Salt-resistant filtrate loss reducer for grafted starch drilling fluid

A technology of grafting starch and fluid loss reducer, which is applied in drilling compositions, chemical instruments and methods, etc., can solve problems affecting the stability of oil and gas formations and product quality, high equipment investment and raw material costs, and liquid phase infiltration of drilling fluids. formation and other problems, to achieve the effect of being beneficial to the control of the process, improving the drilling efficiency and oil quality, and improving the solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

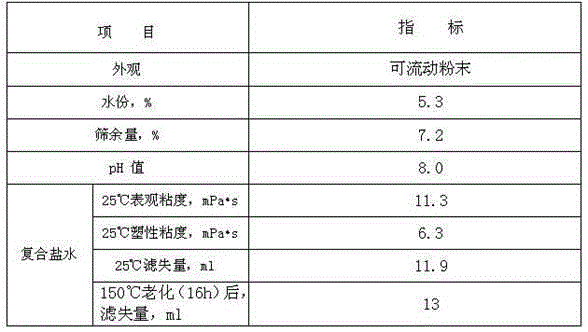

Image

Examples

Embodiment 1

[0026] The raw materials of embodiment 1 are selected: acrylamide 2400kg, 2-acrylamide-2-methylpropanesulfonic acid 50kg, soda ash 240kg, starch 1500kg.

[0027] The preparation process of the present embodiment is:

[0028] Step (1) Raw material preparation: Prepare acrylamide aqueous solution and soda ash aqueous solution respectively. The total mass of water used is 3-5 times the mass of acrylamide. After the preparation is completed, mix the two aqueous solutions to obtain a feed liquid. After adding to the reactor, close the reaction Nitrogen is fed into the kettle valve, and then an auxiliary agent is added; the consumption of the auxiliary agent is 0.5% of the acrylamide quality, and the auxiliary agent is potassium persulfate;

[0029] Step (2) Polymerization reaction: Initiate at a low temperature of 5-11°C, without temperature control to 60-90°C;

[0030] Step (3) Hydrolysis reaction: After the polymerization reaction, keep the temperature in the kettle at 60°C-90°C...

Embodiment 2-7

[0041] The difference between Examples 2-7 and Example 1 lies in the raw materials and proportioning ratio, and the proportioning ratio is in kg, see Table 2 for details.

[0042] The raw material of table 2 embodiment 2-7 and proportioning

[0043]

[0044] The anti-salt and dehumidifying agent of this embodiment is non-toxic, harmless to the environment and the human body, and its safety index conforms to the International Material Safety Data Sheet (MSDS).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com