Pneumatic tires for trucks

A technology of pneumatic tires and tires, which is applied in the direction of heavy tires, tire parts, tire treads/tread patterns, etc., and can solve problems such as rubber defects and defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

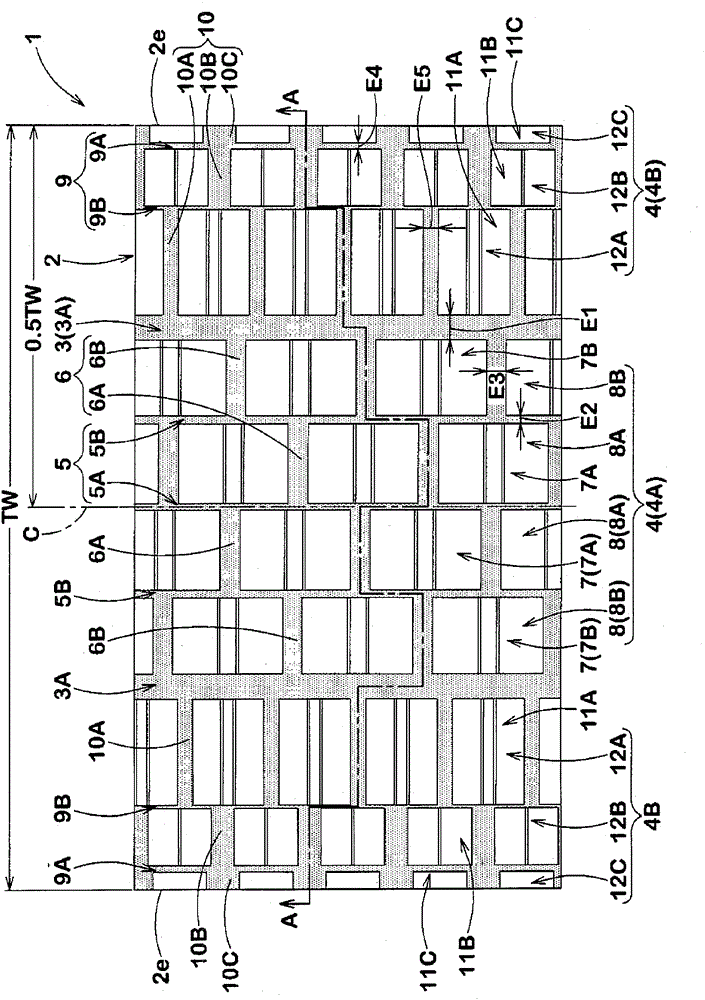

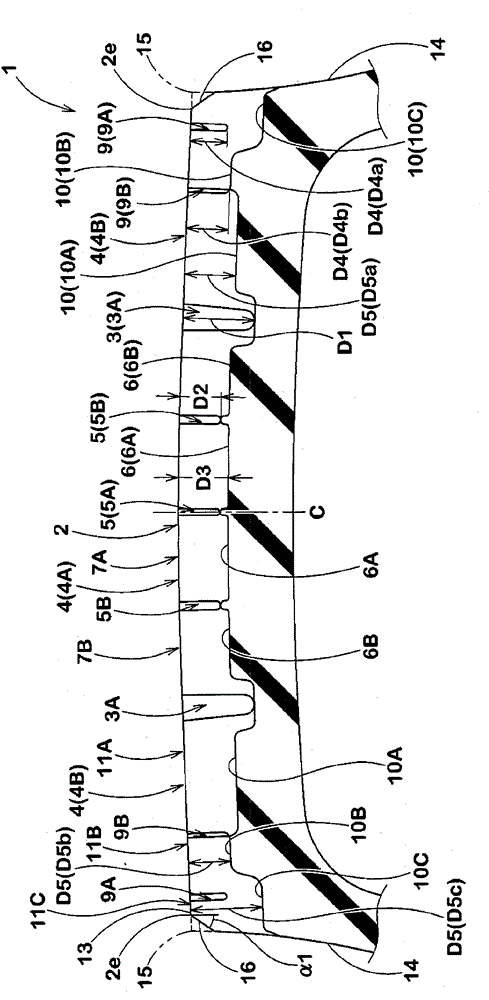

[0090] made into figure 1 The tires having the basic structure shown in Table 1 and the shoulder land portions shown in Table 1 were evaluated for their performance. And, as a comparison, for having Figure 6 The same evaluation was performed on the tire of the shown shoulder land portion (Comparative Example 4). Among them, the common specifications are as follows.

[0091] Tire size: 11R22.5

[0092] Rim size: 22.5×7.50

[0093] Tread half width 0.5TW: 121mm

[0094] Shoulder main groove:

[0095] Groove width E1: 7.9mm

[0096] Groove depth D1: 20.6mm

[0097]Ratio (E1 / 0.5TW): 6.53%

[0098] Ratio (D1 / 0.5TW): 17.02%

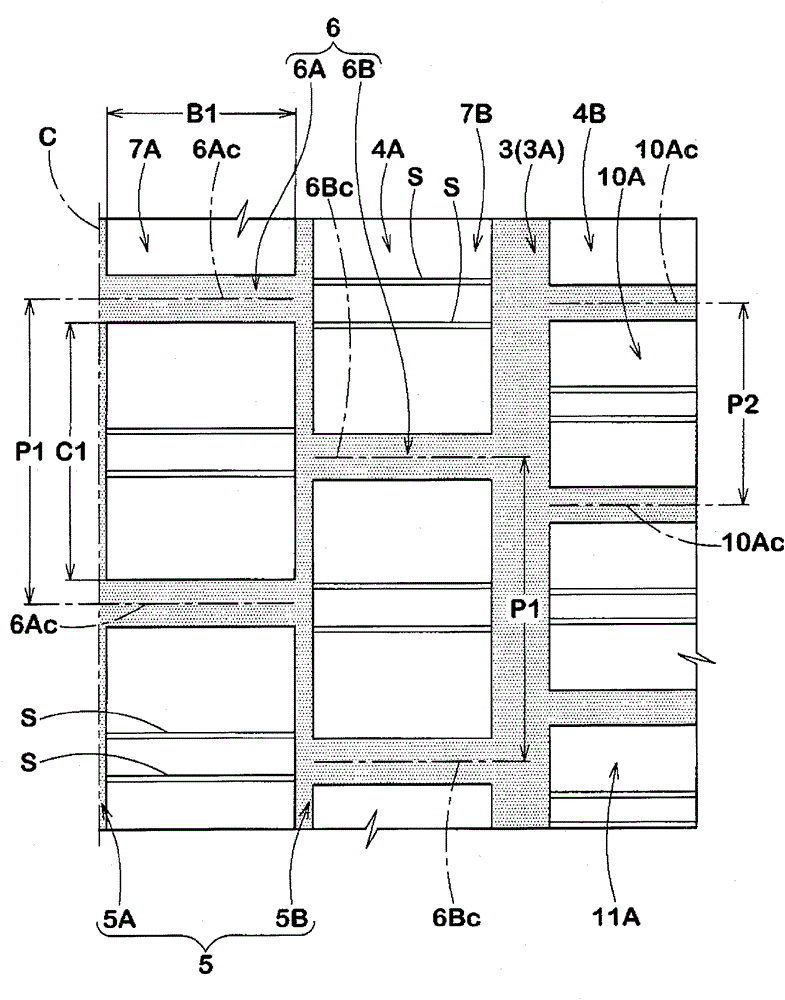

[0099] Medial and lateral central auxiliary groove:

[0100] Groove width E2: 2.0mm

[0101] Groove depth D2: 12.0mm

[0102] Ratio (E2 / 0.5TW): 1.7%

[0103] Ratio (D2 / 0.5TW): 9.9%

[0104] Medial and lateral central transverse grooves:

[0105] Groove width E3: 6.2mm

[0106] Groove depth D3: 14.5mm

[0107] Ratio (E3 / 0.5TW): 5.12%

[0108] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com