Compound corrosion and scale inhibitor

A technology of corrosion and scale inhibitor, acrylic acid, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., to solve corrosion, wide application range, good corrosion and scale inhibition performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

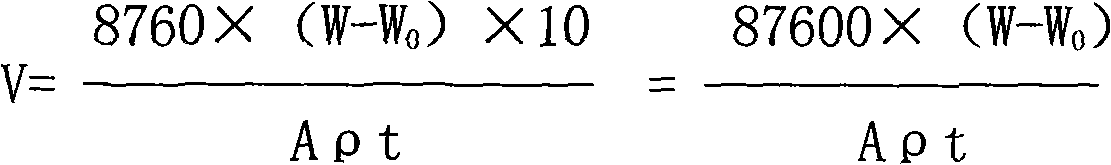

Method used

Image

Examples

Embodiment 1

[0038] Take 100g of raw materials used in the preparation of composite corrosion and scale inhibitor as an example and its mass ratio is as follows:

[0039] Hydroxyethylene diphosphonic acid 25g

[0040] Polyacrylic acid 20g

[0041] Hydrolyzed Polymaleic Anhydride 5g

[0042] Benzotriazole 2g

[0043] Triethylenetetramine hexamethylenesulfonate 18g

[0044] Alcohol 4g

[0045] water 26g

[0046] The molecular weight of above-mentioned polyacrylic acid is 2000~10000, and solid content is 30%, and the molecular weight of hydrolyzed polymaleic anhydride is 400~800, and solid content is 48%, and the active component of hydroxyethylene diphosphonic acid is 60%, , the active ingredient of triethylenetetramine hexamethylenesulfonate is 50%.

[0047] Its preparation method is as follows:

[0048] Stir and mix hydroxyethylene diphosphonic acid, polyacrylic acid, hydrolyzed polymaleic anhydride, triethylenetetramine hexamethylene sulfonate, alcohol, and water, and then add diss...

Embodiment 2

[0050] Take the raw material 100g used for preparing composite corrosion and scale inhibitor as an example and its preparation method is as follows:

[0051] Hydroxyethylene diphosphonic acid 21g

[0052] Polyacrylic acid 20g

[0053] Hydrolyzed Polymaleic Anhydride 2g

[0054] Benzotriazole 1g

[0055] Triethylenetetramine hexamethylenesulfonate 15g

[0056] Alcohol 6g

[0057] water 35g

[0058] The molecular weight of above-mentioned polyacrylic acid is 2000~10000, and solid content is 30%, and the molecular weight of hydrolyzed polymaleic anhydride is 400~800, and solid content is 48%, and the active component of hydroxyethylene diphosphonic acid is 60%, , the active ingredient of triethylenetetramine hexamethylenesulfonate is 50%.

[0059] Its preparation method is identical with embodiment 1.

Embodiment 3

[0061] Take the raw material 100g used for preparing composite corrosion and scale inhibitor as an example and its preparation method is as follows:

[0062] Hydroxyethylene diphosphonic acid 30g

[0063] Polyacrylic acid 10g

[0064] Hydrolyzed Polymaleic Anhydride 10g

[0065] Benzotriazole 3g

[0066] Triethylenetetramine hexamethylenesulfonate 15g

[0067] Alcohol 4g

[0068] water 28g

[0069] The molecular weight of above-mentioned polyacrylic acid is 2000~10000, and solid content is 30%, and the molecular weight of hydrolyzed polymaleic anhydride is 400~800, and solid content is 48%, and the active component of hydroxyethylene diphosphonic acid is 60%, , the active ingredient of triethylenetetramine hexamethylenesulfonate is 50%.

[0070] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com