Cutting insert and cutting tool and cutting method employing it

A technology for cutting inserts and cutting tools, which is applied in the direction of milling cutting blades, manufacturing tools, accessories of tool holders, etc. It can solve the problems of cutting edge defects and cracks easily, and achieve the effect of suppressing defects and superior machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]

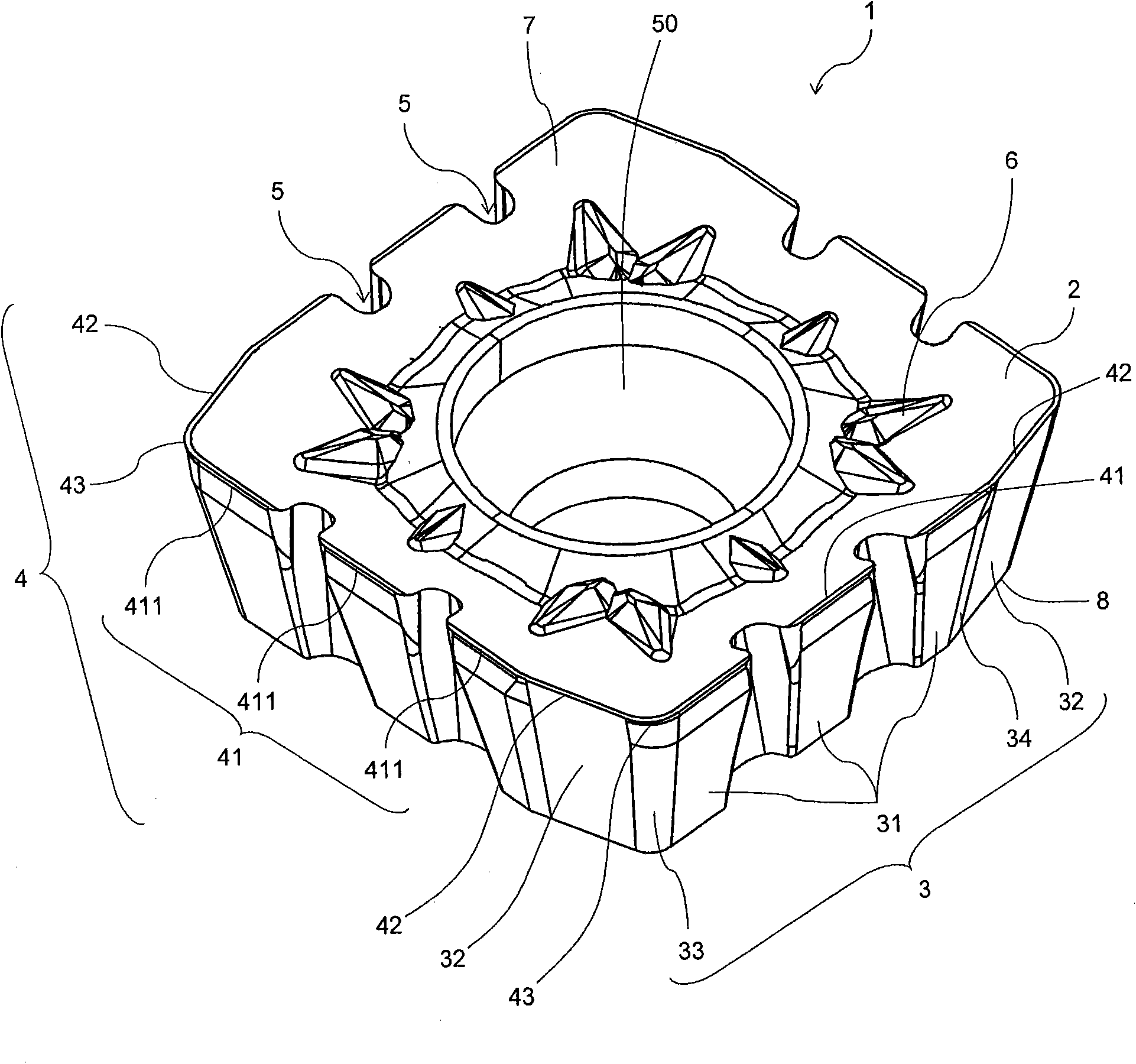

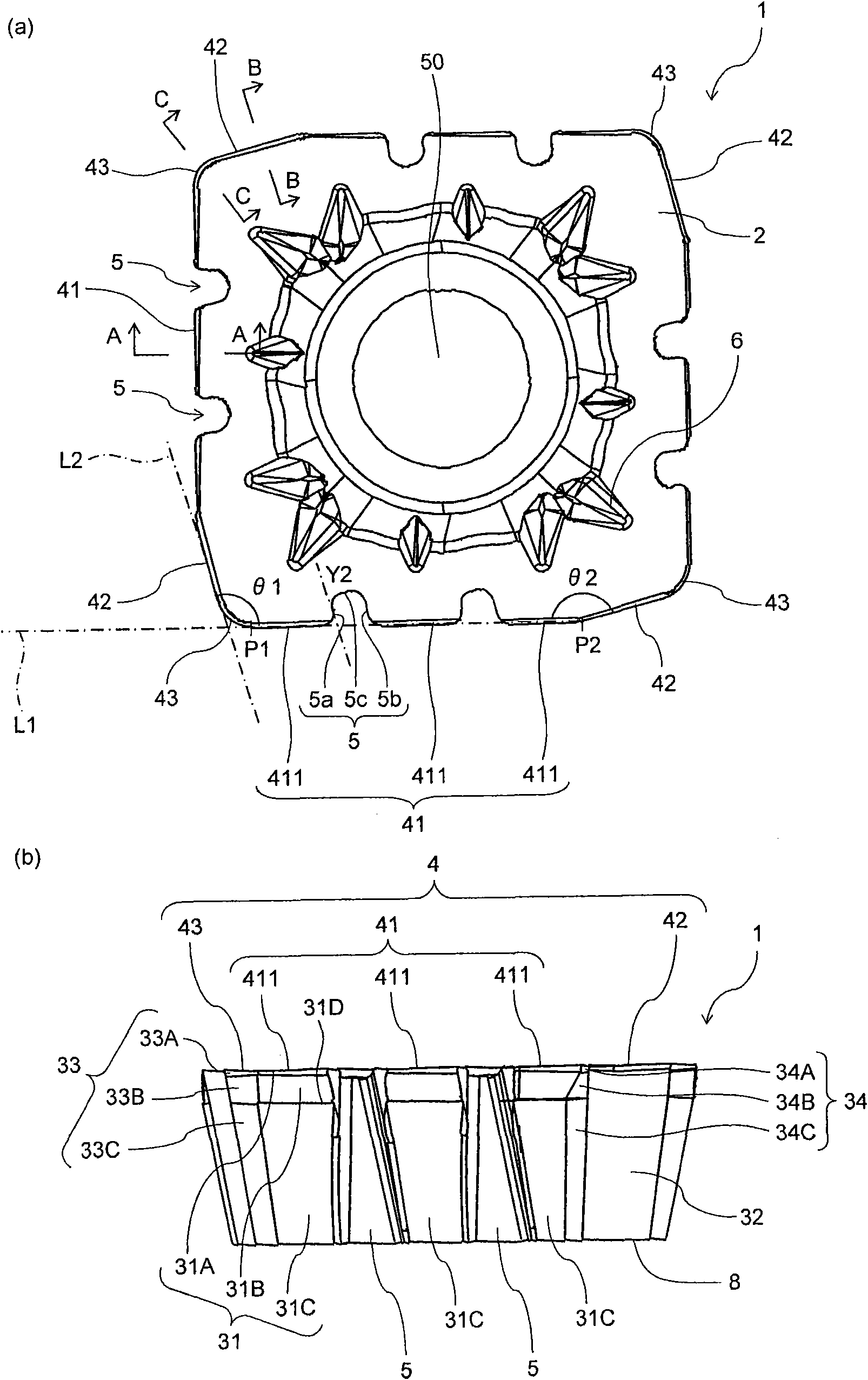

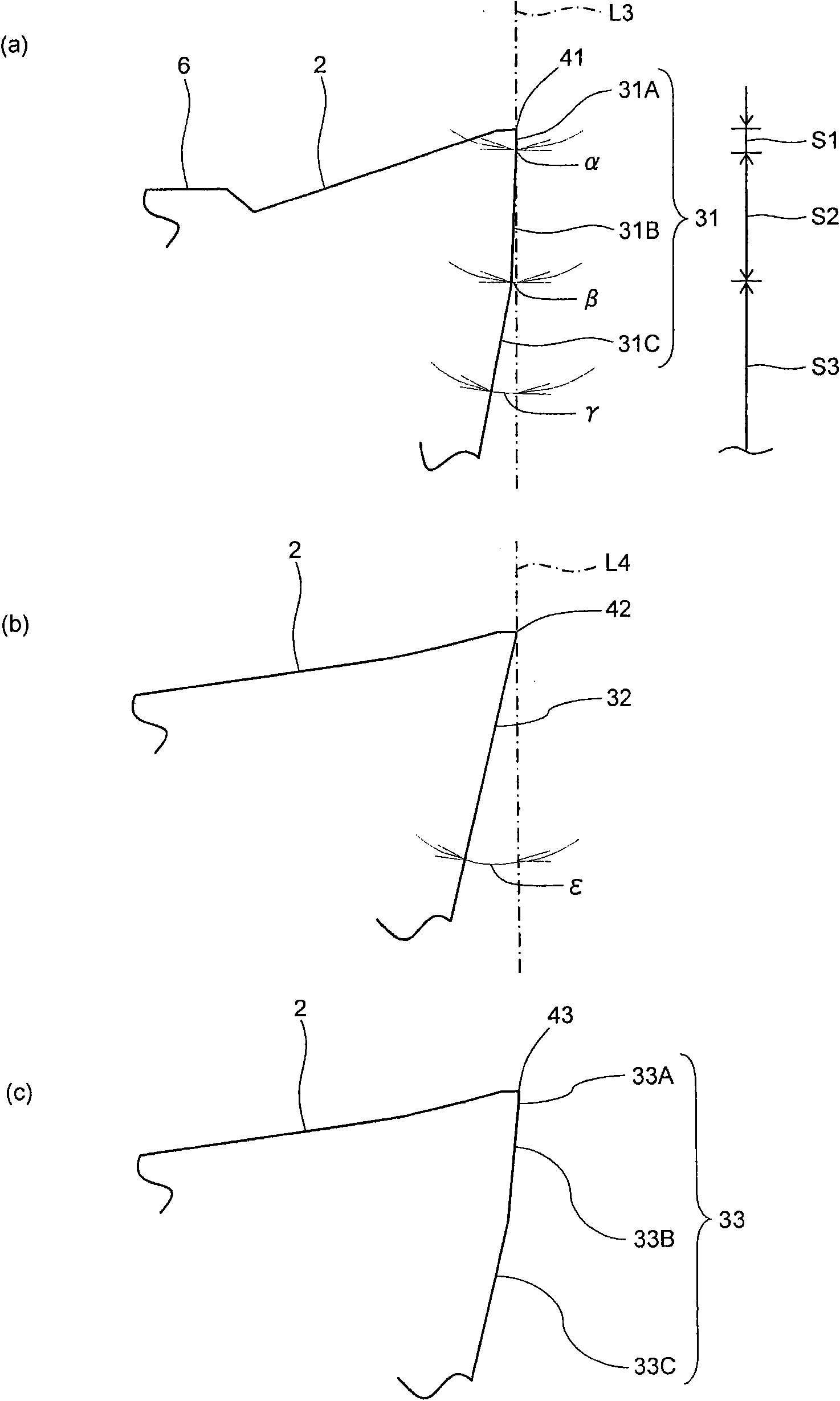

[0023] Below, refer to Figure 1 ~ Figure 4 One embodiment of the cutting insert (hereinafter referred to as insert) of the present invention will be described in detail. Such as figure 1 As shown, the insert 1 of the present embodiment has a main body portion 7 , wherein the main body portion 7 has: a substantially polygonal upper surface; a lower surface 8 ; and side surfaces. The body portion 7 has a rake face 2 formed on at least a part of the upper surface; a flank face 3 formed on at least a part of the side face; and a cutting edge 4 formed at the intersection of the rake face 2 and the flank face 3 .

[0024] The cutting edge 4 has: a first cutting edge 41 ; a second cutting edge 42 ; and a third cutting edge 43 . The third cutting edge 43 is located between the first cutting edge 41 and the second cutting edge 42 and is located at a substantially polygonal corner in plan view. The first cutting edge 41 functions as a main cutting edge. The second cuttin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com