Lubricating inhibitor for drilling fluid and preparation method thereof and drilling fluid containing lubricating inhibitor for drilling fluid

A drilling fluid and inhibitor technology, applied in the field of drilling, can solve the problems of polluting the environment, affecting the oil and gas formation, and high cost, achieving the effects of good thermal stability, excellent inhibition of lubrication, and reduction of water activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

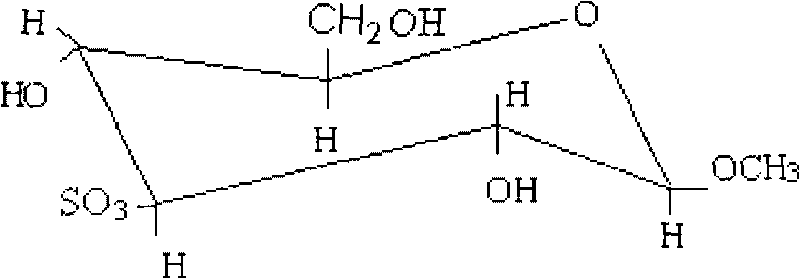

[0020] Dissolve 300g of methyl glucoside in 200g of water, add 0.5g of anhydrous zinc chloride, add dropwise 60g of hydrochloric acid with a concentration of 31% while stirring, after the addition is completed, heat up to 70°C, and keep the reaction in airtight heat preservation for 2 hours. Add 60g of Na to it 2 SO 3 , stir evenly, open the door and heat up to 90°C, and react for 1 hour. Dry the obtained product at 30°C, pulverize, and sieve to obtain the lubrication inhibitor for drilling fluid of this embodiment, which contains the methyl glucoside compound shown in the following formula:

[0021]

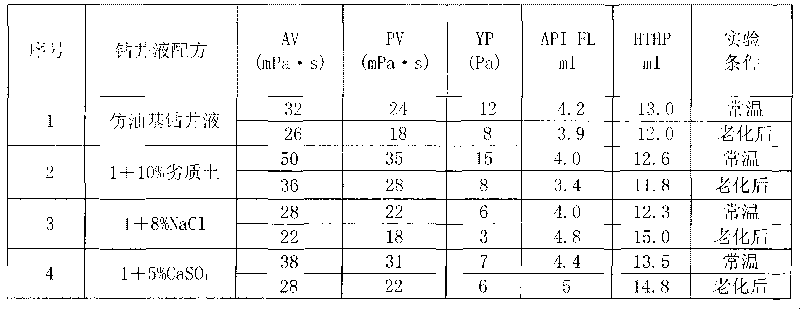

[0022] In some other embodiments, the lubrication inhibitor for drilling fluid of the present invention can also be prepared according to the reaction conditions shown in the following table 1, all can realize the lubrication inhibitor for drilling fluid of the present invention:

[0023] Table 1 Preparation method of lubrication inhibitor for drilling fluid

[0024] ...

Embodiment 2

[0027] The preparation method of the lubrication inhibitor for drilling fluid of the present embodiment is as follows: on the basis of Example 1, it also includes the steps of adding bactericide and antioxidant and pulverizing and mixing uniformly, and the addition amount of the bactericide is: Example 0.2‰ of the quality of the substance obtained in 1, the addition of the antioxidant is: 0.2‰ of the quality of the substance obtained in Example 1. The bactericide is quaternary ammonium salt bactericide 1227, and the antioxidant is sodium bisulfite. During the specific preparation of the lubrication inhibitor for drilling fluid in this example, the methyl glucoside compound, quaternary ammonium salt fungicide 1227 and sodium bisulfite were added according to the above ratio, pulverized and mixed uniformly to obtain The lubrication inhibitor for drilling fluid in this embodiment.

Embodiment 3

[0029] The preparation method of the lubrication inhibitor for drilling fluid of the present embodiment is as follows: on the basis of Example 1, it also includes the steps of adding bactericide and antioxidant and pulverizing and mixing uniformly, and the addition amount of the bactericide is: Example 0.1‰ of the quality of the substance obtained in 1, the addition of the antioxidant is: 0.1‰ of the quality of the substance obtained in Example 1. The bactericide is isothiazolinone, and the antioxidant is sodium sulfite. When the lubrication inhibitor for drilling fluid of this embodiment is specifically prepared, the methyl glucoside compound, isothiazolinone and sodium sulfite are added according to the above ratio, pulverized and mixed uniformly to obtain the drilling fluid of this embodiment Use a lubricant inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com