Efficient low-phosphorus corrosion and scale inhibitor

A technology of corrosion and scale inhibitor, copper corrosion inhibitor, applied in descaling and water softening, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as application limitations and reduce environmental hazards , Excellent anti-CaCO3 scaling function, small dosage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

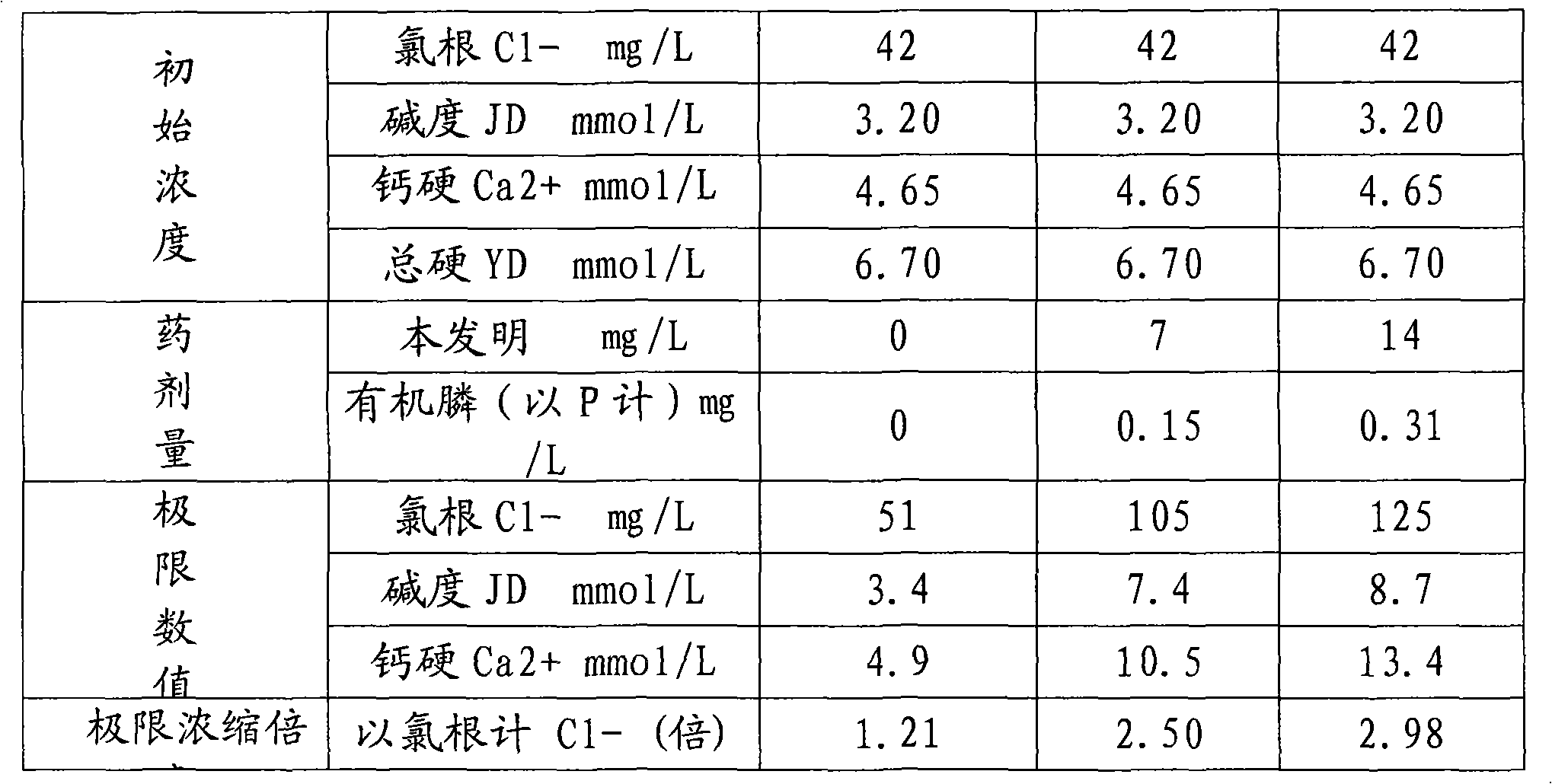

Embodiment 1

[0011] Embodiment 1: A kind of efficient low-phosphorus corrosion and scale inhibitor, including hydroxyethylidene diphosphonic acid (HEDP) 5.76%; 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) 2.5% %; Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid multi-polymer (AA / AMPS) 3%; Maleic acid-acrylic acid copolymer (MA / AA) 21.6%; Benzotriazole (BTA) 1.2%; balance water.

[0012] Preparation method: Prepared in a 1-ton reactor

[0013] 1. Dissolve 12kgBTA in commercially available earlier, and solid content is 450kg in the maleic acid-acrylic acid copolymer of 48%;

[0014] 2 Add 96 kg of HEDP (commercially available, with a solid content of 60%), 50 kg of PBTCA (commercially available, with a solid content of 50%), and 100 kg of AA / AMPS (commercially available, with a solid content of 30%) in the reactor, and start stirring;

[0015] 3 With stirring, slowly add the maleic acid-acrylic acid mixture dissolved in BTA into the reaction kettle;

[0016] 4 Add 292kg of wat...

Embodiment 2

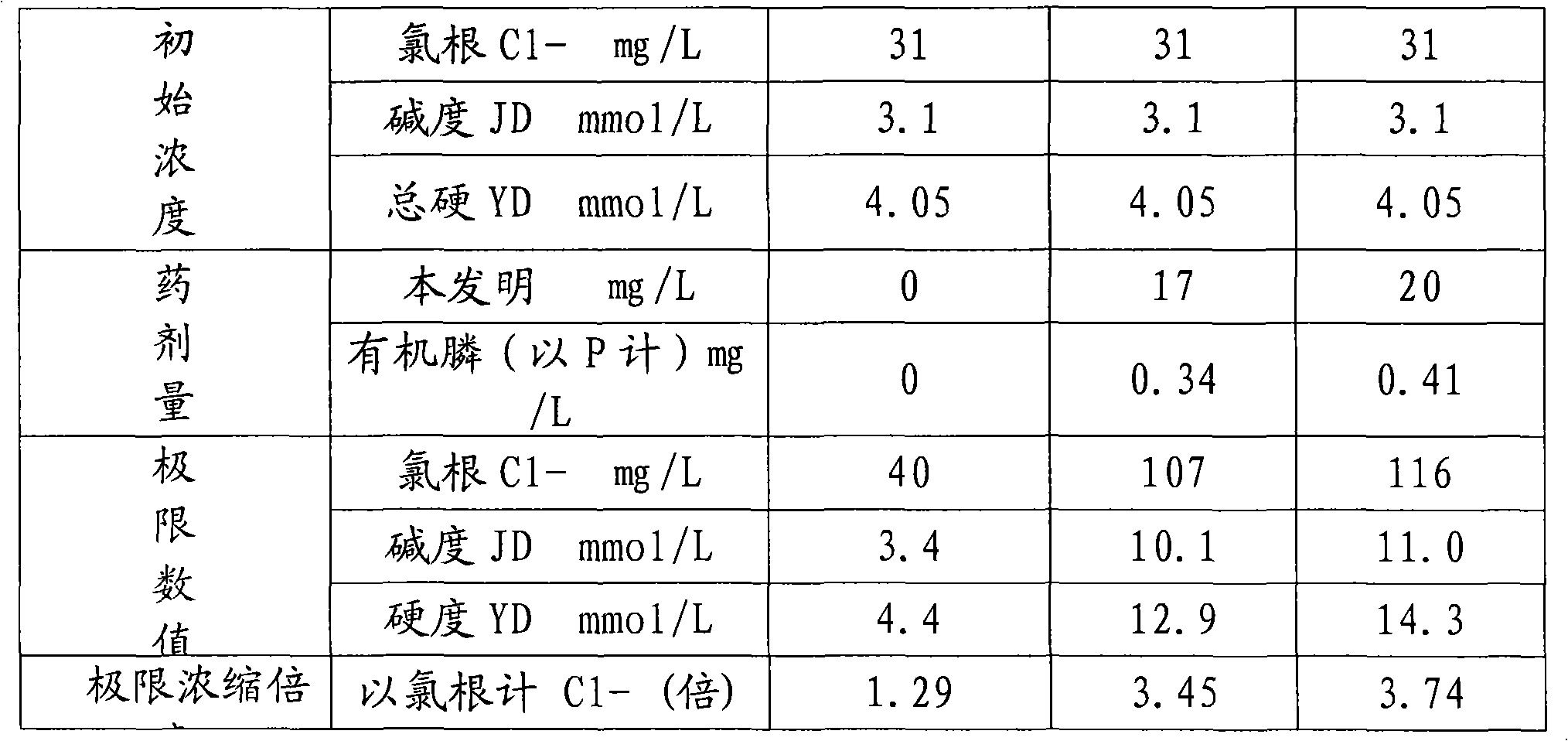

[0022] Embodiment 2: A kind of efficient low-phosphorus corrosion and scale inhibitor, including hydroxyethylidene diphosphonic acid (HEDP) 4.8%; 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) 5 %; Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid multi-polymer (AA / AMPS) 6%; Maleic acid-acrylic acid copolymer (MA / AA) 14.4%; Benzotriazole (BTA) 2%; the balance is water.

[0023] Preparation method: Prepared in a 1-ton reactor

[0024] 1. Dissolve 20kgBTA in the commercially available, solid content is 300kg in the maleic acid-acrylic acid copolymer of 48%;

[0025] 2 Add 80 kg of HEDP (commercially available, with a solid content of 60%), 100 kg of PBTCA (commercially available, with a solid content of 50%), and 200 kg of AA / AMPS (commercially available, with a solid content of 30%) in the reactor, and start stirring;

[0026] 3 With stirring, slowly add the maleic acid-acrylic acid mixture dissolved in BTA into the reaction kettle;

[0027] 4 Add 300kg of water and...

Embodiment 3

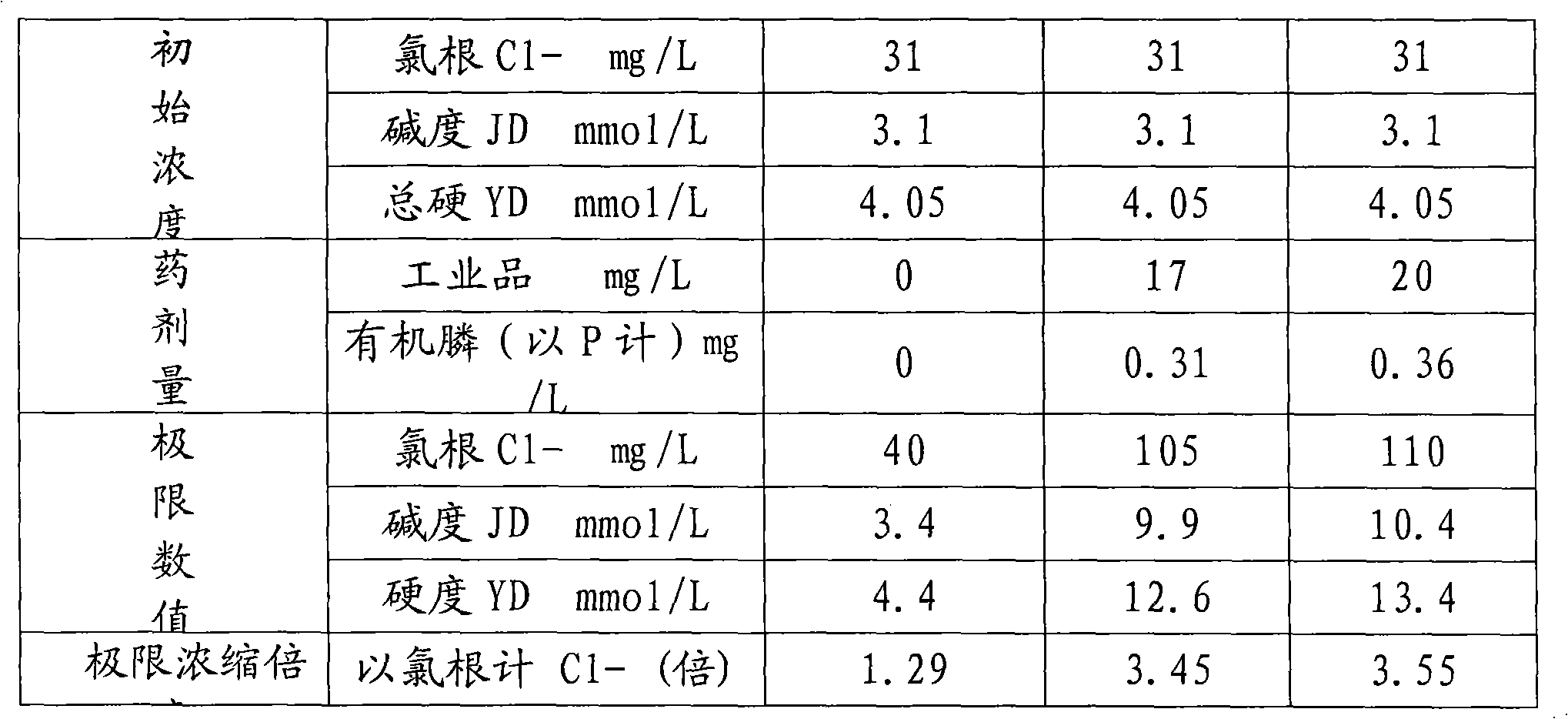

[0032] Embodiment 3: A kind of efficient low-phosphorus corrosion and scale inhibitor, including 4.32% of hydroxyethylidene diphosphonic acid (HEDP); 2-phosphonobutane-1,2,4-tricarboxylic acid (PBTCA) 4.5% %; Acrylic acid-2-acrylamide-2-methylpropanesulfonic acid multi-polymer (AA / AMPS) 5.4%; Maleic acid-acrylic acid copolymer (MA / AA) 12.96%; Polyacrylic acid (PAA) 6.5%; Benzotriazole (BTA) 1%; the balance is water.

[0033] Preparation method: Prepared in a 1-ton reactor

[0034] 1. Dissolve 10kg of BTA in the commercially available, 300kg of maleic acid-acrylic acid copolymer with a solid content of 48%;

[0035] 2 Add HEDP (commercially available, solid content is 60%) 72kg successively in the reaction kettle, PBTCA (commercially available, solid content is 50%) 90kg, AA / AMPS (commercially available, solid content is 30%) 180kg, PAA (commercially available, solid content is 30%) 180kg, PAA (commercially available, solid content is 30%) sale, solid content 50%) to start st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com