Styrene-series ion-exchange fiber applied to boron adsorption and preparation method thereof

A technology of ion exchange fiber and styrene, which is applied in the direction of ion exchange, anion exchange, ion exchange treatment devices, etc., can solve the problems of non-patented technology, and achieve the effect of high water content and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

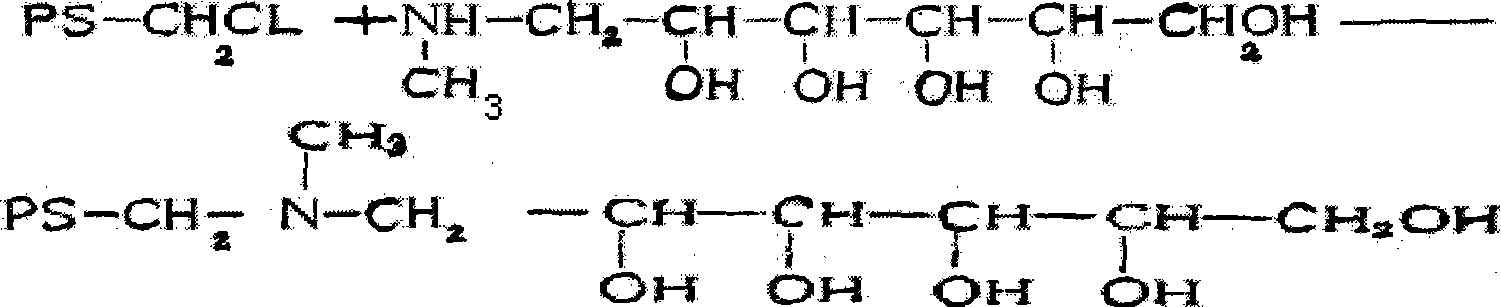

Method used

Image

Examples

Embodiment 1

[0022] 1. Test device

[0023] Constant temperature water bath (0—120°C)

[0024] Adjustable electric mixer (0-2000 rpm)

[0025] Three-neck bottle (2000ml)

[0026] plastic mixing paddle

[0027] Thermometer (0-150℃)

[0028] Rubber stopper (No. 5)

[0029] Beaker (400ml, 1000ml)

[0030] Balance (0—1000g)

[0031] 2. Main raw materials

[0032] 2.1. Composite fiber products of polypropylene fiber grafted with styrene, outsourced

[0033] 2.2. Chloromethyl ether, analytically pure

[0034] 2.3. Benzene, analytically pure

[0035] 2.4. Methanol, analytically pure

[0036] 2.5. N-methylglucamine, analytically pure

[0037] 2.6. Anhydrous zinc chloride, analytically pure

[0038] 3. Brief description of the process

[0039] 3.1. Swelling

[0040] Take 100 grams of polypropylene fibers grafted with styrene composite fiber products into a three-necked flask, add 200 grams of benzene, 350 grams of methanol, and stir at room temperature for 10 hours.

[0041] 3.1. Chl...

Embodiment 2

[0049] It is 100 parts (weight) to reduce N-methylglucamine consumption, and other is with example one. The resulting product number is KRB-2.

Embodiment 3

[0051] It is 300 parts (weight) to improve N-methylglucamine consumption, and other is with example one. The resulting product number was KRB-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com