Composite microbial multi-element film coating synergistic fertilizer and preparation method thereof

A technology of composite microorganisms and composite microbial agents, which is applied to fertilizers made from biological waste, urea compound fertilizers, microbial treatment, etc., can solve problems such as difficult to degrade, high cost of coating, negative environmental effects, etc., and achieve dissolution rate High efficiency, low operating cost, outstanding fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

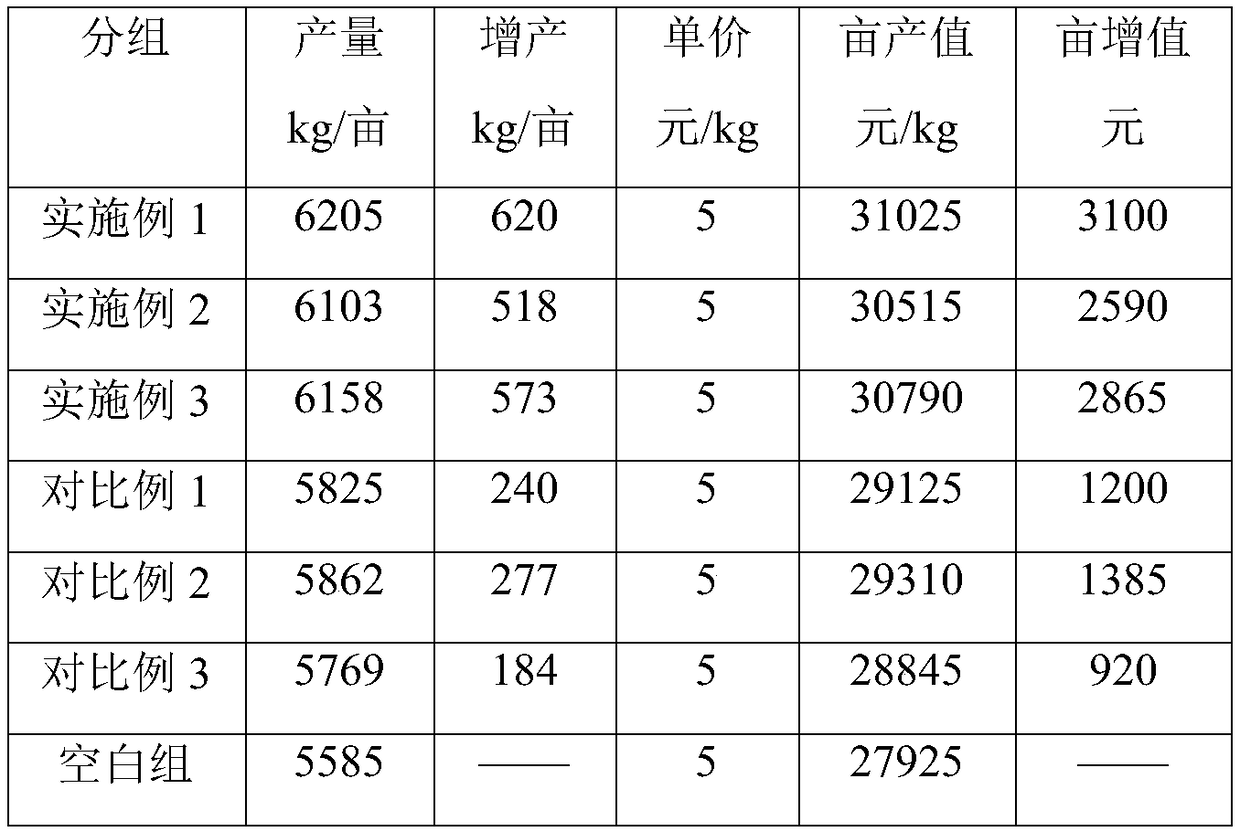

Examples

Embodiment 1

[0033] A composite microbial multi-element coating synergistic fertilizer is prepared from the following raw materials in parts by weight: 100 parts of granular fertilizer core, 2.5 parts of coating agent, and 2 parts of composite microbial bacterial agent;

[0034] The granular fertilizer core is made from the following raw materials in parts by weight: 100 parts of urea, 15 parts of ammonium sulfate, 25 parts of monoammonium phosphate, 50 parts of double superphosphate, 30 parts of potassium chloride, and 20 parts of potassium dihydrogen phosphate , 4 parts of ammonium molybdate, 13 parts of magnesium sulfate, 50 parts of fermented fertilizer, 40 parts of bentonite, 8 parts of γ-polyglutamic acid / chitooligosaccharide hydrogel;

[0035] The coating agent is prepared from the following raw materials in parts by weight: 24 parts of urea, 28 parts of formaldehyde, 2 parts of α-methylglucoside, and 1 part of diethylenetriaminepentaacetic acid;

[0036] The composite microbial bac...

Embodiment 2

[0054] A composite microbial multi-element coating synergistic fertilizer is prepared from the following raw materials in parts by weight: 100 parts of granular fertilizer core, 2 parts of coating agent, and 3 parts of composite microbial bacterial agent;

[0055] The granular fertilizer core is made from the following raw materials in parts by weight: 100 parts of urea, 10 parts of ammonium sulfate, 30 parts of monoammonium phosphate, 60 parts of double superphosphate, 20 parts of potassium chloride, and 25 parts of potassium dihydrogen phosphate , 3 parts of ammonium molybdate, 15 parts of magnesium sulfate, 40 parts of fermented fertilizer, 50 parts of bentonite, 5 parts of γ-polyglutamic acid / chitooligosaccharide hydrogel;

[0056] The coating agent is prepared from the following raw materials in parts by weight: 18 parts of urea, 29 parts of formaldehyde, 1 part of α-methylglucoside, and 1.1 parts of diethylenetriaminepentaacetic acid;

[0057] The composite microbial bac...

Embodiment 3

[0062] A composite microbial multi-element coating synergistic fertilizer is prepared from the following raw materials in parts by weight: 100 parts of granular fertilizer core, 3 parts of coating agent, and 1 part of composite microbial bacterial agent;

[0063] The granular fertilizer core is made from the following raw materials in parts by weight: 100 parts of urea, 20 parts of ammonium sulfate, 20 parts of monoammonium phosphate, 40 parts of superphosphate, 40 parts of potassium chloride, and 15 parts of potassium dihydrogen phosphate , 5 parts of ammonium molybdate, 10 parts of magnesium sulfate, 60 parts of fermented fertilizer, 30 parts of bentonite, 10 parts of γ-polyglutamic acid / chitooligosaccharide hydrogel;

[0064] The coating agent is prepared from the following raw materials in parts by weight: 28 parts of urea, 27 parts of formaldehyde, 3 parts of α-methylglucoside, and 0.9 part of diethylenetriaminepentaacetic acid;

[0065] The composite microbial bacterial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com