Polyurethane thickener compound with mixed side long-chain alkyl group, and preparation method thereof

A polyurethane thickener and long-chain alkyl technology, which is applied in the field of polyurethane thickener compound and its preparation, can solve the problem that the thickener cannot be fully dissolved or dispersed, affects product quality and use effect, and is inconvenient to organize large-scale Production and other problems, to achieve the effect of enriching thickening, reducing critical association concentration, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

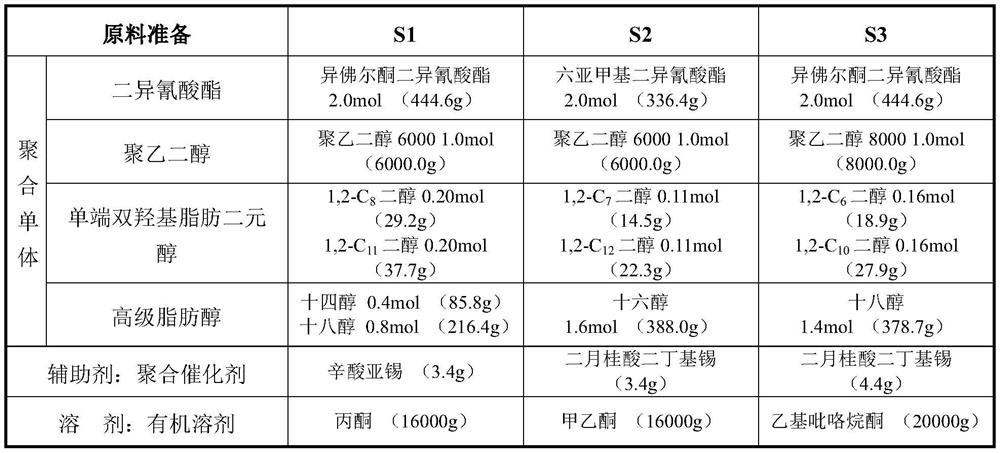

[0057] One aspect of the present invention provides a method for preparing a polyurethane thickener compound with mixed side long-chain alkyl groups, the method comprising the following steps

[0058] (1) Preparation of raw materials: the raw materials contain polymerized monomers, solvents and auxiliary agents; wherein, the polymerized monomers include diisocyanate, polyethylene glycol, single-ended dihydroxy aliphatic diols and higher aliphatic alcohols; the solvent is an organic solvent; The auxiliary agent is a polymerization catalyst;

[0059] Diisocyanate is a kind of in isophorone diisocyanate and hexamethylene diisocyanate;

[0060] Polyethylene glycol is one of the polyethylene glycols with a moisture content not higher than 2‰ and a molecular weight of 4000-8000;

[0061] The single-ended dihydroxy fatty diol is 1,2-C 6~12 2 of diols, and 2 of 1,2-C 6~12 The difference in carbon chain length between diols is 3 to 6, two kinds of 1,2-C 6~12 The molar ratio between...

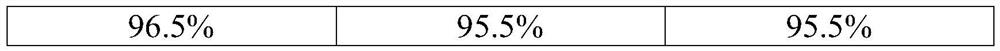

Embodiment 1

[0104] The preparation process of the high-concentration polyurethane thickener S1 with mixed side long-chain alkyl groups is as follows:

[0105] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0106] (2) Prepolymerization: Polyethylene glycol is prepolymerized with diisocyanate, a polymerization catalyst and some organic solvents to prepare a polyurethane thickener prepolymer with mixed side long-chain alkyl groups;

[0107] (2.1) Put diisocyanate and a total amount of 25% organic solvent into the reactor, and heat up to 72°C;

[0108] (2.2) Within 50 minutes, add polyethylene glycol slowly and keep stirring, and control the temperature of the reaction system to 72°C;

[0109] (2.3) After maintaining the temperature of the reaction system at 72°C and keeping it warm for 50 minutes, put in the polymerization catalyst at a constant speed within 12 minutes;

[0110] (2.4) Raise the temperature and contr...

Embodiment 2

[0142] The preparation process of the high-concentration polyurethane thickener S1 with mixed side long-chain alkyl groups is the same as in Example 1.

[0143] The preparation process of the high-concentration polyurethane thickener S3 with mixed side long-chain alkyl groups is as follows:

[0144] (1) raw material preparation, the concrete selection and consumption of described raw material are as shown in table 1;

[0145] (2) Prepolymerization: Polyethylene glycol is prepolymerized with diisocyanate, a polymerization catalyst and some organic solvents to prepare a polyurethane thickener prepolymer with mixed side long-chain alkyl groups;

[0146] (2.1) Put diisocyanate and a total amount of 30% organic solvent into the reactor, and heat up to 78°C;

[0147] (2.2) Within 58 minutes, add polyethylene glycol slowly and keep stirring, and control the temperature of the reaction system to be 78°C;

[0148] (2.3) After maintaining the temperature of the reaction system at 78°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com