Well cementing high-temperature inhibiting agent for oil gas well and preparation method

A retarder and technology for oil and gas wells, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as relatively large stability restrictions, and achieve the effect of wide operating temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

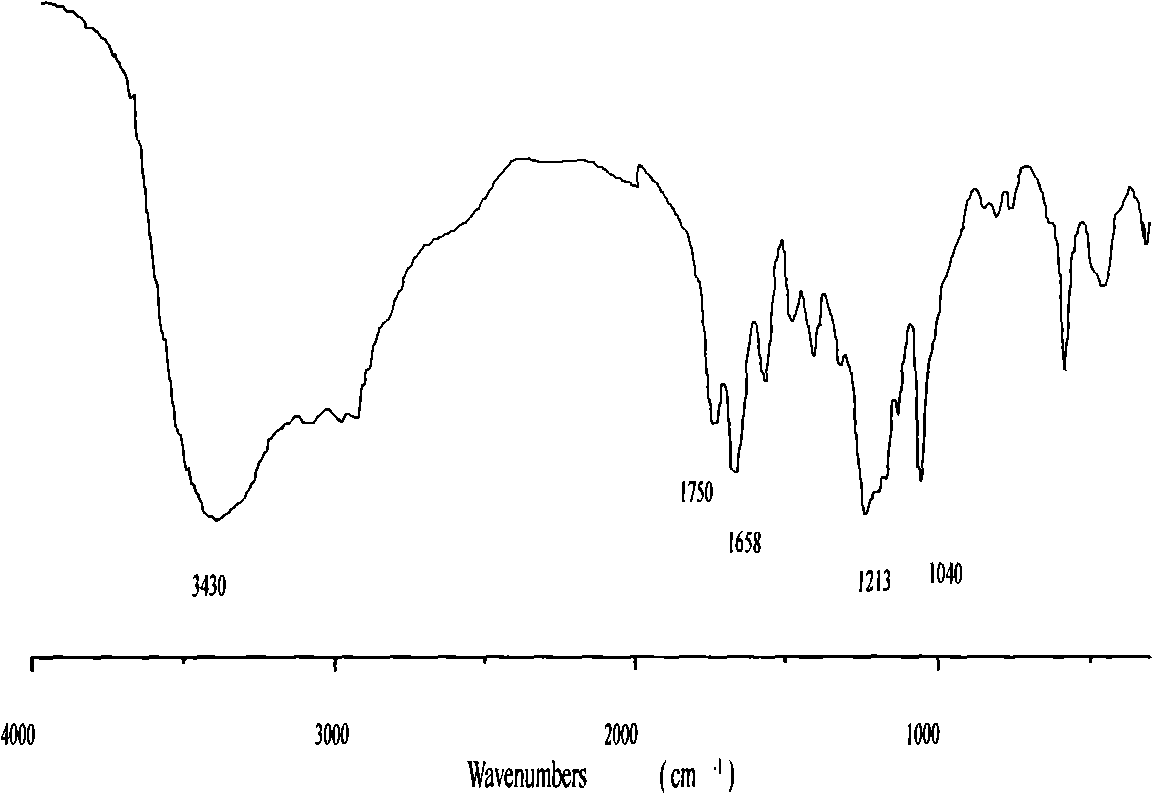

[0023] (1) Dissolving and recrystallizing itaconic acid in deionized water for purification. Benzoyl peroxide was dissolved in a mixed solution of chloroform-methanol and recrystallized for purification.

[0024] (2) Weigh a certain amount of AMPS according to the mass ratio of AMPS to itaconic acid of 73:27.

[0025] (3) according to 2mol L -1 The concentration of N,N-dimethylpropanamide was weighed, added to a four-neck flask covered with a polyethylene lid, heated to 70°C, and nitrogen gas was passed for 10 minutes to remove oxygen.

[0026] (4) According to the order of itaconic acid first and then AMPS, add it to N,N-dimethylpropionamide in sequence, then pass nitrogen gas for 5 minutes, raise the temperature to 75°C, and add 0.05mol·L -1 benzoyl peroxide as the initiator. After reacting for one hour, it was cooled to room temperature.

[0027] (5) Add a large amount of acetone to the reacted solution at room temperature to precipitate the polymer. Redissolve the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com