Compound corrosion and scale inhibitor

A technology of corrosion and scale inhibitors and compound preparations, which is applied in the fields of scale removal and water softening, special treatment targets, water/sludge/sewage treatment, etc. It is difficult to pre-membrane effect and other issues, to achieve the effect of reducing power consumption, reducing the amount of supplementary water, and saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

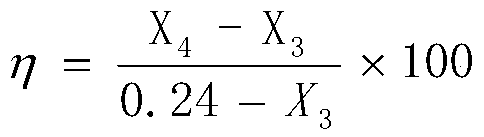

Method used

Image

Examples

Embodiment 1

[0047] Composite corrosion and scale inhibitors include liquid preparation A and liquid preparation B, wherein: the weight ratio of each component of liquid preparation A is: 5 g of hydroxyethylidene diphosphonic acid, 5 g of potassium aminotrimethylene phosphonate, hydrolyzed polymaleic anhydride 5g, 5g of maleic acid-acrylic acid copolymer, 15g of DISPERBYK series dispersant of German BYK company, 65g of water, put it into a beaker and stir evenly.

[0048] Liquid preparation B is a composite preparation made of solid medicament and water at a weight ratio of 1:1, wherein the weight ratio of solid medicament is: sodium humate 15g, sodium carbonate 25g, mercaptobenzothiazole 5g, zinc sulfate 5g, and It is put in a container and mixed with 50 g of water to prepare 100 g of liquid preparation B, and it can be stirred evenly.

[0049] Experimental water quality: make up water quality, calcium hardness is 350mg / L, total alkalinity is 350mg / L, chloride ion (Cl - ) content is 80mg...

Embodiment 2

[0081] The composite corrosion and scale inhibitor of the present invention includes liquid preparation A and liquid preparation B, wherein: the weight ratio of each component of liquid preparation A is: 5 g of hydroxyethylidene diphosphonic acid, 10 g of potassium aminotrimethylene phosphonate, hydrolysis poly Add 5 g of maleic anhydride, 10 g of acrylic acid-hydroxypropyl acrylate copolymer, 20 g of Elvacite series dispersants from DuPont, USA, and 50 g of water into a beaker and stir evenly.

[0082] Liquid preparation B is a compound preparation made of solid medicine and water at a weight ratio of 1:1, wherein the weight ratio of solid medicine is: sodium humate 12.5g, sodium carbonate 25g, mercaptobenzothiazole 5g, zinc sulfate 7.5g , put it in a container and mix with 50g of water to prepare 100g of liquid preparation B, and stir evenly.

[0083] Experimental water quality: make up water quality, calcium hardness is 300mg / L, total alkalinity is 300mg / L, chloride ion (Cl...

Embodiment 3

[0088] The composite corrosion and scale inhibitor of the present invention includes liquid preparation A and liquid preparation B, wherein: the weight ratio of the components of liquid preparation A is: 15 g of hydroxyethylidene diphosphonic acid, 10 g of potassium aminotrimethylene phosphonate, hydrolyzed Add 10g of polymaleic anhydride, 10g of maleic acid-acrylic acid copolymer, 25g of Disperse-AYD series W-22 type, and 30g of water, put them into a beaker and stir evenly.

[0089] Liquid preparation B is a composite preparation made of solid medicament and water at a weight ratio of 1:1, wherein the weight ratio of solid medicament is: sodium humate 5g, sodium carbonate 30g, mercaptobenzothiazole 5g, zinc sulfate 10g, It is put in a container and mixed with 50 g of water to prepare 100 g of liquid preparation B, and it can be stirred evenly.

[0090] Experimental water quality: make up water quality, calcium hardness is 250mg / L, total alkalinity is 250mg / L, chloride ion (C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com