Preparation method of high-temperature resistant composite humidity-controlling material

A technology of humidity-controlling materials and high-temperature resistance, which is applied in the field of preparation of high-temperature-resistant composite humidity-conditioning materials, which can solve the problems of small humidity release, space pollution and instability of stored items, and achieve the effect of increasing humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

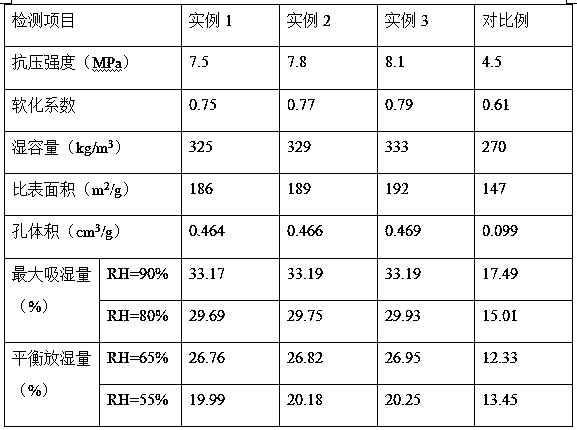

Examples

Embodiment Construction

[0024]Weigh 200-300g of diatomaceous earth, put it into a beaker, add 300-400mL of water, stir for 5-10 minutes and let it stand until the suspension is divided into three layers, pour out the floating matter on the top layer, and slowly pour out the middle layer, To obtain high-purity diatomite, filter the remaining suspension in the lower layer, remove the filtrate to obtain a precipitate, put the high-purity diatomite and the precipitate into an oven, heat up to 100-120°C, and dry for 2-3 hours to obtain Dry diatomaceous earth, dry sediment; in parts by weight, weigh 20-30 parts of feldspar, 30-40 parts of 200-mesh talcum powder, 40-50 parts of clay and 20-30 parts of dry sediment, and mix to obtain a mixed Raw materials, mix the mixed raw materials and balls according to the mass ratio of 1:15, put them into the ball mill tank, and perform ball milling at a speed of 300-400r / min for 11-13 hours, then add 5-10 parts of water and Continue ball milling 30-40 parts of dry diat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com