Salt-resistant filtrate-loss reducer for drilling fluid and preparation method of salt-resistant filtrate-loss reducer

A fluid loss control agent and drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of equipment and operators, such as safety, inability to effectively adjust flow patterns, and low polymer molecular weight, etc. Achieve the effect of inhibiting clay dispersion, good compatibility and high charge density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] An anti-salt fluid loss reducer for drilling fluid, which includes the following raw materials: 2400kg of acrylamide, 240kg of soda ash, 50kg of AMPS, 200kg of calcium hydroxide, and 7.2kg of N, N methylenebisacrylamide.

[0017] The preparation method of the above-mentioned anti-salt fluid loss reducer for drilling fluid:

[0018] (1) Add an appropriate amount of water to the acrylamide and soda ash to make a solution with a total mass concentration of 25%. Under the protection of nitrogen, add 11.2 kg of potassium persulfate to carry out polymerization reaction. Reaction ends; Continue heat preservation hydrolysis reaction 6h to obtain colloid;

[0019] (2) Add the 2-acrylamide-2-methylpropanesulfonic acid, calcium hydroxide and N,N-methyleneacrylamide to the colloid obtained in step (1), and react at 80°C for 5 hours;

[0020] (3) Dry and pulverize the obtained product.

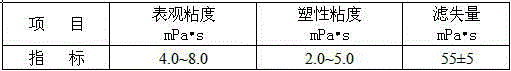

[0021] The performance test of the fluid loss control agent is carried out, and the fluid loss...

Embodiment 2

[0084] An anti-salt fluid loss reducer for drilling fluid, which includes the following raw materials: 3600kg of acrylamide, 180kg of soda ash, 200kg of AMPS, 100kg of calcium hydroxide, and 5kg of N,N methylenebisacrylamide.

[0085] The preparation method of the above-mentioned anti-salt fluid loss reducer for drilling fluid:

[0086] (1) Add an appropriate amount of water to the acrylamide and soda ash to make a solution with a total mass concentration of 35%. Under the protection of nitrogen, add 3.6 kg of potassium persulfate to carry out polymerization reaction. The reaction is over; heating to 80°C for 7 hours of heat preservation and hydrolysis reaction to obtain colloid;

[0087] (2) Add the 2-acrylamide-2-methylpropanesulfonic acid, calcium hydroxide and N,N-methyleneacrylamide to the colloid obtained in step (1), and react at 80°C for 5 hours;

[0088] (3) Dry and pulverize the obtained product.

Embodiment 3

[0090] An anti-salt fluid loss reducer for drilling fluid, which comprises the following raw materials: 3000 kg of acrylamide, 350 kg of soda ash, 300 kg of calcium hydroxide, and 10 kg of N, N methylenebisacrylamide.

[0091] The preparation method of the above-mentioned anti-salt fluid loss reducer for drilling fluid:

[0092] (1) Add an appropriate amount of water to the acrylamide and soda ash to make a solution with a total mass concentration of 30%. Under the protection of nitrogen, add 12 kg of potassium persulfate to carry out polymerization reaction. The reaction is over; adjust the temperature to 80°C and heat-preserve the hydrolysis reaction for 8 hours to obtain the colloid;

[0093] (2) Add the 2-acrylamide-2-methylpropanesulfonic acid, calcium hydroxide and N,N-methyleneacrylamide to the colloid obtained in step (1), and react at 80°C for 4 hours;

[0094] (3) Dry and pulverize the obtained product.

[0095] The performance of the fluid loss control agent obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com