Microbial preparation for restoring fertilizer plant sewage and application thereof

A microbial preparation and microbial technology, applied in the field of microorganisms, can solve problems such as hindering the application process of biological treatment of sewage, unreasonable compatibility of bacteria and microorganisms, and unacceptable by enterprises, so as to improve the efficiency of biological oxidation, improve the efficiency of biological treatment, and be easily accepted Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A microbial preparation for repairing sewage from chemical fertilizer plants, which is prepared according to the following method:

[0029] Step 1) Preparation of adsorbent: first, crush the zeolite to obtain zeolite powder with a particle size of 50, and then mix it with silicon dioxide and humic acid in a weight ratio of 1:2:2 to obtain; The particle size of silicon or humic acid is 50 mesh.

[0030] Step 2) Preparation of microbial carbon source: dry the rice straw and crush it into rice straw powder with a pulverizer; dry the peanut shells and pulverize them into peanut shell powder with a pulverizer; Then add soybean meal and water, stir at a speed of 500 rpm for 15 minutes, then send the materials in the stirred tank into the reactor, feed water vapor into the reactor, keep the temperature of the reactor at 95°C, keep warm React for 30 minutes, and finally cool naturally; the mass ratio of rice straw powder, peanut shell powder, soybean meal and water is 2:2:3:5;...

Embodiment 2

[0035] A microbial preparation for repairing sewage from chemical fertilizer plants, which is prepared according to the following method:

[0036] Step 1) Preparation of adsorbent: first, crush the zeolite to obtain zeolite powder with a particle size of 100 meshes, and then mix it with silicon dioxide and humic acid in a weight ratio of 1:2:2 to obtain; The particle size of silicon or humic acid is 100 mesh;

[0037] Step 2) Preparation of microbial carbon source: dry the rice straw and crush it into rice straw powder with a pulverizer; dry the peanut shells and pulverize them into peanut shell powder with a pulverizer; Then add soybean meal and water, stir at a speed of 500 rpm for 15 minutes, then send the materials in the stirred tank into the reactor, feed water steam into the reactor, keep the temperature of the reactor at 100°C, keep warm React for 30 minutes, and finally cool naturally; the mass ratio of rice straw powder, peanut shell powder, soybean meal and water is ...

Embodiment 3

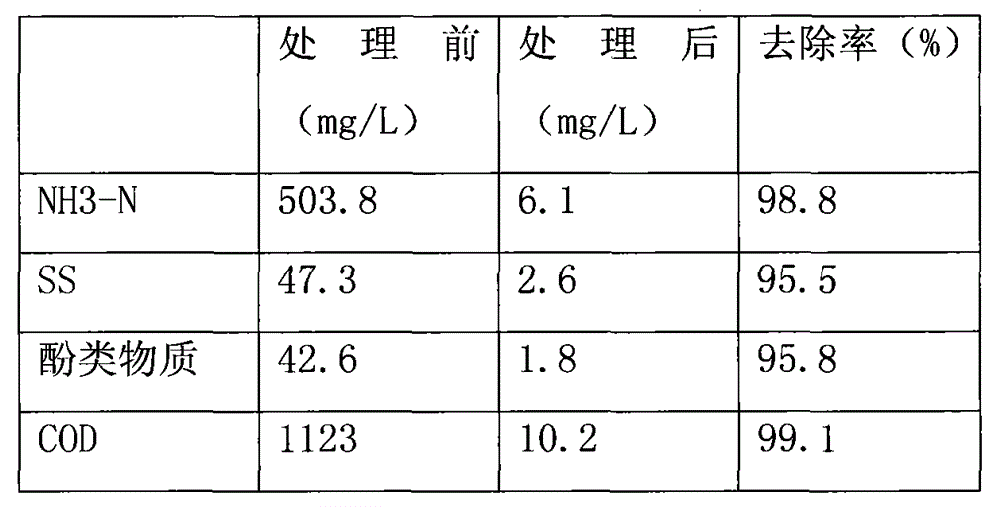

[0049] Taking the sewage of a chemical fertilizer factory in this city as an example, first remove the suspended matter in the sewage, and then enter the sedimentation tank. The sedimentation tank is laid with fine sand with a thickness of 50cm, and settle for 12 hours. Then it enters the biochemical reaction tank, and the pH of the sewage is adjusted by adding hydrochloric acid. 7. Dosing 20 grams of microbial preparations per cubic meter of liquid each time, once a day, after three days of continuous dosing, let it stand for another week, filter and sterilize the liquid, and finally discharge it. Three water samples were taken for each test, and the average value was calculated; after testing, all indicators reached the ideal discharge standard, and the detection indicators of sewage are shown in Table 1:

[0050] Table 1

[0051]

[0052] Conclusion: The microbial preparation of the present invention can effectively remove ammonia nitrogen, SS and phenolic substances in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com