Replaceable cutter blade and replaceable cutter

A cutting tool and blade technology, applied in the field of replaceable cutting tools, can solve the problems of high cutting resistance and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0095] Hereinafter, another example of the replaceable blade of the present invention is referred to as Embodiment 2, according to Figure 5 For description, the same or the same parts as the replaceable blade 1 of the first embodiment are described with the same symbols.

[0096] Figure 5 (a) is a top view of the replaceable blade in this embodiment, Figure 5 (b) is Figure 5 (a) The side view of the replaceable blade E1 direction shown, Figure 5 (c) is Figure 5 (a) The side view of the replaceable blade in the direction of F1, Figure 5 (d) is Figure 5 (a) Side view of the replaceable blade G1 direction.

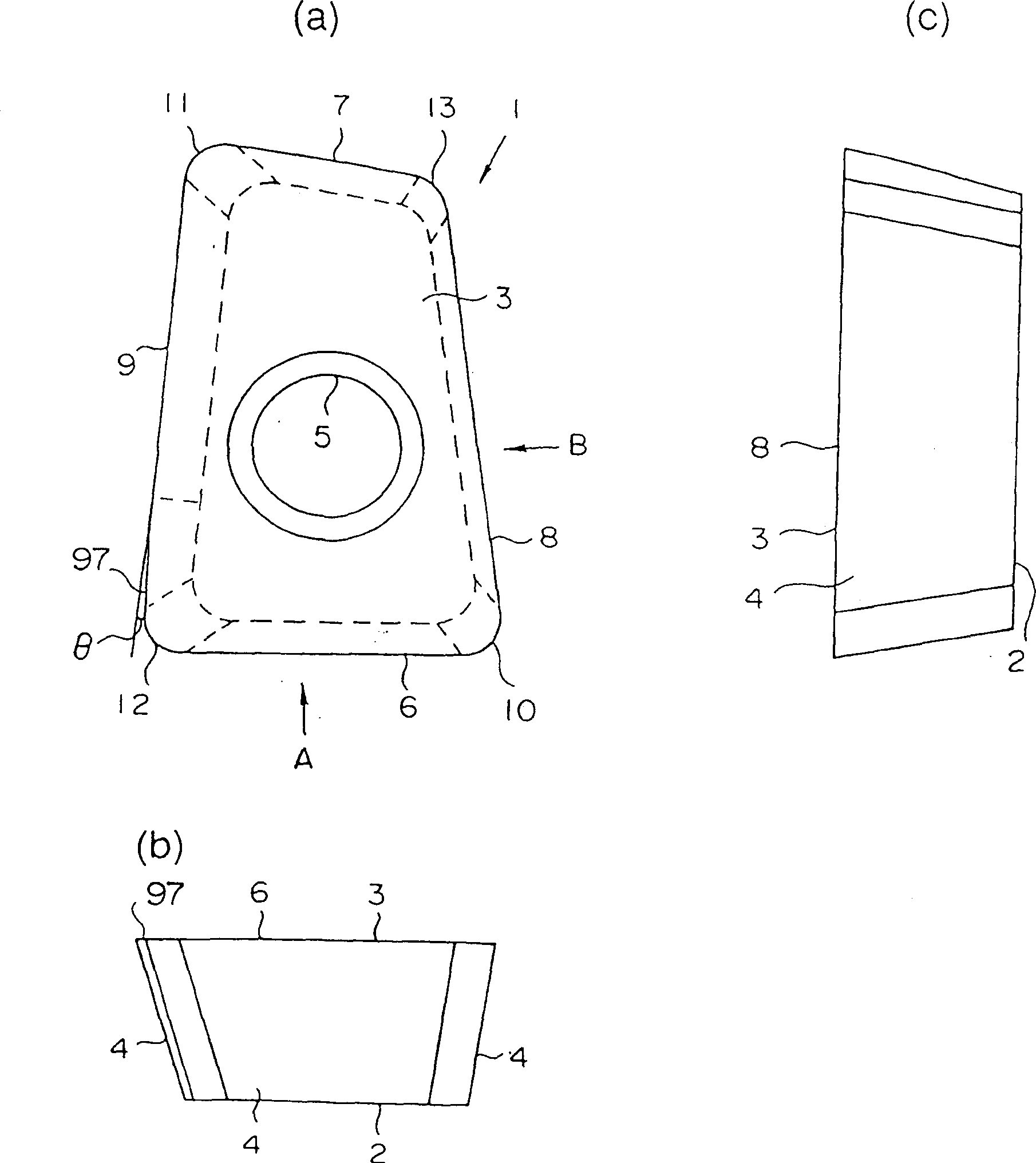

[0097] Figure 5 The replaceable blade (hereinafter also referred to as the blade) 40 of the illustrated embodiment 2 is approximately in the shape of a quadrangular plate, and the top surface 41 facing the bottom surface 2 constituting the support surface is from the first short edge 6 to the opposite second short edge. 7. The distance from the bottom surface...

Embodiment 3

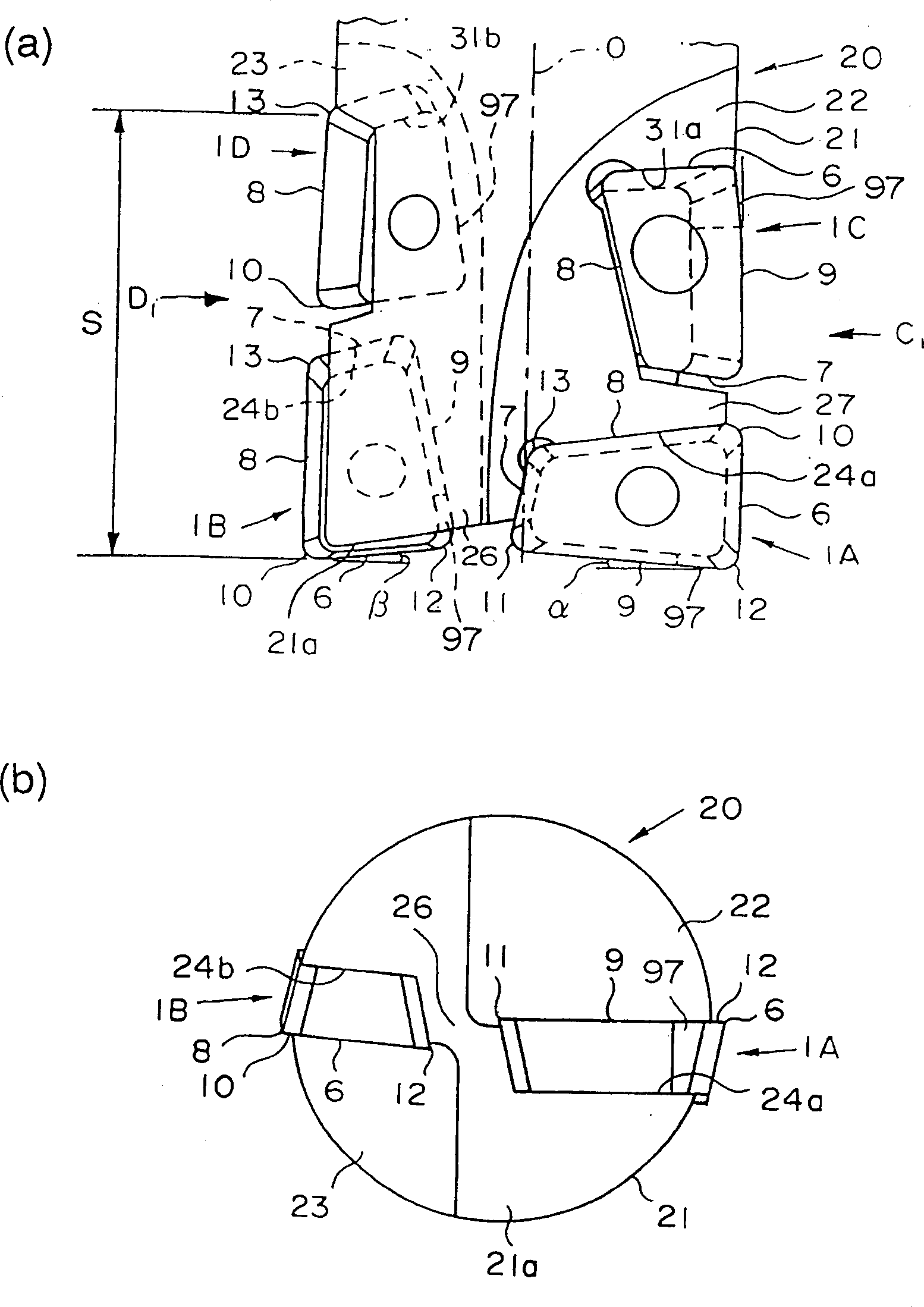

[0111] Next, the replaceable blade and the replaceable blade end mill of Embodiment 3 of the present invention will be described with reference to the accompanying drawings, and the same symbols as those of the above-mentioned embodiments, or the same parts, will not be repeated. Figure 10 , Figure 11 It is the figure which shows the replaceable blade of Example 3, Figure 12 , Figure 13 It is a figure which shows the replaceable-tip type end mill of Example 3. Figure 10 is a top view of the replaceable blade, Figure 11 yes means Figure 10 A cross-sectional view of the cross-sectional shape of each part of the replaceable blade shown, Figure 11 (A) is Figure 10 The L-L line profile, Figure 11 (b) is Figure 10 The M-M line profile, Figure 12 is installed with Figure 10 Side view of important parts of end mill with replaceable insert shown, Figure 13 yes Figure 12 Front view of end mill shown, Figure 14 Viewed from the peripheral edge side Figure 12 ...

Embodiment 4

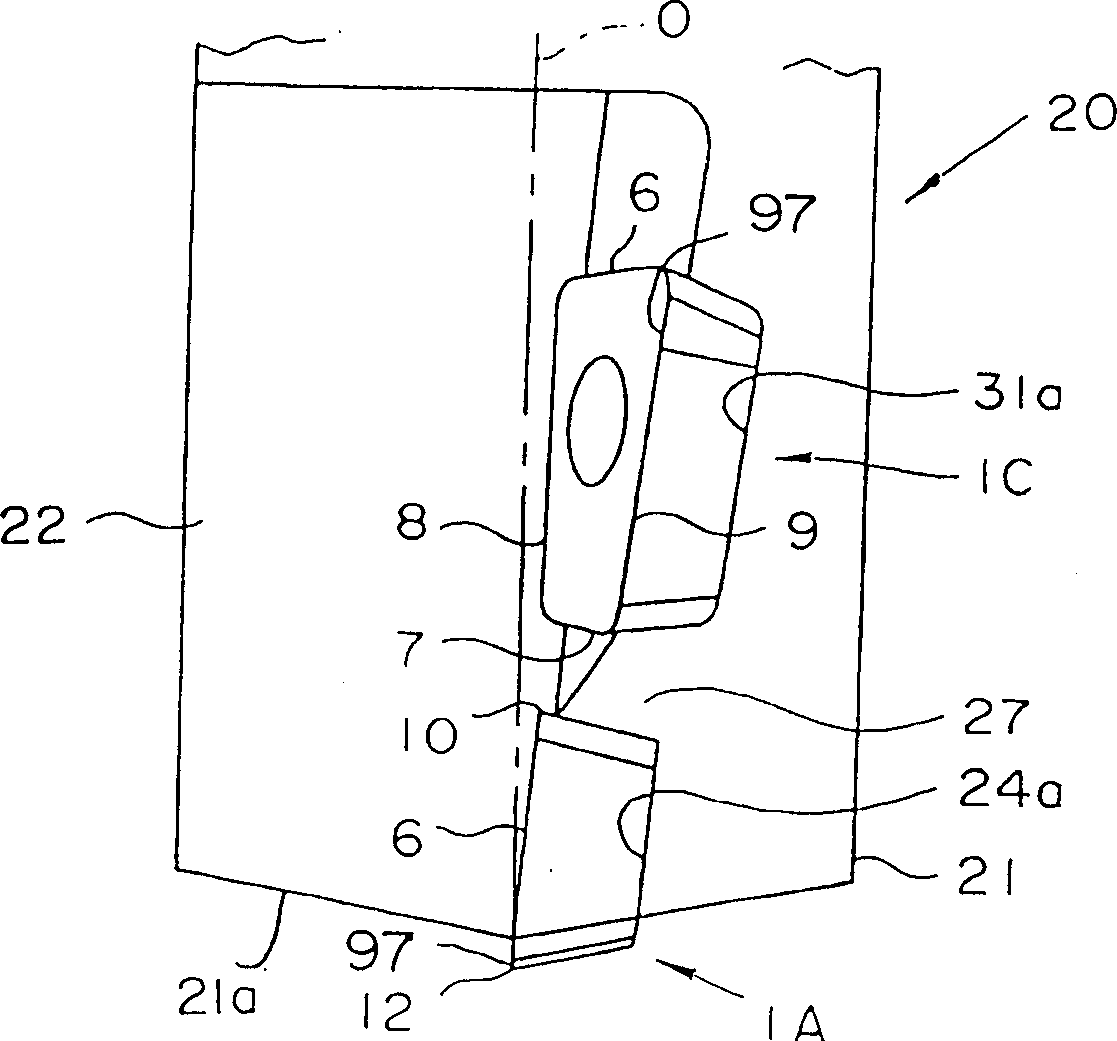

[0129] Below, according to Figure 15 , Figure 16 , Figure 17 Embodiment 4 of the present invention will be described, and the same reference numerals will be used for the same or identical parts as those of the above-mentioned embodiments, and the description thereof will be omitted. Figure 15 It is a side view of the replaceable insert type end mill of Embodiment 4, Figure 16 yes Figure 15 C2 direction side view of end mill shown, Figure 17 yes Figure 15 D2 side view of end mill shown.

[0130] Figure 15 , Figure 16 , Figure 17 The replaceable-blade end mill 30 of the illustrated embodiment 4 has the same structure as the replaceable-blade end mill 20 of the above-mentioned embodiment 1, and does not use the replaceable blade 1 but is equipped with the replaceable blade 1 of the present invention. Insert 101 for an end mill. That is, two grooves 22 and 23 cut into a fan-shaped cross section are provided at the front end of the tool body 21, and these two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com