Treatment method of ammonia-nitrogen-containing industrial wastewater

A technology for industrial wastewater and treatment methods, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems that are not suitable for large-scale industrial applications, and chemical methods are easy to cause other pollution , Unreasonable compatibility of bacterial agents and other problems, to achieve the effect of improving biological treatment efficiency, easy acceptance, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1) Preparation of composite bacterial agent: Culture Alcaligenes faecalis, Bacillus licheniformis, Acinetobacter baumannii, Rhodococcus and Pseudomonas fluorescens respectively to a concentration of 1×10 8 Bacteria solution per ml, mixed according to the volume ratio of 1:1:2:2:3, then mixed and stirred evenly with the carrier according to the mass ratio of 1:1, and finally dried at low temperature, the drying temperature was 20°C, and after drying, the The water content is 10%, that is, the carrier is prepared by mixing diatomite and chitosan uniformly according to the mass ratio of 1:1;

[0036] Step 2) Precipitation and impurity removal: cooling the waste water to 20°C, and then entering the sedimentation tank, the sedimentation time is 12 hours, and then discharged; the bottom of the sedimentation tank is laid with fine sand with a thickness of 1 meter;

[0037] Step 3) adjust the pH: the waste water enters the acid-base adjustment pool, and 1M hydrochloric aci...

Embodiment 2

[0042] A method for treating industrial wastewater containing ammonia nitrogen, comprising the steps of:

[0043] Step 1) Preparation of composite bacterial agent: Culture Alcaligenes faecalis, Bacillus licheniformis, Acinetobacter baumannii, Rhodococcus and Pseudomonas fluorescens respectively to a concentration of 1×10 8 Bacteria solution per ml, mixed according to the volume ratio of 1:1:2:2:3, then mixed and stirred evenly with the carrier according to the mass ratio of 1:1, and finally dried at low temperature, the drying temperature was 30°C, and after drying, the The water content is 10%, that is, the carrier is prepared by mixing diatomite and chitosan uniformly according to the mass ratio of 1:1;

[0044]The Alcaligenes faecalis is Alcaligenes faecalis ATCC 31555 (Structural studies of an extracellular polysaccharide (S-130) elaborated by Alcaligenes ATCC31555, Carbohydrate Research, 1986);

[0045] The Bacillus licheniformis is CCTCC NO.M206082 (CN101037659A);

[0...

Embodiment 3

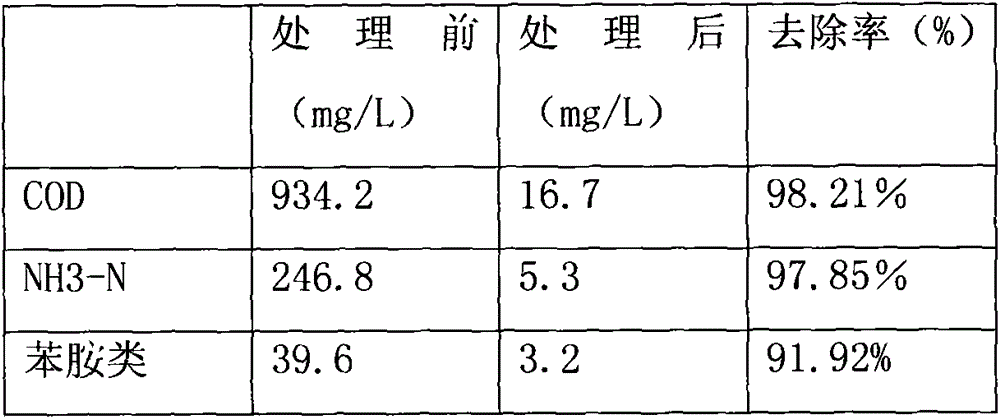

[0055] Take the waste water of a certain factory in this city as an example, detect the waste water treatment effect of embodiment 2, take three water samples for each test sample, get the average value of the three test results, and detect that each index has reached the ideal discharge standard, and the detection index of waste water See Table 1:

[0056] Table 1

[0057]

[0058] Conclusion: After treatment, the contents of heavy COD, ammonia nitrogen and aniline substances in industrial wastewater are greatly reduced, which meets the discharge standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com