Single-lip drill

A single-edged drill bit and drill bit technology, which is applied in the direction of drill repair, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of not being able to maintain the original function for a long time, insufficient blade tip strength, and loss of adhesion. Achieves the effect of suppressing chipping or breakage of the chisel edge, preventing unstable adhesion, and stabilizing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

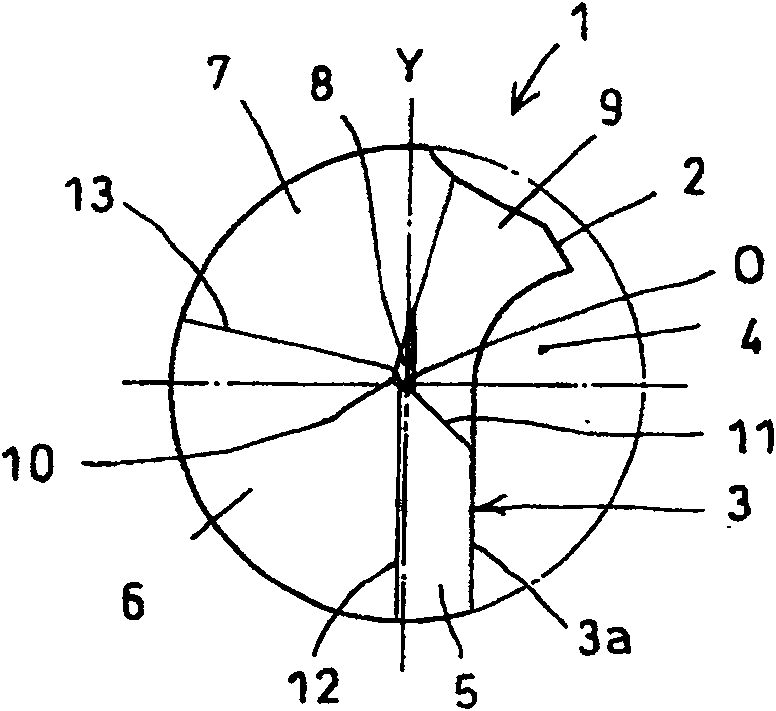

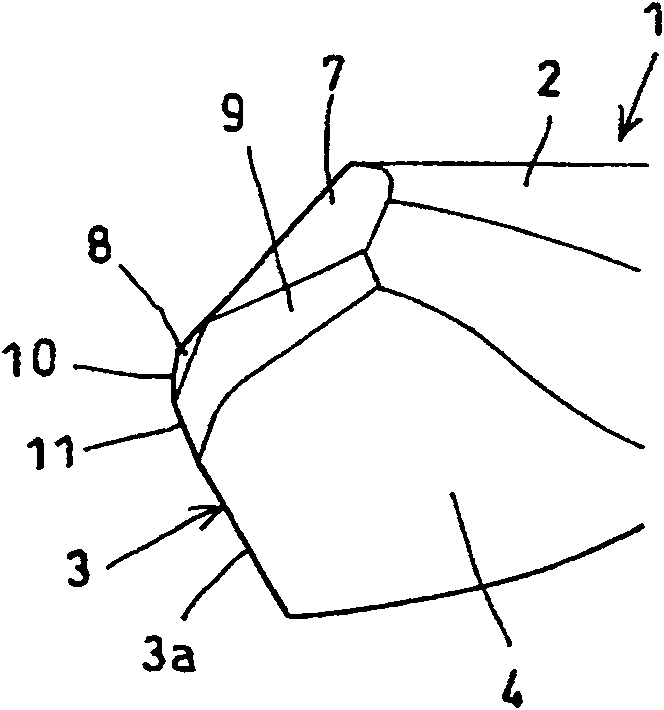

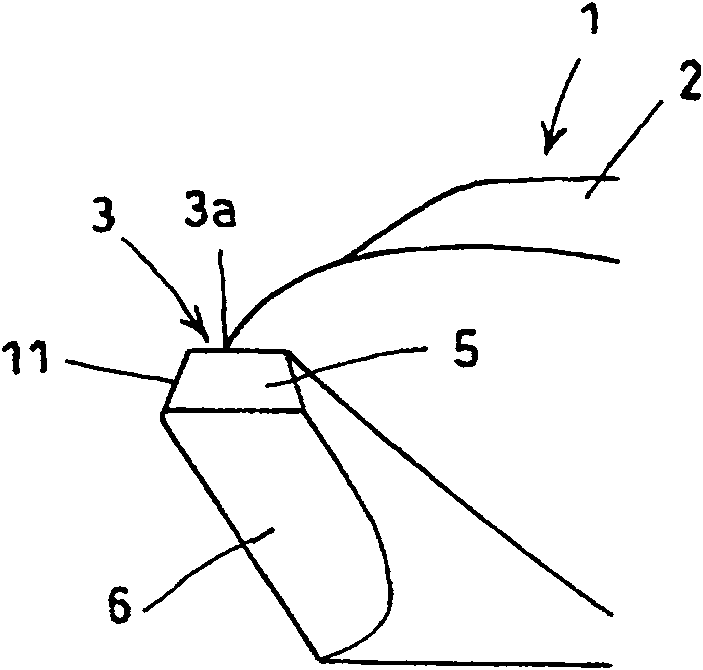

[0034] The following is based on the attached Figure 1-7 Embodiments of the present invention will be described. Figure 1 to Figure 6 A single-edged drill according to the first embodiment is shown. Each figure is enlarged for easy understanding. The drill 1 has a main body 2 integrally formed with a shank (not shown), a cutting edge 3 is formed at the front end of the main body 2, and a chip discharge groove 4 is formed on the main body. The chip discharge groove 4 is preferably a spiral groove as shown in the figure. The main cutting edge portion 3 a of the cutting edge 3 is located just past the center (in front of a line Y passing through the axis O in the drill rotation direction). In addition, the rotation direction of the drill bit in the present invention refers to the forward rotation direction of the drill bit.

[0035] In addition, in this drill 1, the relief portion at the front end is formed by a plurality of stages of relief surfaces. In the first embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com