Method for catalyzing glucose by using magnetic solid acid to produce methyl glucoside

A technology of methyl glucoside and magnetic solid acid, applied in the field of chemical conversion of biomass, can solve the problems of strong corrosion, high pollution, high price, etc., and achieve the effects of less equipment corrosion, abundant sources and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] Preparation of nano-magnetic solid acid SZT: refer to the literature Jun Wang, Piaoping Yang, Meiqing Fan, et al.Materials Letters, 2007, 61, 2235-2238. Prepared a magnetic solid superacid for the glucose glycoside involved in the present invention reaction.

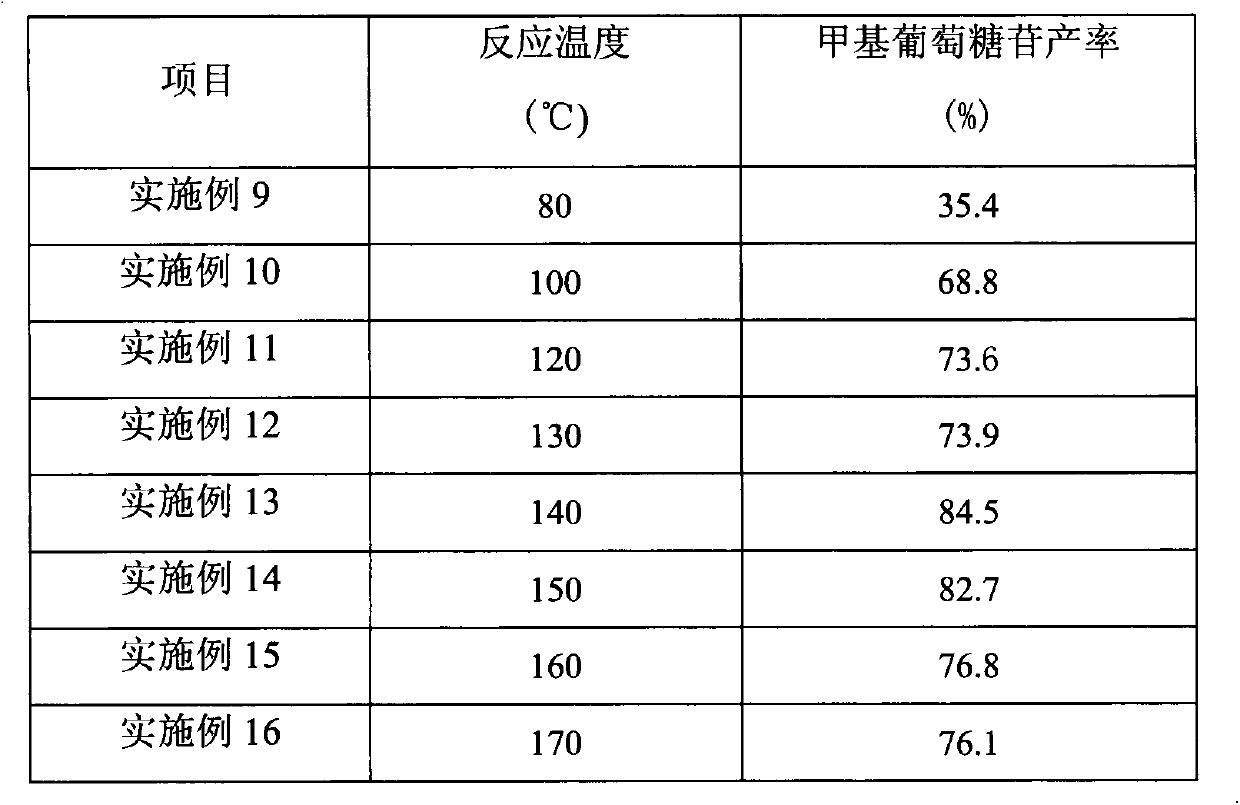

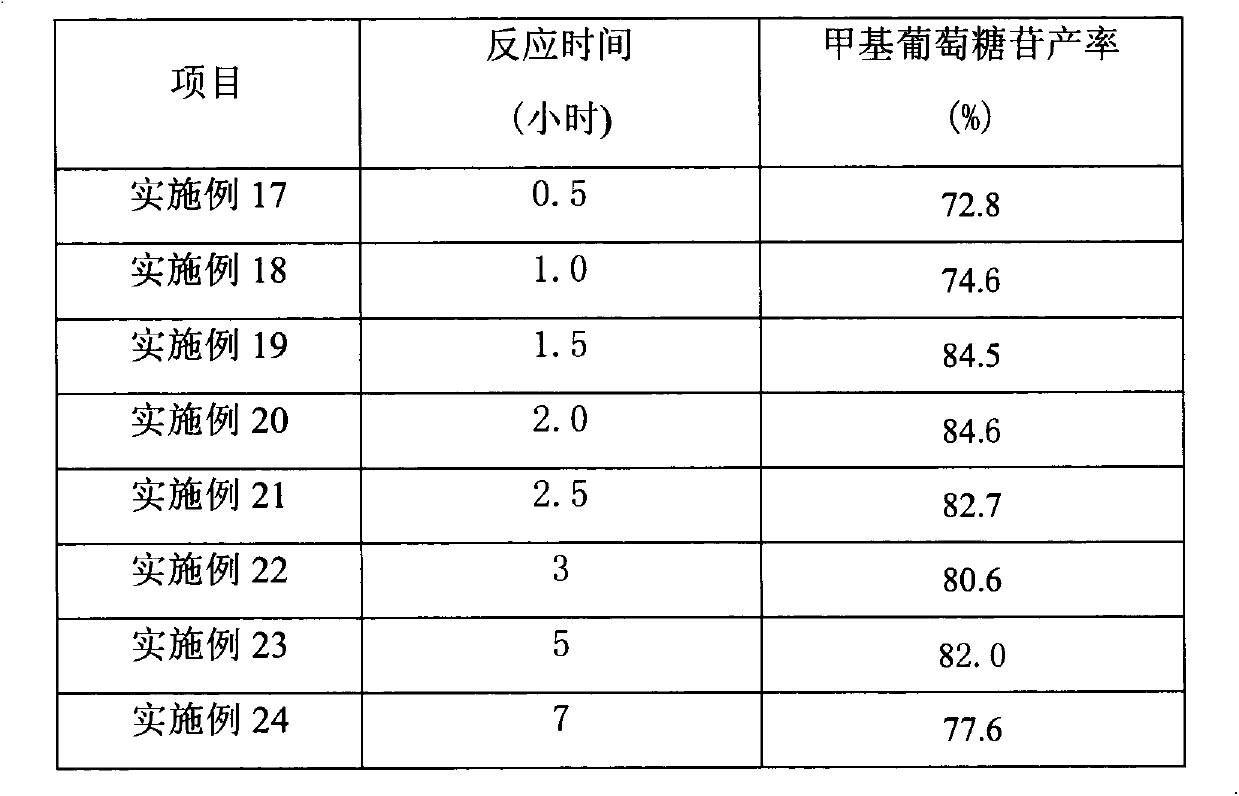

[0016] The implementation process of producing methyl glucoside from glucose: use glucose as raw material, magnetic solid acid as catalyst, and react under subcritical methanol conditions at a temperature of 130-170°C for 1.5-7 hours to obtain methyl glucoside in high yield . After the reaction, the magnetic technology separates the nano-magnetic solid acid, and the methanol is removed by rotary evaporation to obtain methyl glucoside. The yield of the methyl glucoside obtained by the present invention is as high as 84.6%.

Embodiment 1

[0018] Take anhydrous glucose (0.6g), magnetic solid acid (0.3g) and methanol (12mL) in a 25mL hydrothermal kettle, stir magnetically, react at 140°C for 1.5 hours, and stop the reaction. Magnetic technology is used to separate nano-magnetic solid acid, and the reaction solution is concentrated using a rotary evaporator; the concentrated solution is subjected to column chromatography (silica gel is used as a filler, and the eluent is methanol to ethyl acetate at a ratio of 1:6), and methylglucose is separated to obtain Glycosides.

[0019] The nuclear magnetic spectrum data of product methyl glucoside is: 1 HNMR (D 2 O, 400Hz, TMS) δ (ppm): 3.39 (m, 1H), 3.43 (s, 1H), 3.57 (m, 1H), 3.65 (m, 1H), 3.68 (m, 1H), 3.77 (m, 1H), 3.88(m, 1H), 4.8(s, 1H). The infrared spectrum data is: IR(KBr, cm -1 ):-OH(3542,3296);-CH 3 (2913); -CH 2 -(1464); C-O-C(1145).

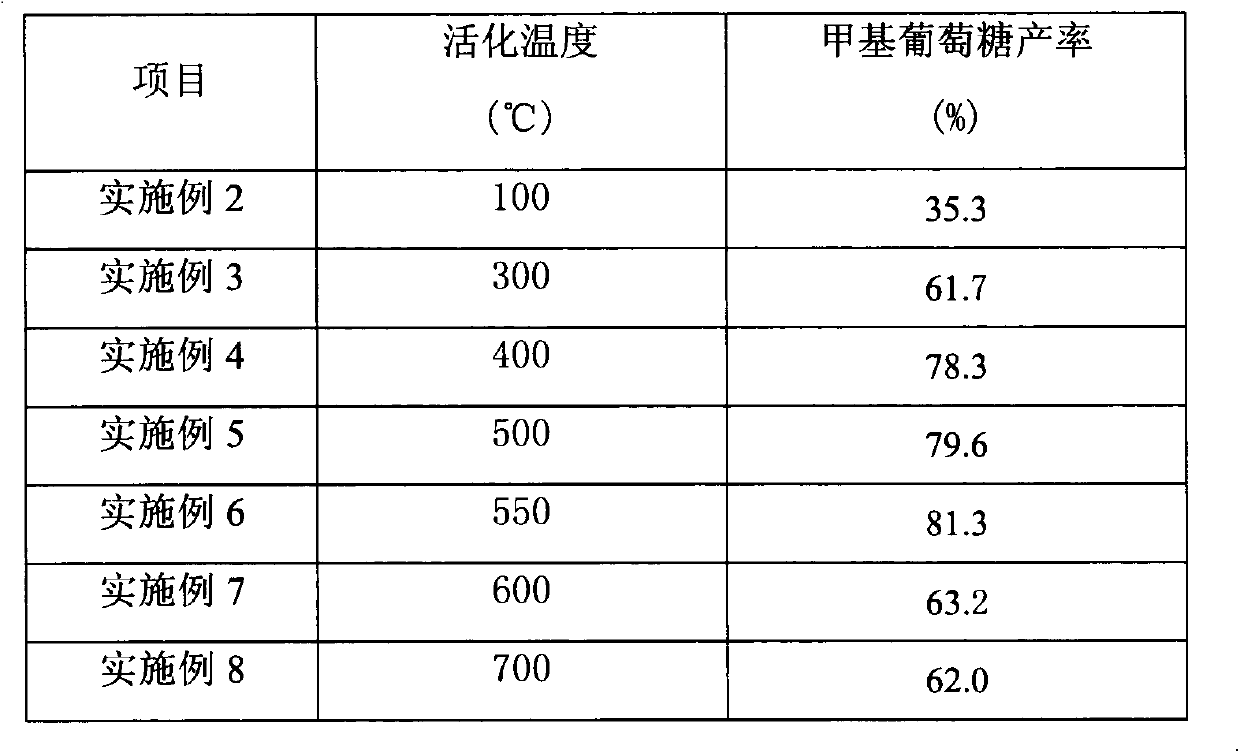

Embodiment 2~8

[0021] Other process conditions and reaction steps are the same as Example 1, but the temperature of magnetic solid acid activation is different (100~700 DEG C), react at 140 DEG C for 1.5 hours, stop reaction. Magnetic technology is used to separate nano-magnetic solid acid, and the reaction solution is concentrated using a rotary evaporator; the concentrated solution is subjected to column chromatography (silica gel is used as a filler, and the eluent is methanol to ethyl acetate at a ratio of 1:6), and methylglucose is separated to obtain Glycosides.

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com