Multifunctional scale and corrosion inhibitor and preparation method thereof

A scale and corrosion inhibitor, corrosion inhibition technology, applied in chemical instruments and methods, descaling and water softening, complex / solubilizer treatment, etc., can solve the problem that the use of phosphorus and nitrite cannot be completely avoided and cannot be universally applied and other problems, to achieve the effect of obvious scale and corrosion inhibition, strong biodegradability, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

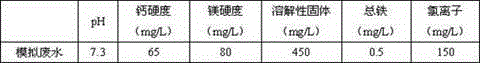

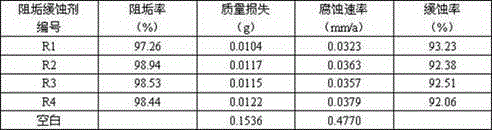

Embodiment 1

[0024] Weigh 10.5kg of polyaspartic acid, 3kg of hydrolyzed polymaleic anhydride, 15kg of sodium gluconate, 3kg of sodium molybdate, and 0.75kg of methylbenzotriazole; the scale and corrosion inhibitor No. R1 was prepared according to the above preparation method .

Embodiment 2

[0026] Weigh 12kg of polyepoxysuccinic acid, 3kg of hydrolyzed polymaleic anhydride, 15kg of sodium gluconate, 3kg of sodium molybdate, and 0.75kg of methylbenzotriazole; prepare the scale and corrosion inhibitor number R2 according to the above preparation method.

Embodiment 3

[0028] Weigh 4.5kg of polyaspartic acid, 7.5kg of polyepoxysuccinic acid, 3kg of hydrolyzed polymaleic anhydride, 15kg of sodium gluconate, 3kg of sodium molybdate, and 0.75kg of methylbenzotriazole; The scale and corrosion inhibitor number R3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com