Coated inhibitor for drilling fluid and its preparation method and application

A technology of coating inhibitors and drilling fluids, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost of polymerization reaction, high cost of drilling fluid, high monomer price, etc., and achieve the purpose of inhibiting hydration dispersion , prevent well wall collapse, easy biodegradable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

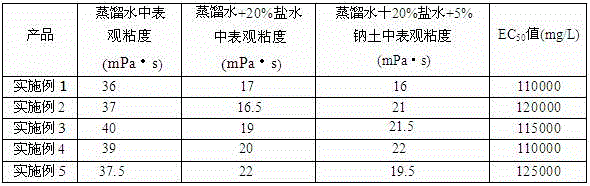

Embodiment 1

[0027] Take 250 parts of konjac gum by weight and dissolve in a mixed solution of 900 parts of 95% ethanol and 220 parts of water, then add 2.4 parts of anhydrous sodium carbonate, 6 parts of glycerin, 280 parts of 30% trimethylamine and 420 parts of epoxy chloride Propane was reacted in the reaction kettle under reflux condensation conditions for 4.5 hours, centrifuged for half an hour, the solid particles were separated, and dried at 100°C for 7 hours to obtain the natural polymer strong coating inhibitor for drilling fluid in this example .

Embodiment 2

[0029] Take 260 parts of Tianqing glue by weight and dissolve in a mixed solution of 1000 parts of 95% ethanol and 230 parts of water, then add 2.5 parts of anhydrous sodium carbonate, 8 parts of glycerin, 290 parts of 30% trimethylamine and 410 parts of epoxy Chloropropane was reacted in the reaction kettle under the condition of reflux condensation for 5 hours, centrifuged for half an hour to separate the solid particles, and dried at 90°C for 8 hours to obtain the natural polymer strong coating inhibitor for drilling fluid in this example. agent.

Embodiment 3

[0031] Take 240 parts of coriander gum by weight and dissolve it in a mixed solution of 900 parts of 95% ethanol and 240 parts of water, then add 2.6 parts of anhydrous sodium carbonate, 9 parts of glycerin, 300 parts of 30% trimethylamine and 430 parts of epoxy Chloropropane was reacted in the reaction kettle under reflux condensation conditions for 4.5 hours, centrifuged for half an hour to separate solid particles, and dried at 105°C for 6 hours to obtain the natural polymer strong coating inhibitor for drilling fluid in this example. agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com