Modified polyphenylene sulfide coating and application thereof

A technology of polyphenylene sulfide and polyphenylene sulfide resin, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of peeling, low wear resistance and low corrosion resistance, and achieve high insulation, excellent impact resistance, good compatibility effect

Active Publication Date: 2012-09-19

CHENGDU LETIAN PLASTICS

View PDF3 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to overcome the metal-coating composite material formed by spraying paint on the surface of the metal base material in the prior art. Polyphenylene sulfide modified coating with good adhesion to substrate materials, good wear resistance and corrosion resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~7

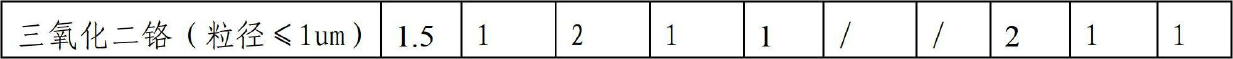

[0038] The polyphenylene sulfide modified coatings in Examples 1 to 7 are prepared by mixing the components shown in Examples 1 to 7 in Table 1, respectively, in terms of weight percentage.

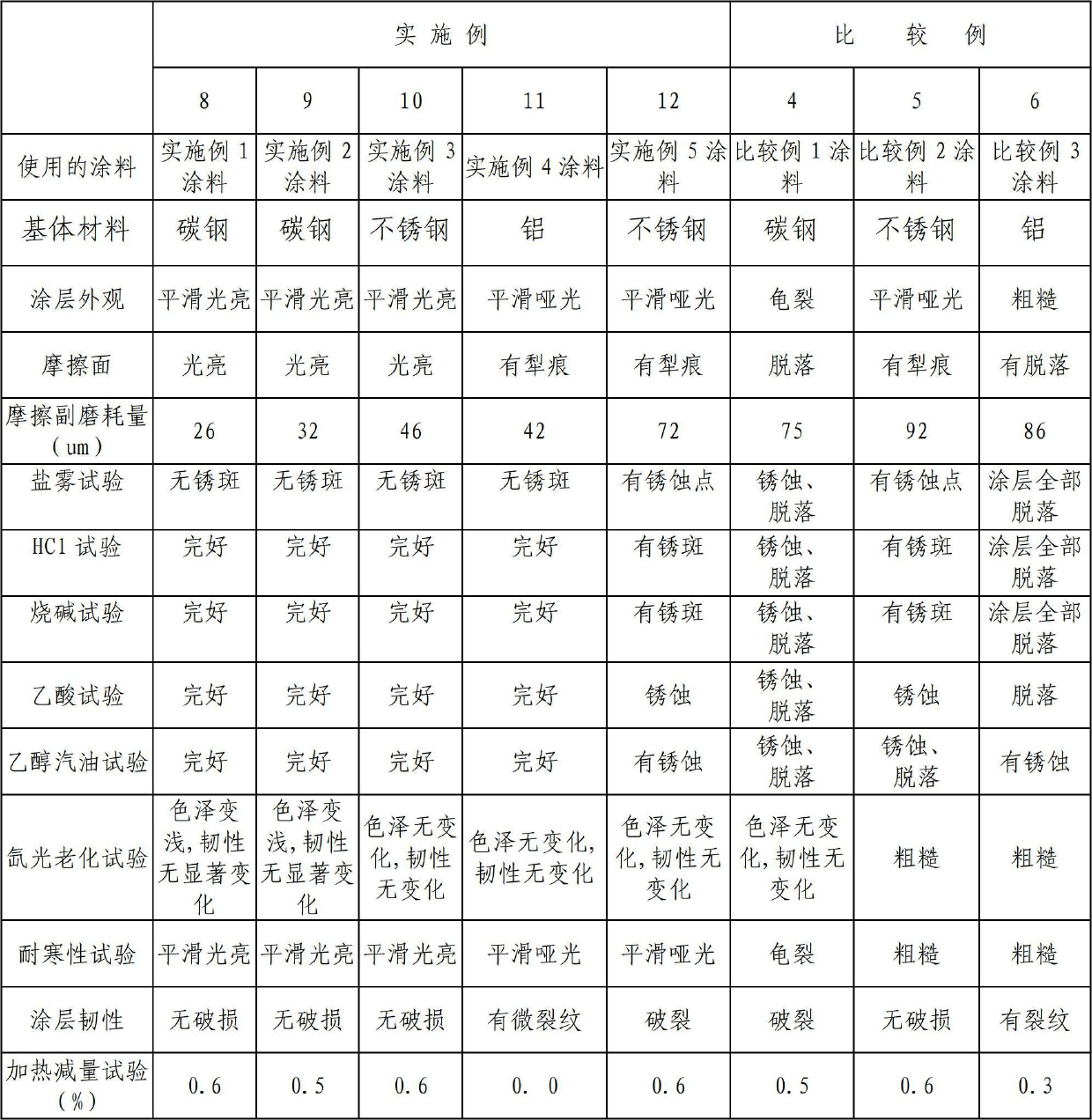

Embodiment 8~12

[0049] Examples 8-12 Preparation of wear-resistant and corrosion-resistant composite materials with polyphenylene sulfide modified coatings

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a modified polyphenylene sulfide coating and the application thereof. The modified polyphenylene sulfide coating consists of the following components by weight percentage: 60-90 percent of polyphenylene sulfide resin, 3-25 percent of poly-perfluorinated ethylene propylene resin, 3-20 percent of ethylene-tetrafluoroethylene copolymer resin, 1-5 percent of molybdenum disulfide, 1-5 percent of graphite and the balance of filler, wherein the filler is any one of or a mixture of zinc oxide, aluminum oxide, silicon carbide and chromium sesquioxide. The modified polyphenylene sulfide coating disclosed by the invention has the advantages that the compatibility among the components is good; a prepared coating layer has higher corrosion resistance, higher self-lubricity and strong wear-resistant ability, is resistant to high temperature, is highly insulated, has good toughness, can bear impact force capable of being borne by a metal surface, has excellent bond performance with a metal material and is particularly suitable for the using and working condition of cold / hot sudden changes which cannot be borne by glass lining equipment; and through spraying the coating disclosed by the invention on the surface of the metal matrix material, a manufactured work piece has excellent physical-chemical performance, a long service life and a wide application range.

Description

technical field [0001] The invention relates to polyphenylene sulfide modified coatings and applications thereof, in particular to anti-wear and corrosion-resistant polyphenylene sulfide modified coatings and applications thereof. Background technique [0002] In industrial production equipment, the dynamic friction mechanism of the equipment, the crude oil pipeline that transports gravel, the chemical pipeline that transports granular materials, and the flue gas pipeline that discharges dust, etc., are used in corrosive environments, especially in severe cold and high temperature for a long time Crude oil pipelines containing gravel and flue gas discharge pipelines containing dust in the environment will be subject to double hazards of abrasion and corrosion during use, resulting in short service life of the components and high frequency of replacement, increasing operating costs and causing The continuity and safety of industrial production bring great difficulties. [00...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D181/02C09D127/18C09D123/08C09D5/08

Inventor 古旗高

Owner CHENGDU LETIAN PLASTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com