System and method for treating wastewater by applying activated sludge

A technology for activated sludge and wastewater treatment, applied in water/sludge/sewage treatment, water/sewage treatment, biological water/sewage treatment, etc. To achieve the effect of improving the purification strength, not easy to sludge bulking, and obvious effect of phosphorus removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

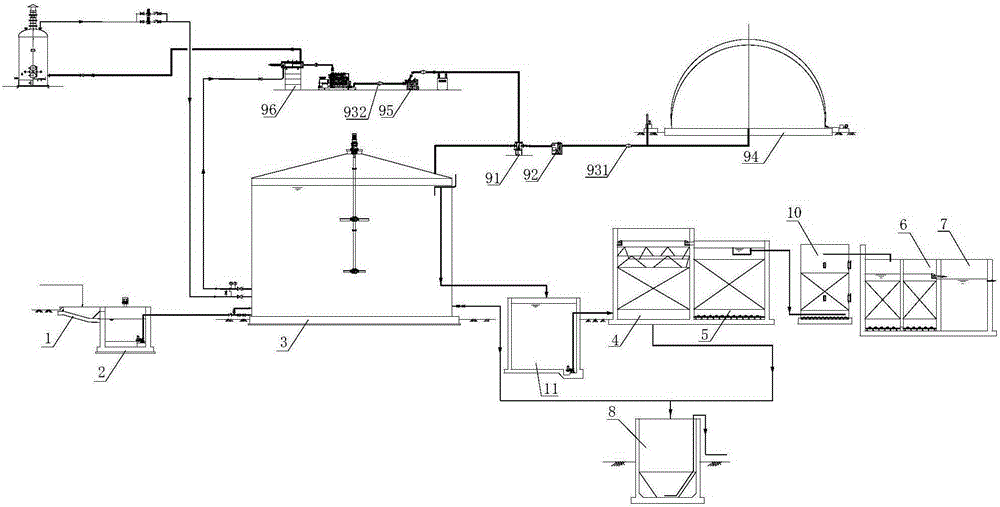

[0038] Systems that use activated sludge to treat wastewater, such as Figure 1-2 As shown, it includes sequentially connected feed hopper 1, homogenization tank 2, biogas digester 3, upflow anaerobic sludge bed reactor 4, activated sludge reaction tank 5, micro-electrolysis reactor 10, baffled aerated biological The filter tank 6 and the ozone disinfection tank 7, the biogas tank is connected with the sludge thickening tank 8; the biogas tank 3 is also connected with the biogas net storage and gas supply system, and the biogas net storage and gas supply system successively includes a gas-water separator 91 and a biogas desulfurization device 92 , the first flame arrester 931, the gas storage tank 94, and the gas-water separator 91 are also connected to the biogas booster device 95, the second flame arrester 932, and the waste heat recovery device 96.

Embodiment 2

[0040] Systems that use activated sludge to treat wastewater, such as Figure 1-2 As shown, it includes sequentially connected feed hopper 1, homogenization tank 2, biogas digester 3, upflow anaerobic sludge bed reactor 4, activated sludge reaction tank 5, micro-electrolysis reactor 10, baffled aerated biological The filter tank 6 and the ozone disinfection tank 7 are connected with a sludge thickening tank 8 , and a regulating tank 11 is provided between the biogas tank 3 and the upflow anaerobic sludge bed reactor 4 . The biogas digester 3 is also connected with a biogas net storage and gas supply system. The biogas net storage and gas supply system sequentially includes a gas-water separator 91, a biogas desulfurization device 92, a first flame arrester 931, and a gas storage cabinet 94. The gas-water separator 91 is also connected to A biogas booster device 95 , a second flame arrester 932 , and a waste heat recovery device 96 .

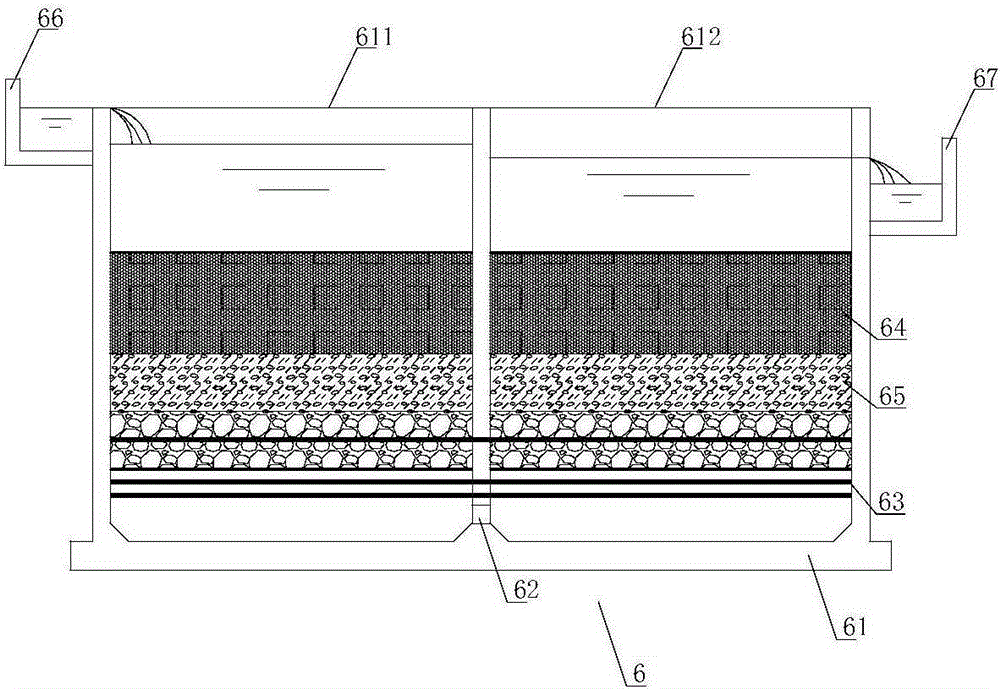

[0041] The baffle biological aerated filt...

Embodiment 3

[0045] The method for using activated sludge to treat wastewater comprises the following steps,

[0046] A. Anaerobic digestion treatment:

[0047] The aquaculture wastewater enters the homogenization tank 2 through the feed hopper 1, and after being evenly prepared under the stirring action of the stirring device of the homogenization tank 2, it is passed into the biogas tank 3;

[0048] The aquaculture wastewater forms a mixed state under the action of the stirring device and the reflux spray system in the biogas tank 3, and the sediment produced in the anaerobic digestion process is discharged to the sludge concentration tank 8 through the sludge discharge port. The sludge pump is pumped away, and the remaining aquaculture wastewater is then passed into the upflow anaerobic sludge bed reactor 4;

[0049] The aquaculture wastewater decomposes the organic matter in the remaining aquaculture wastewater into methane and carbon dioxide under the joint action of anaerobic bacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com