Microbial preparation for processing industrial fermentation wastewater

A technology for fermenting wastewater and preparations, which is applied in the direction of microorganism-based methods, microorganisms, and natural water treatment. It can solve the problems of large one-time investment in chromatographic separation, low threonine content in the extract, and large consumption of ion-free water. The effect of increasing the amount of treated water, unique treatment effects, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) The industrial waste water produced by threonine produced by the concentrated isoelectric process enters the pre-anaerobic tank UASB, controls a certain hydraulic retention time, and the effluent enters the sedimentation tank;

[0033] (2) The sedimentation tank adds microbial preparation advanced treatment, and described microbial preparation, it comprises the raw material of following weight portion:

[0034] 7 parts of nitrosative bacteria, 7 parts of Trichoderma longibrachiae, 5 parts of aerobic denitrifying bacteria, 5 parts of Acinetobacter baumannii, 4 parts of Aspergillus niger, 3 parts of Alcaligenes faecalis, 3 parts of Streptomyces rubrum, white Candida 1 part, Paenibacillus polymyxa 1 part.

[0035] The nitrosogenic bacteria are specifically Nitrosomonaseuropaea ATCC19718;

[0036] The long branch Trichoderma is Trichoderma longibrachinatum (Trichodermallongibrachinatum) CGMCCNO.8331 (see CN103710267A)

[0037] The aerobic denitrifying bacteria is aero...

Embodiment 2

[0052] Example 2 of the effect of treating waste water

[0053] Get threonine fermentation wastewater, enter the sewage treatment system according to the method of embodiment 1, and take samples to measure COD, ammonia nitrogen, and sulfide data;

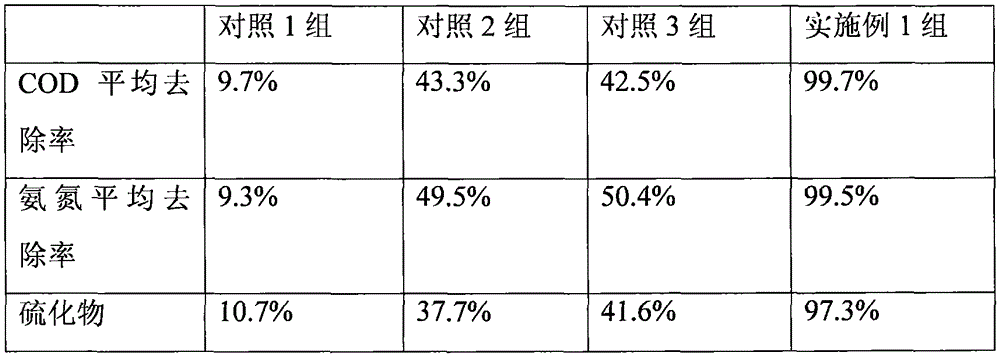

[0054] Compared with Example 1, the control group 1 did not add compound bacterial agents; compared with Example 1, the control group 2 had only straw as the adsorbent carrier, and compared with Example 1, the control group 3 had only humic acid as the adsorbent carrier. Sampling and determination of COD, ammonia nitrogen, and sulfide data, the test data are as follows in Table 1:

[0055] Table 1

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com