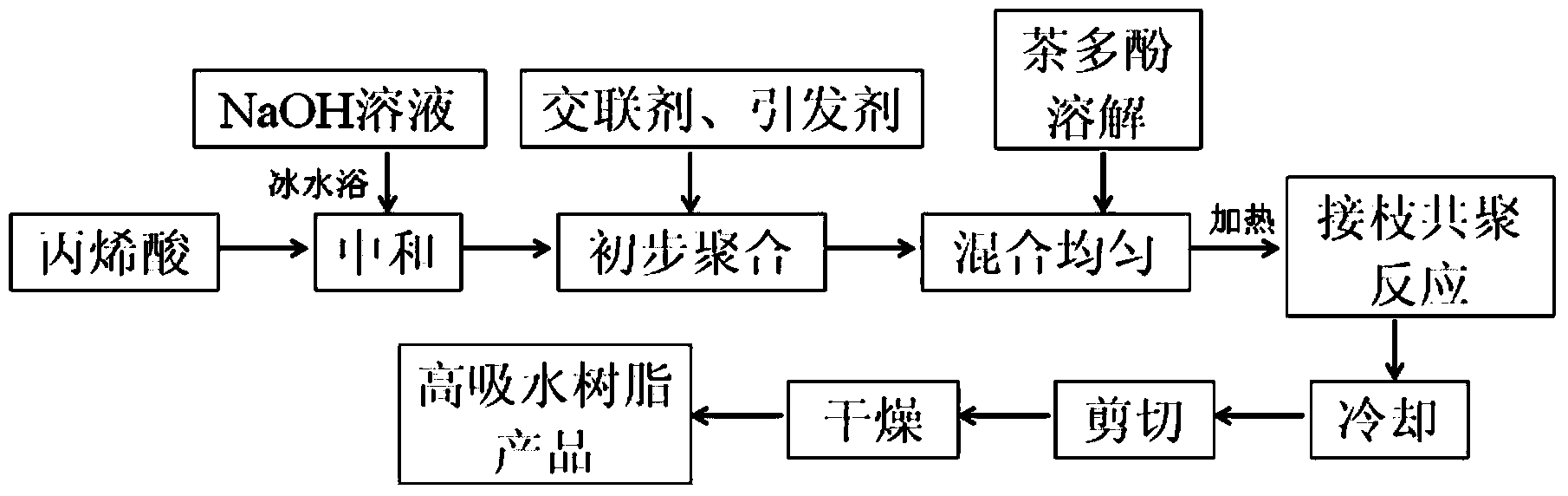

Method used

Image

Examples

Embodiment 1

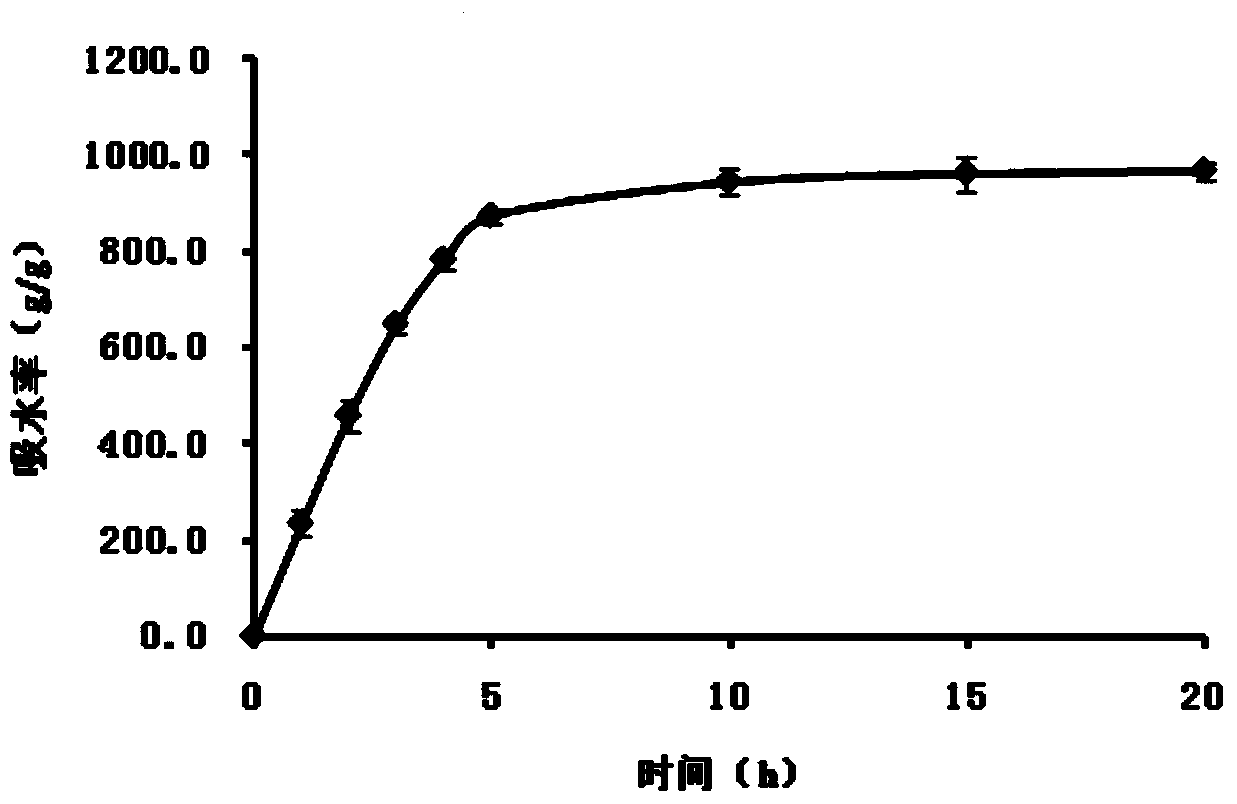

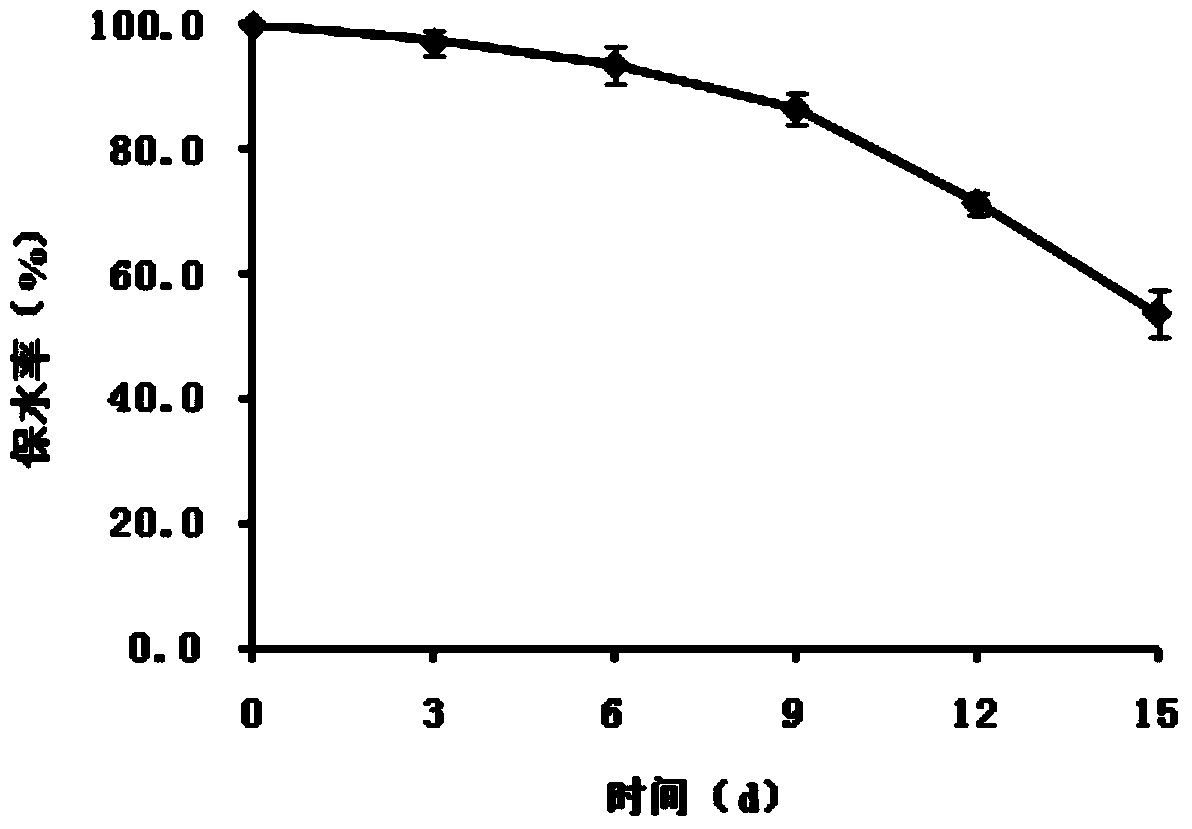

[0027] Accurately weigh 25.00g of NaOH and 100mL of distilled water to prepare a 25% NaOH solution, and neutralize it with 50g of acrylic acid in an ice-water bath and stirring. Weigh 0.01g of N,N'-methylenebisacrylamide, dissolve it in 20mL of distilled water to make an aqueous solution, add 20mL of N,N'-methylenebisacrylamide to the neutralized acrylic acid and its sodium salt solution aqueous solution, stirred for 5min, then added 0.07g K 2 S 2 o 8 Initiator, stirred until completely dissolved. Then add 10 mL of an aqueous solution in which 0.035 g of tea polyphenols is dissolved in the reaction system, stir and mix. The obtained mixed solution is placed in an oven, polymerized at 80°C for 2 hours, and the obtained transparent gel is cooled, sheared, and dried to obtain a granular superabsorbent resin with a water absorption rate of more than 950 times.

Embodiment 2

[0029] Accurately weigh 25.00g of NaOH and 100mL of distilled water to prepare a 25% NaOH solution, and neutralize it with 50g of acrylic acid in an ice-water bath and stirring. Weigh 0.025g of N,N'-methylenebisacrylamide, dissolve it in 30mL of distilled water to make an aqueous solution, add 30mL of N,N'-methylenebisacrylamide to the neutralized acrylic acid and its sodium salt aqueous solution aqueous solution, stirred for 10min, and then added 0.05g K 2 S 2 o 8 Initiator, stirred until completely dissolved. Then add 0.05 g of tea polyphenol powder into the reaction system, and stir until it dissolves. The obtained mixed solution is placed in an oven, and the gel is polymerized at 60°C for 5 hours. The obtained transparent gel is cooled, sheared, and dried to obtain a granular superabsorbent resin with a water absorption rate of more than 900 times.

Embodiment 3

[0031] Accurately weigh 25.00g of NaOH, measure 100mL of distilled water, prepare a 25% NaOH solution, and neutralize it with 50g of acrylic acid in an ice-water bath and stirring conditions. Weigh 0.05g N,N'-methylenebisacrylamide, dissolve it in 50mL distilled water to make an aqueous solution, add 50mL N,N'-methylenebisacrylamide to the solution of neutralized acrylic acid and its sodium salt aqueous solution, stirred for 5min, and then added 0.03g K 2 S 2 o 8 Initiator, stirred until completely dissolved. Then add 10 mL of an aqueous solution in which 0.025 g of tea polyphenols is dissolved in the reaction system, stir and mix. The obtained mixed solution is placed in an oven, and the gel is polymerized at 70°C for 3.5 hours. The obtained transparent gel is cooled, sheared, and dried to obtain a granular superabsorbent resin with a water absorption rate of more than 860 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com