Patents

Literature

123 results about "O methylglucose" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sheet-like shampoo product

InactiveCN106726634AAvoid the problem of excessive water consumptionReduce storage costsCosmetic preparationsHair cosmeticsBetaineVitamin C

The invention provides a sheet-like shampoo product. The sheet-like shampoo product comprises the following components in percentage by weight: 10 to 20 percent of a film-forming agent, 10 to 40 percent of sodium lauryl sulfate, 1 to 10 percent of polyoxyethylene fatty alcohol sodium sulfate, 1 to 10 percent of fatty acid diethanol amide, 1 to 5 percent of polyalcohol, 1 to 5 percent of polyethylene glycol-methyl glucose ester, 0 to 10 percent of coconut oil amide propyl betaine, 0 to 10 percent of coconut oil betaine, 10 to 30 percent of sodium lauroyl glutamate, 0 to 5 percent of sodium citrate, 0.1 to 1 percent of vitamin E, 0.1 to 1 percent of vitamin C, 0.1 to 1 percent of panthenol, 0 to 10 percent of traditional Chinese medicine extracts and the balance of deionized water. The sheet-like shampoo product is excellent and reasonable in formula and convenient to use, the problem that water resource is consumed excessively because the shampoo product contains a large amount of water is solved, the product volume is shortened, a large amount of transportation cost and warehousing cost are reduced, and environmental pollution can be reduced.

Owner:GUANGZHOU LANJIEBAO BIOTECH CO LTD

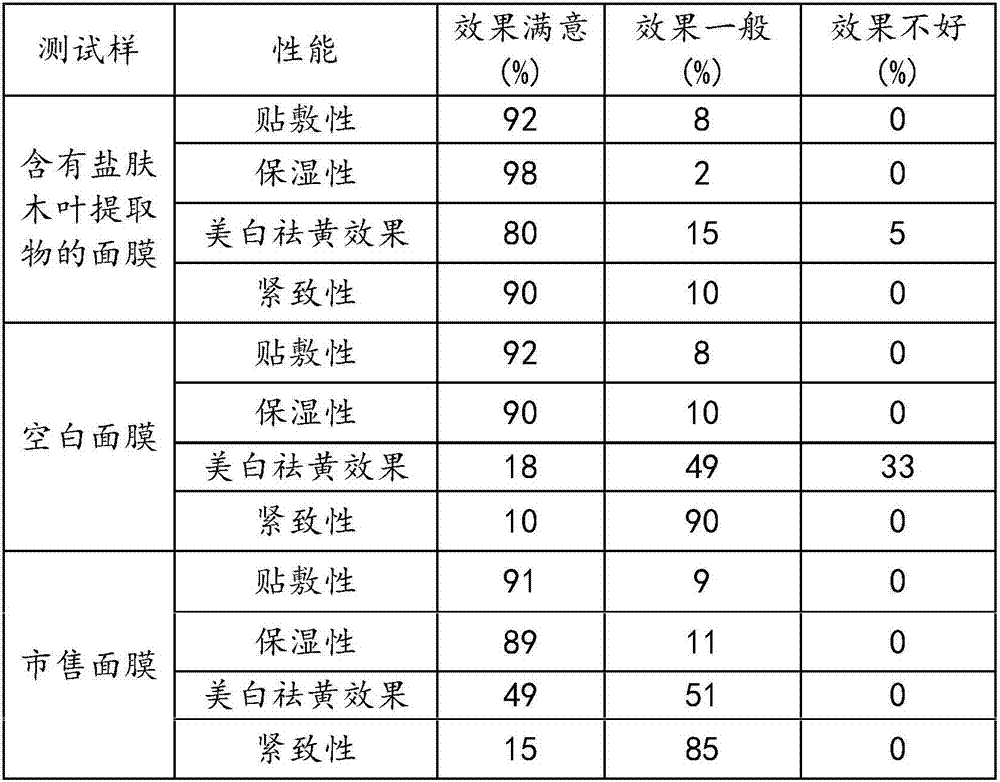

Facial mask with rhus chinensis leaf extract and method for preparing facial mask

InactiveCN107362084ABiologically activeWide range of pharmacological effectsCosmetic preparationsToilet preparationsBetainePolyethylene glycol

The invention provides a facial mask with rhus chinensis leaf extract and a method for preparing the facial mask. The facial mask comprises facial mask base cloth and facial mask essence. The facial mask essence comprises allantoin, methylparaben, EDTA (ethylene diamine tetraacetic acid) disodium, glycerin, betaine, xanthan gum, polyacrylate cross-linked polymers-6, methyl glucitol polyether-10, panthenol, PEG-40 (polyethylene glycol-40) hydrogenated castor oil, beta-glucan, ceramide 3, chitosan oligosaccharide, hyaluronic acid, caprylyl hydroximic acid, polypeptides, the rhus chinensis leaf extract and water. The method for preparing the facial mask includes steps of 1), preparing the rhus chinensis leaf extract by the aid of steps of repeated extraction, micro-filtration and ultra-filtration, reduced-pressure distillation and concentration, spray drying and the like; 2), preparing the facial mask with the rhus chinensis leaf extract. The facial mask and the method have the advantages that a main active component of the facial mask is the natural plant extract, and accordingly obvious tightening, anti-wrinkle, moisturizing and skin whitening effects can be realized by the facial mask; raw materials for the facial mask can come from wide sources, and the method is simple.

Owner:张家界久瑞健康产业发展有限公司

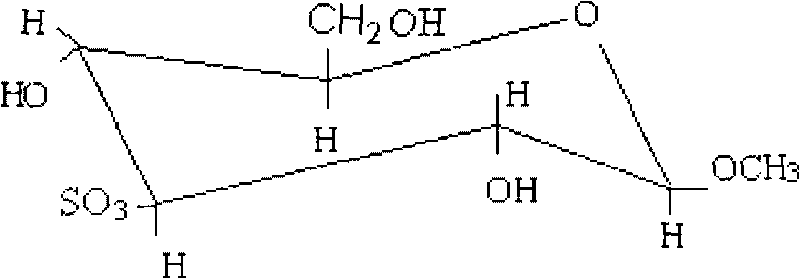

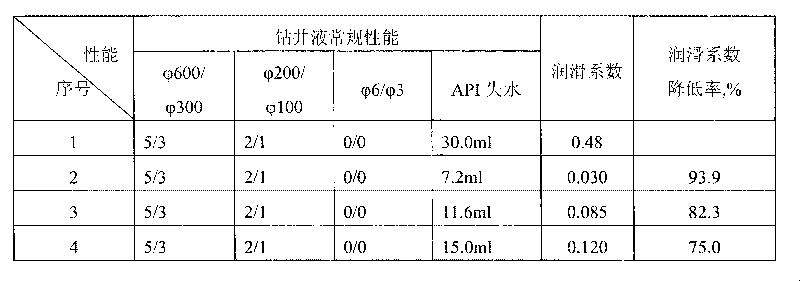

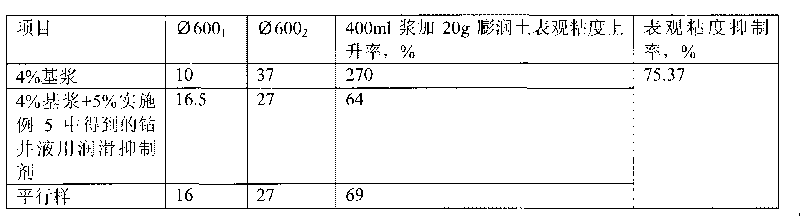

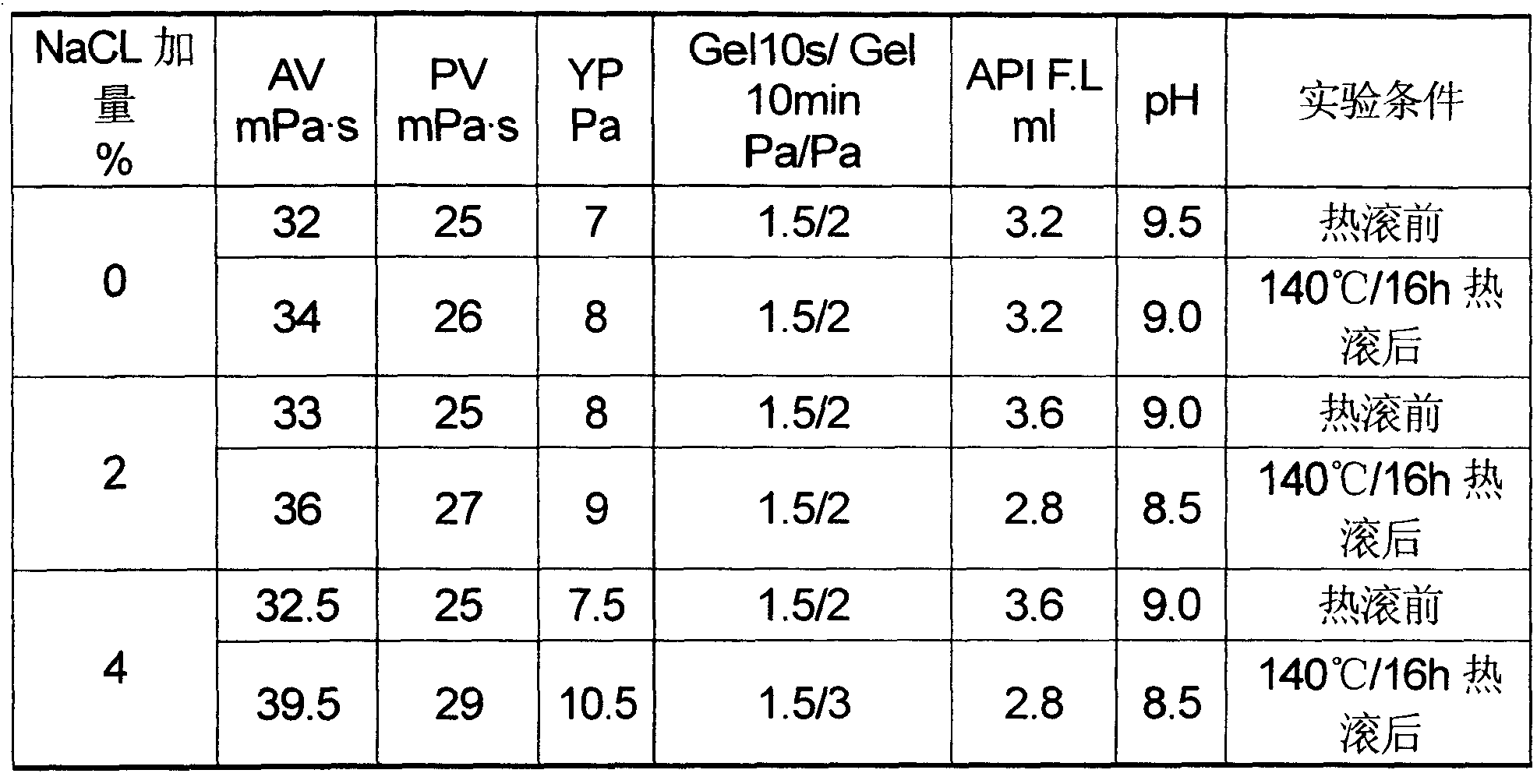

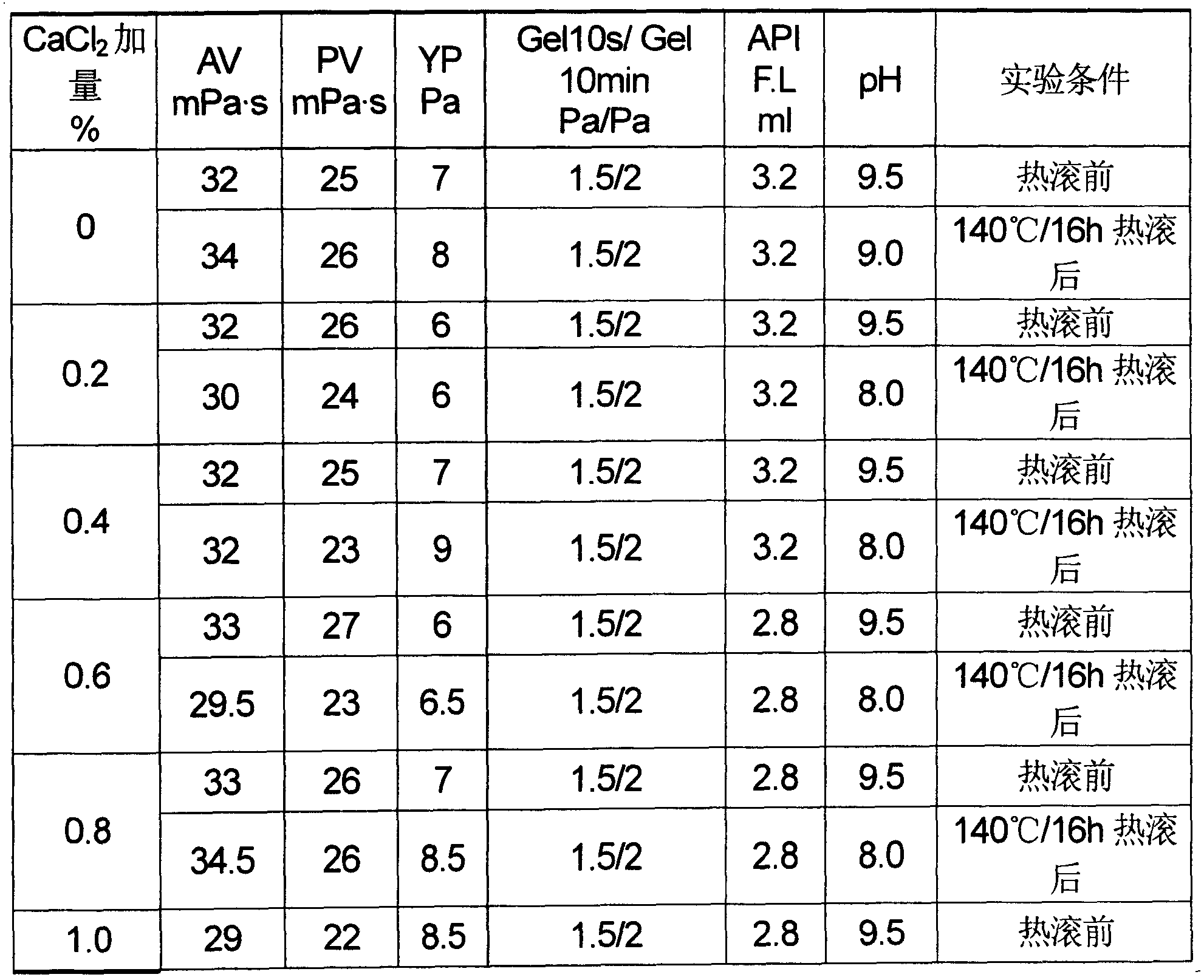

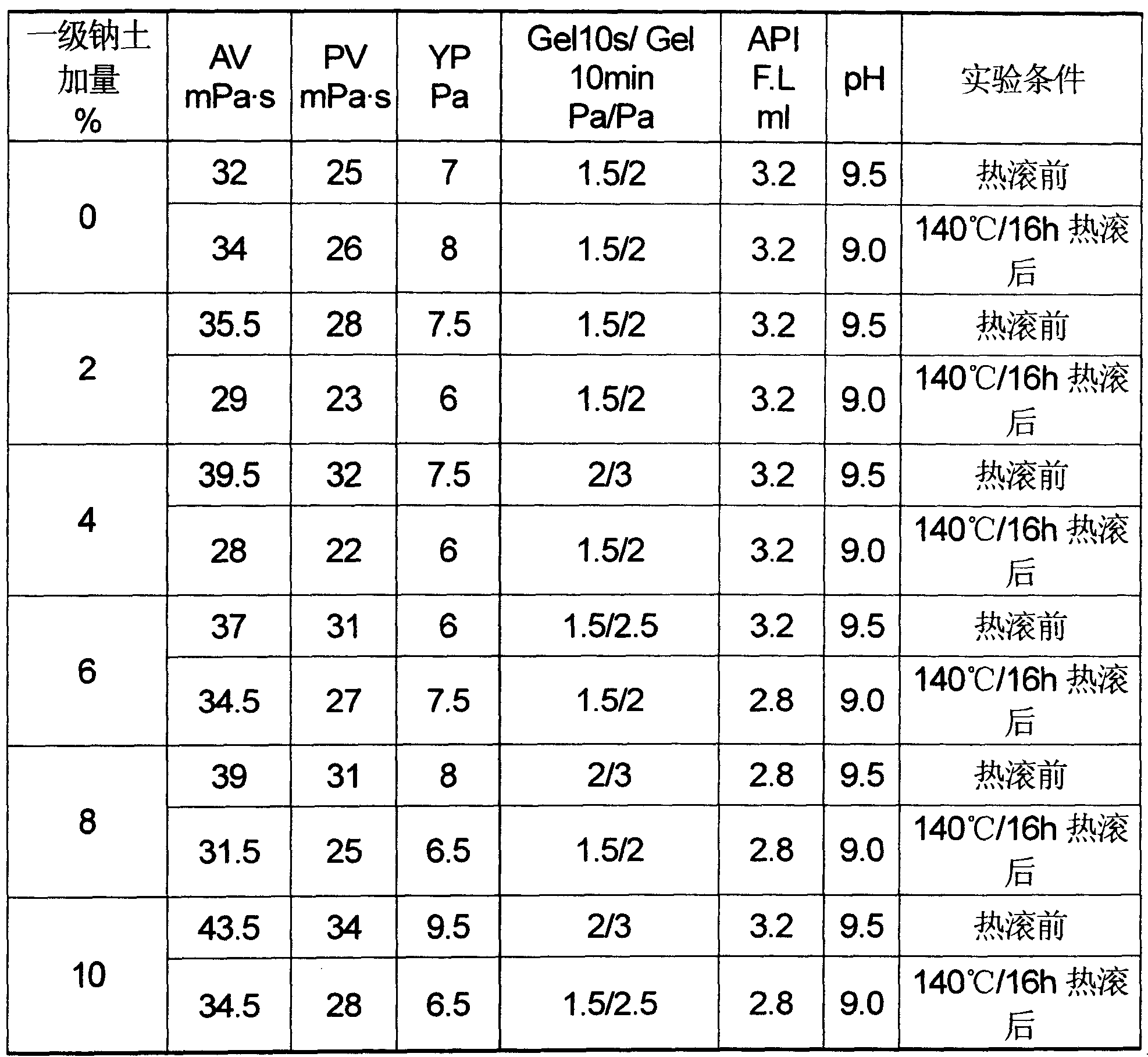

Lubricating inhibitor for drilling fluid and preparation method thereof and drilling fluid containing lubricating inhibitor for drilling fluid

ActiveCN101717622AImprove thermal stabilityImprove stabilitySugar derivativesDrilling compositionWell drillingO methylglucose

The invention relates to a lubricating inhibitor containing methylglucoside compounds for a drilling fluid and a preparation method of the lubricating inhibitor for the drilling fluid and the drilling fluid containing the lubricating inhibitor for the drilling fluid. The comprehensive performance of the drilling fluid can be compared with that of an oil-based drilling fluid; in addition, the invention can overcome the defects that the oil-based drilling fluid pollutes the environment, influences the display of an oil-gas layer and has high cost.

Owner:北京奥凯立科技发展股份有限公司

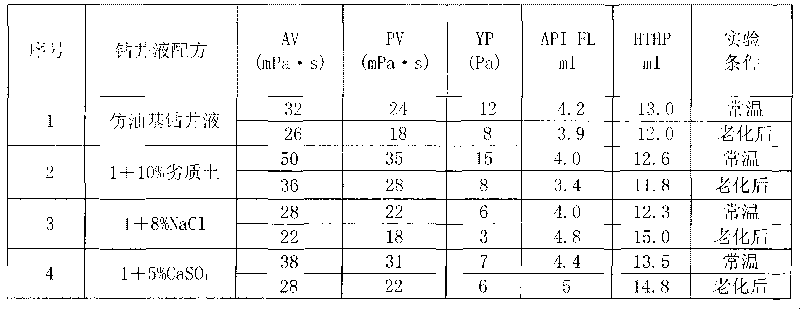

Biology modified silicate drilling fluid system

The invention relates to an environment-friendly and anti-sloughing water-based bio-modified silicate drilling fluid system, which consists of freshwater or seawater slurry, xanthan gum, low viscosity polyanionic cellulose, sulfonated phenolic resin, methylglucoside, non-permeation treatment agent, hydroxy film forming agent, low fluorescence asphalt, extreme pressure lubricator, sodium silicate, potassium chloride and fresh water or sea water. The drilling fluid system of the invention is an environment-friendly anti-sloughing water-based bio-modified silicate drilling fluid system, the comprehensive properties of which can be compared with that of oil-based drilling fluid, but the plugging capacity is greatly better than that of oil-based drilling fluid.

Owner:北京奥凯立科技发展股份有限公司

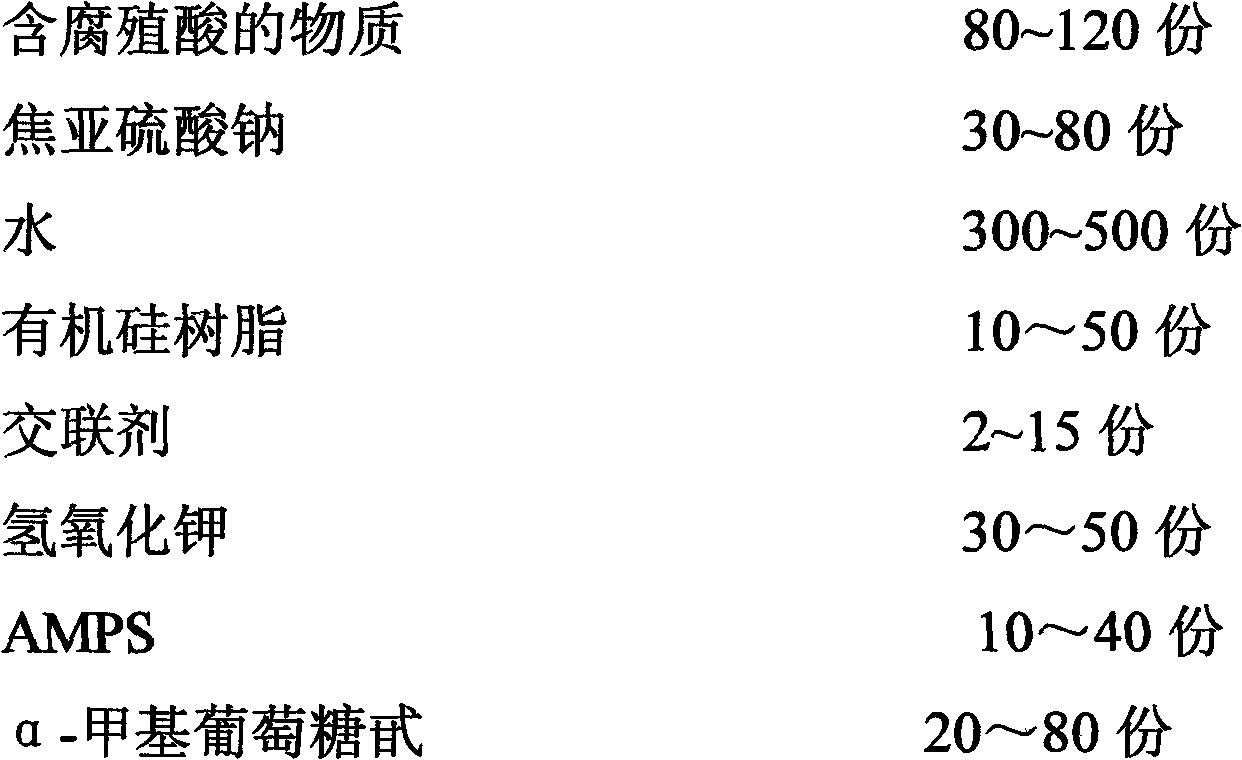

Petroleum drilling additive high temperature-resistant filtrate reducer and preparation method thereof

ActiveCN102344782AImprove temperature resistanceReduce fluid lossDrilling compositionCross-linkFiltration

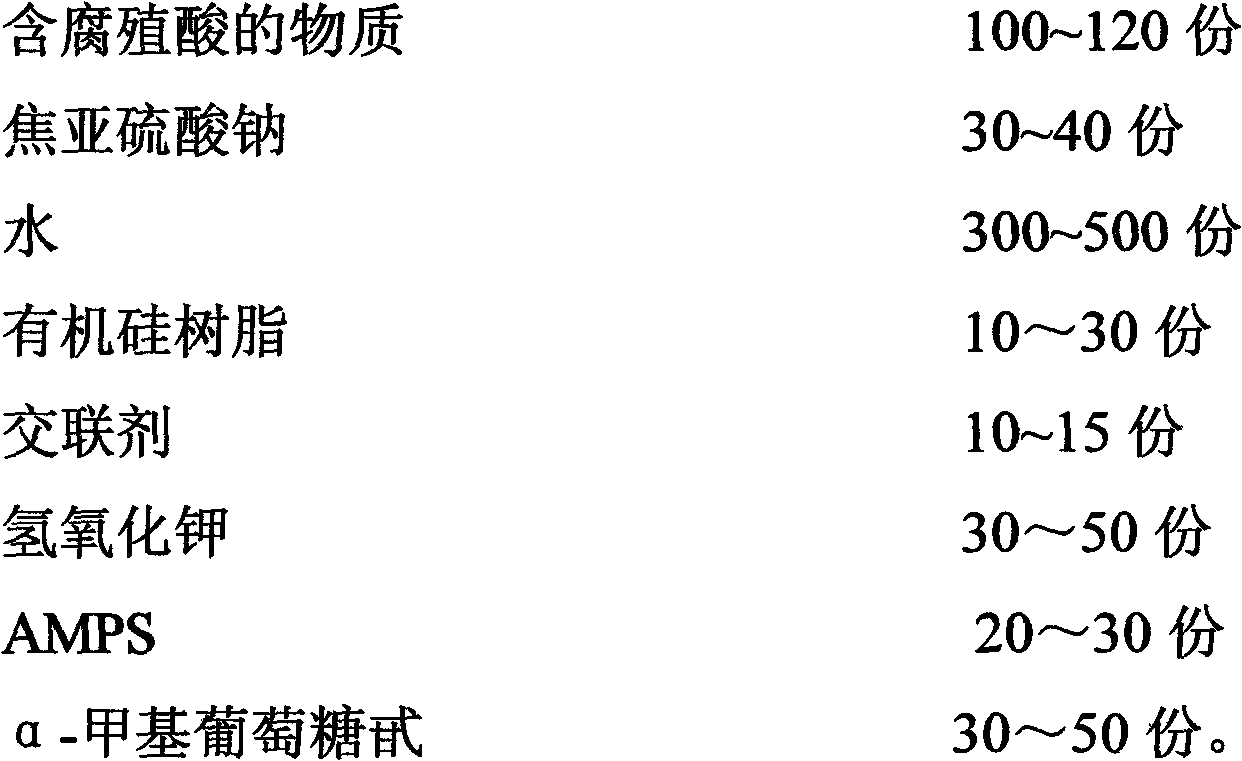

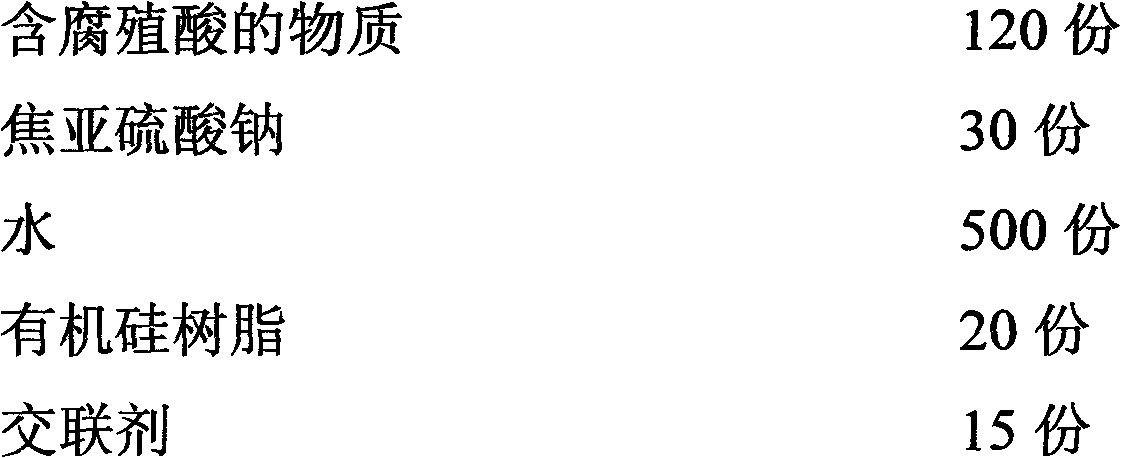

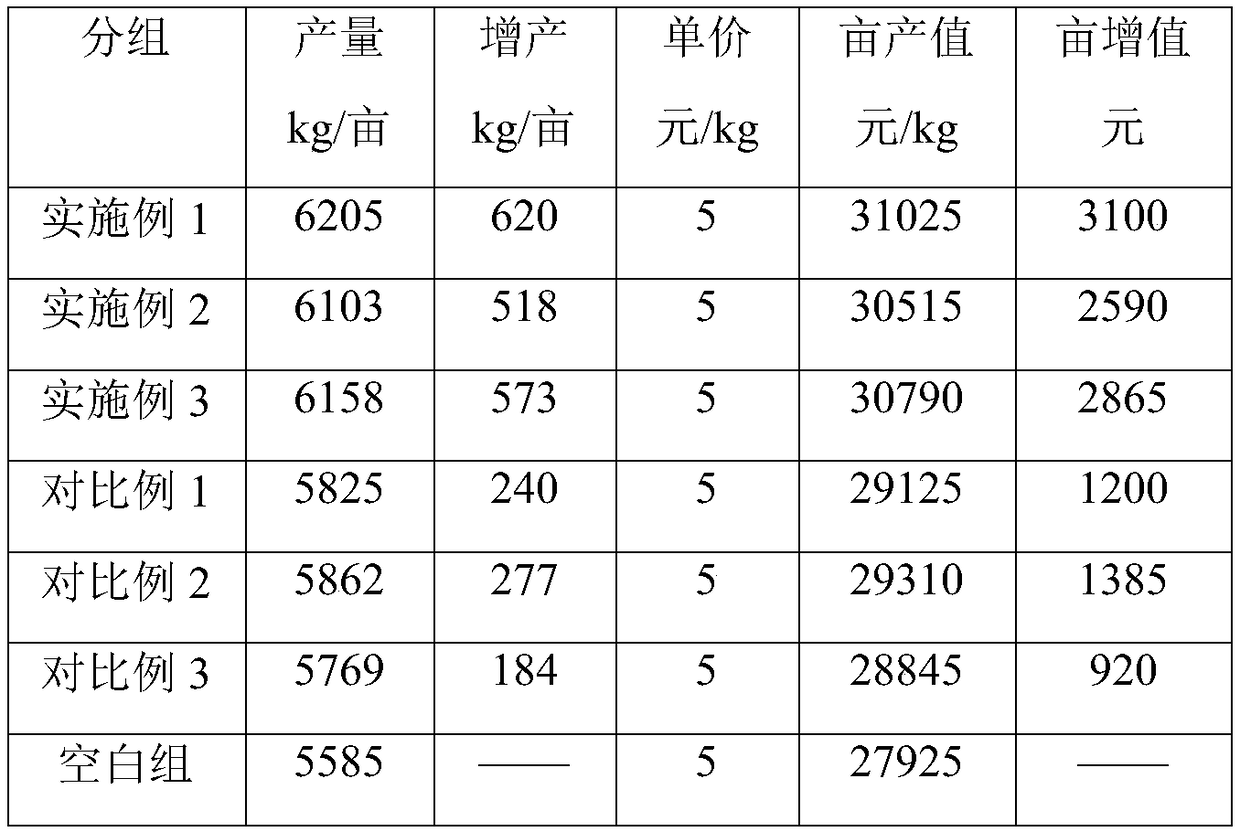

A petroleum drilling additive high temperature-resistant filtrate reducer and a preparation method thereof. The filtrate reducer is prepared by the following raw materials by weight: a humic acid-containing substance, sodium pyrosulfite, water, organic silicon resin, a cross-linking agent, potassium hydroxide, AMPS, alpha-methylglucoside. The preparation method of the filtrate reducer comprises the following steps: weighing water, potassium hydroxide, lignite or peat or weathered coal, sodium pyrosulfite according to the weight parts, adding into a stirring reaction vessel, sealing, heating, reacting, cooling; adding organic silicon resins, cross-linking agents, AMPS, alpha-methylglucoside weighed according to the weight parts into the stirring reaction vessel, sealing, heating, stirring and reacting; discharging the materials, drying the product to obtain a finished product. The finished product can resist a high temperature of 220 DEG C, can resist saturated brine and seawater, effectively reduces drilling mud filtration loss, does not cause tackification, and thus solves the problems of temperature resistance and salt resistance of mud in deep well, ultra-deep well drilling.

Owner:石家庄华莱鼎盛科技有限公司

Composite microbial multi-element film coating synergistic fertilizer and preparation method thereof

InactiveCN108191574AHigh densityNutritional diversityMagnesium fertilisersAnimal corpse fertilisersSodium BentoniteDiethylenetriamine

The invention discloses composite microbial multi-element film coating synergistic fertilizer and a preparation method thereof. The composite microbial multi-element film coating synergistic fertilizer is prepared from the following raw materials in parts by weight: 100 parts of particle fertilizer cores, 2 to 3 parts of film coating agents and 1 to 3 parts of composite microbial bacterial agents.The particle fertilizer cores are prepare from urea, ammonium sulphate, monoammonium phosphate, triple superphosphate, potassium chloride, monopotassium phosphate, ammonium molybdate, magnesium sulfate, fermentation fertilizer, bentonite, gamma-polyglutamic acid / chitooligosaccharide hydrogel; the film coating agents are prepared from urea, formaldehyde, alpha-methyl glucoside and diethylenetriamine pentaacetic acid; the composite microbial bacterial agents are prepared from bacillus subtilis, bacillus lateraporus and trichoderma viride. The composite microbial multi-element film coating synergistic fertilizer has the excellent performance that the nutrition is comprehensive; the fertilizer effect is good; the soil microenvironment is obviously improved; the soil quality is improved; the hardened soil is loosened. The fertilizer belongs to the fertilizer meeting the requirements of fertilizer reduction, effect enhancement and green and environmentally friendly effects.

Owner:河北百禾丰化肥有限公司

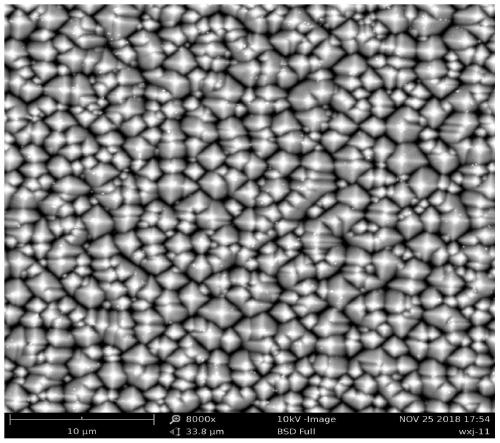

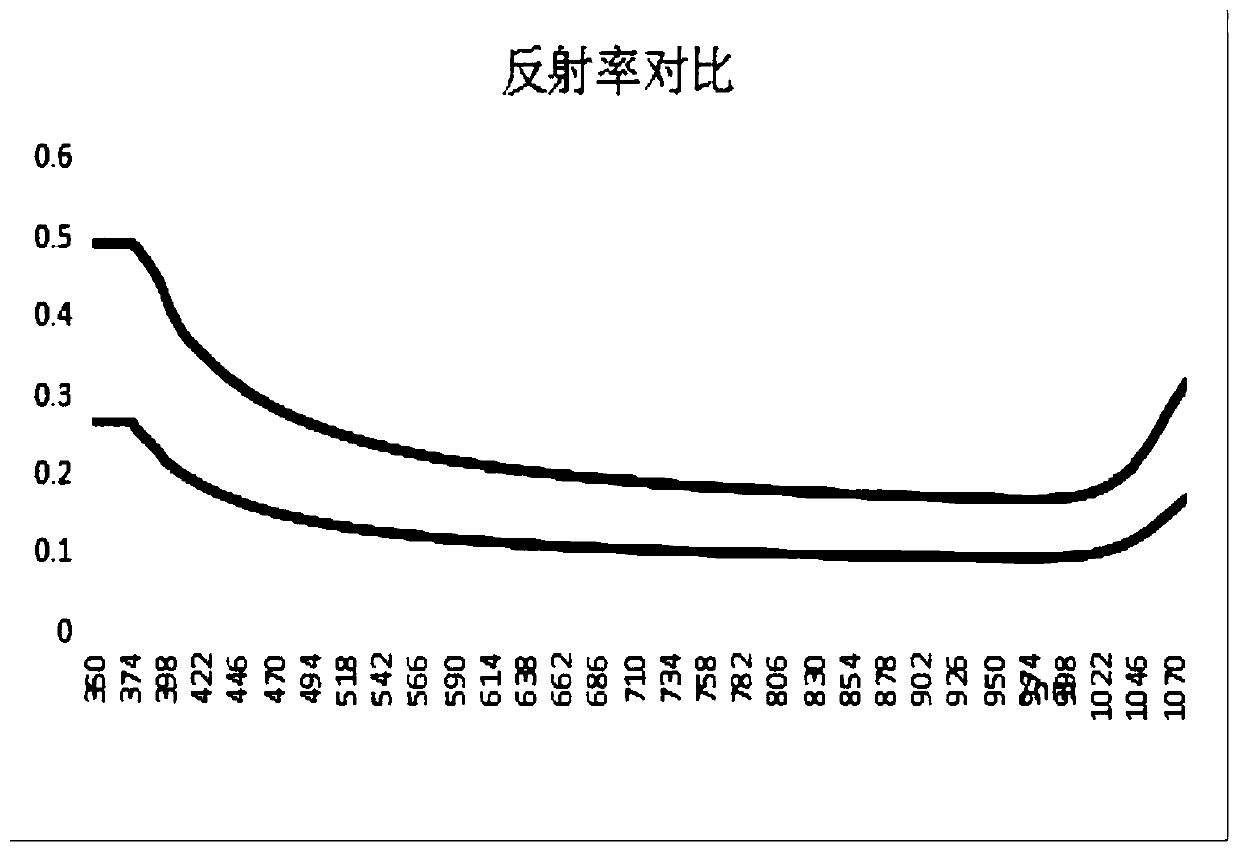

Monocrystalline silicon solar cell texturing additive and application thereof

InactiveCN110042474AFacilitated releasePrevent white spotsPolycrystalline material growthAfter-treatment detailsD-GlucoseGlucose polymers

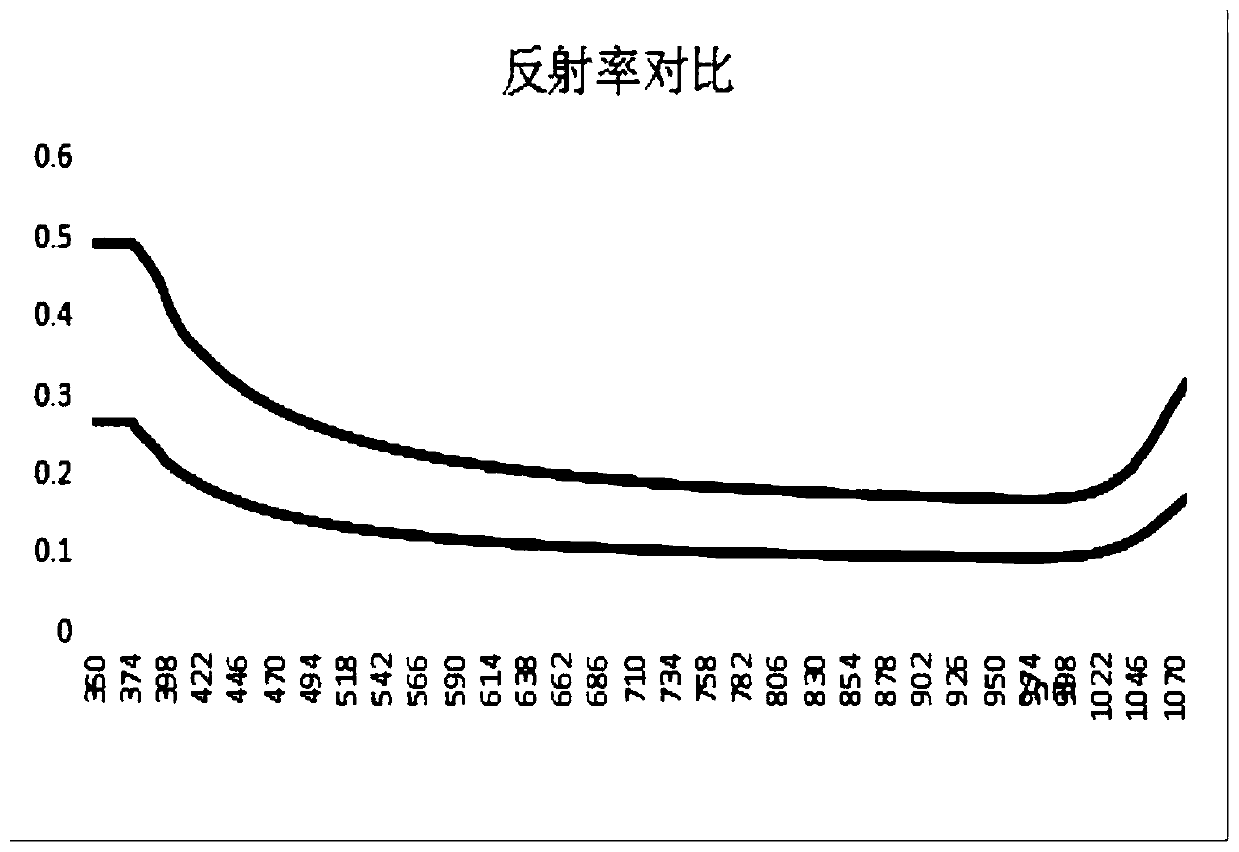

The invention discloses a monocrystalline silicon solar cell texturing additive and an application thereof, and relates to the technical field of silicon chip texturing. The technical point of the monocrystalline silicon solar cell texturing additive is that the monocrystalline silicon solar cell texturing additive comprises the following components, by mass percent: 0.05-0.2% of alkalis, 0.5-2% of methyl glucose polyoxyethylene ether, 0.3-0.5% of glucose, 0.01-0.05% of polyacrylamide, 0.1-5% of lactic acid, and 0.2-2% of a surfactant, with the balance being deionized water. The monocrystalline silicon solar cell texturing additive has the advantages of rapid texture surface making, small and uniform texture surfaces and low reflectivity.

Owner:SHANGHAI HANYAO NEW MATERIAL TECH

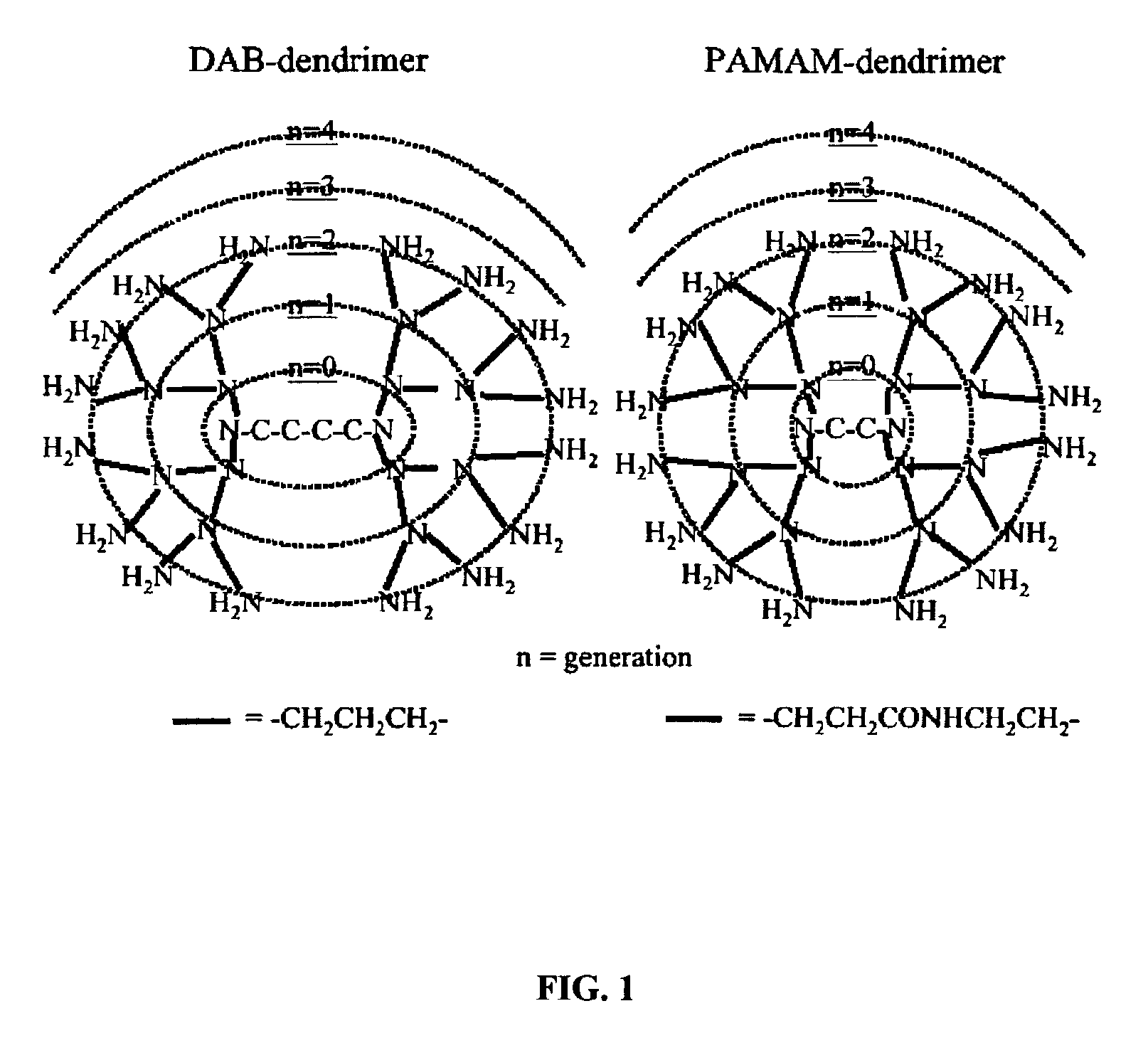

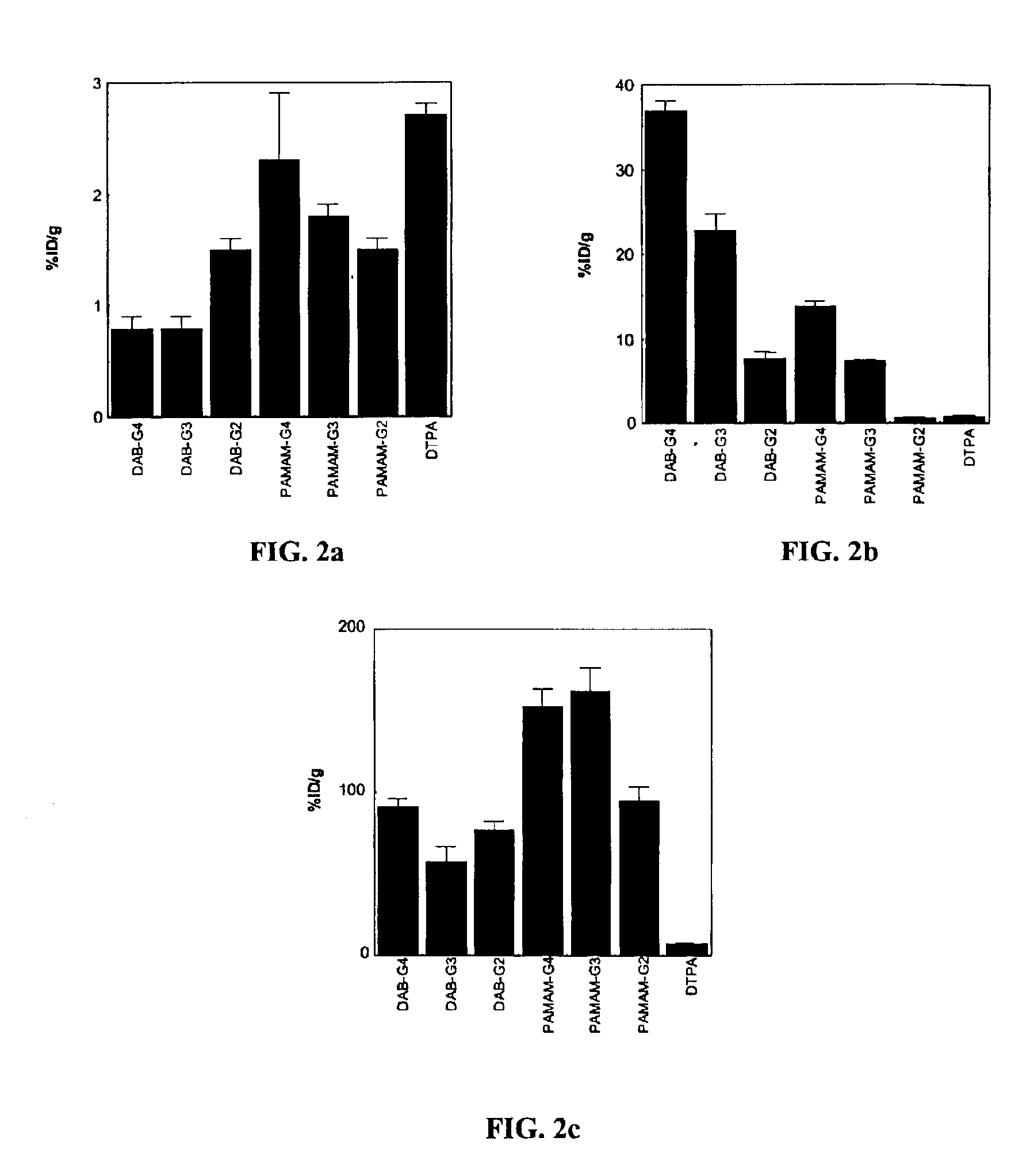

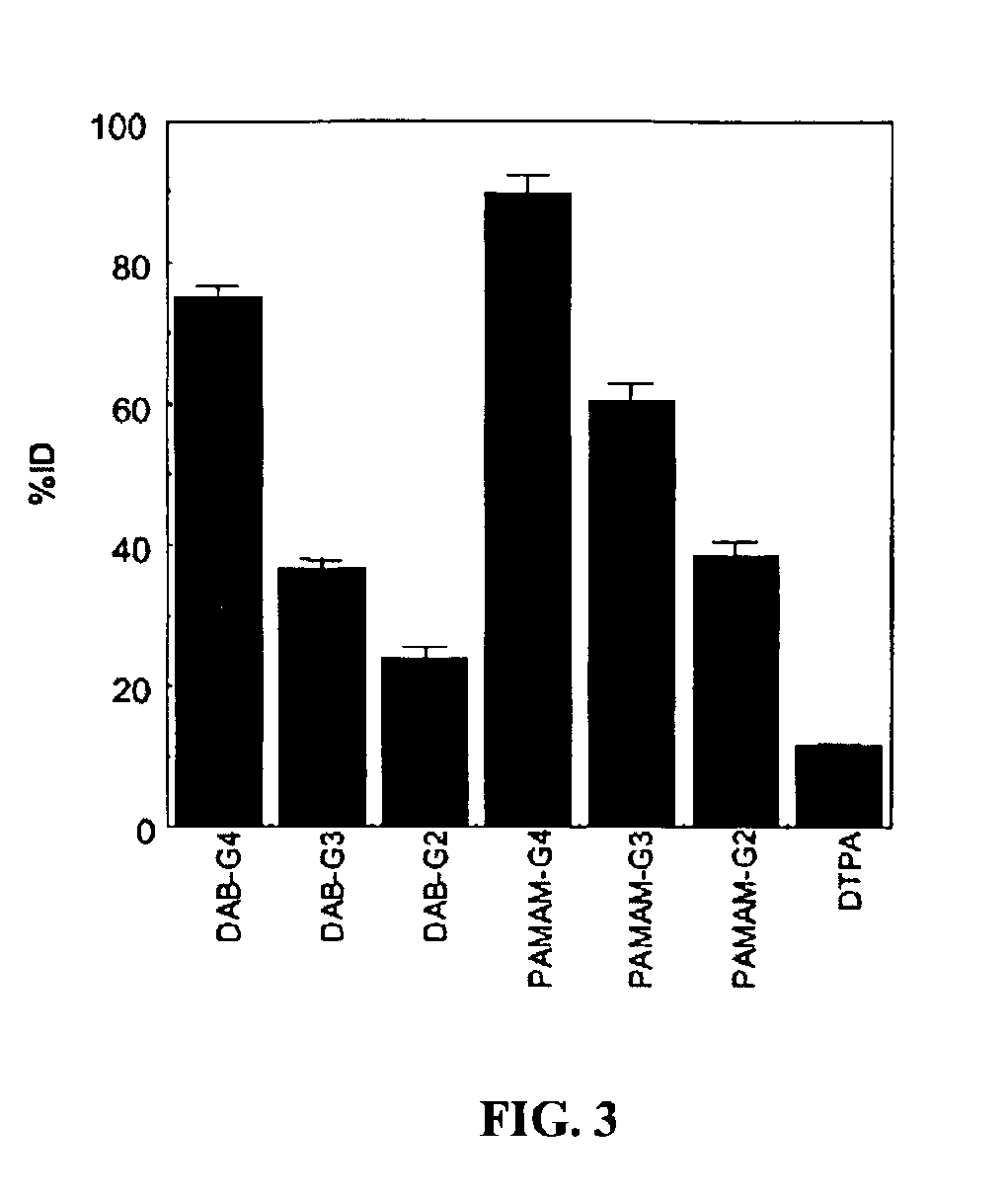

Methods for functional kidney imaging using small dendrimer contrast agents

Small dendrimer-based MRI contrast agents are disclosed to accumulate in renal tubules. The accumulation enables visualization of renal structure and function, permitting assessment of structural and functional damage to the kidneys. In a disclosed embodiment, six, small dendrimer-based MRI contrast agents were synthesized, and their pharmacokinetics, whole body retention, and renal MRI images were evaluated in mice. Surprisingly, despite having unequal renal clearance properties, all of the dendrimer agents clearly visualized the renal anatomy and proximal straight tubules of the mice better than Gd-[DTPA]-dimeglumine. Dendrimer conjugate contrast agents prepared from PAMAM-G2D, DAB-G3D, and DAB-G2D dendrimers were excreted rapidly and may be acceptable for use in clinical applications.

Owner:US DEPT OF HEALTH & HUMAN SERVICES

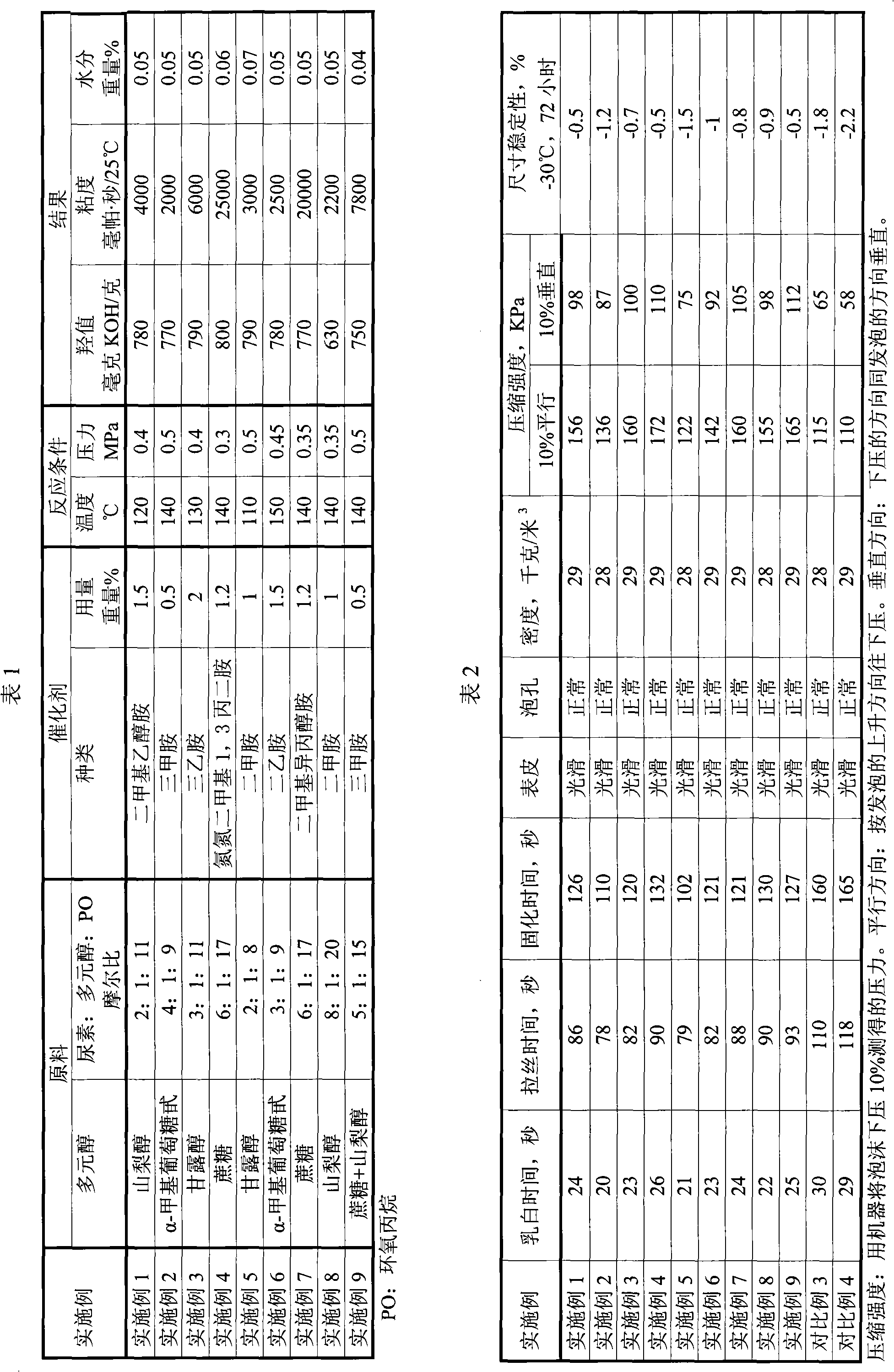

Preparation method of polyether polyol cross-coupling agent

ActiveCN102040732AImprove mechanical compressive strengthGood dimensional stabilityEther preparation from oxiranesReaction temperatureMechanical property

The invention relates to a preparation method of a polyether polyol cross-coupling agent, which is mainly used for solving the problems that the reaction procedure of preparing the polyether polyol is complicated, post treatment is necessary for removing metal ions after a polymerization reaction and the prepared polyether polyol has low activity and poor mechanical property and size stability when used for preparing polyurethane foam plastics. The polyether polyol cross-coupling agent is prepared by using urea and polyol as a co-initializing agent and epoxypropane as a polymerization monomer through carrying out catalytic reaction on reaction raw materials and a catalyst under the conditions that the mol ratio of the urea to the polyol to the epoxypropane is (1-20):1:(1-40), the reaction temperature is 60-180 DEG C and the reaction pressure is less than 0.6MPa, wherein the polyol is selected from at least one of cane sugar, sorbierite, alpha-methyl glucoside or mannitol, the catalyst is selected from at least one of trimethylamine, dimethylamine, triethylamine, dimethylethanolamine, dimethylisopropanolamine or N,N'-dimethyl-1,3-propanediamine, and the consumption of the catalyst accounts for 0.1-5 percent by weight of the raw materials. The technical scheme provided by the invention better solves the problems and can be used in the industrial production of the polyether polyol cross-coupling agent.

Owner:CHINA PETROCHEMICAL CORP

Polyurethane rigid foam with low density and low thermal conductivity

the invention discloses a low-density low-conductive polyurethane rigid foam, which comprises the following parts: (a) 30-60 wt% polyether, which adopts sucrose as initiator to addition with oxidized olefin; 10-30wt% polyether, which adopts toluenediamine as initiator to addition with oxidized olefin; 20-50wt% polyether, which adopts pentaerythrite and methylglucoside as initiator to addition with oxidized olefin; 5-20wt% polyether, which adopts glycerin as initiator to addition with oxidized olefin; (b) 1.5-3.5 wt% compound catalyst; (c) 7-17wt% foamer; (d) 1.5-2.8wt% water; (e) 1.4-4.0wt% foam stabilizer; (f) polyisocyanates, which adopts compound as datum polyether and water with index at 0.95- 1.50.

Owner:红宝丽集团泰兴化学有限公司 +1

Application and preparation method of Beauveria sp extract having tyrosinase inhibition activity

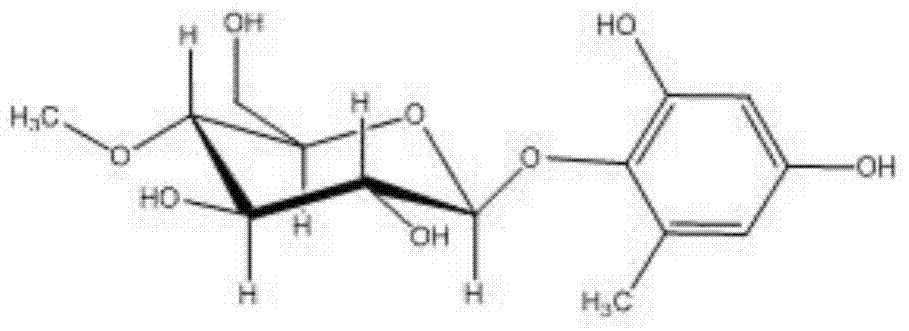

InactiveCN103751030AWide range of usesNot affectedCosmetic preparationsOrganic active ingredientsMethyl beta-D-glucopyranosideHypopigmentation

The invention relates to an application and a preparation method of a Beauveria sp extract having tyrosinase inhibition activity, specifically to an application of the Beauveria sp extract in preparation of pigmentation and melanoma prevention and treatment tyrosinase inhibitors. According to the present invention, the main effective component in the Beauveria sp extract is 6'-methyl-2',4'-dihydroxyphenyl-4-O-methyl-beta-D-glucopyranoside, and the content is 5-99%; the activity is characterized in that the half-inhibition concentration (IC50) on the tyrosinase is 37.6-638.5 mug / mL; and the Beauveria sp extract having the tyrosinase inhibitor has wide uses, can be adopted as the daily chemical additive, and provides effects of whitening, anti-blackening, anti-aging, pigmentation and melanoma prevention and treatment, and the like.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Treatment method for fused ring compound wastewater

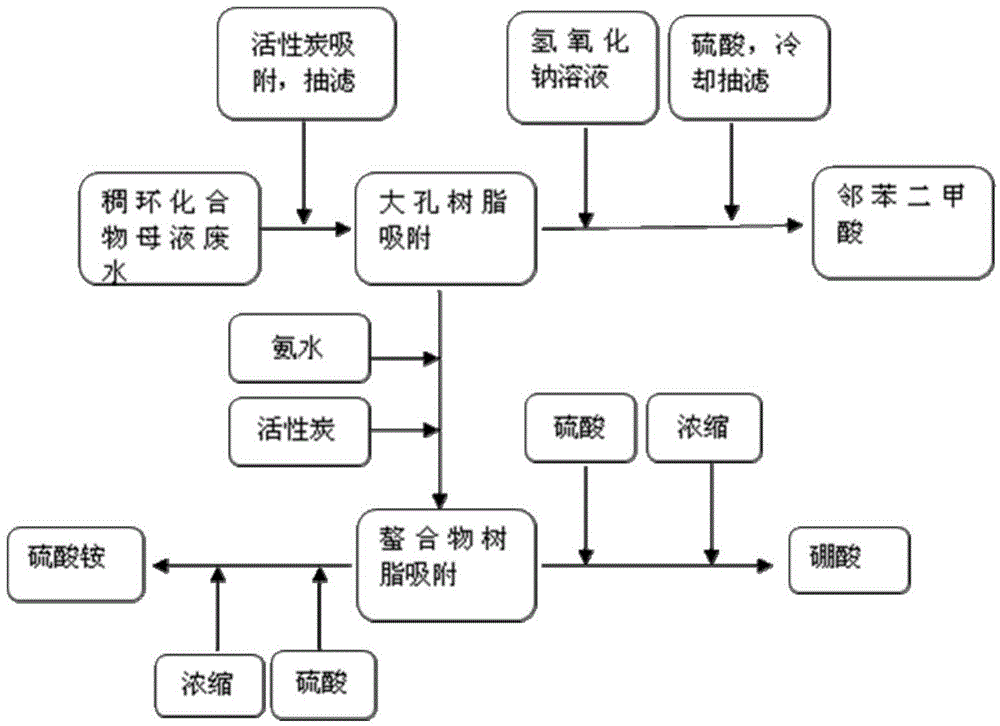

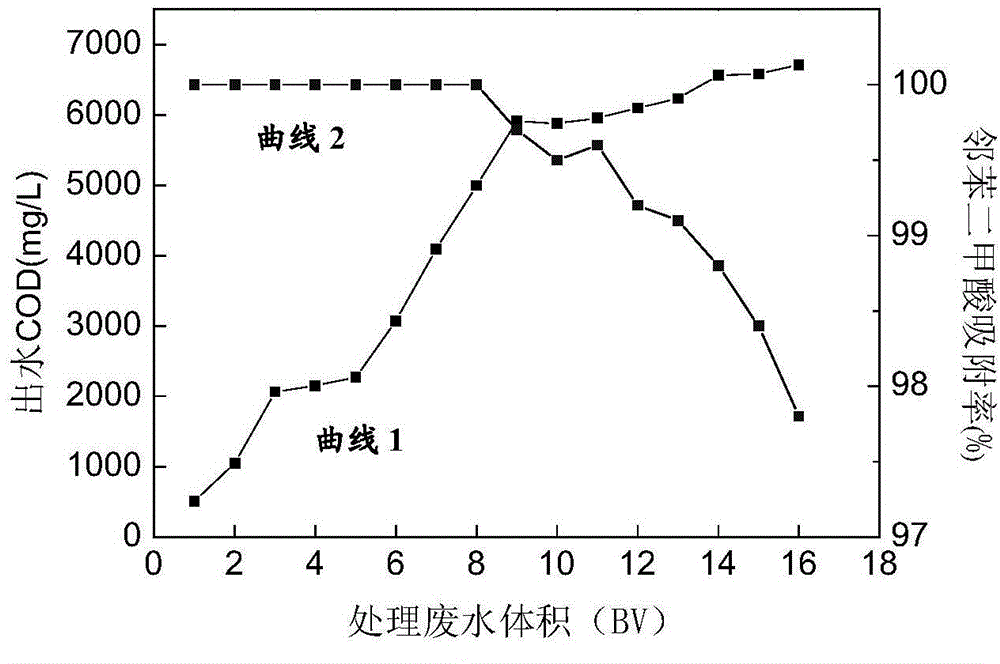

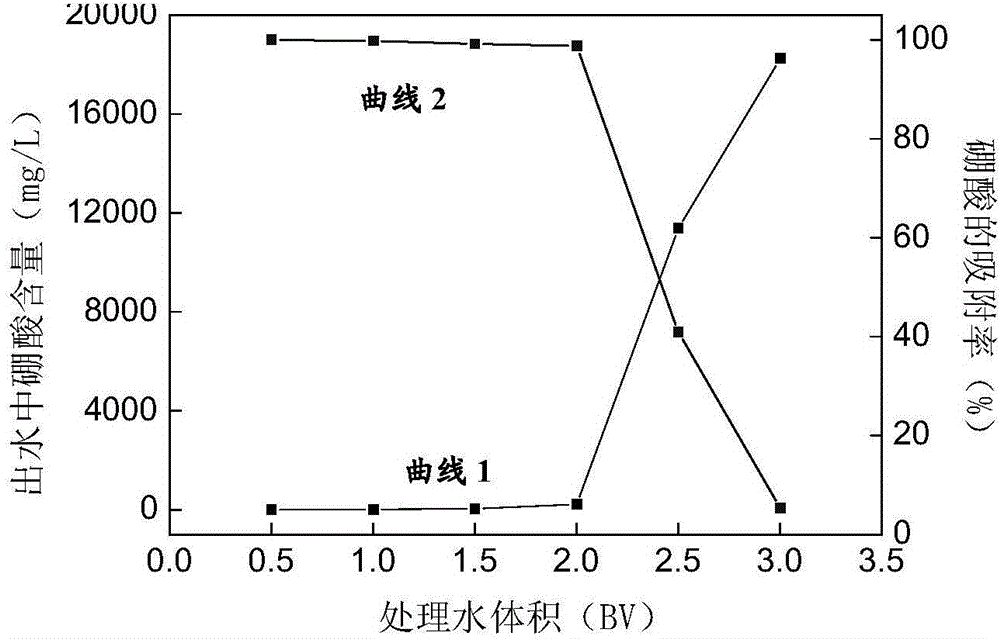

ActiveCN104445781AResolve separabilityFix extraction issuesWater contaminantsMultistage water/sewage treatmentChemical treatmentChelating resin

The invention discloses a treatment method for fused ring compound wastewater. According to the treatment method, the fused ring compound wastewater is taken as the raw material, subjected to styrene-toluylene copolymerized macroporous resin absorption treatment, and then desorbed to recover phthalic acid, and an effluent liquid I is obtained for standby application; and the effluent liquid I is neutralized by ammonia water until the pH ranges from 7 to 8, is subjected to N-methyl glucamine amino chelate resin absorption treatment and is desorbed to recover boric acid, and an effluent liquid II is obtained for standby application; concentrated sulfuric acid is added to the effluent liquid II to regulate the pH to be 5.0-5.5 and is distilled at normal pressure to obtain ammonium sulfate. According to the disclosed treatment method for the fused ring compound wastewater, phthalic acid, boric acid and ammonium sulfate are recovered in a high yield manner sequentially through specific steps, and the method for comprehensively treating chemical wastewater is provided by means of combination of multi-stage resin technologies and physical and chemical treatment.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

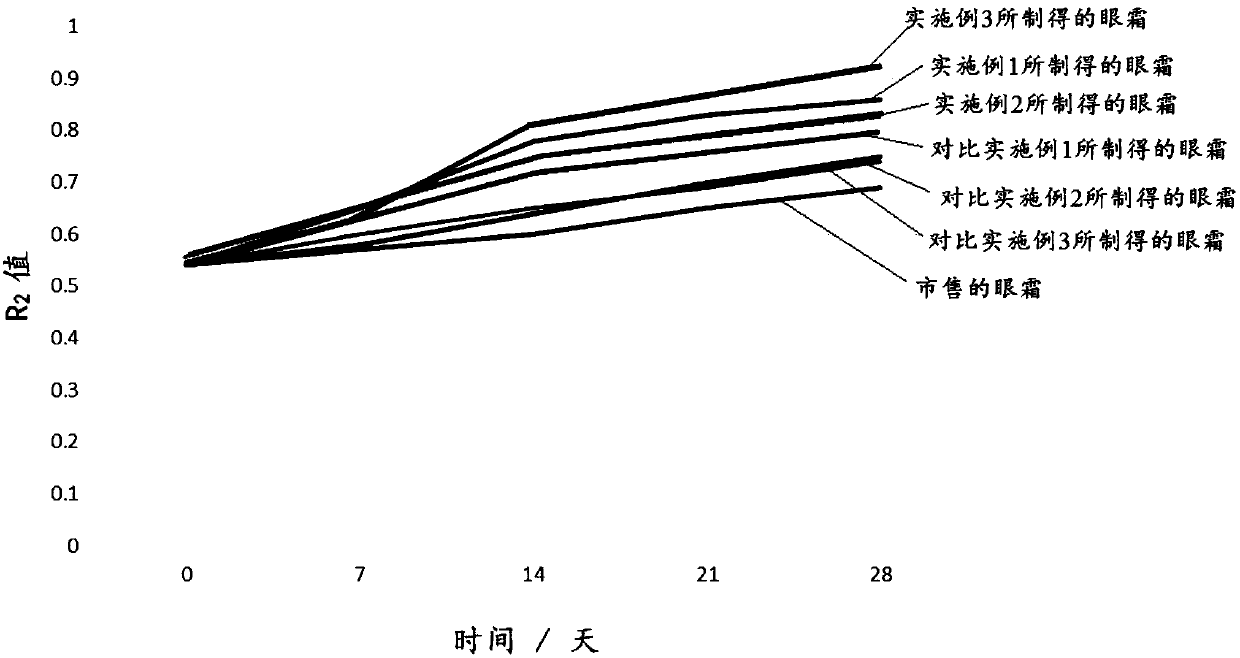

Wrinkle-relieving eye cream containing traditional Chinese medicine components as well as preparation method and application thereof

InactiveCN105943475AStay hydratedPromote blood circulationCosmetic preparationsToilet preparationsIrritationRHODIOLA ROSEA ROOT

The invention discloses a wrinkle-relieving eye cream containing traditional Chinese medicine components as well as a preparation method and application thereof. The wrinkle-relieving eye cream is prepared from the following raw materials in parts by weight: 50-60 parts of water, 2.0-4.0 parts of glycerol, 0.5-0.8 part of methyl glucoside eicoepoxyethane, 0.2-0.6 part of stearic acid, 0.1-0.3 part of cyclopentasiloxane, 0.02-0.04 part of hyaluronic acid, 0.3-0.8 part of isomerized sugar, 0.02-0.05 part of rose essential oil, 0.05-0.1 part of radix astragali extractive, 0.05-0.1 part of eleutherococcus extractive, 0.05-0.1 part of rhodiola rosea extractive, 0.05-0.1 part of fiveleaf gynostemma herb extractive and 0.05-0.1 part of radix lithospermi extractive. The wrinkle-relieving eye cream is refreshing, smooth, mild and irritation-free, and is capable of retaining moisture of eye skin for a long time, accelerating eye blood circulation and effectively reducing eye fine wrinkles; the main additives of the wrinkle-relieving eye cream are natural plants, so that the wrinkle-relieving eye cream is green, safe and environmental-friendly.

Owner:广州花出见生物科技有限公司

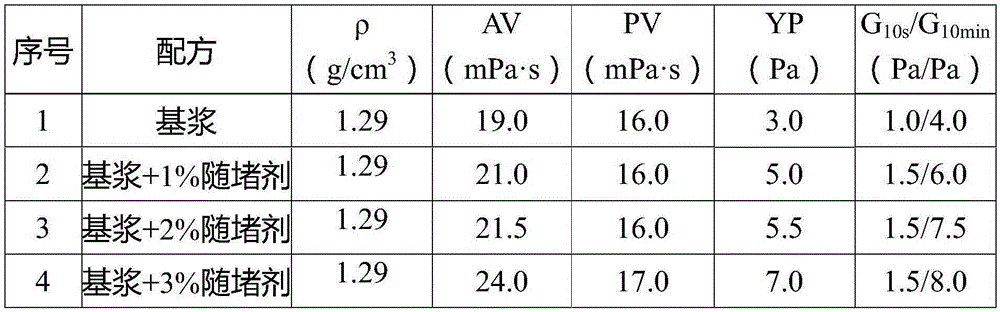

Organic salt polyamine drilling fluid and preparation method thereof

The invention relates to the technical field of a drilling fluid, in particular to an organic salt polyamine drilling fluid and a preparation method thereof. The organic salt polyamine drilling fluid comprises the following raw materials in parts by weight: water, methyl glucoside, a polyamine mud shale inhibitor, a blocking agent, an organic salt, a filtrate reducer, a capsulating agent, a flow pattern regulator, a lubricant, a weighting agent and KCL (polyamine class mud). Compared with the organic salt polyamine drilling fluid in the prior art, the organic salt polyamine drilling fluid obtained by the preparation method has the advantages that the recovery rate is greatly improved, the inhibitive ability of a drilling liquid system is enhanced, and underground safety is guaranteed; the cost is averagely reduced by 20 to 50 percent, and the production cost is greatly reduced; meanwhile, the preparation of the organic salt polyamine drilling fluid is simple, and the workload is greatly reduced.

Owner:CNPC XIBU DRILLING ENG

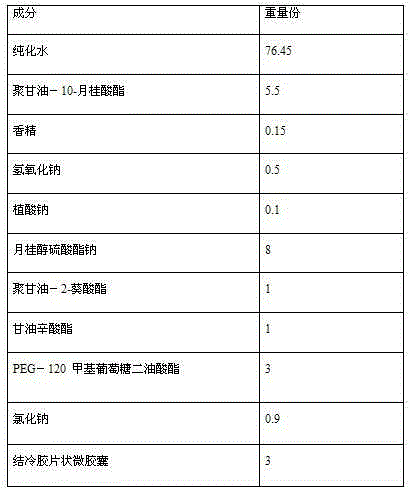

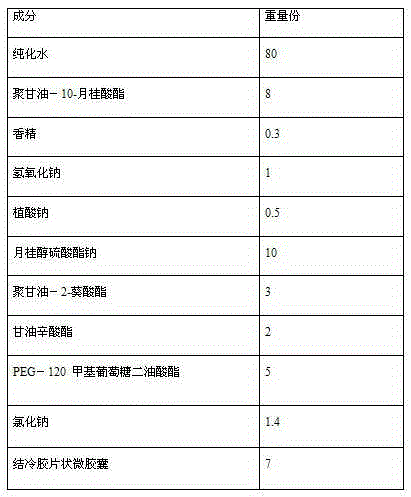

Body wash with gellan gum flaky microcapsules

ActiveCN105326660AEasy to push and wipeGood spreadabilityCosmetic preparationsToilet preparationsGlycerolMethyl palmoxirate

The invention discloses body wash with gellan gum flaky microcapsules. The body wash is prepared from the following components in parts by weight: 76-80 parts of deionized water, 5-8 parts of polyglycerol-10-laurate, 0.15-0.3 parts of essence, 0.5-1 part of sodium hydroxide, 0.1-0.5 parts of sodium phytate, 8-10 parts of laurinol sodium sulfovinate, 1-3 parts of polyglycerol-2-canoic acid ester, 1-2 parts of glycerinum octoate, 3-5 parts of PEG-120 methyl glucose dioleate, 0.9-1.4 parts of sodium chloride and 3-7 parts of gellan gum flaky microcapsules. When the components are adopted, the gellan gum flaky microcapsules can be softened in the body wash medium and can be easily smeared.

Owner:CHONGQING PELLETS TECHN & TRADE

Non-greasy sunscreen cream

InactiveCN102871917AIncrease viscosityImprove refreshmentCosmetic preparationsToilet preparationsDissolutionPalmitates

The invention relates to a non-greasy sunscreen cream. Components and the mass percentage of each component are as follows: 5-6% of octyl-methoxycinnamic acid, 2-4.0% of natural aloe extraction liquid, 1-3% of vitamin E, 2-3% of licorice extract, 2-5% of sodium hyaluronate, 1-3% of vitamin A palmitate, 0.3-1.0% of methyl glucose fatty acid ester, 2-4% of octocrylene, 0.8-1.6% of ethoxylation methyl glucose fatty acid ester, 3-7% of 1,3-butylene glycol, 8.2-10% of terephthalylidene dicamphor sulfonic acid, and the balance being deionized water. The sodium hyaluronate added in the water solution has very high viscosity, and has an thickening effect and a stabilizing effect, without presence of a greasy sense; the added 1,3-butylene glycol can promote dissolution of sunscreen components; and the added vitamin A palmitate can form a film having the functions of lubrication and protection on the surface of skins, and prolong the contact time of the sunscreen cream and the skins.

Owner:SUZHOU GULI BIOTECH

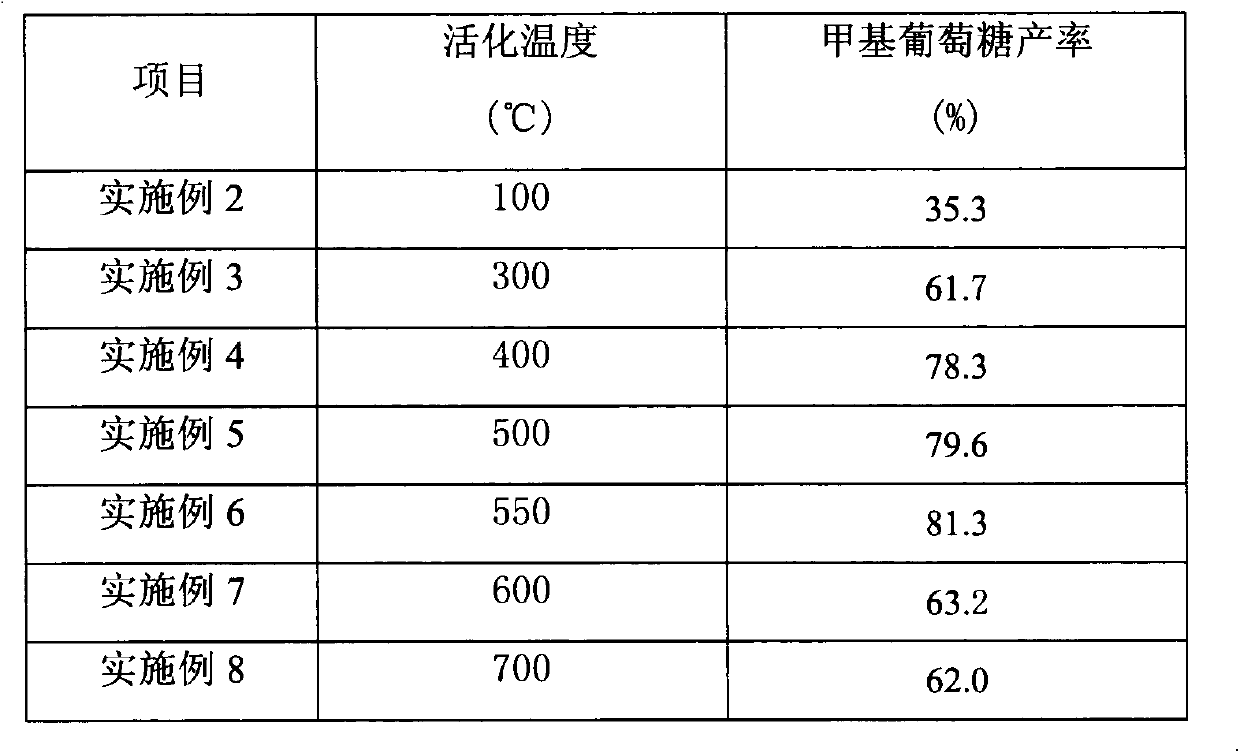

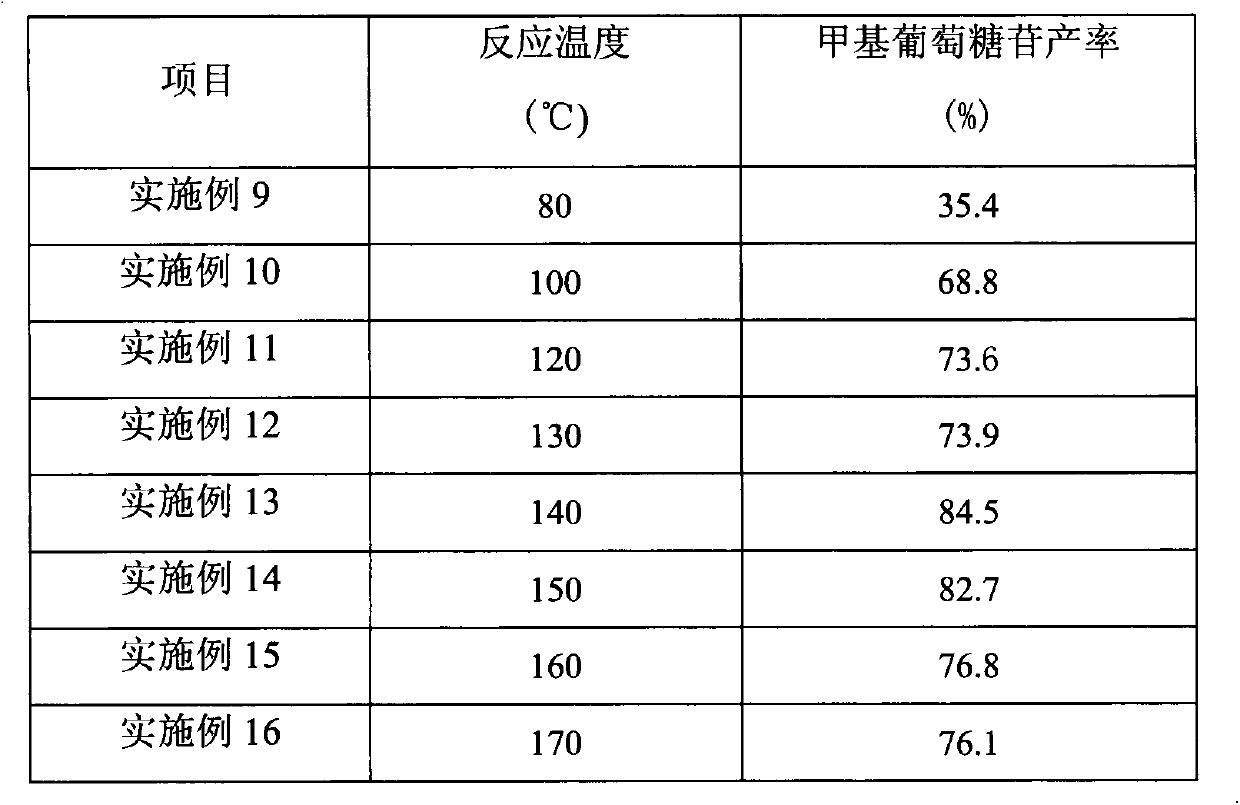

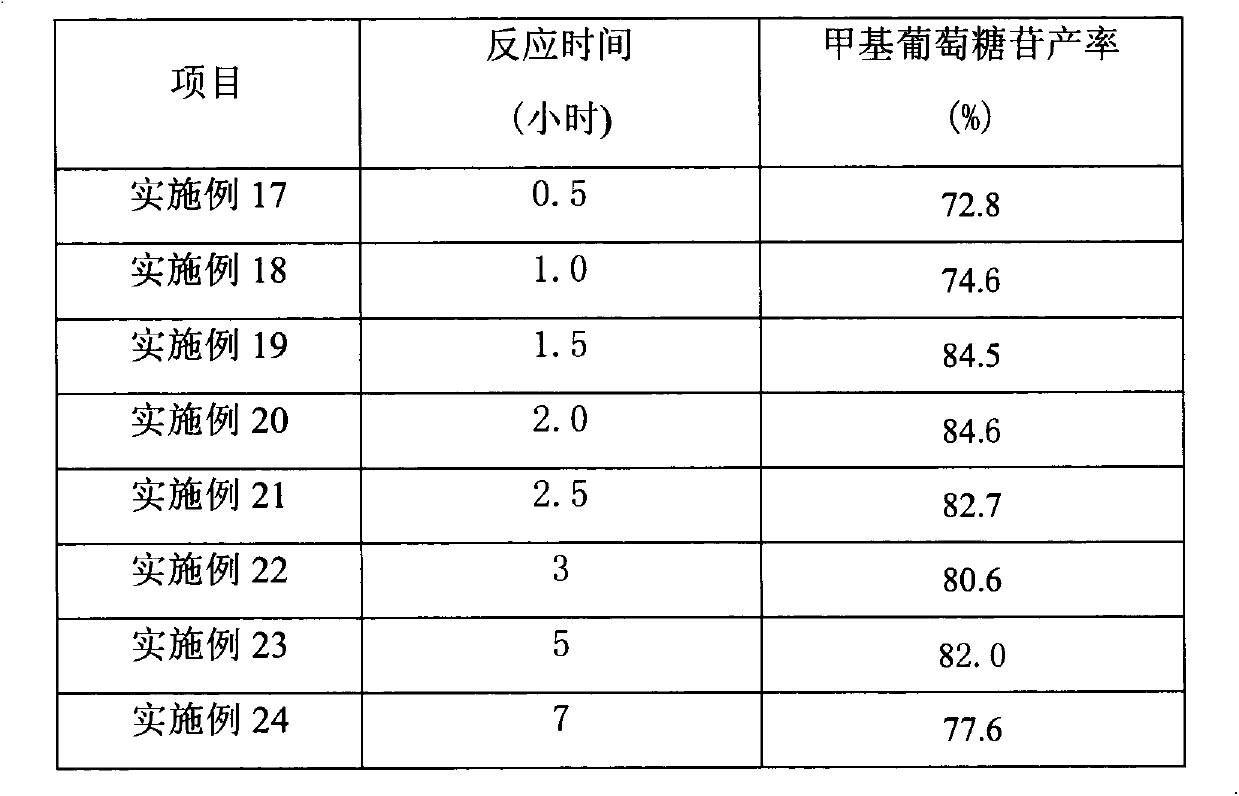

Method for catalyzing glucose by using magnetic solid acid to produce methyl glucoside

InactiveCN103626810ARich sourcesReduce pollutionSugar derivativesChemical recyclingSolid acidGlucoside

The invention discloses a method for producing methyl glucoside by using reproducible raw material glucose. The method comprises the following step: by using glucose as a raw material and magnetic solid acid as a catalyst, reacting for 1.5-7 hours under the condition of subcritical methanol at the temperature of 100-170 DEG C to obtain methyl glucoside at the high yield rate. According to the method, the raw material of the catalyst is bulk commodity, nanometer magnetic solid superacid is prepared in a chemical coprecipitation method, so that nanometer magnetic solid superacid can be quickly separated from the product to be recycled; the obtained methyl glucoside is an important platform chemical compound and can be used as an intermediate or a monomer to be used in the fields of food, living beings, oil extraction and the like.

Owner:JIANGNAN UNIV

High-efficiency flocculating agent for waste water treatment

InactiveCN103880138AFoamingBiodegradableWater/sewage treatment by flocculation/precipitationWater qualityWaste treatment

The invention discloses a high-efficiency flocculating agent for waste water treatment. The flocculating agent is a segmented-copolymer flocculating agent; and a segmented copolymer is one of the segmented copolymers with a linear structure, a star-shaped structure or high branching degree. The segmented-copolymer flocculating agent comprises at least two types of monomers which are acrylamide, acrylamide homologue, chitosan, glucose, aminoglucose, alkyl glucose, acyl glucose, glucuronic acid or carboxymethyl glucose. The high-efficiency flocculating agent disclosed by the invention has the beneficial effects that the whole segmented copolymer has higher molecular weight and more functional groups, so that various impurities in water are easily caught and the water quality is improved; the high-efficiency flocculating agent has excellent properties such as no toxicity, degradability, no pollution to environment, bacterium resistance, gel property, foamability, thickening property and surface activity; in addition, by forming of the segmented copolymer, the flocculation of all monomers is maximized, and the removal rate of suspended matters in sewage is more than 90%.

Owner:SHANGHAI HESHUN CHEM TECH

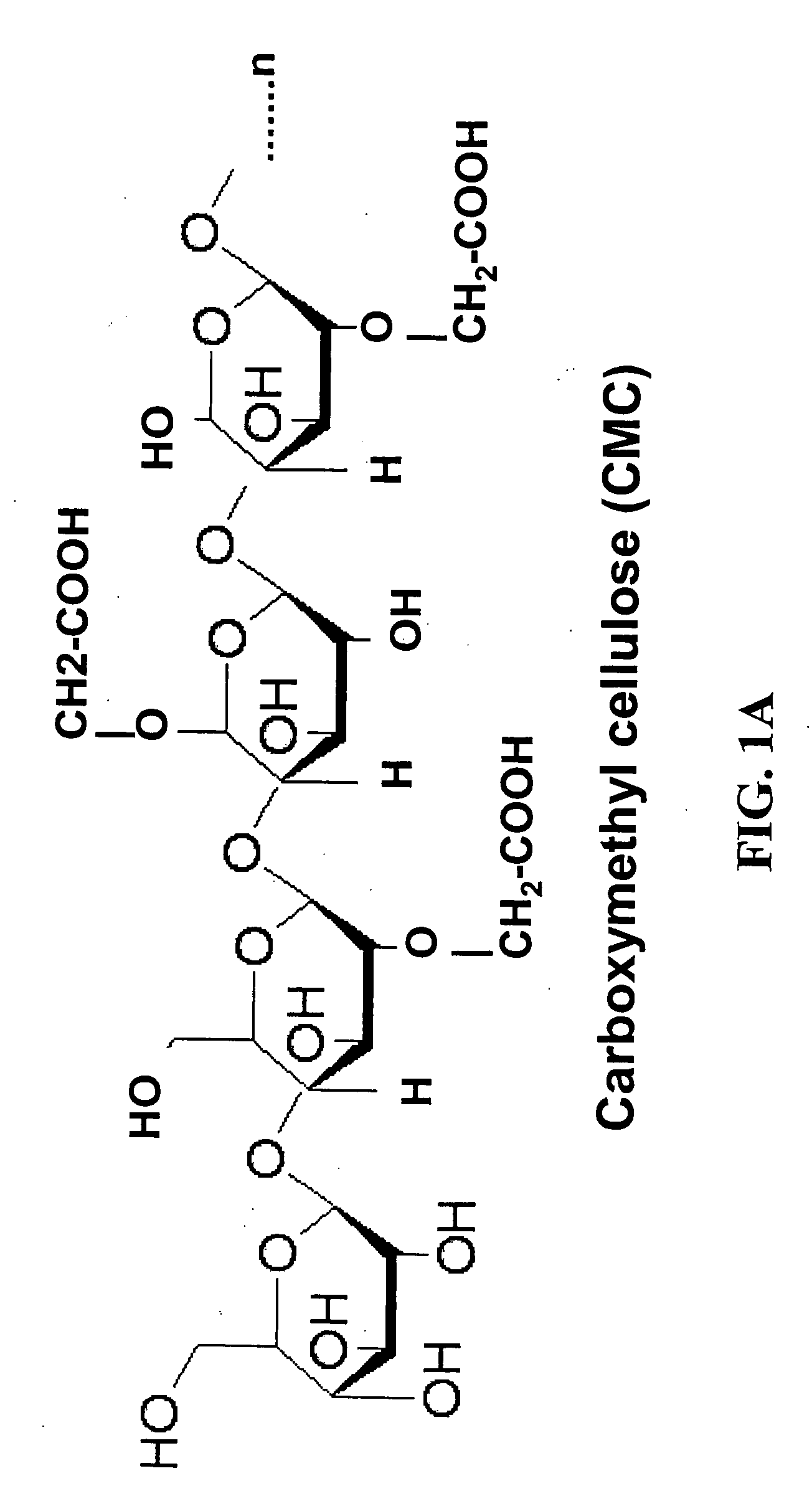

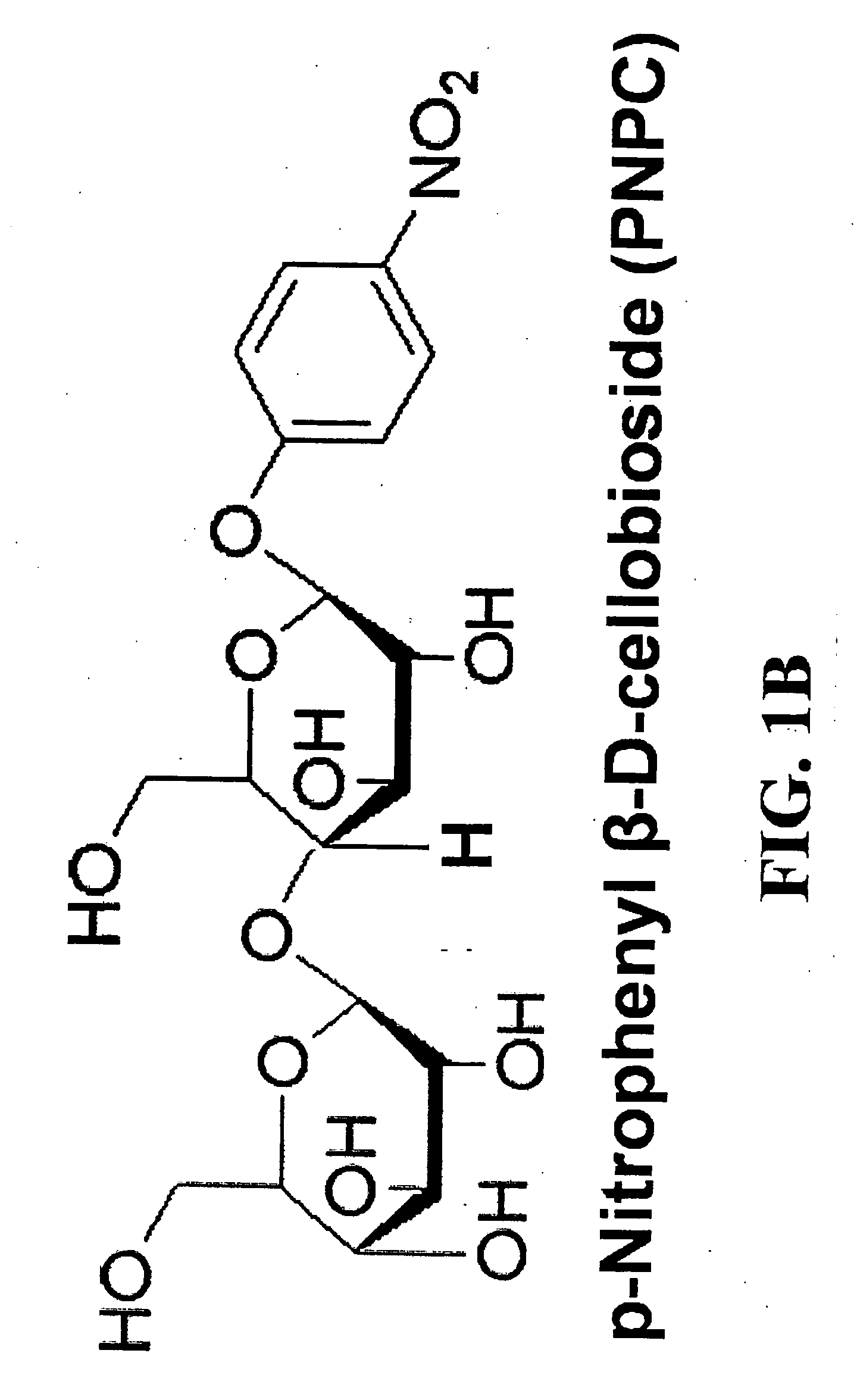

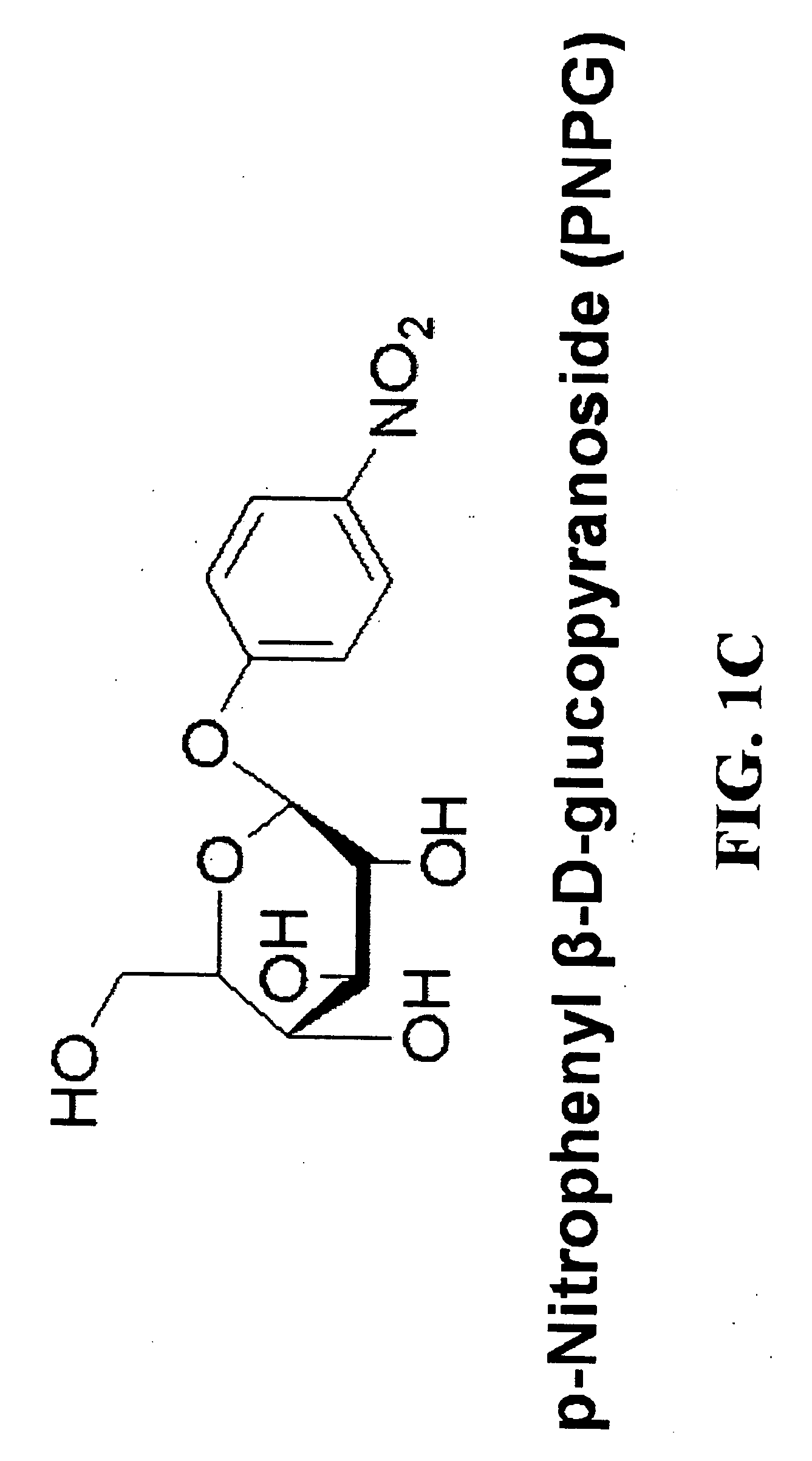

Carbohydrate based cellulase inhibitors as feeding stimulants in termites

InactiveUS20080107619A1Increase feed rateIncrease termite mortalityBiocideAnimal repellantsEndoglucanase activityDigestion

A method, composition and system for controlling termites wherein single carbohydrate-based compounds are used as both cellulase inhibitors and feeding stimulants. Di-saccharides, cellobioimidazole (CBI), fluoro-methyl cellobiose (FMCB), and mono-saccharides, fluoro-methyl glucose (FMG) and analogs thereof inhibit termite cellulose digestion, which leads to starvation or stimulates termite feeding to cause mortality. CBI, FMCB and FMG were tested against enzyme fractions that represented endogenous (foregut / salivary gland / midgut) and symbiotic (hindgut) termite cellulases in vitro and in vivo. Feeding stimulation by di-saccharides results in greater cellulase inhibitor intake throughout midrange concentrations (1 mM-10 mM), which is associated with significant termite mortality. In contrast, the monosaccharide inhibitor, FMG did not stimulate feeding, but did inhibit feeding at concentrations above 1 mM, causing mortality. With modification to create longer β-glycosidic chain lengths, the cellulase inhibitors identified herein can also be targeted to endoglucanase activity for increased efficacy and use as novel termite control compositions.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Anti-pollution flashover coating cleaning agent

InactiveCN103255001AImprove surface activityImprove permeabilitySurface-active detergent compositionsCleaning using liquidsSolventCleansing Agents

The invention introduces an anti-pollution flashover coating cleaning agent. The cleaning agent is prepared by mixing the following preparation raw materials in percentage by weight: 1-5% of alkyl polyglucoside, 1-5% of N-alkyl acyl-N-O-methylglucose, 0.2-5% of a non-ionic type Gemini surfactant, 1-5% of hetero-alcohol polyoxyethylene polyoxypropylene, 0.01-0.05% of an organic silicon defoamer and the balance of water. The cleaning agent can be used for cleaning transformer oil on an anti-pollution flashover coating surface under the comprehensive action of mechanisms such as permeating, emulsifying, dispersing and the like. The cleaning agent has excellent wettability and permeability; the cleaning agent can permeate into the pores of silicon rubber and remove oil dirt absorbed in the pores, so that the oil dirt cleaning efficiency is increased; and the cleaning agent has excellent permeating, emulsifying and dispersing performances and good compatibility with various surfactants, auxiliaries, additives and solvents. The cleaning agent has the advantages of thorough oil dirt removing, no toxicity, no stimulus, no corrosion and high biodegradability.

Owner:STATE GRID CORP OF CHINA +2

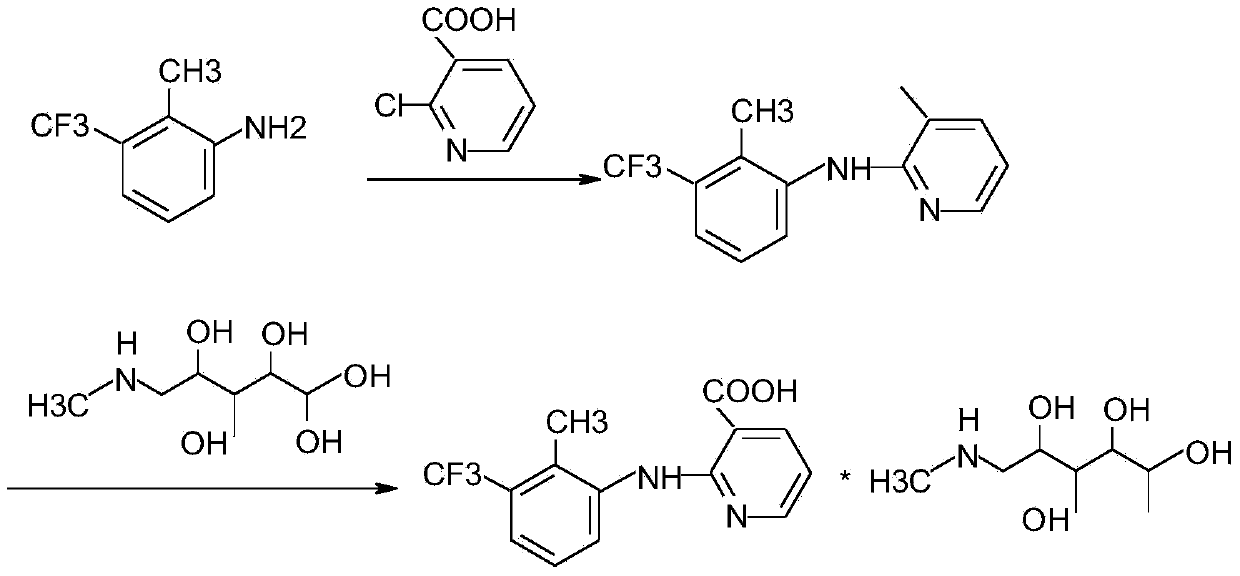

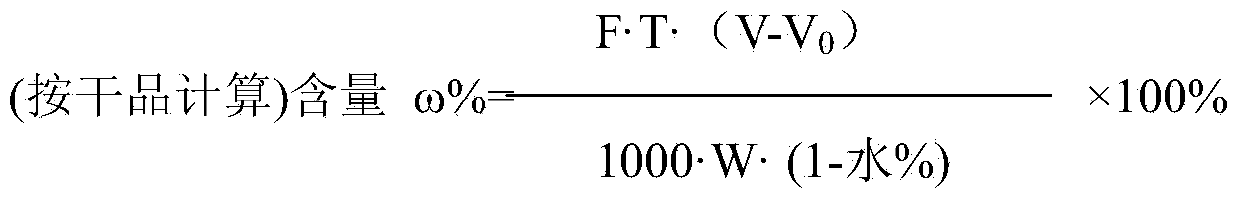

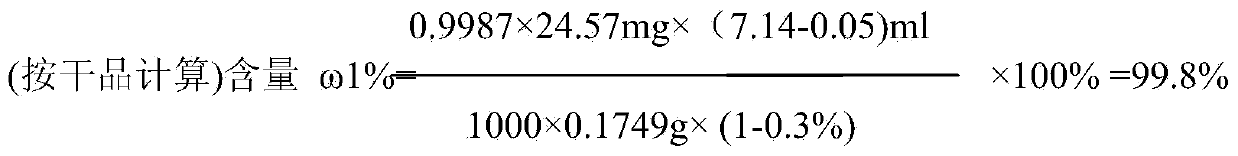

Synthesis method of flunixin meglumine

ActiveCN104193674AThorough responseHigh yieldOrganic compound preparationAmino-hyroxy compound preparationFLUNIXIN MEGLUMINESynthesis methods

The invention discloses a synthesis method of flunixin meglumine, which comprises the following steps: adding 2-chloronicotinic acid and 2-methyl-3-trifluoromethyl aniline into a sodium hydroxide water solution, stirring, adding toluene and a phase-transfer catalyst, reacting at controlled temperature of 40-45 DEG C for 4-5 hours, regulating the pH value of the solution to 10-11, stirring, standing to stratify, regulating the pH value of the water layer to 5-6, stirring, filtering, washing the filter cake, and drying to obtain flunixin, reacting flunixin and N-methylglucosylamine in isopropanol, heating under reflux for 0.5-1.5 hours, filtering, cooling to 50-60 DEG C, and stirring to crystallize; and when the system temperature drops to 25 DEG C below, continuing stirring for 1 hour, carrying out vacuum filtration on the crystal, and washing with isopropanol to obtain the flunixin meglumine. The method lowers the reaction temperature, saves the energy, shortens the reaction time, and is simple for synthesis operation, low in facility requests and convenient for industrialized operation.

Owner:济南久隆医药科技有限公司 +1

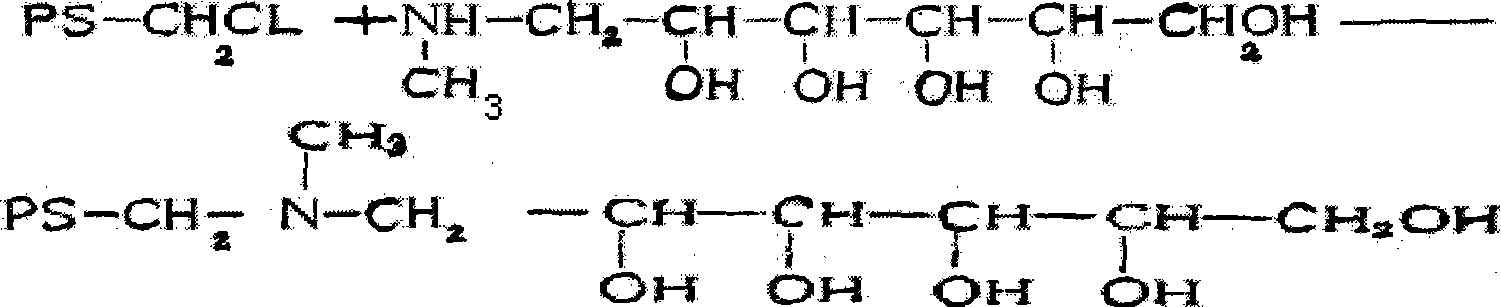

Styrene-series ion-exchange fiber applied to boron adsorption and preparation method thereof

InactiveCN101444756AIncrease moisture contentLow costIon-exchange process apparatusAnion exchangersIon exchangeBoric acid

The invention relates to a styrene-type ion-exchange fiber applied to boron adsorption and a preparation method thereof. The ion-exchange fiber is prepared according to the following steps: taking a composite fiber product, which is made by grafting market polypropylene fiber onto styrene, as a framework; and carrying out chloromethylating and introducing in N-methyl glucosamine for ammoniation so as to obtain ion-exchange fiber with boron selectively adsorbed thereon. The selective ion-exchange fiber is independent from a large amount of coexisted salts and is capable of selectively capturing boric acid only, thus having highly practical value.

Owner:KAIRUI ENVIRONMENTAL PROTECTION TECH

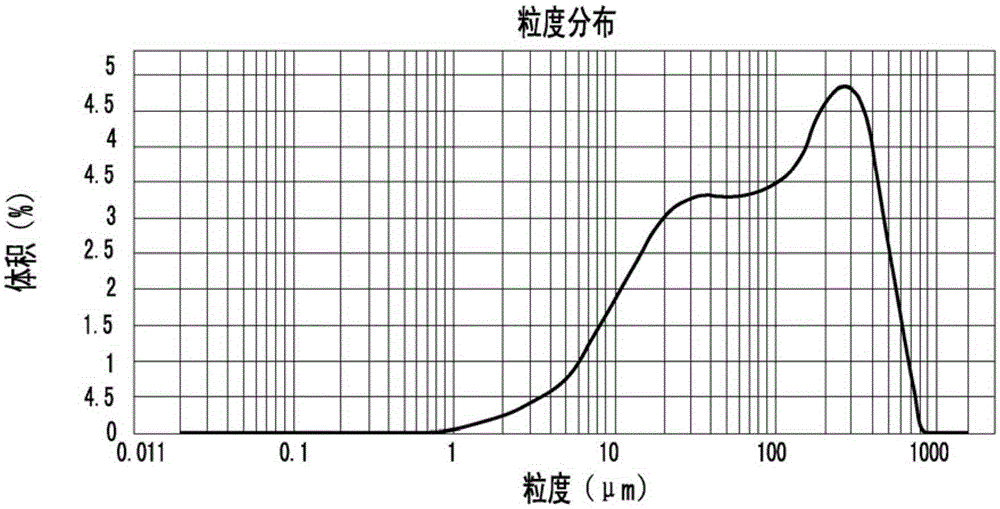

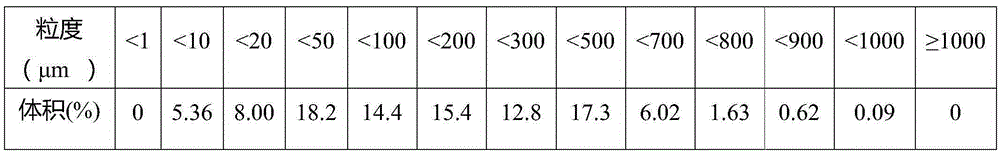

Following-drilling plugging agent and preparation technology thereof

The invention provides a following-drilling plugging agent. The following-drilling plugging agent comprises limestone powder, aluminum oxide, quicklime powder, sodium bentonite, an expanding agent, methyl glucosides and mineral fibers; the diameter of the the mineral fibers is smaller than or equal to 60 microns, the length ranges from 0.5 mm to 1 mm, and the mineral fibers can bear the temperature over 170 DEG C. A preparation technology of the following-drilling plugging agent comprises the steps of mixing, grinding and stirring. The following-drilling plugging agent is applied to stratum leakage of pores with the diameters of the pore throat smaller than or equal to 1 mm and microcracks with the widths of cracks smaller than or equal to 1 mm in well drilling, a mud cake can be rapidly formed, the microcracks with different widths can be plugged, and therefore the purposes of following-drilling leakage prevention and leakage stoppage are achieved; good compatibility is achieved, the following-drilling plugging agent can be suitable for drilling fluid with different densities for different systems, effective plugging for leakage of the microcracks can be achieved, the preparation technology is simple, and operation is convenient.

Owner:CHINA PETROCHEMICAL CORP +2

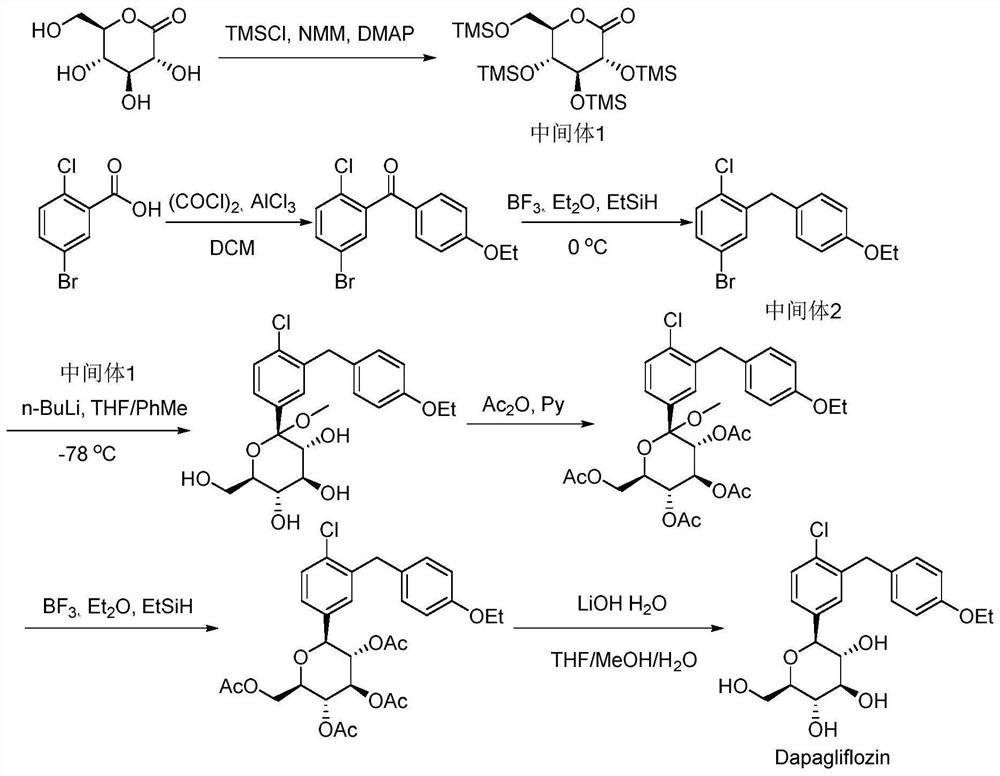

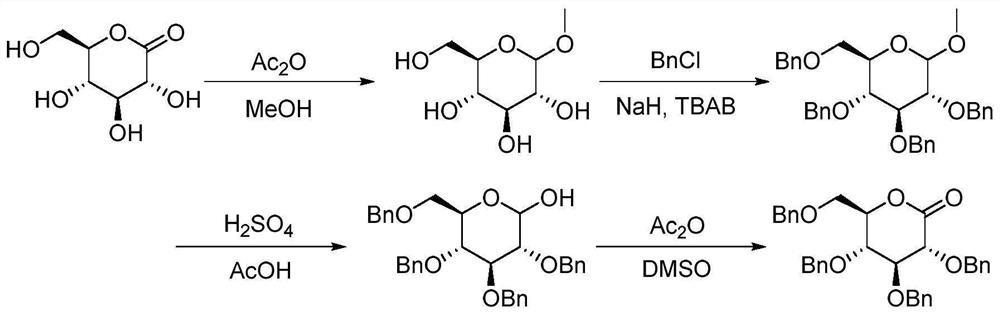

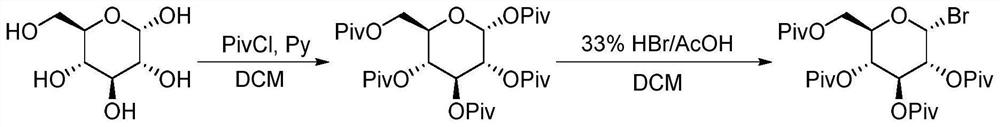

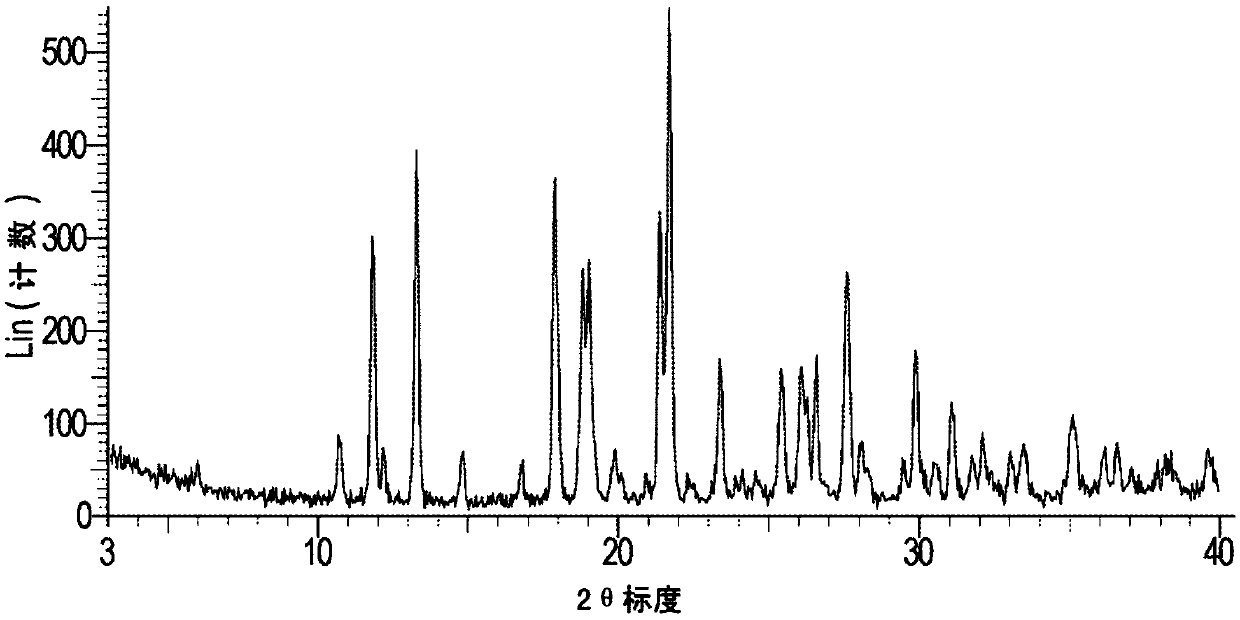

Method for continuously synthesizing benzyl-substituted glucolactone by adopting microchannel reaction device

ActiveCN112961135ADoes not reduce consumptionReduce consumptionOrganic chemistryGluconic acidBenzyl chloride

The invention discloses a method for continuously synthesizing benzyl-substituted glucolactone by adopting a microchannel reaction device. The method comprises the following steps: taking methyl-alpha-D-mannopyranoside as an initial raw material, preparing the methyl-alpha-D-mannopyranoside into an old organic solvent solution, and reacting the old organic solvent solution with an organic solvent solution of benzyl chloride in a first microreactor to generate methyl glucose with hydroxyl protected by benzyl; reacting a homogeneous solution formed by mixing a reaction solution of benzyl-substituted gluconic acid and a small amount of hydrochloric acid solution in a second microreactor for demethylation to generate hydroxyl benzyl-substituted glucose; and finally, reacting the reaction solution with an aqueous solution of hydrogen peroxide and sodium hydroxide and an organic solvent solution of tetramethylpiperidine nitrogen oxide in a third microreactor to generate the high-purity hypoglycemic drug Dapagliflozin intermediate benzyl substituted glucolactone. The method disclosed by the invention is higher in heat and mass transfer efficiency and easier to industrially amplify, the initial materials are simple, cheap and easily available, the process is simple, the obtained intermediate is high in purity and high in yield, the production cost can be effectively reduced, and the method is suitable for industrial production.

Owner:安庆奇创药业有限公司

Solid forms of transthyretin dissociation inhibitors

The present invention relates to solid forms of the N-methyl-D-glucamine (meglumine) salt of 6-carboxy-2-(3,5-dichlorophenyl)-benzoxazole and a process for its preparation. The invention also relates to pharmaceutical compositions comprising at least one solid form, and the therapeutic or prophylactic use of such solid forms and compositions.

Owner:PFIZER INC

Preparation method of composite sandwiched biomass foam partition wall material

InactiveCN105462163AHigh reactivityAccelerate the liquefaction conversion rateLayered product treatmentLaminationPolyethylene glycolPhosphoric acid

The invention discloses a preparation method of a composite sandwiched biomass foam partition wall material. The method comprises the technological steps of preparing a sandwiched biomass foam material, and gluing the sandwiched biomass foam material and a panel. A multiphase composite liquefying agent containing phenol, polyethylene glycol and cyclic carbonates and a mixed catalyst containing concentrated sulfuric acid and phosphoric acid are adopted, so that not only is the liquefying conversion rate increased, but also flame-retardant phosphorus-containing groups are introduced; in the resinification process, solid paraformaldehyde is used for substituting a formaldehyde solution, and methyl glucoside is added to form a multi-phase tool system, so that the reaction activity is further improved, the release amount of formaldehyde is reduced, the flexibility of resin is further improved, the hard brittleness and scaling-off defects of the foam material are improved, and the solid content of the resin is also enabled to reach 75 percent or more suitable for foaming; and in the foaming process, methyl benzenesulfonic acid is selected to be compounded with N-hydroxymethyl acrylamide, so that not only can the curing efficiency be increased, but also the flame-retardant effect can be improved.

Owner:NANJING FORESTRY UNIV

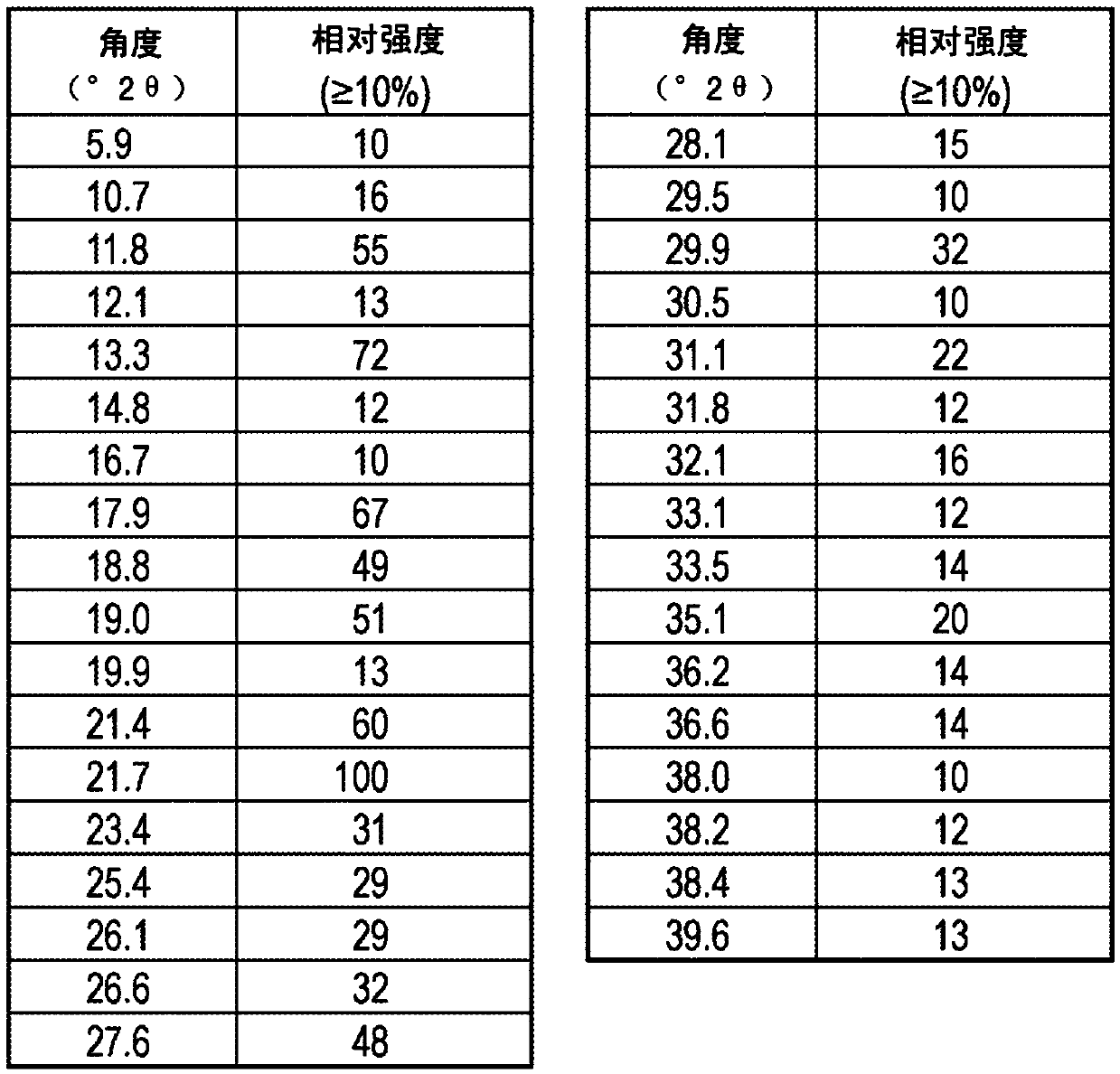

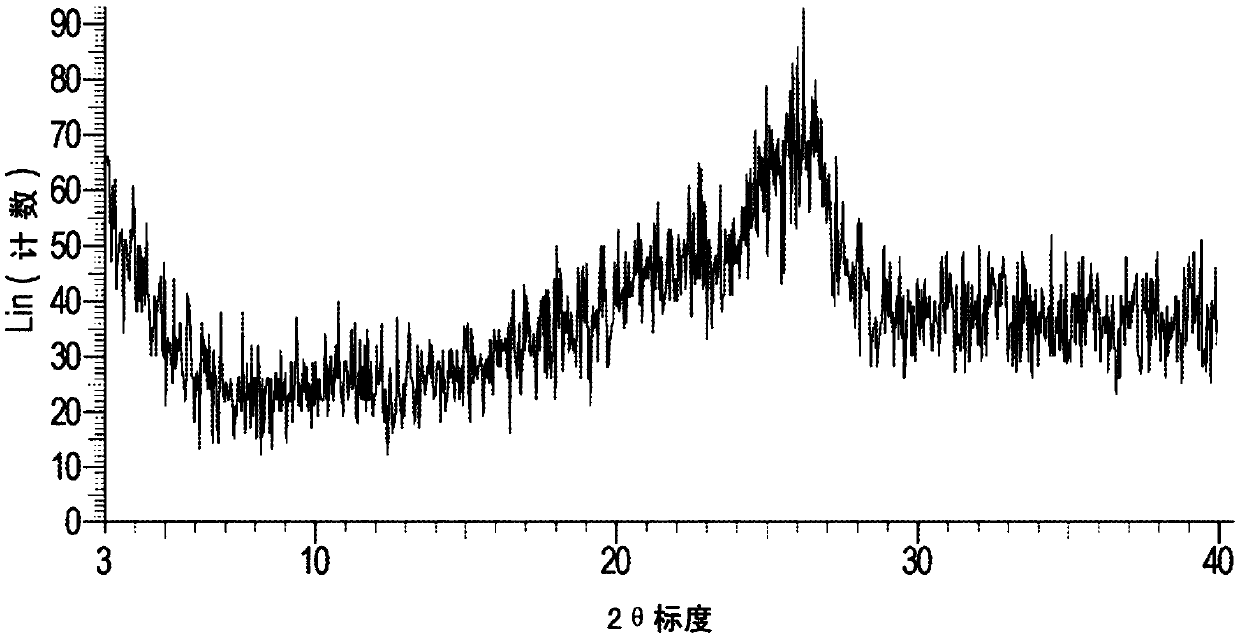

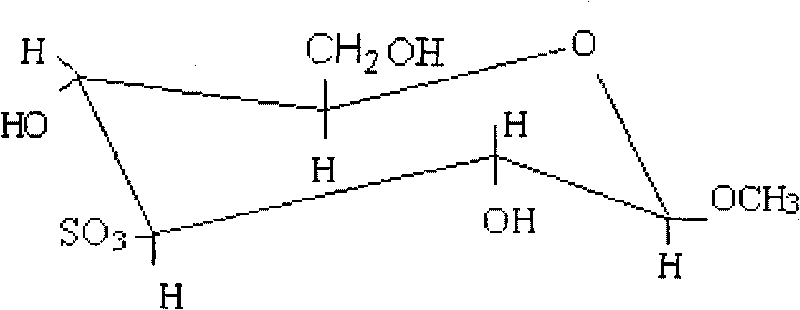

Methyl glucoside compound, preparation method thereof, lubrication inhibitor containing methyl glucoside compound for drilling fluid

ActiveCN101723992ABiodegradableEnhanced inhibitory effectSugar derivativesDrilling compositionGlucosideLubrication

The invention discloses a methyl glucoside compound for drilling fluid, and a preparation method of the methyl glucoside compound; meanwhile, the invention provides a lubrication inhibitor containing methyl glucoside compound for drilling fluid; the lubrication inhibitor is composed of methyl glucoside compound, bactericide and antioxidant, has strong inhibitive ability and favourable lubricity, has no side effect on drilling fluid property, has no negative effect on other drilling operation programs and is capable of biodegradation.

Owner:北京奥凯立科技发展股份有限公司

Biology modified silicate drilling fluid system

The invention relates to an environment-friendly and anti-sloughing water-based bio-modified silicate drilling fluid system, which consists of freshwater or seawater slurry, xanthan gum, low viscosity polyanionic cellulose, sulfonated phenolic resin, methylglucoside, non-permeation treatment agent, hydroxy film forming agent, low fluorescence asphalt, extreme pressure lubricator, sodium silicate,potassium chloride and fresh water or sea water. The drilling fluid system of the invention is an environment-friendly anti-sloughing water-based bio-modified silicate drilling fluid system, the comprehensive properties of which can be compared with that of oil-based drilling fluid, but the plugging capacity is greatly better than that of oil-based drilling fluid.

Owner:北京奥凯立科技发展股份有限公司

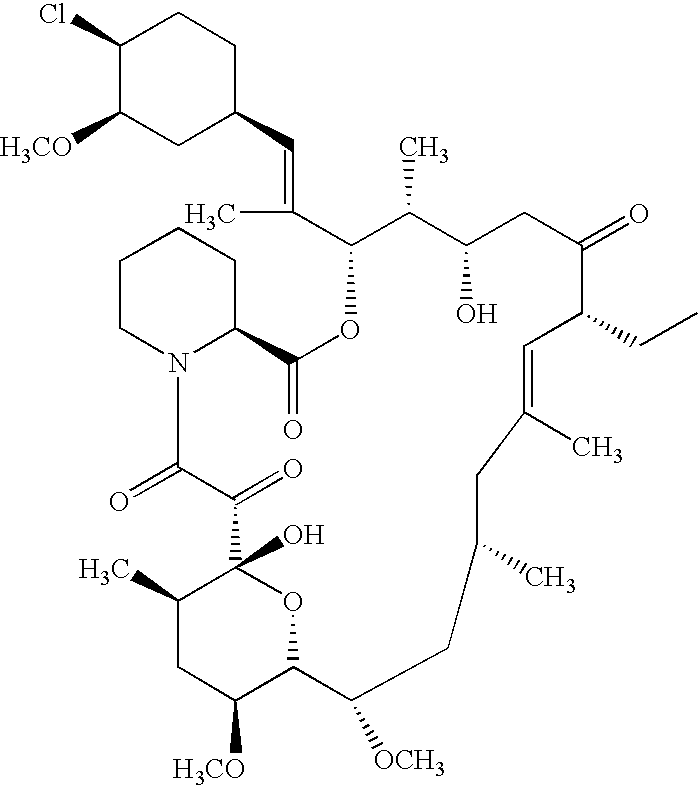

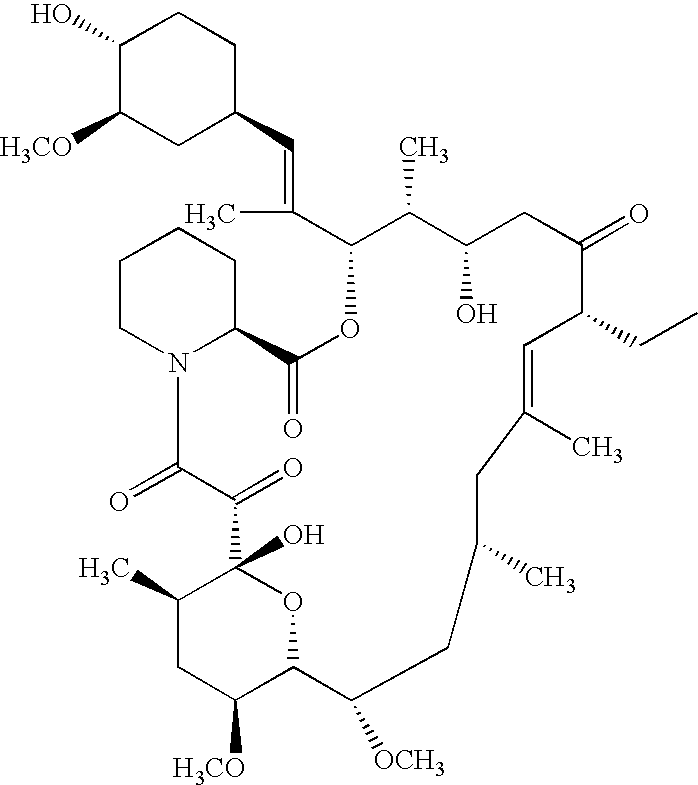

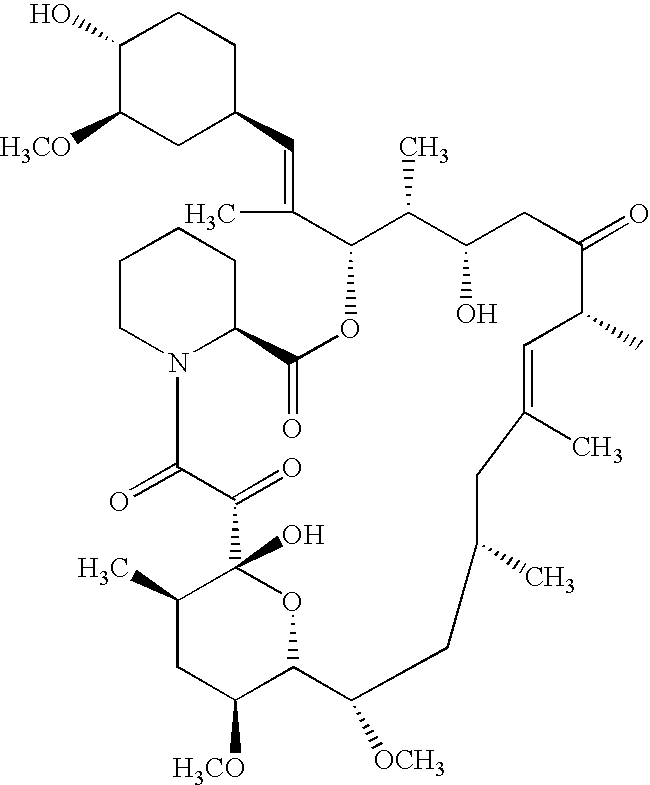

Ascomycin and pimecrolimus having reduced levels of desmethylascomycin and 32-deoxy-32-epichloro-desmethylascomycin respectively, and methods for preparation thereof

Owner:TEVA PHARM USA INC

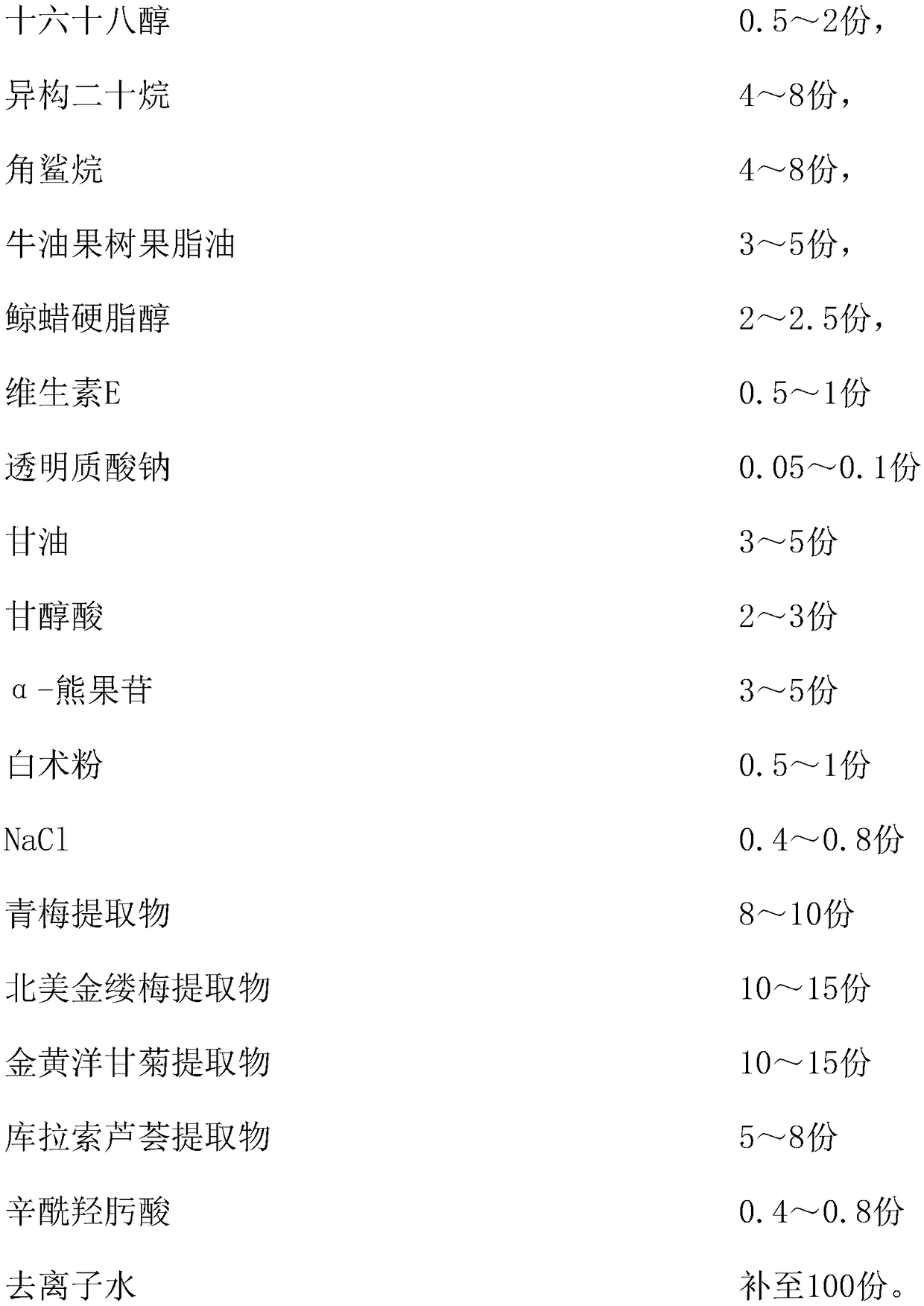

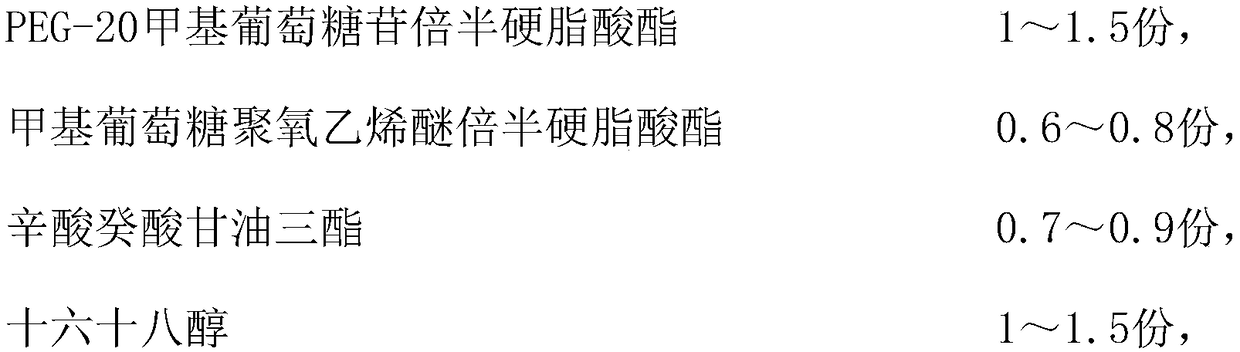

Skin whitening speckle removal cream containing plant acid and production process thereof

InactiveCN108743504ATo promote metabolismGood restorativeCosmetic preparationsToilet preparationsALPHA-ARBUTINHamamelis virginiana

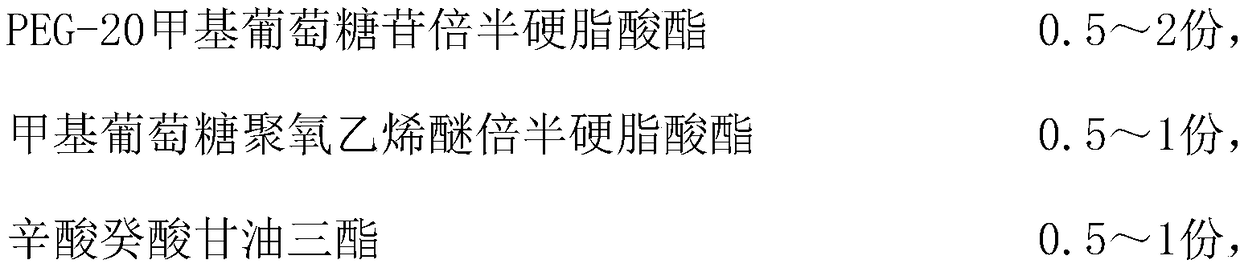

The invention discloses a skin whitening speckle removal cream. The cream is prepared from, by weight part, PEG-20 methyl glucoside sesquistearate, methyl glucoside polyoxyethylene ether sesquistearate, tricaprin octanoate, cetearyl alcohol, isomeric eicosane, squalene, fruit fatty oil of avocado trees, cetostearyl alcohol, vitamin E, sodium hyaluronate, glycerin, glycolic acid, alpha-arbutin, rhizoma atractylodis powder, NaCl, greengage extracts, hamamelis virginiana extracts, chrysanthellum indicum extracts, aloe barbadensis extracts, capryloyl hydroximic acid and deionized water. The skin whitening speckle removal cream is great in speckle removal and remediation effect, capable of achieving the effects of preserving moisture, resisting wrinkling and aging and promoting cell metabolismat the same time, suitable for application to people different in skin type, high in cost performance and environmentally friendly.

Owner:湖南慕她生物科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com