Clay-free low-solid horizontal drilling fluid and preparation method thereof

A technology of horizontal well section and low solid phase, applied in petroleum drilling engineering and drilling fluid fields, can solve the problems of inability to drill deep wells, inability to drill for a long time, poor temperature resistance of drilling fluid, etc. Ensure wellbore cleanliness and good temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

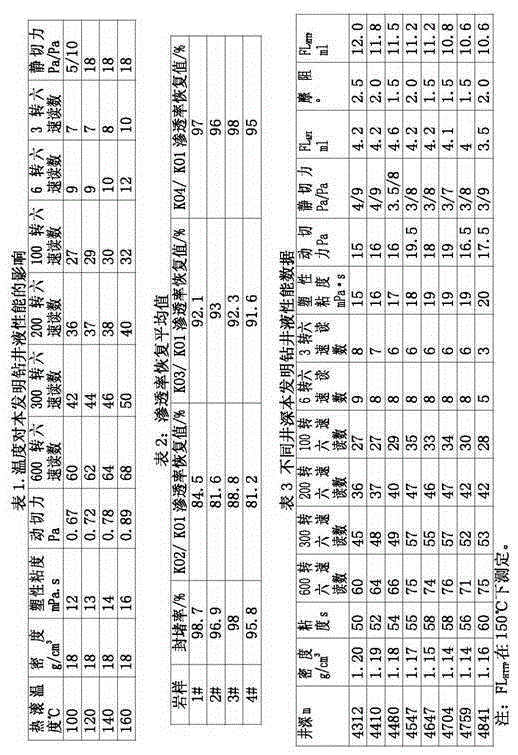

Examples

Embodiment 1

[0014] Embodiment 1, this clay-free low-solid phase horizontal drilling fluid is obtained according to the following preparation method: add 0.2 grams to 0.4 grams of alkalinity regulator and 2 grams to 3 grams of fluid loss reducer per 100 milliliters of water, extract Cutting agent 0.5g to 1g, superfine calcium carbonate 5g to 10g, liquid lubricant 2g to 3g and potassium chloride 3g to 15g, and mix well to obtain clay-free low solid phase horizontal drilling fluid . The application of liquid lubricants in this system mainly includes oil-based liquid lubricants with waste engine oil, aviation kerosene, and mineral oil as the continuous phase.

Embodiment 2

[0015] Embodiment 2, this clay-free low-solid phase horizontal drilling fluid is obtained according to the following preparation method: add 0.2 grams or 0.4 grams of alkalinity modifier, 2 grams or 3 grams of fluid loss reducer, and extract Cutting agent 0.5g or 1g, superfine calcium carbonate 5g or 10g, liquid lubricant 2g or 3g and potassium chloride 3g or 15g, and mix well to obtain clay-free low-solid horizontal drilling fluid .

Embodiment 3

[0016] Embodiment 3, as the preference of the above embodiment, the alkalinity regulator is sodium hydroxide or potassium hydroxide or calcium hydroxide; or / and, the fluid loss control agent is a composite of cellulose and modified starch in a mass ratio of 1:4 , the cellulose is polyanionic cellulose or low viscosity sodium carboxymethyl cellulose or hydroxyethyl cellulose, the modified starch is hydroxypropyl starch derivatives or sodium carboxymethyl starch or hydroxyethyl starch; or / and , the cutting agent is xanthan gum or solid-free drilling fluid weak gel cutting agent or biopolymer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com