CBN sintered body cutting tool with excellent toughness

A cutting tool and sintered body technology, which is applied in the field of cBN sintered body cutting tools with excellent toughness, can solve the problems of tool tip chipping or defect, insufficient toughness, and inability to use cutting performance for a long time, so as to maintain cutting performance, The effect of excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

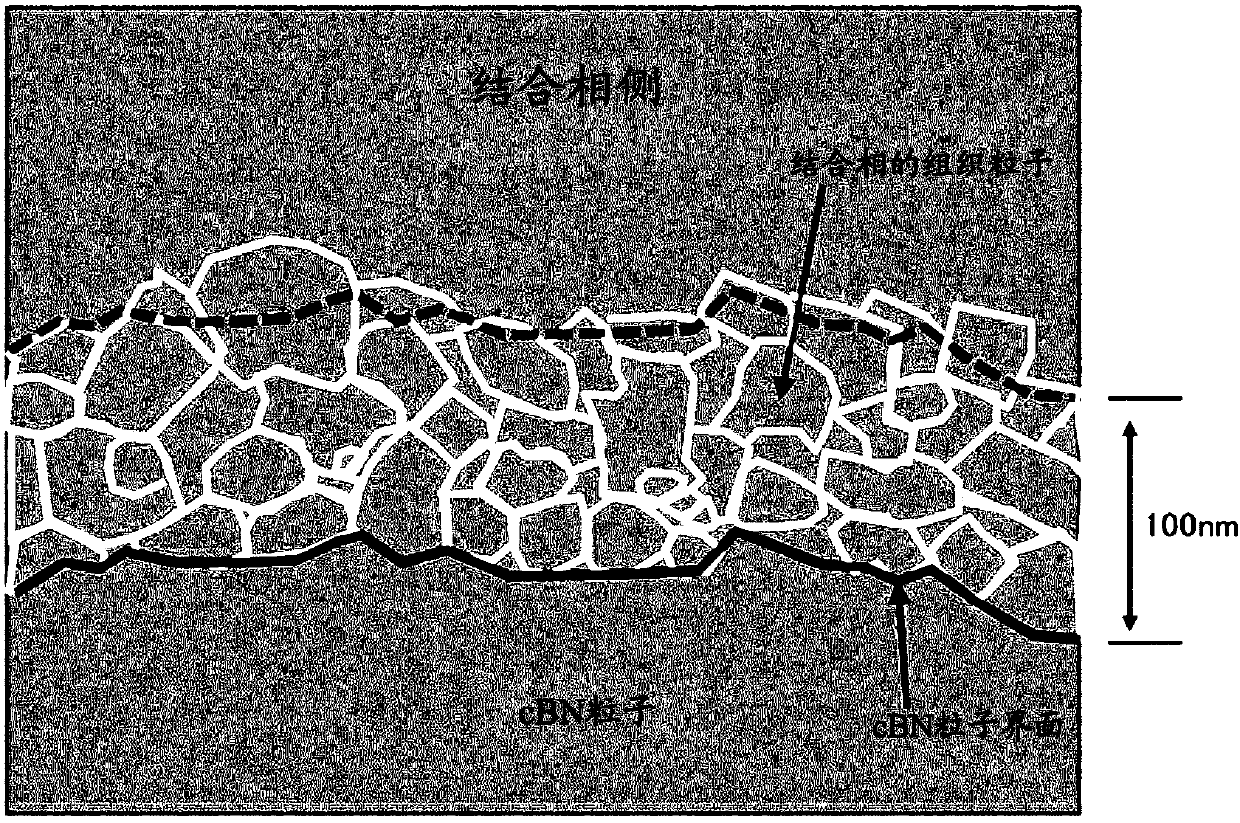

Image

Examples

Embodiment

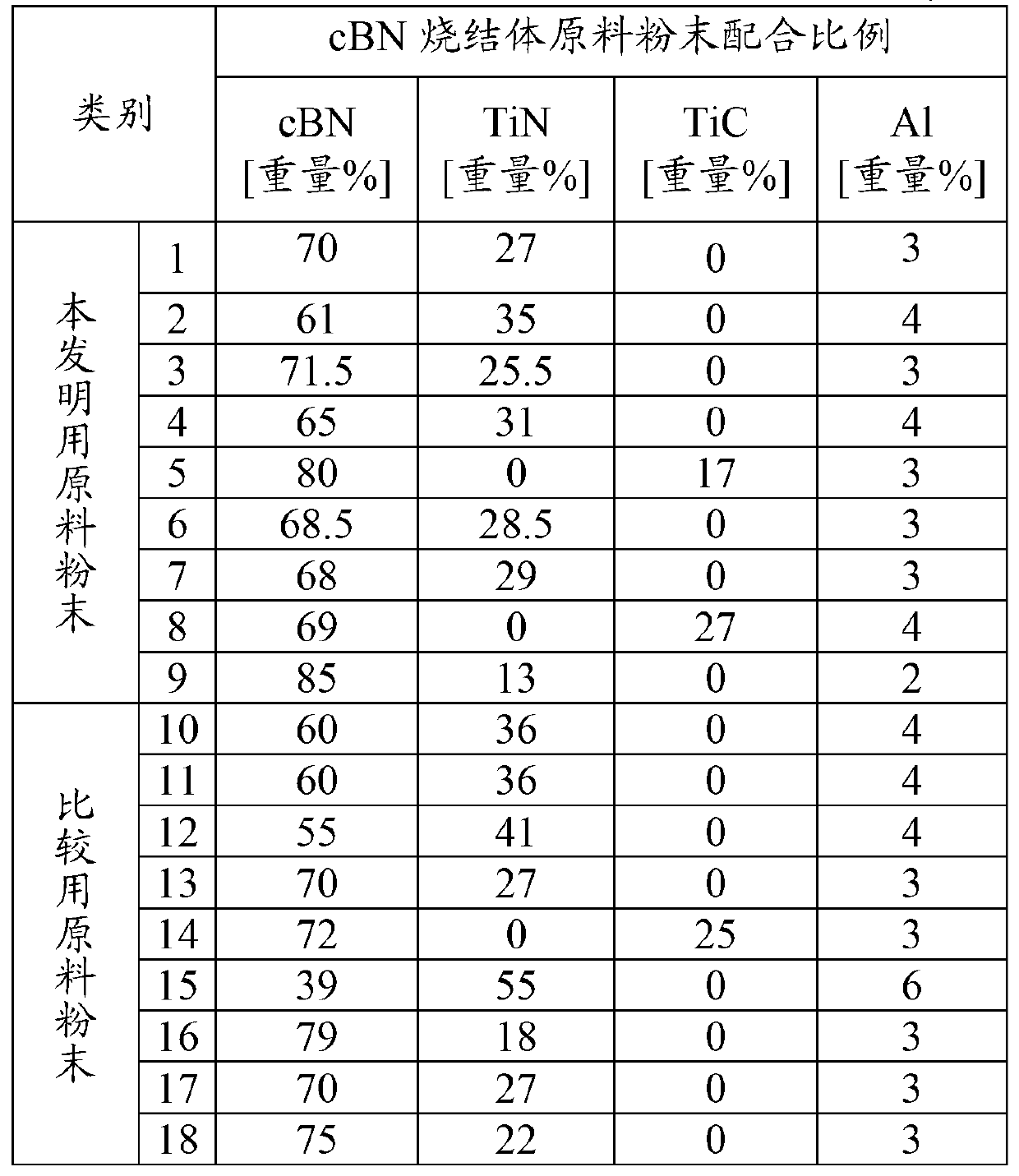

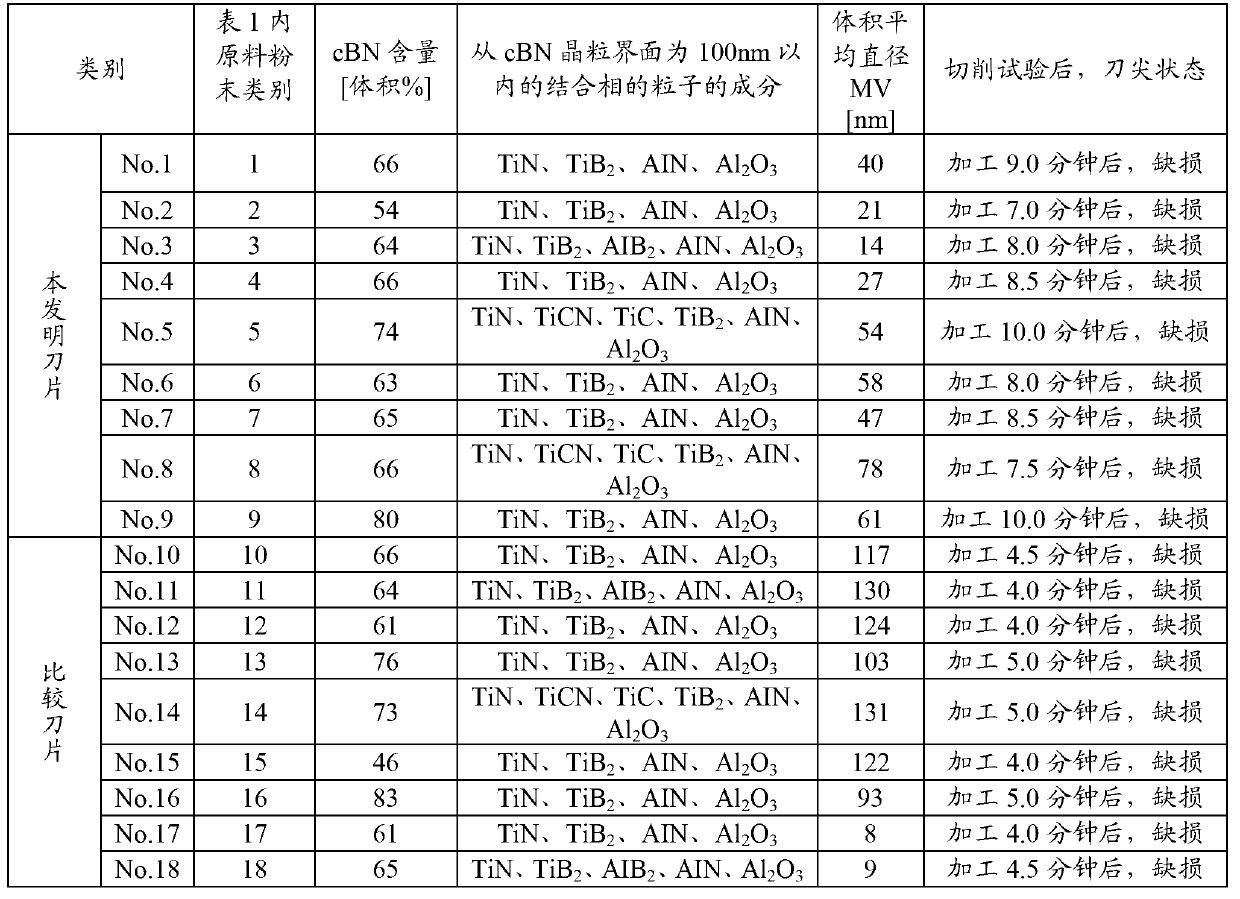

[0046] In Table 2, inserts 1 to 9 of the present invention produced as examples of the present invention and comparative inserts 10 to 18 produced for comparison are shown.

[0047] First, a method for producing a cBN sintered body using inserts 1 to 9 of the present invention will be described.

[0048] 1) Formation of granular TiN on raw cBN powder

[0049] 1-1) A TiN film was formed on cBN powder with an average particle size of 3 μm by atomic layer deposition (ALD: Atomic Layer Deposition).

[0050] When coating cBN powder with two kinds of raw material gases A and B by the ADL method, the cBN particles are charged into the fluidized bed furnace, the temperature is raised to a predetermined temperature, and the raw material gas A is flowed into the process, the Ar gas purge process, the raw material The gas B inflow process and the Ar gas purge process constitute one cycle, and this cycle is repeated until the target layer thickness is reached to obtain a TiN film with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com