A dendritic quaternary ammonium salt shale inhibitor and its preparation method and application

A shale inhibitor and dendritic technology, applied in the field of mud shale inhibitor for drilling fluid and its preparation, can solve the problems of low temperature resistance, limited wide application, etc. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045]With ethylenediamine as the initiator nucleus, methyl acrylate and ethylenediamine as the reaction raw materials, Michael addition reaction and amidation reaction are alternately carried out to obtain polyamide-amine dendrimers of different generations (PAMAM-Gn, n is Algebra), the specific synthesis steps refer to Chinese patent document CN201110073112.6.

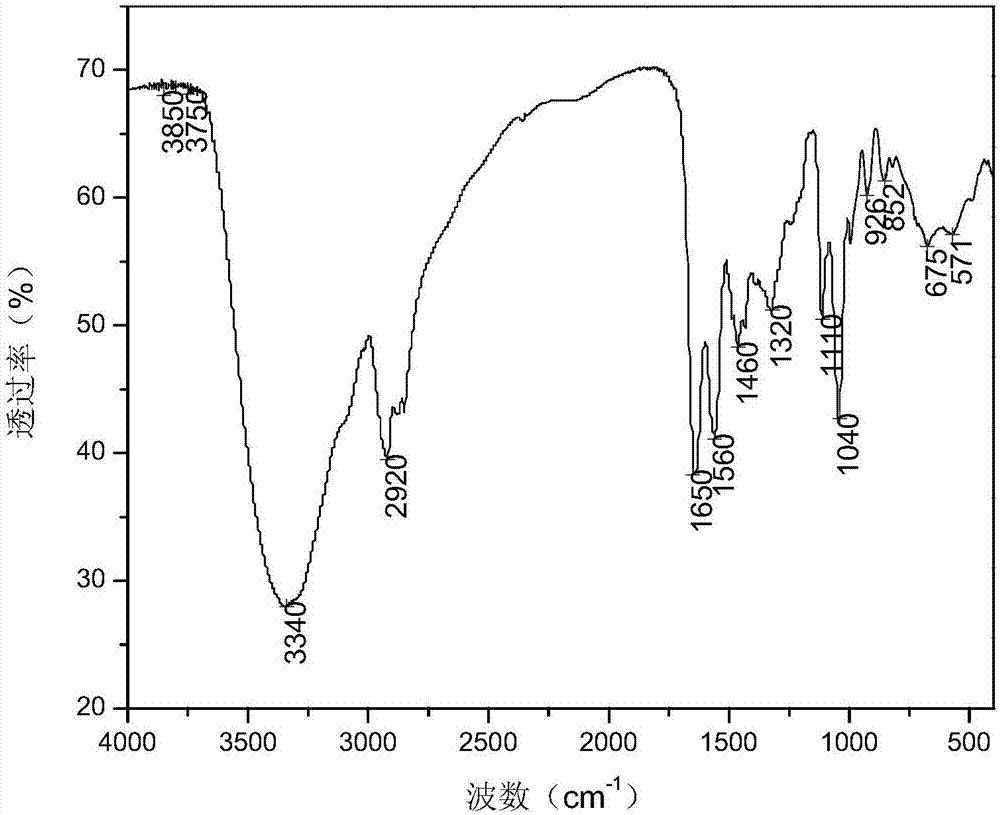

[0046] Then polyamide-amine dendrimers of different generations react with epichlorohydrin and triethylamine to undergo quaternization to obtain modified cationic polyamide-amine dendritic quaternary ammonium salts. The synthetic route is as follows:

[0047]

[0048] In a 250mL four-neck flask with a condenser, add 100mL of anhydrous methanol as a solvent, weigh 10.0g of PAMAM-G0 and 8.0g of triethylamine and dissolve in anhydrous methanol, and stir at room temperature for 1h. After it was fully dissolved, 7.2 g of epichlorohydrin was slowly added dropwise at a rate of 20 drops / min. After the dropwise addition, ...

Embodiment 2

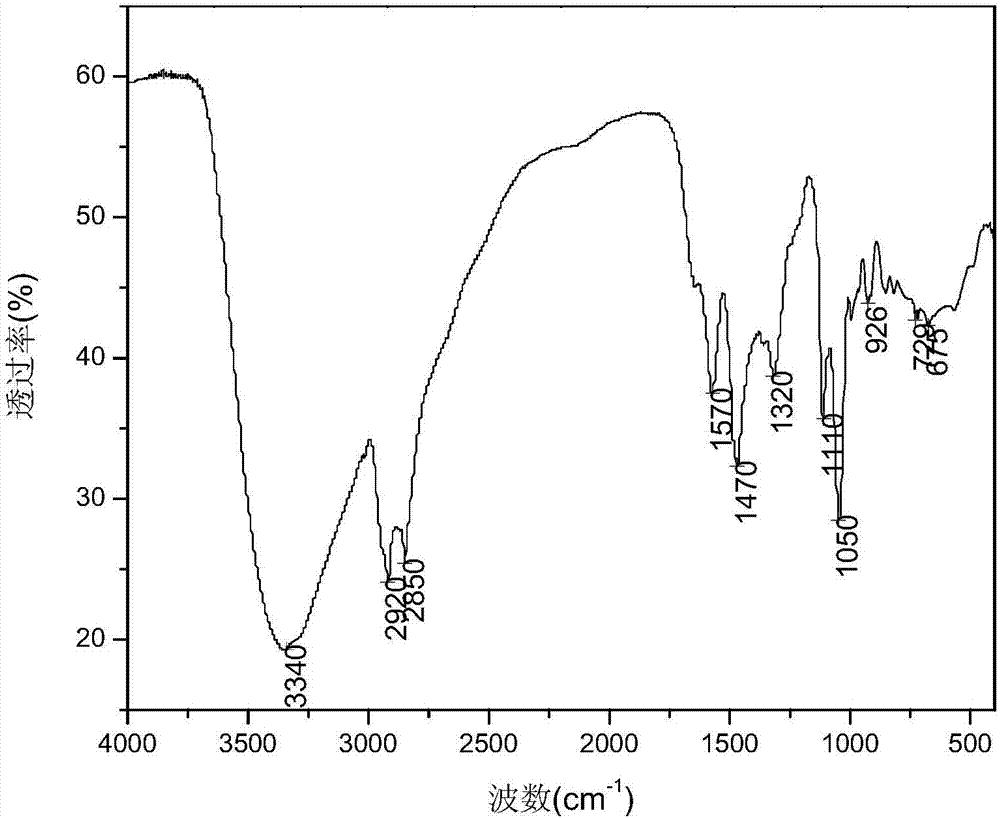

[0052] With ethylenediamine as the initiator nucleus and acrylonitrile as the repeating unit, the N-alkylation reaction and the reduction reaction of polynitriles are alternately repeated to obtain polypropyleneimine dendrimers of different generations (PPI-Gn, n is the generation number ), its synthesis method refers to Chinese patent documents CN201010586069.9 and 201210290336.7.

[0053] Then the polypropyleneimine dendrimers of different generations react with epichlorohydrin and trimethylamine to obtain a modified cationic polypropyleneimine dendritic quaternary ammonium salt. The synthetic route is as follows:

[0054]

[0055] In a 250mL four-necked flask with a condenser, add 100mL of anhydrous methanol as a solvent, weigh 10.0g of G1-generation PPI and 12.7g of trimethylamine, dissolve in anhydrous methanol, and stir magnetically at room temperature for 0.5h. After it was fully dissolved, 19.9 g of epichlorohydrin was slowly added dropwise at a rate of 20 drops / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com