Oil field compound type anti-scale corrosion inhibitor and preparation method thereof

A scale and corrosion inhibitor, oilfield technology, used in earth-moving drilling, wellbore/well components, etc., can solve the problems of high maintenance cost of uphole facilities, casualties of production stoppages, large direct losses, etc., and achieve good scale and corrosion inhibition. Effect, simple formula, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

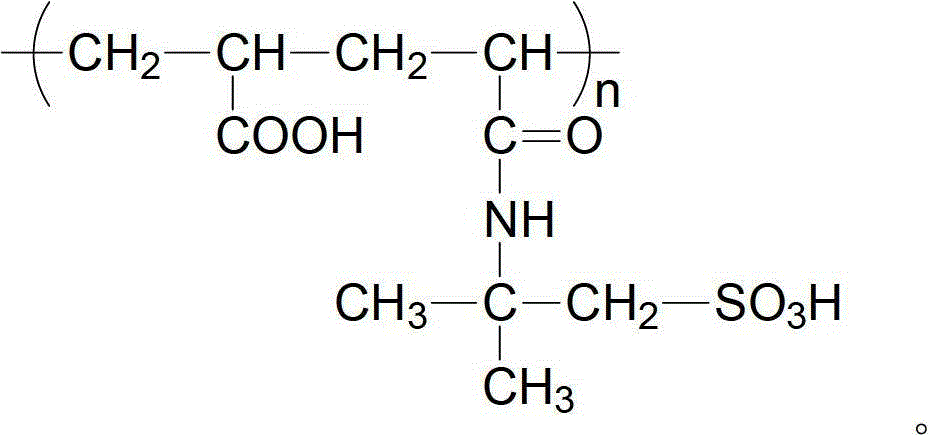

Method used

Image

Examples

Embodiment 1

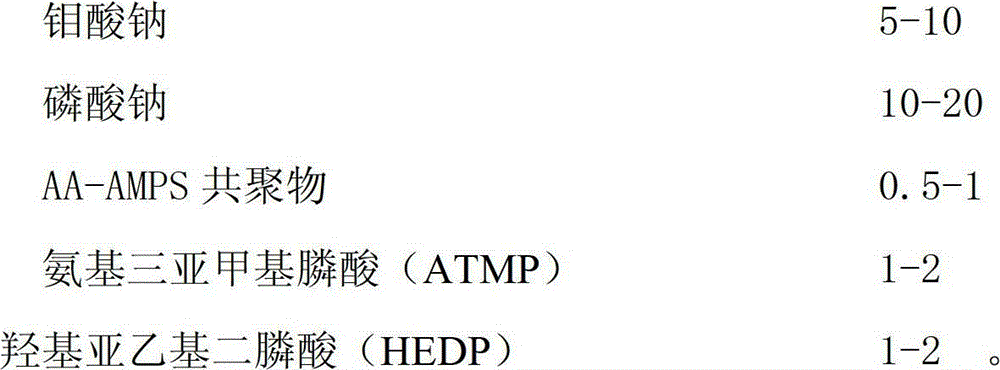

[0023] The mass ratio of each component of the compound scale and corrosion inhibitor for oil field is as follows:

[0024]

[0025] The preparation process of compound scale and corrosion inhibitors for oilfields: first dissolve sodium molybdate and sodium phosphate completely with hot water, then stir vigorously, add AA-AMPS copolymer during the stirring process, add ATMP and HEDP after fully dissolved , continue to stir and dissolve, add water to 1000g, and obtain a compound scale and corrosion inhibitor for oil fields.

[0026] The test temperature is 70°C, and the corrosion inhibitor is soaked in the coupon for 72 hours. The corrosion inhibition effect is as follows:

[0027] Table 1 Sustained-release efficiency of different dosing concentrations

[0028]

Embodiment 2

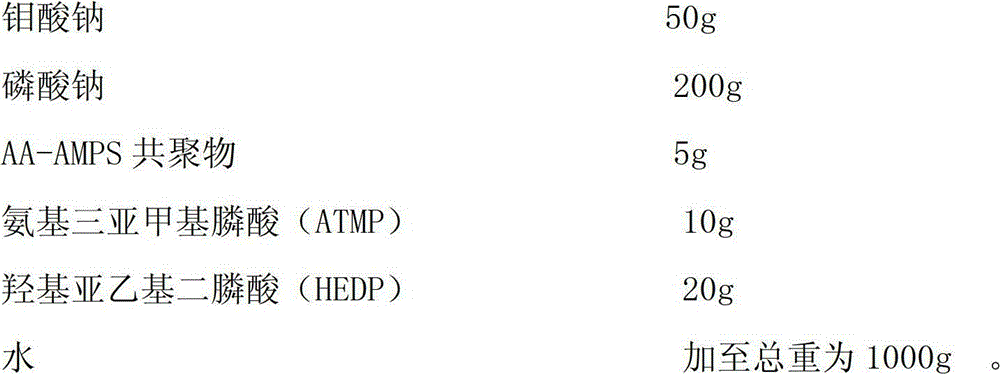

[0030] The mass ratio of each component of the compound scale and corrosion inhibitor for oil field is as follows:

[0031]

[0032] The preparation process of the composite scale and corrosion inhibitor for oil field is the same as that in Example 1.

[0033] The test temperature is 70°C, and the corrosion inhibitor is soaked in the coupon for 72 hours. The corrosion inhibition effect is as follows:

[0034] Table 2 Sustained-release efficiency of different dosing concentrations

[0035]

Embodiment 3

[0037] The mass ratio of each component of the compound scale and corrosion inhibitor for oil field is as follows:

[0038]

[0039] The preparation process of the composite scale and corrosion inhibitor for oil field is the same as that in Example 1.

[0040] The test temperature is 70°C, and the corrosion inhibitor is soaked in the coupon for 72 hours. The corrosion inhibition effect is as follows:

[0041] Table 3 Sustained-release efficiency of different dosing concentrations

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com