Shale gas acid fracturing drag reducer and reparation method thereof

A technology of acid fracturing and drag reducer, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of small molecular weight, poor acid resistance, and low content of polymers, and achieve safe and stable transportation and storage High resistance, the effect of improving the anti-acid ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation of shale gas acidizing fracturing drag reducer

[0027] Mix monomer acrylic acid and 2-acrylamide-2 methyl propane sulfonic acid, dissolve in aqueous solution, adjust pH=7, add acrylamide to dissolve, acrylamide: acrylic acid: 2-acrylamide-2 methyl propane sulfonic acid The mass ratio is 3.8:0.5:1; then add disodium ethylenediaminetetraacetic acid to make the concentration 30mg / L; it is the water phase, and the mass fraction of water is 50%.

[0028] Mix and dissolve aviation kerosene and compounded surfactant at a mass ratio of 0.284:1, and add it to a 250mL three-necked flask equipped with a stirrer, wherein the surfactant Span-80 and Tween-80 are compounded at a mass ratio of 5.25:1 Formed, the HLB value is 6.0. Add the water phase into the three-necked flask, the mass ratio of the oil phase to the water phase is 0.595:1, stir and emulsify at 1000r / min for 30 minutes, then place the three-necked flask at a water temperature of 45°C, Nitrogen g...

Embodiment 2

[0029] Indoor measurement of embodiment 2 drag reducer acid resistance

[0030] (1) Dissolve the drag reducer in clear water to prepare drag reducer solutions with different concentrations;

[0031] (2) The power unit of the test is a screw pump to avoid the shear degradation of the molecular segment of the drag reducer by centrifugal pumps and gear pumps;

[0032] (3) Use a circular pipeline as the test pipe section, install pressure sensors at both ends of the test pipe section, adjust the flow rate of the screw pump, record the readings of the pressure sensors at both ends of the test pipe section under different flow rates, and calculate the water and drag reducer solution at The pressure drop △P generated by flowing through the test pipe section under different flow rates;

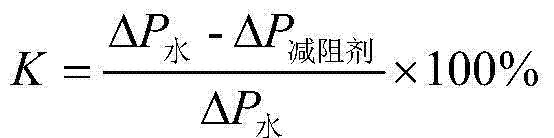

[0033] (4) The resistance reduction rate is calculated by the following formula

[0034]

[0035] In the formula: K—drag reduction rate, %

[0036] ΔP 水 ——The pressure drop produced when clean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com