Harm-free core-drilling fluid, and its preparing method and use

A drilling fluid, non-destructive technology, used in the field of coring drilling fluid and its preparation, can solve the problems of strong chip carrying ability, no consideration of other aspects, and high requirements for filtration equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0245] Water 100000kg NaCl 15000kg NaCl 2 CO 3 200kg NaOH 50kg

[0246] Sodium Carboxymethyl Cellulose PAC-SL 150kg Xanthan Gum FLOWZAN 200kg

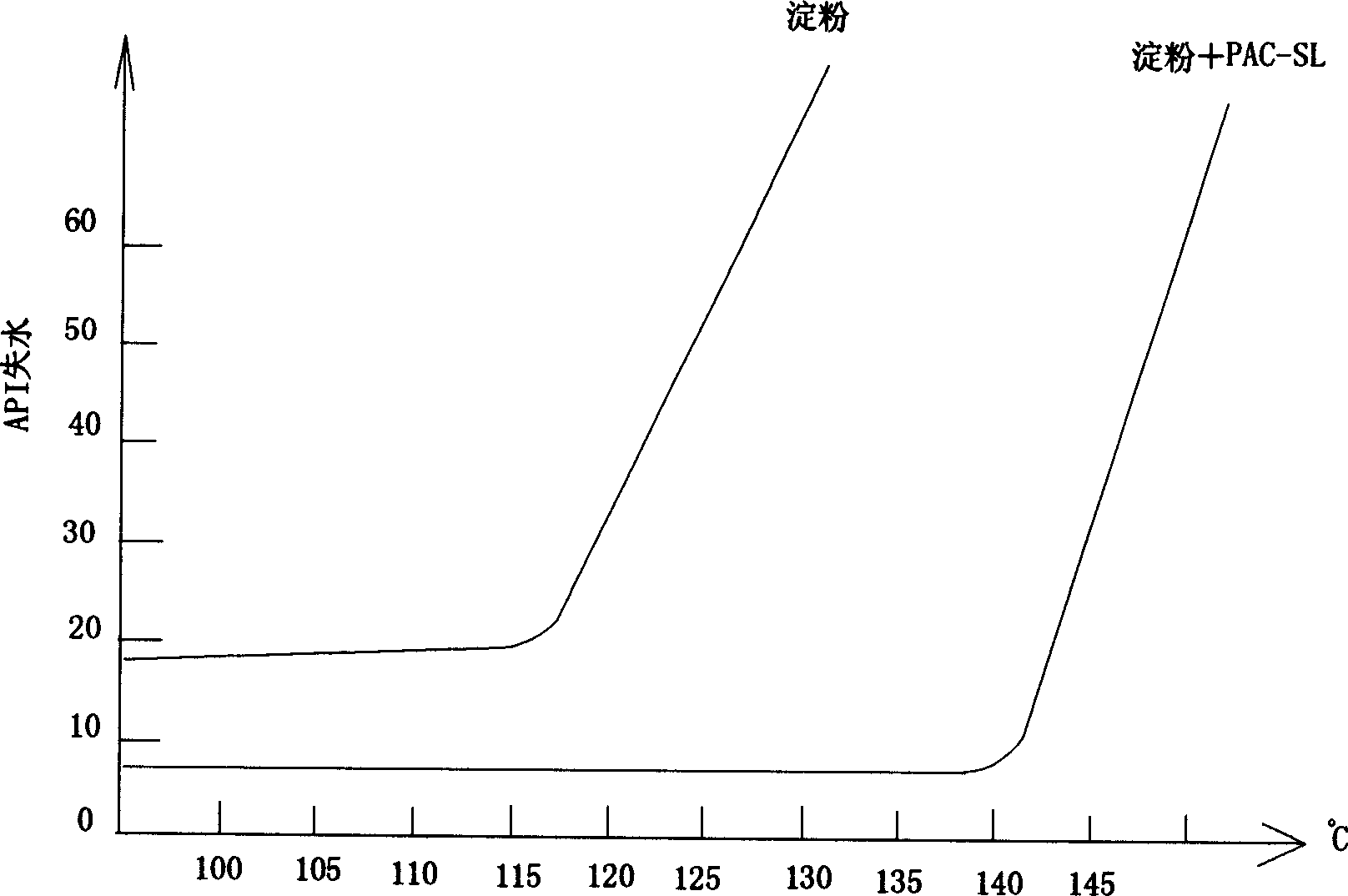

[0247] Water loss reducing agent starch Stacrch 1200kg Modified asphalt SOLTEX 1200kg

[0248] Baracarb (5) calcium carbonate a 2000kg Baracarb (50) calcium carbonate b 2000kg

[0249] Baracarb (600) calcium carbonate c 2000kg

[0250] A kind of preparation method of non-damaging coring drilling fluid:

[0251] (a) In terms of weight ratio, add a certain amount of Na to water 2 CO 3 , used to remove the calcium Ca contained in the water, and then add a certain amount of NaOH in the water to remove the magnesium Mg contained in the water;

[0252] (b) In terms of weight proportion, xanthan gum FLOWZAN needs to be slowly added to the treated water with a high-shear rate shear pump, generally at a rate of 20 minutes per bag, until the viscosity of the aqueous solution is about 35s. Shear value 10pa;

[0253] (c) In terms of weig...

Embodiment 2

[0257] Water 160000kg NaCl 19000kg Na 2 CO 3 400kg NaOH 150kg

[0258] Sodium Carboxymethyl Cellulose PAC-SL 550kg Xanthan Gum FLOWZAN 600kg

[0259] Water loss reducing agent starch Stacrch 1800kg Modified asphalt SOLTEX 1800kg

[0260] Baracarb (5) calcium carbonate a 4000kg Baracarb (50) calcium carbonate b 4000kg

[0261] Baracarb (600) calcium carbonate c 4000kg

[0262] Its preparation method is with embodiment 1.

Embodiment 3

[0264] Water 120000kg NaCl 16000kg Na 2 CO 3 250kg NaOH 70kg

[0265] Sodium Carboxymethyl Cellulose PAC-SL 200kg Xanthan Gum FLOWZAN 300kg

[0266]Water loss reducing agent starch Stacrch 1400kg Modified asphalt SOLTEX 1400kg

[0267] Baracarb (5) calcium carbonate a 2500kg Baracarb (50) calcium carbonate b 2500kg

[0268] Baracarb (600) calcium carbonate c 2500kg

[0269] Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com