Salt-tolerant highly-inhibitive foaming agent for foam drilling of shale formation

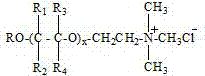

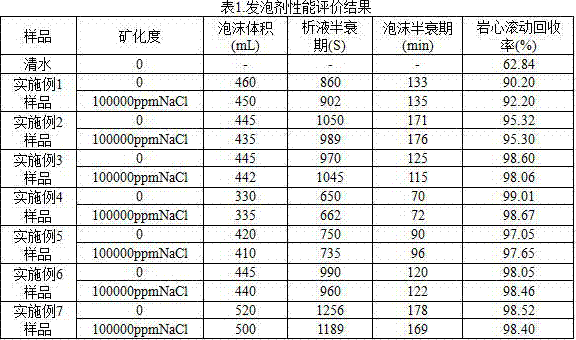

A foaming agent, mud shale technology, applied in drilling composition, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of drilling failure, difficult mud maintenance, general temperature resistance, etc. The effect of inhibiting hydration dispersion, excellent inhibiting property, and good foaming property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

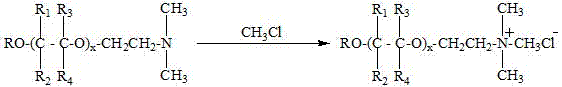

[0019] Embodiment 1~7: the preparation of blowing agent.

Embodiment 1

[0021] Add 0.10mol of dodecyl polyoxypropylene ether dimethyl tertiary amine (the number of propylene oxide repeating units is 2) and 0.105mol of methylene chloride into a 250mL reaction kettle, then add 110.0g of toluene, start stirring and seal the heating After reaching 50°C, the reaction was stopped after 5 hours, and the solvent toluene and excess chloromethane were distilled off to obtain a paste sample.

Embodiment 2

[0023] Add 0.10mol cetyl polyoxypropylene ether dimethyl tertiary amine (the number of repeating units of propylene oxide is 5) and 0.105mol methylene chloride into a 250mL reaction kettle, then add 90.0g toluene, start stirring and seal the heating After reaching 80°C, the reaction was stopped after 3 hours, and the solvent toluene and excess methylene chloride were distilled off to obtain a paste sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com