Environment-friendly pseudo oil-based drilling fluid and preparation method thereof

A drilling fluid imitation oil-based technology, applied in the field of drilling fluid, can solve the problems of difficult environmental protection disposal of cuttings and waste fluid, high cost of oil-based drilling fluid preparation, difficult rheological control, etc., to achieve environmental protection disposal, The effect of low requirements for solid control equipment and easy control of rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

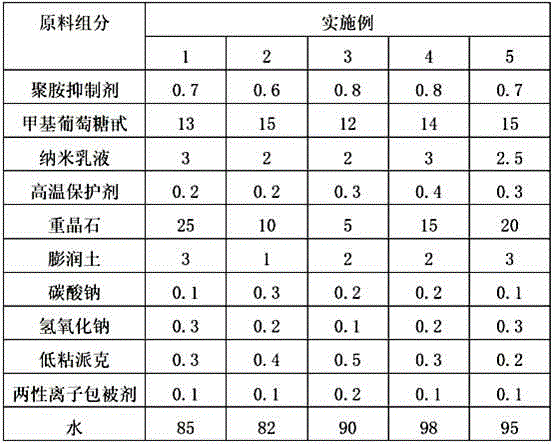

[0030] A number of preferred embodiments of the present invention are enumerated below in the form of a list, so as to describe the content of the present invention in detail. The preferred 5 embodiments of the present invention are shown in Table 1.

[0031] Table 1 Five groups of formulas of the present invention (raw material components and content, unit: weight part)

[0032]

[0033] The above-mentioned polyamine inhibitor adopts polyamine inhibitor NH-1; the nanoemulsion adopts lubricating plugging agent SDJ-2; the high-temperature protective agent adopts high-temperature protective agent GBH; the density of barite is 4.2g / cm 3 , The particle size of barite can be adjusted; NV-1 is used for bentonite; LV-PAC is used for low viscosity Parker; Zwitterionic coating agent is zwitterionic polymer coating agent.

[0034] The preparation method of each of the above examples includes the following sequential steps: 1). Add sodium hydroxide and sodium carbonate to water respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com