Pneumatic tire

一种充气轮胎、轮胎的技术,应用在轮胎零部件、轮胎胎面/胎面花纹、运输和包装等方向,能够解决很难兼顾、操纵稳定性和抗不均匀磨损性变差、花纹块刚性降低等问题,达到提高排水性、确保抗不均匀磨损性、确保操纵稳定性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

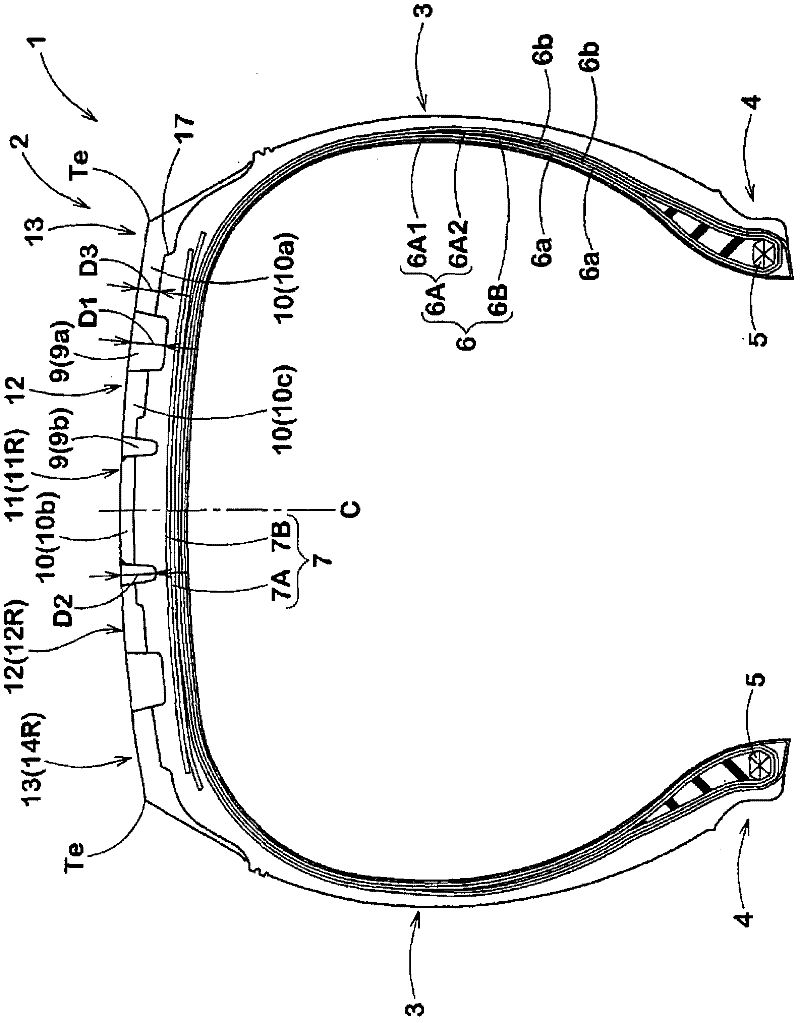

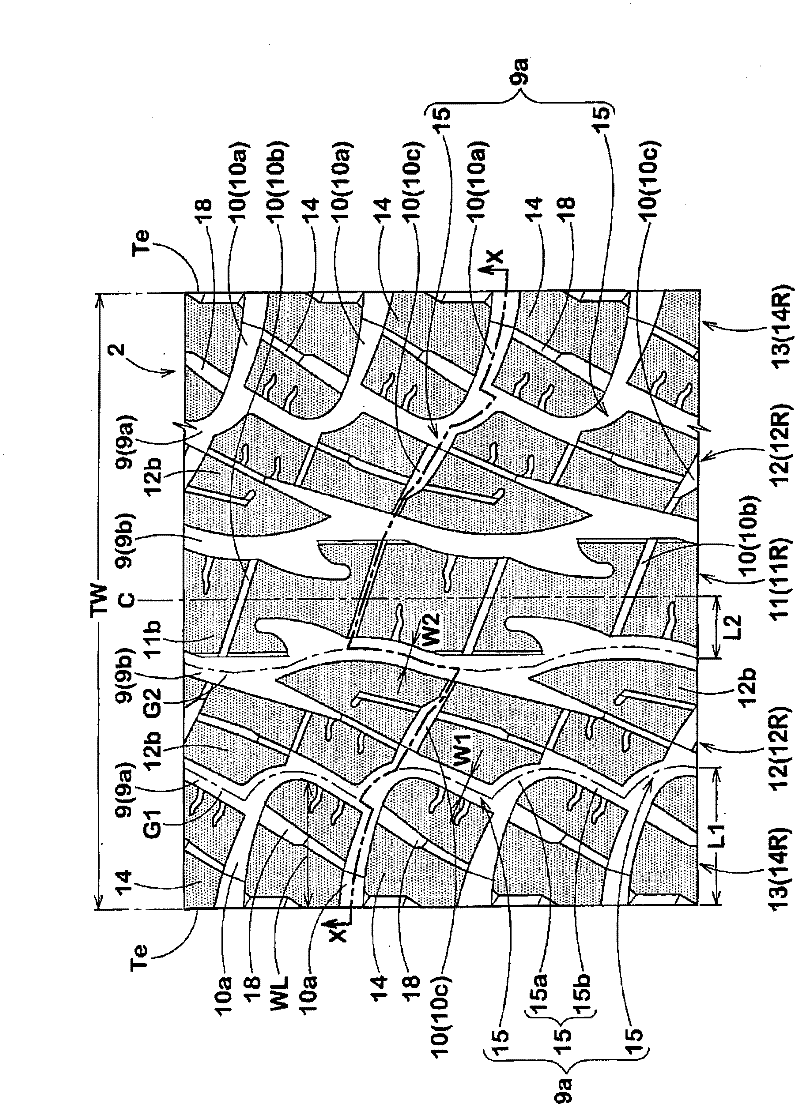

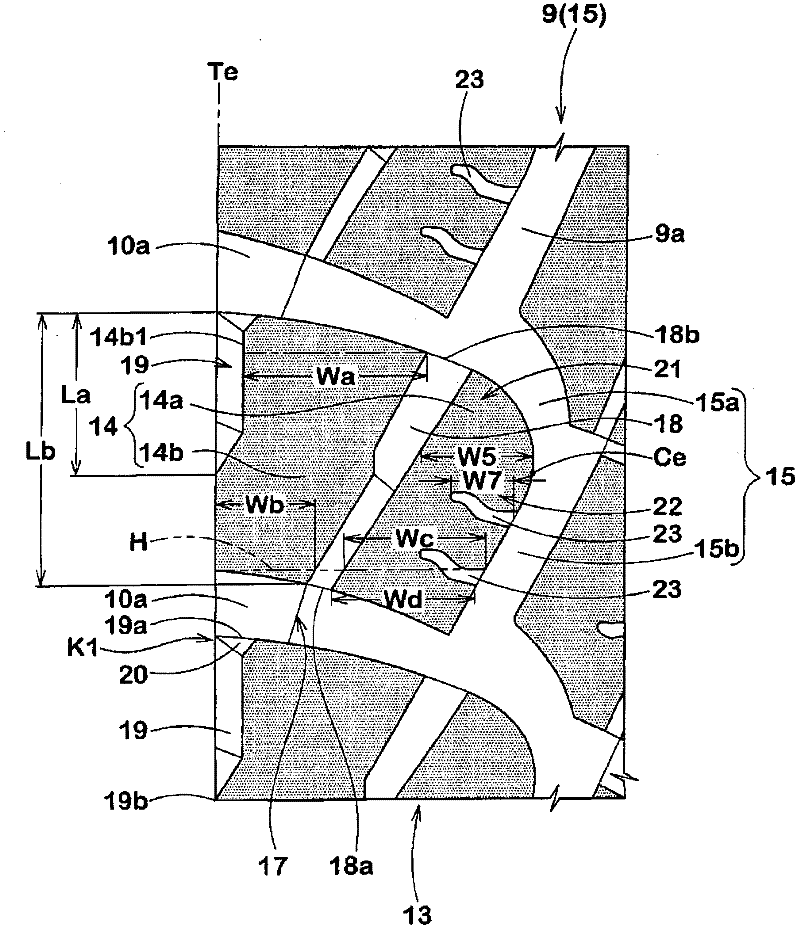

[0027] Hereinafter, one embodiment of the present invention will be described based on the drawings.

[0028] Such as figure 1 As shown, the pneumatic tire 1 of the present embodiment has a carcass 6 extending from the tread portion 2 to the bead core 5 of the bead portion 4 through the sidewall portion 3 ; and a belt layer 7 arranged on the carcass 6 On the outside in the radial direction and inside the tread portion 2 , a tire for a small truck is shown in this embodiment.

[0029] The above carcass 6 has, for example, a so-called 2-1 structure composed of two folded cords 6A and one turned cord 6B disposed outside the folded cords 6A.

[0030] The folded cord 6A is composed of an inner folded cord 6A1 disposed inside in the tire radial direction at the position of the tire equator C, and an outer folded cord 6A2 disposed outside the folded cord 6A1. Each of the folded cords 6A1 and 6A2 includes: an annular main body portion 6a extending from the tread portion 2 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com