Polyaspartic acid complex for scale inhibitor

A technology for polyaspartic acid and composites, applied in the field of polyaspartic acid composites, can solve the problems of reduced reaction efficiency, easy agglomeration, and inability to complete the reaction, so as to improve the reaction efficiency and avoid adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 60ml of water to a three-necked flask equipped with a stirring bar and a thermometer, then add 50g of maleic anhydride (manufacturer name Changzhou Shuguang Chemical Factory, brand name Shuguang), then heat to 60°C in a water bath, and maleic anhydride Stir for 30 minutes after dissolving, keep the system temperature at about 60°C, stop stirring, and slowly add 50g of ammonium bicarbonate (Huzhou Huijing Chemical Factory, purity 98.5%). Then gradually raise the temperature and start stirring, and react at a temperature of about 75° C. for 1 hour to obtain white ammonium maleate solid crystals. Move the ammonium maleate crystal to a 304 stainless steel tray of 500cm × 300cm and spread it to a thickness of 3cm, then place the 304 stainless steel tray filled with ammonium maleate crystal in a half-closed container, and the semi-closed container is connected with a heat air channel. Circulate hot air at 175°C and continue heating for 3.5 hours to cause high-temperature...

Embodiment 2

[0025] Add 70ml of water to a three-necked flask equipped with a stirring bar and a thermometer, then add 50g of maleic anhydride (manufacturer name Changzhou Shuguang Chemical Factory, brand name Shuguang), then heat to 55°C in a water bath, and maleic anhydride Stir for 30 minutes after dissolving, keep the system temperature at about 70°C, stop stirring, and slowly add 60g of ammonium bicarbonate (Huzhou Huijing Chemical Factory, purity 98.5%). Then gradually raise the temperature and start to stir, react at a temperature of about 65° C. for 1.5 hours to obtain white ammonium maleate solid crystals. Move the ammonium maleate crystal to a 304 stainless steel tray of 500cm × 300cm and spread it to a thickness of 3cm, then place the 304 stainless steel tray filled with ammonium maleate crystal in a half-closed container, and the semi-closed container is connected with a heat air channel. Circulating hot air at 185°C was circulated, and the heating was continued for 3 hours to...

experiment example

[0027] Scale inhibition rate test program:

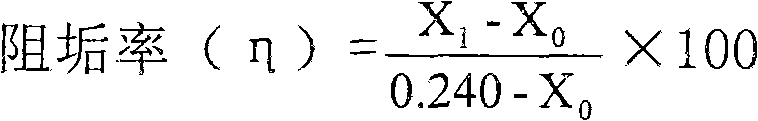

[0028] The scale inhibition performance of polyaspartic acid should use the static calcium carbonate method (GB / T 16632-2008 "Determination of scale inhibition performance of water treatment agents by calcium carbonate deposition method"). The condition is that the calcium ion concentration is 0.240 mg / mL; the bicarbonate ion concentration is 0.732 mg / mL. A 500ml glass bottle with a condensing reflux tube, kept at 80°C for 10 hours. Titrate with EDTA solution, measure the calcium ion concentration in the solution after constant temperature, and calculate the scale inhibition rate. The scale inhibition rate calculation formula is:

[0029]

[0030] x 1 ...calcium ions (Ca 2+ ) concentration, the unit is mg / mL;

[0031] x 0 ...calcium ions (Ca 2+ ) concentration, the unit is mg / mL;

[0032] 0.240... Calcium ions (Ca 2+ ) concentration in mg / mL.

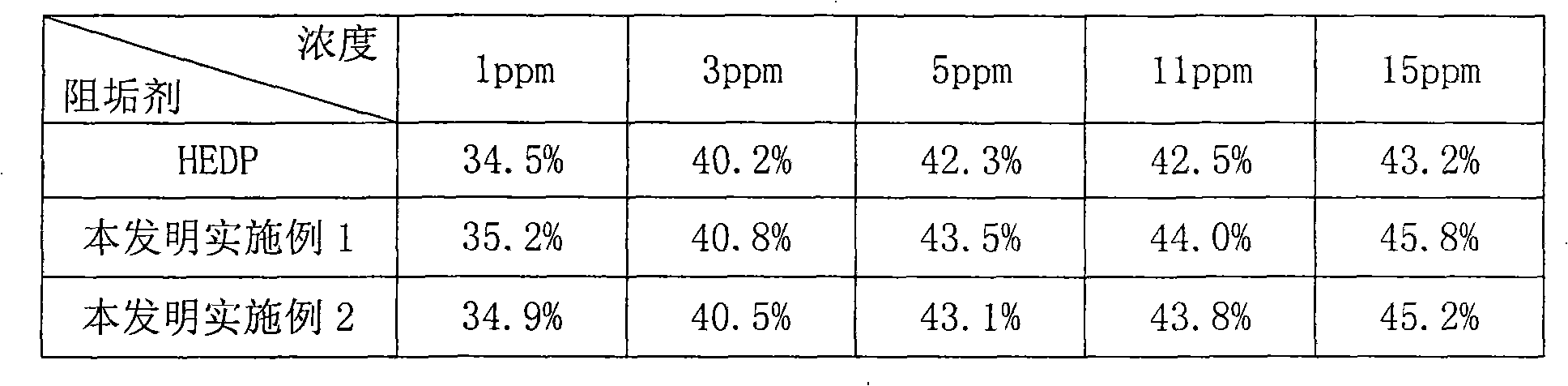

[0033] According to the above-mentioned experimental method, the polyaspartic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com