Composite metal zwitterion polymer and its prepn and use

A composite metal and amphoteric ion technology, applied in the direction of drilling equipment, etc., can solve the problems that the dynamic-plastic ratio is not as high as that of MMH, does not control mud filtration loss, and the starting pressure of mud pump is high, so as to achieve low apparent viscosity and inhibit dispersion slurry making performance, improve the effect of ROP

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055]Mix 71.5Kg powdered aluminum hydroxide, 40.0kg powdered magnesium hydroxide, 5.0kg powdered lithium hydroxide and 3.0kg powdered beryllium hydroxide in a mixer and set aside.

[0056] Add 250kg of deionized water, 350kg of acrylamide, 180kg of acrylic acid, 50kg of acrylonitrile, and 150kg of N,N-dimethyl-N-benzylallyl ammonium chloride into the reactor in turn at room temperature, and stir well. Neutralize with 45kg calcium hydroxide and 65kg potassium hydroxide, control the pH value to be equal to 6.5, and keep the system temperature not higher than 30°C during the process of adjusting the system pH value. Then add the previously prepared composite metal hydroxide. The materials in the reactor were fully stirred evenly, and 14.6 kg of ammonium persulfate aqueous solution (10%) and 14.6 kg of sodium bisulfite aqueous solution (10%) were added, and vaporization desolvation instant polymerization occurred within 5 minutes. The product is dried and pulverized at 100-110°C...

Embodiment 2

[0058] 0.60mol aluminum chloride (AlCl 3 66.7kg), 0.30mol magnesium chloride (MgCl 2 ·6H 2 O61.0kg), 0.06mol ferric chloride (FeCl 3 9.7kg) and 0.04mol nickel chloride (NiCl 2 ·6H 2 (9.5kg) was dissolved in 600kg of water, and 266.3kg of 40% aqueous sodium hydroxide solution was added dropwise under stirring, and stirred for 30 minutes. The solution containing a large amount of composite metal hydroxide gel is suction-filtered under vacuum conditions, and then the gel filter cake is washed and suction-filtered three times with 750 kg of water, and the gel filter cake has a water content of 87%. stand-by.

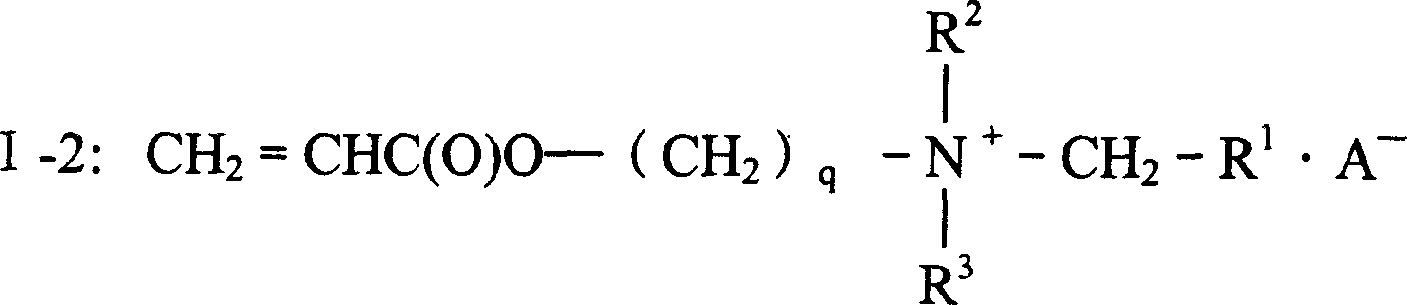

[0059] Add 100kg deionized water, 290kg acrylamide, 190kg acrylic acid, 55kg acrylonitrile, 150kg N,N,N-trimethyl-N-acrylate butyl ammonium chloride, 50kg propylene sulfonate to the reaction kettle in sequence sodium bicarbonate and stir well. Neutralize with 54kg of calcium hydroxide and 45kg of sodium hydroxide, and control the pH value to be equal to 6.5. At the ...

Embodiment 3

[0061] 80kg of powdery aluminum hydroxide and 40kg of powdery magnesium hydroxide were mixed uniformly in a mixer and set aside.

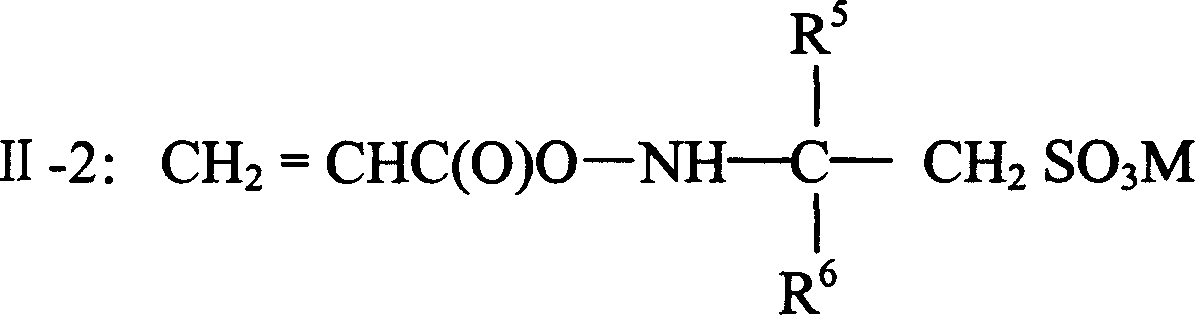

[0062] Add 250kg deionized water, 300kg acrylamide, 120kg acrylic acid, 50kg acrylonitrile, 150kg N,N-diethylallyl ammonium chloride and 100kg 2-acrylamide-2- Sodium methyl propane sulfonate, stir well. Neutralize with 60kg of calcium hydroxide, control the pH value to be equal to 6.5, and keep the system temperature not higher than 30°C during the process of adjusting the pH value of the system. Then add the previously prepared composite metal hydroxide. Stir the materials in the reactor evenly, add 18.0kg ammonium persulfate aqueous solution (10%) and 18.0kg sodium bisulfite aqueous solution (10%), and vaporization desolvation instant polymerization occurs within 5 minutes. The product is dried and pulverized at 100-110°C, and its 1% aqueous solution viscosity is 24.5mPa.S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com