Biology modified silicate drilling fluid system

A biological modification and silicate technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of shale collapse, wellbore pressure imbalance, etc., and achieve good environmental protection performance and good compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Put 20m3 of fresh water in the circulation pool, mix it well and make it into a pre-hydrated soil slurry. The hydration time of the pre-hydrated slurry should not be less than 6 hours. Add 30kg xanthan gum, 150kg low-viscosity polyanionic cellulose, 900kg sulfonated phenolic resin, 1500kg methyl glucoside, 600kg non-permeation treatment agent, 600kg / m3 hydroxyl film-forming agent, 600g low-fluorescence asphalt , 600kg of extreme pressure lubricant, 900kg of sodium silicate, 900kg of potassium chloride, add fresh water to 30m3, and stir well to form the drilling fluid system described in this article.

[0028] Present embodiment also can use seawater, if be seawater, should add 450kg caustic soda earlier, the soda ash of 300kg, react not less than 30 minutes after adding alkali. Then add components such as bentonite, specifically the same process as the above-mentioned method using fresh water.

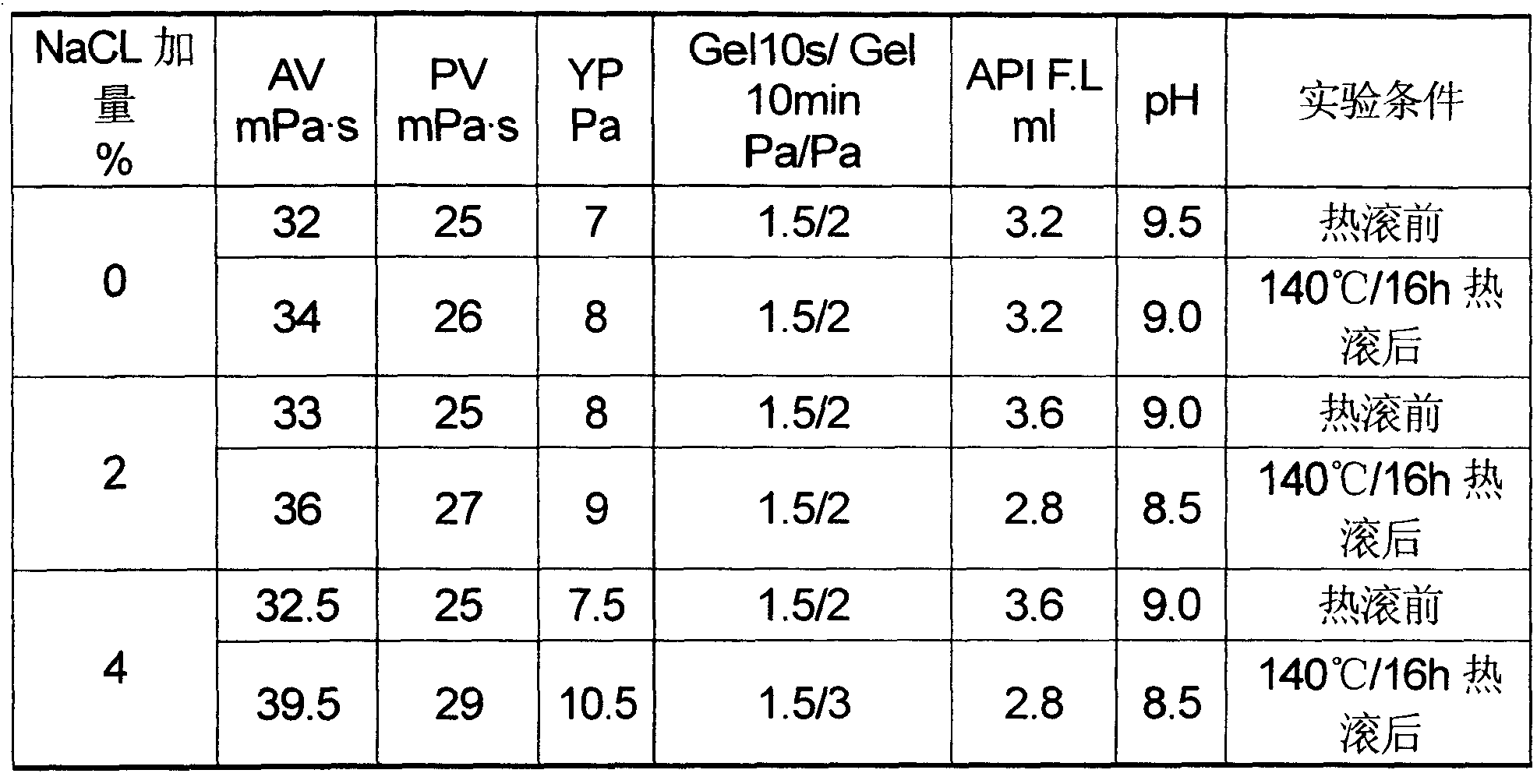

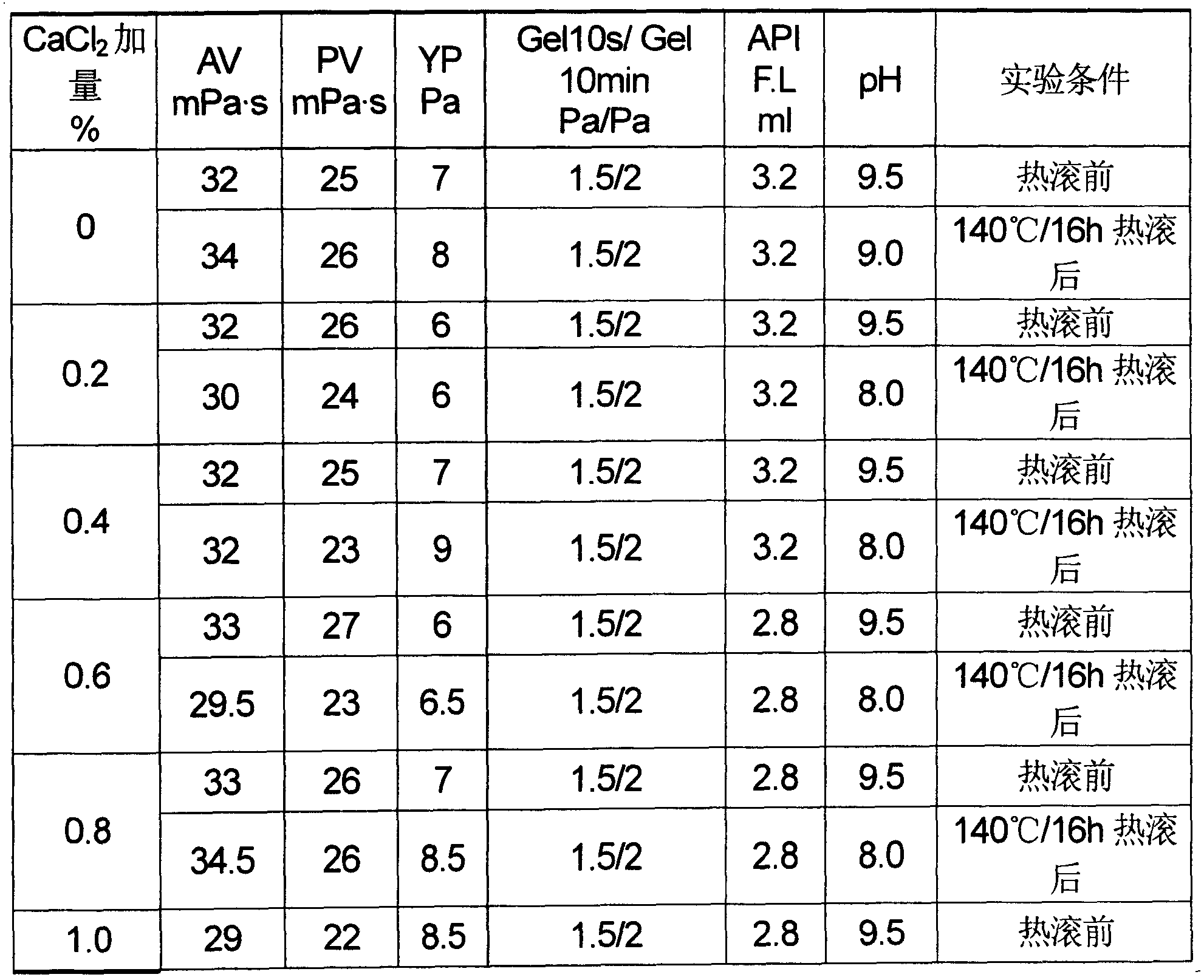

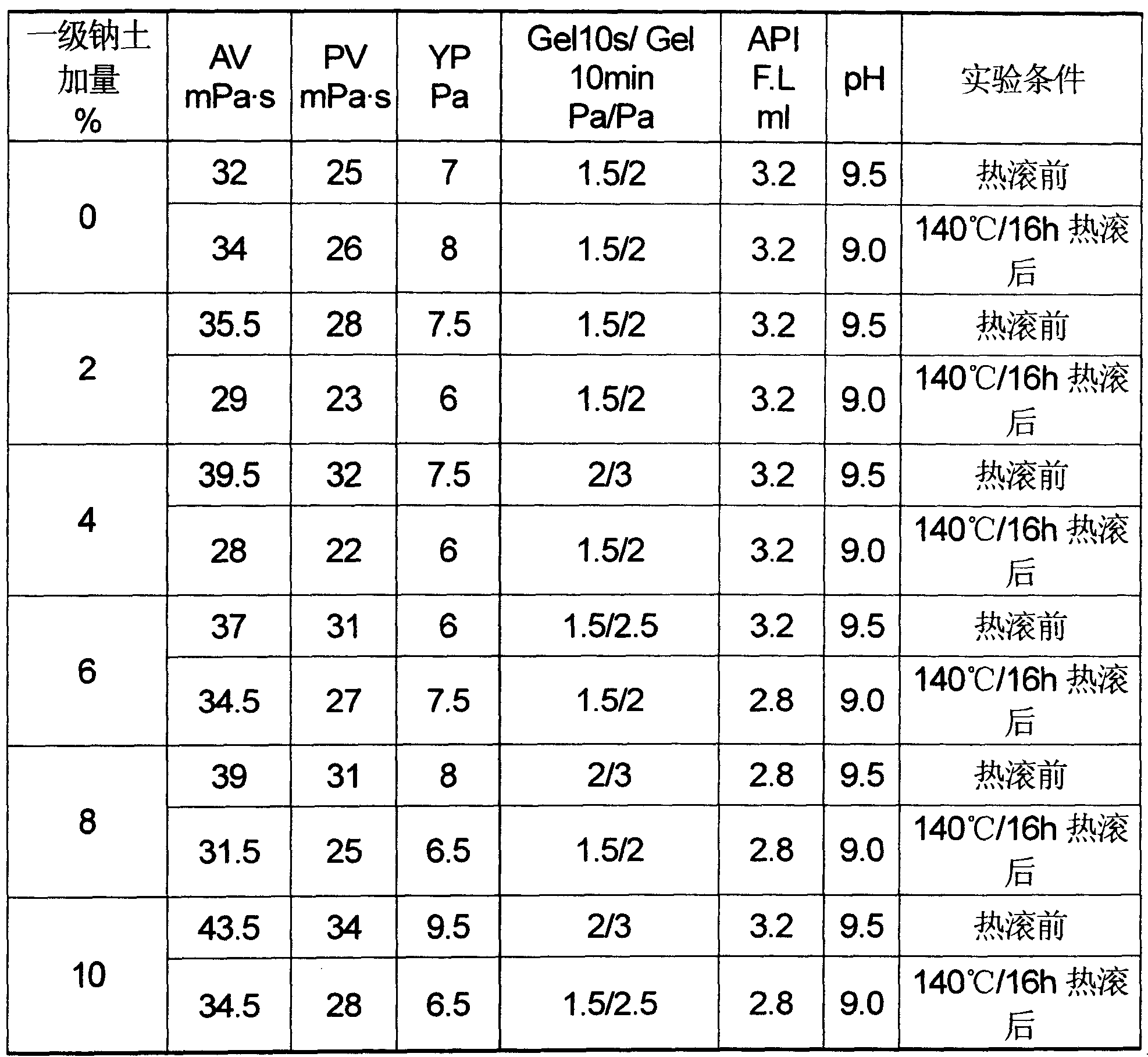

[0029] Performance experiment data of prepared water-based bio-modified si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com