High-early-strength polycarboxylate water reducer as well as synthesis method and application method of polycarboxylate water reducer

A technology of polycarboxylate and water reducing agent, applied in the field of building materials, can solve the problems of difficult popularization and application, large dosage, poor compatibility between components, etc., achieve strong steric hindrance dispersion effect, simple preparation process, excellent performance stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

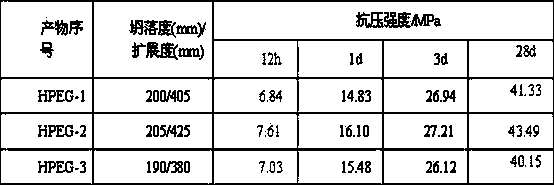

Embodiment 1

[0036] Example 1, an early-strength polycarboxylate water reducer, synthesis process and use method, with isobutenyl alcohol polyoxyethylene ether with a relative molecular weight of 2400, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid , hydrogen peroxide, ascorbic acid, thioglycolic acid, sodium hydroxide and water are synthetic raw materials. The mass ratios of each component are: 100 for isobutylene alcohol polyoxyethylene ether, 4 for acrylic acid, 2 for 2-acrylamide-2-methylpropanesulfonic acid, 0.80 for hydrogen peroxide, 0.08 for ascorbic acid, and 0.25 for mercaptoacetic acid, Take 0.75 for sodium hydroxide and 100 for water. Take the following steps for synthesis: Weigh the raw materials according to the above mass ratio; mix acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid with water in proportion to prepare a solution A material with a mass percentage of 45%; Mix with ascorbic acid and water in proportion to prepare a solution B material with a m...

Embodiment 2

[0037] Example 2, an early-strength polycarboxylate water reducer, synthesis process and use method, with isobutenyl alcohol polyoxyethylene ether with a relative molecular weight of 4400, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid , hydrogen peroxide, ascorbic acid, thioglycolic acid, calcium hydroxide and water are synthetic raw materials. The mass ratios of each component are: 100 for isobutylene alcohol polyoxyethylene ether, 5 for acrylic acid, 4 for 2-acrylamide-2-methylpropanesulfonic acid, 1.35 for hydrogen peroxide, 0.15 for ascorbic acid, and 0.40 for mercaptoacetic acid, Take 0.80 for calcium hydroxide and 150 for water. Take the following steps for synthesis: Weigh the raw materials according to the above mass ratio; mix acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid with water in proportion to prepare a solution A material with a mass percentage of 65%; Mix with ascorbic acid and water in proportion to prepare a solution B material with a...

Embodiment 3

[0038] Example 3, an early-strength polycarboxylate water reducer, synthesis process and use method, with isobutenol polyoxyethylene ether with a relative molecular weight of 5400, acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid , hydrogen peroxide, ascorbic acid, thioglycolic acid, sodium hydroxide and water are synthetic raw materials. The mass ratios of each component are: 100 for isobutylene alcohol polyoxyethylene ether, 10 for acrylic acid, 6 for 2-acrylamide-2-methylpropanesulfonic acid, 2.50 for hydrogen peroxide, 0.25 for ascorbic acid, and 0.55 for mercaptoacetic acid, Take 1.50 for sodium hydroxide and 250 for water. Take the following steps for synthesis: Weigh the raw materials according to the above mass ratio; mix acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid with water in proportion to prepare a solution A material with a mass percentage of 50%; Mix with ascorbic acid and water in proportion to prepare a solution B material with a mass per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com