Patents

Literature

57results about How to "Strong neutralization ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Demulsifying and flocculating treatment method of machining cutting fluid sewage water

InactiveCN102910765ALower surface potentialReduce repulsionMultistage water/sewage treatmentPollutionPolyacrylamide

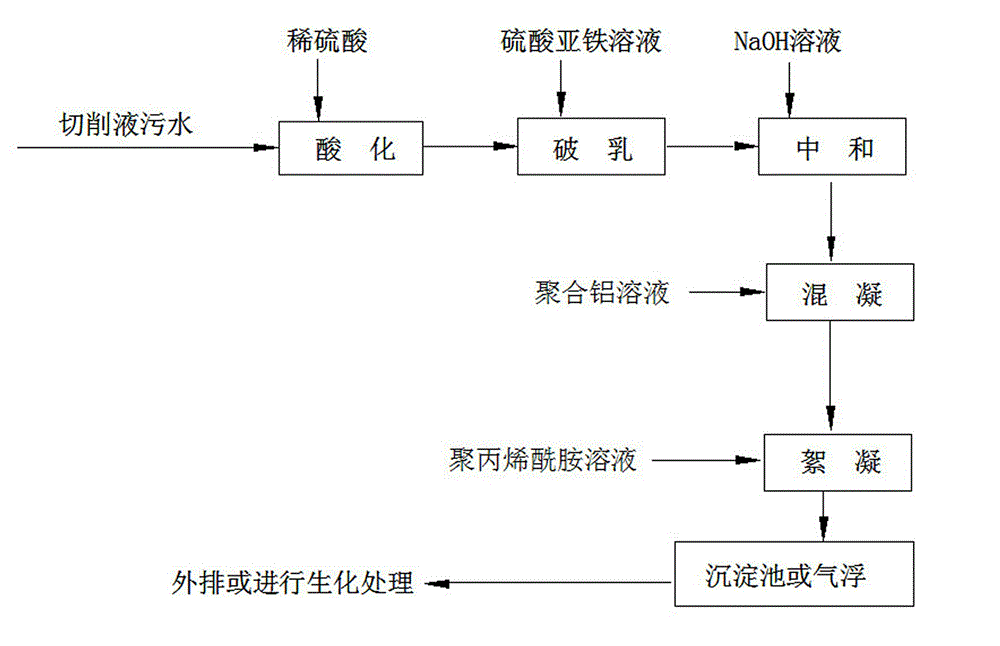

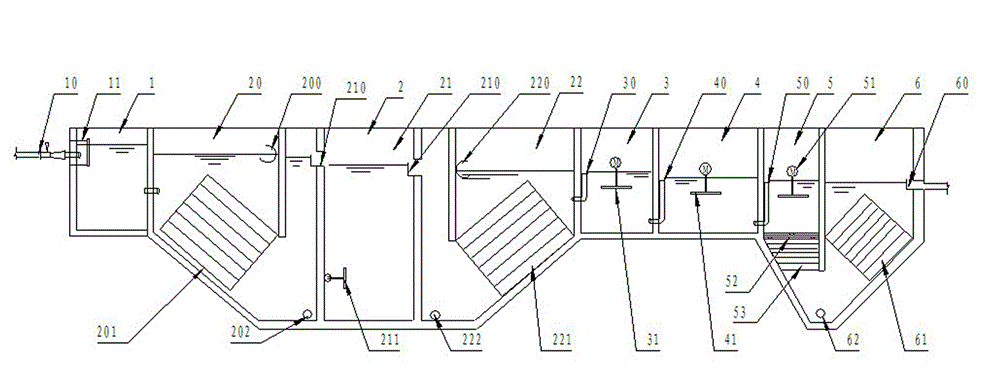

The invention discloses a demulsifying and flocculating treatment method of machining cutting fluid sewage water, comprising the following steps: conveying cutting fluid sewage water in an acidification pool and adding diluted sulfuric acid for acidification; adjusting the pH to be 3.5-5.5; then conveying in a demulsifying device and adding ferrous sulfate solution for demulsification and precipitation; then conveying in a neutralization pond and adding NaOH solution for neutralization; conveying in a coagulating basin after neutralization and adding a coagulating agent for coagulation; then adding polyacrylamide to a flocculation tank; flowing down by a sieve body through the square rectifying plate of the flocculation tank after flocculating; depositing through the sloped tube stuffing body of a flocculation precipitation pool; discharging out supernatant fluid from a water collection weir; and removing precipitated sludge floccule. The method has the characteristics of integrating oil removal, demulsifying and flocculating, and being thorough for pollution control, good in application effect and economic and efficient; the effluent COD (Chemical Oxygen Demand) of cutting fluid sewage water treated through the method can be decreased to below 500mg / L; and the method can be widely applied to sewage water treatment in machining industry.

Owner:安徽新天安全环境科技有限公司

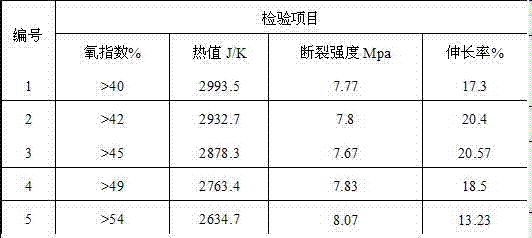

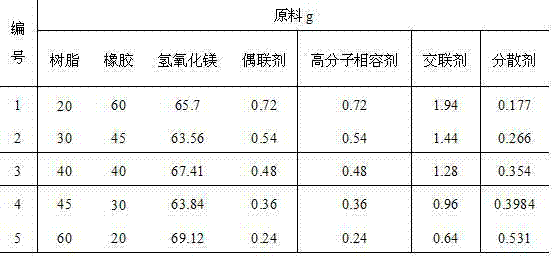

Material special for level-A fire-proof aluminum-plastic board core and preparation method thereof

The invention relates to an aluminum-plastic compound board sandwich layer material, in particular to a material special for a level-A fire-proof aluminum-plastic board core and a preparation method thereof. An inorganic flame retardant, i.e., magnesium hydroxide is taken as a flame retardant, and a high filling technology is adopted. Aids such as a coupling agent, a dispersing agent, a high-molecular compatilizer and the like are used for performing modification pretreatment on magnesium hydrate, so that the magnesium hydrate flame retardant has superior performance, the filling amount of the flame retardant in a substrate is up to 80-90 percent by weight, which is much higher than the adding amount of a flame retardant of the same type of products, the oxygen index of the product is remarkably increased in comparison to that of the same type of products, and the flame-retarding environmental protection performance is improved remarkably. An aluminum-plastic board core material prepared by adopting the method has the characteristics of freeness from halogen, low thermal value, low smoke, flame retardance, drop resistance, nontoxicity and freeness from pollution.

Owner:大连亚泰科技新材料股份有限公司

Acid scouring agent and preparation method thereof

ActiveCN101736618AStrong neutralization abilityHigh chelation valueDyeing processAlkylphenolCellulose fiber

The invention discloses an acid scouring agent and a preparation method thereof. The acid scouring agent comprises a multivariate acidic copolymer, polyvinyl pyrrolidone PVP and sodium gluconate. The scouring agent does not contain phosphorus, alkylphenol ethoxylates and harmful solvents and is degradable; and at the same time, the scouring agent has the characteristics of a little foam, high chelation value and high alkali neutralizing capacity. The scouring agent can be used for scouring cellulose fibers after dyeing, can simplify the traditional process and contributes to energy conservation and emission reduction.

Owner:苏州联胜化学有限公司

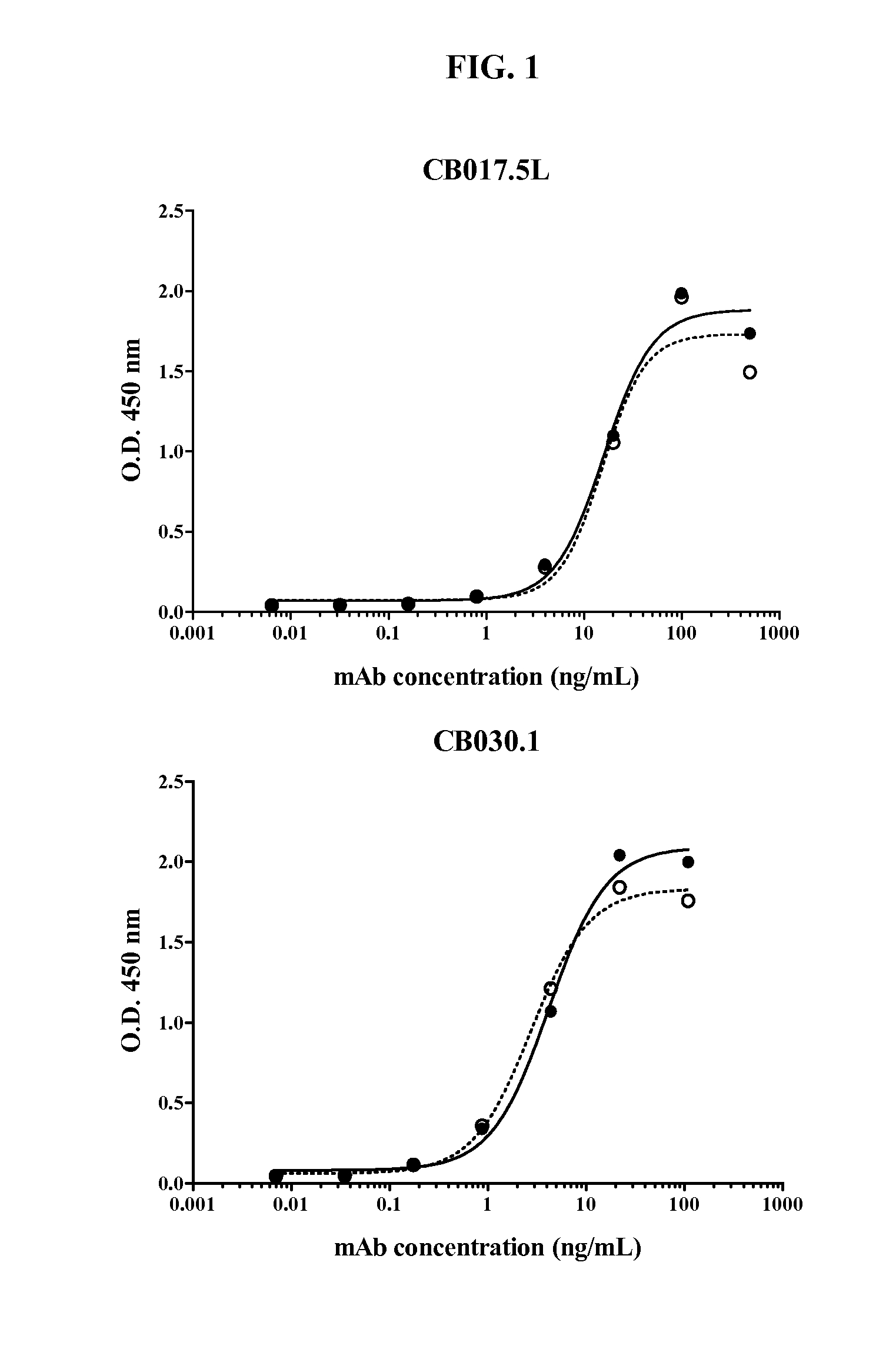

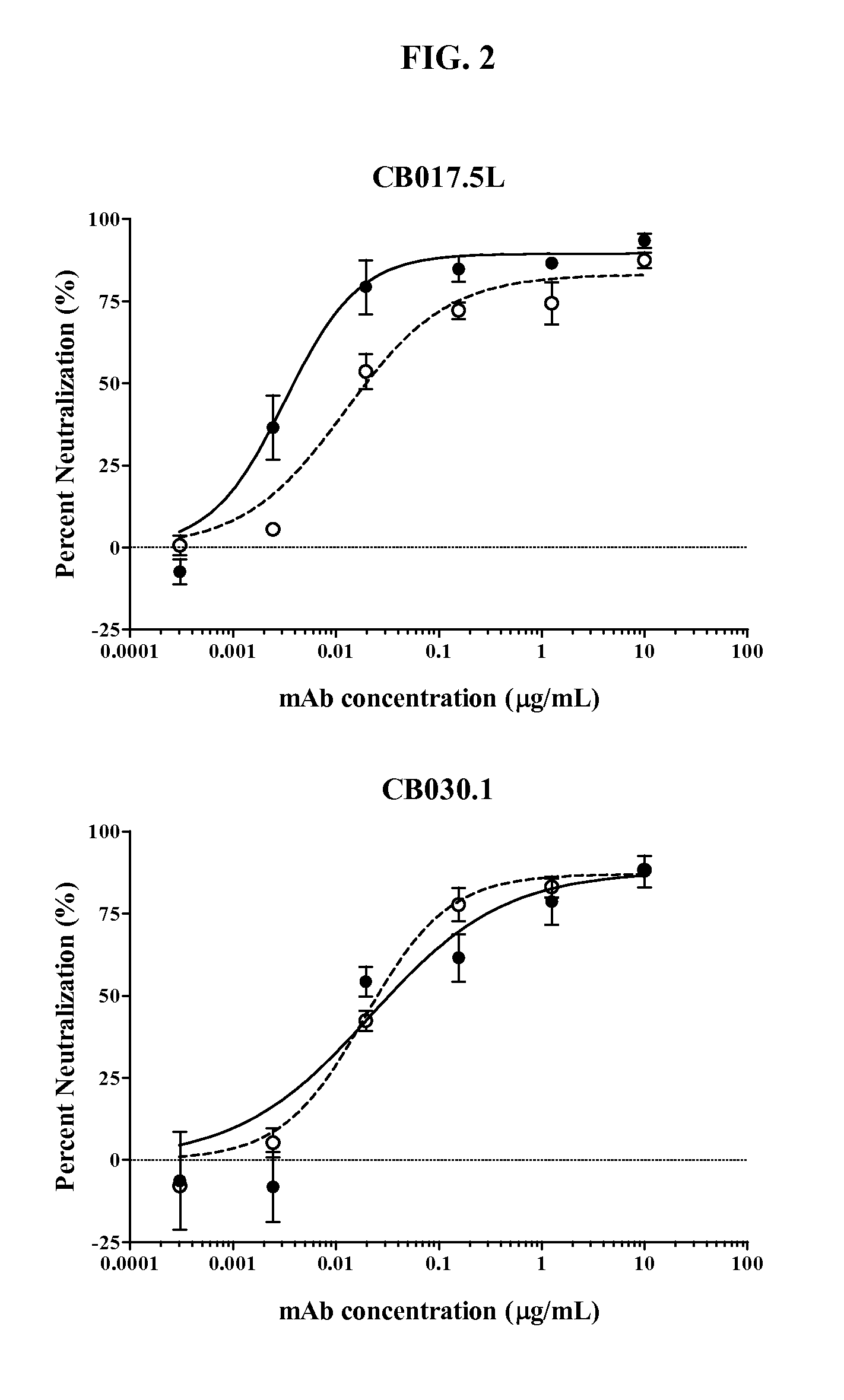

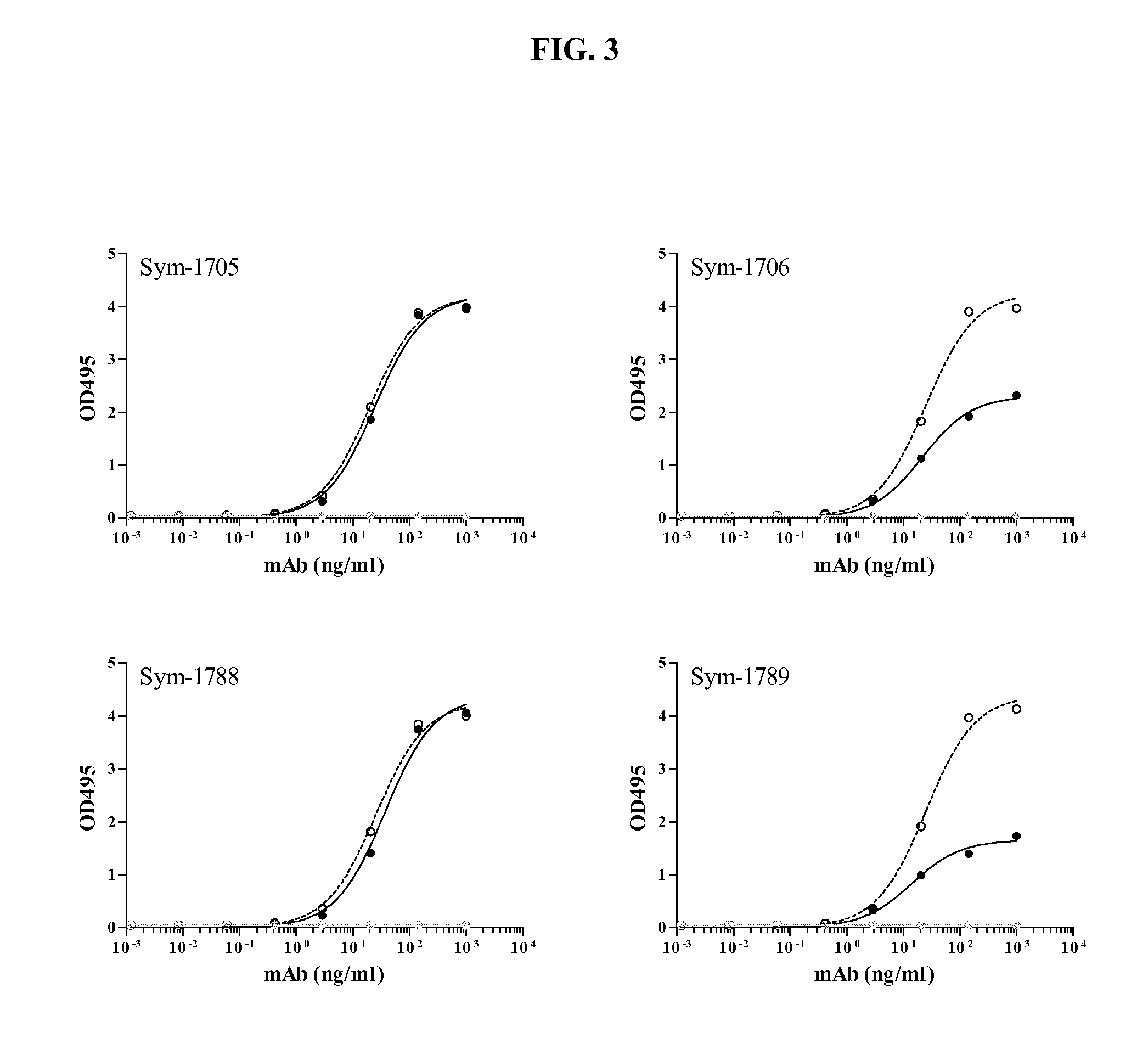

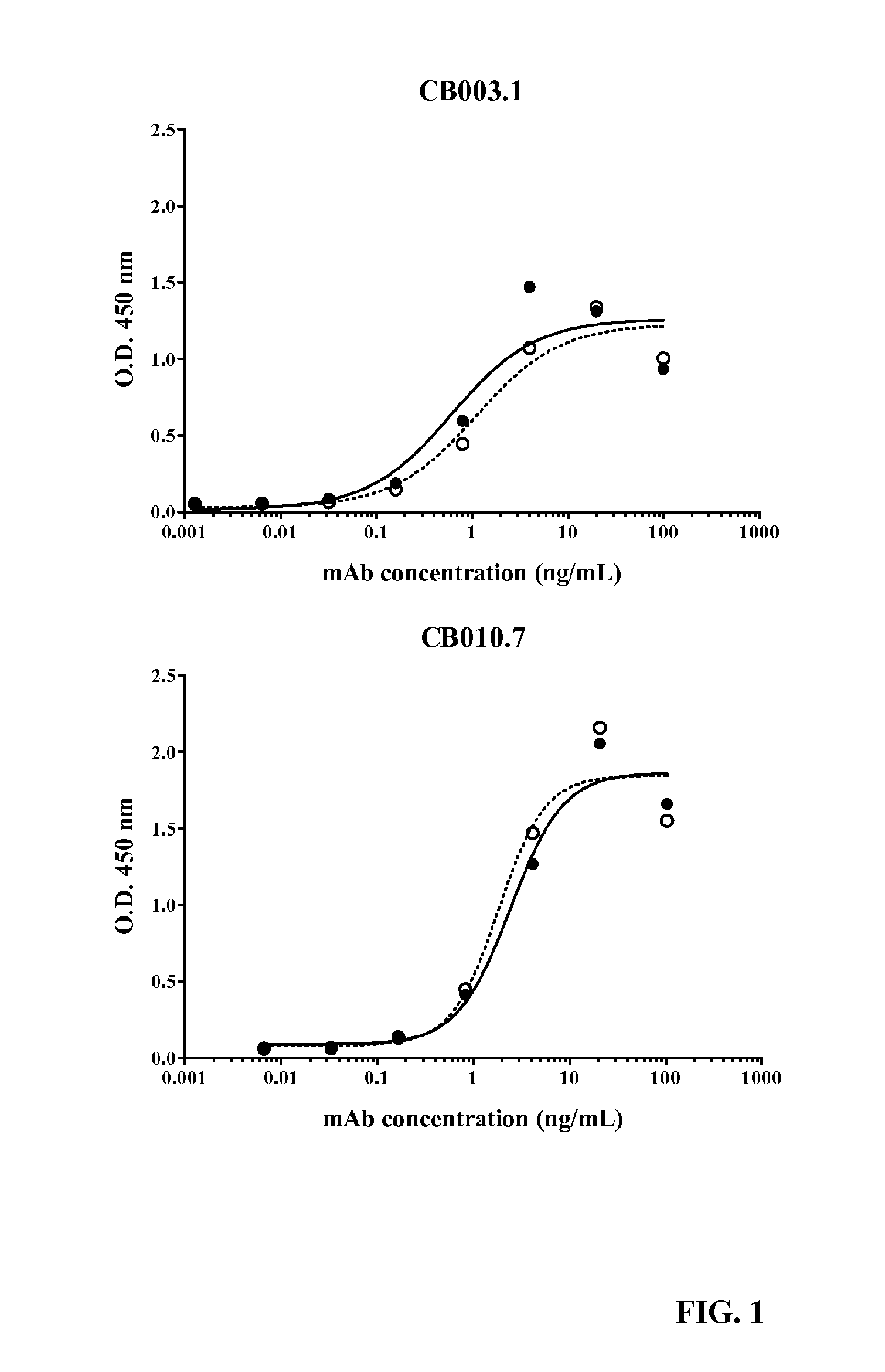

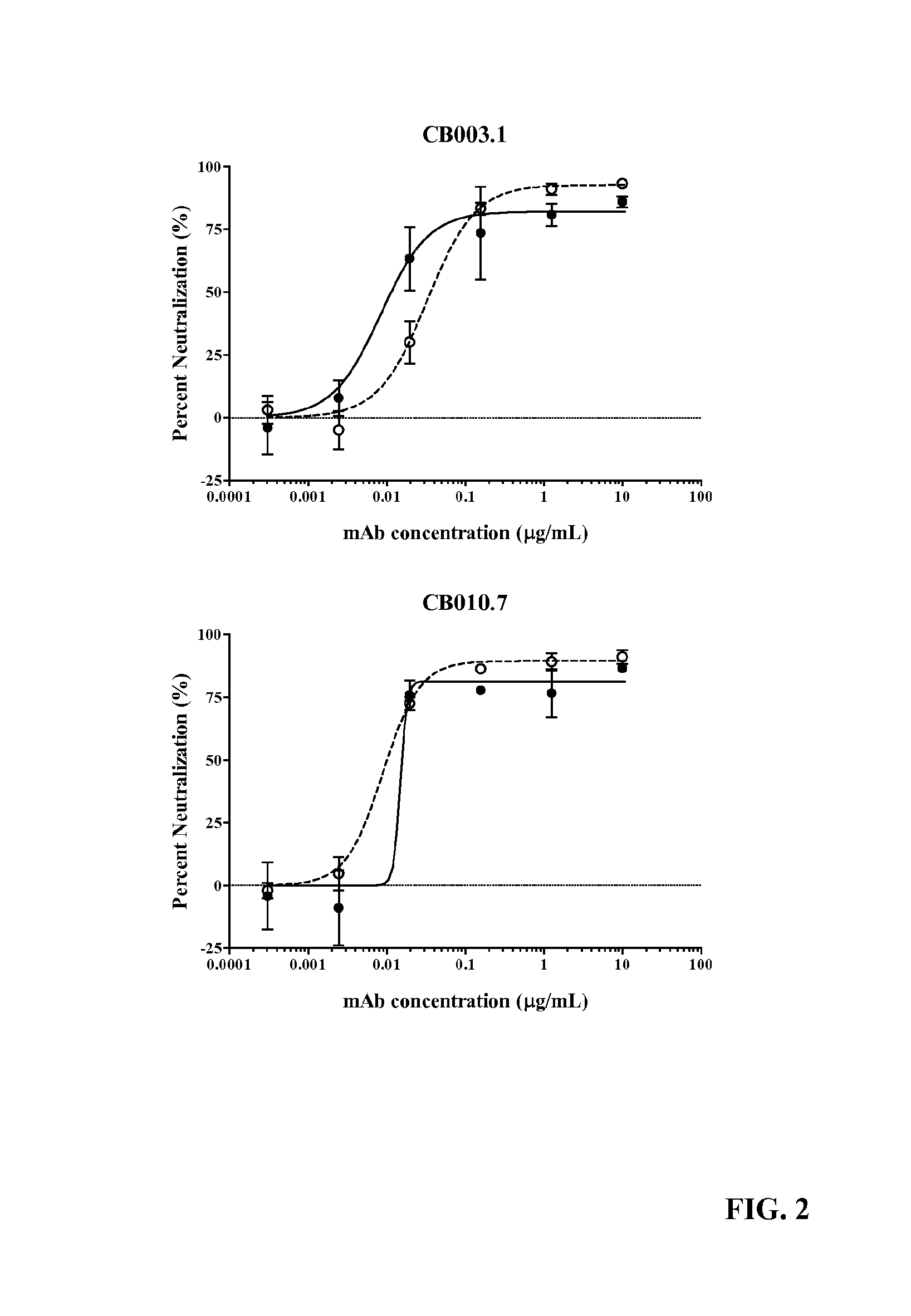

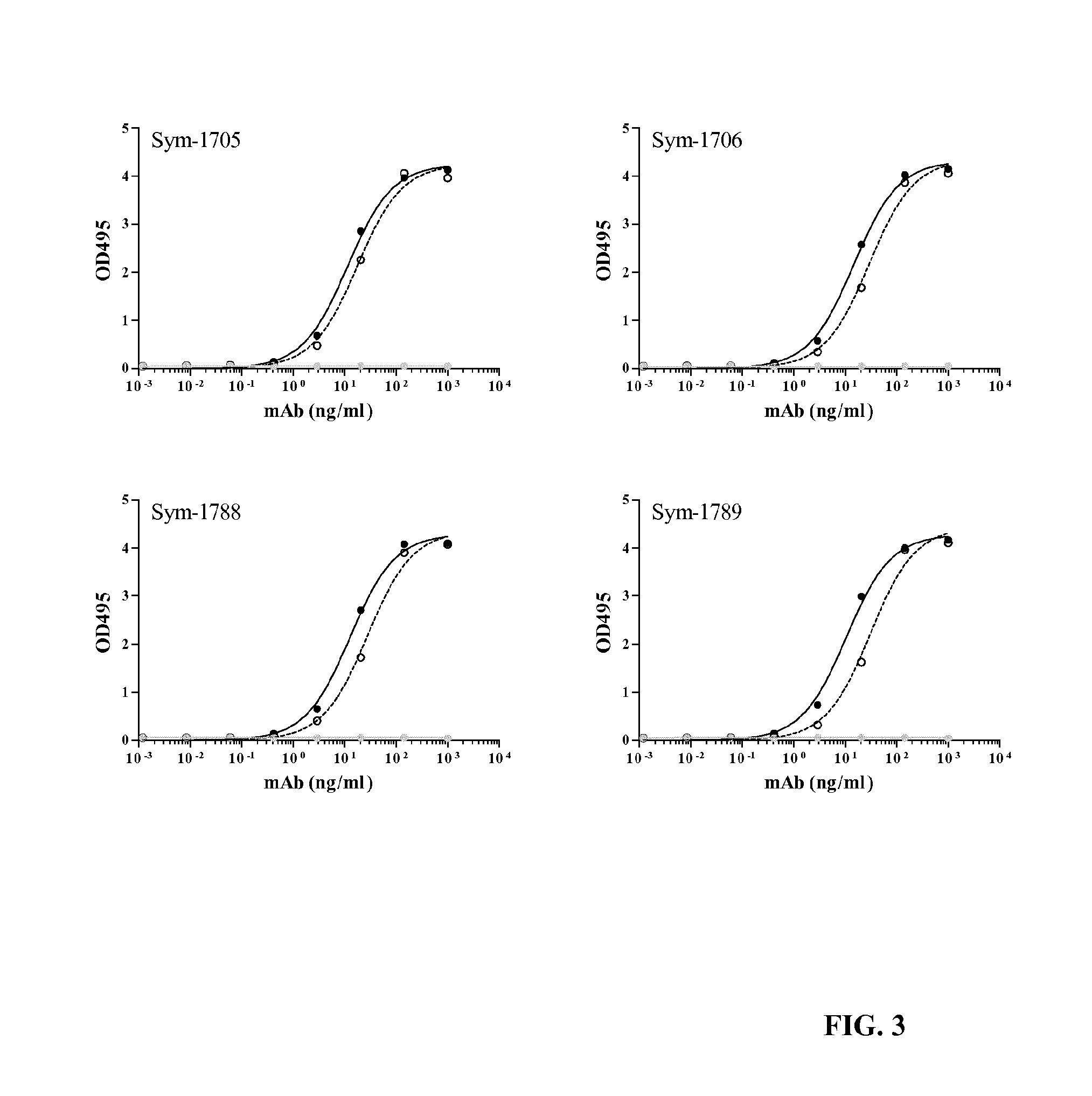

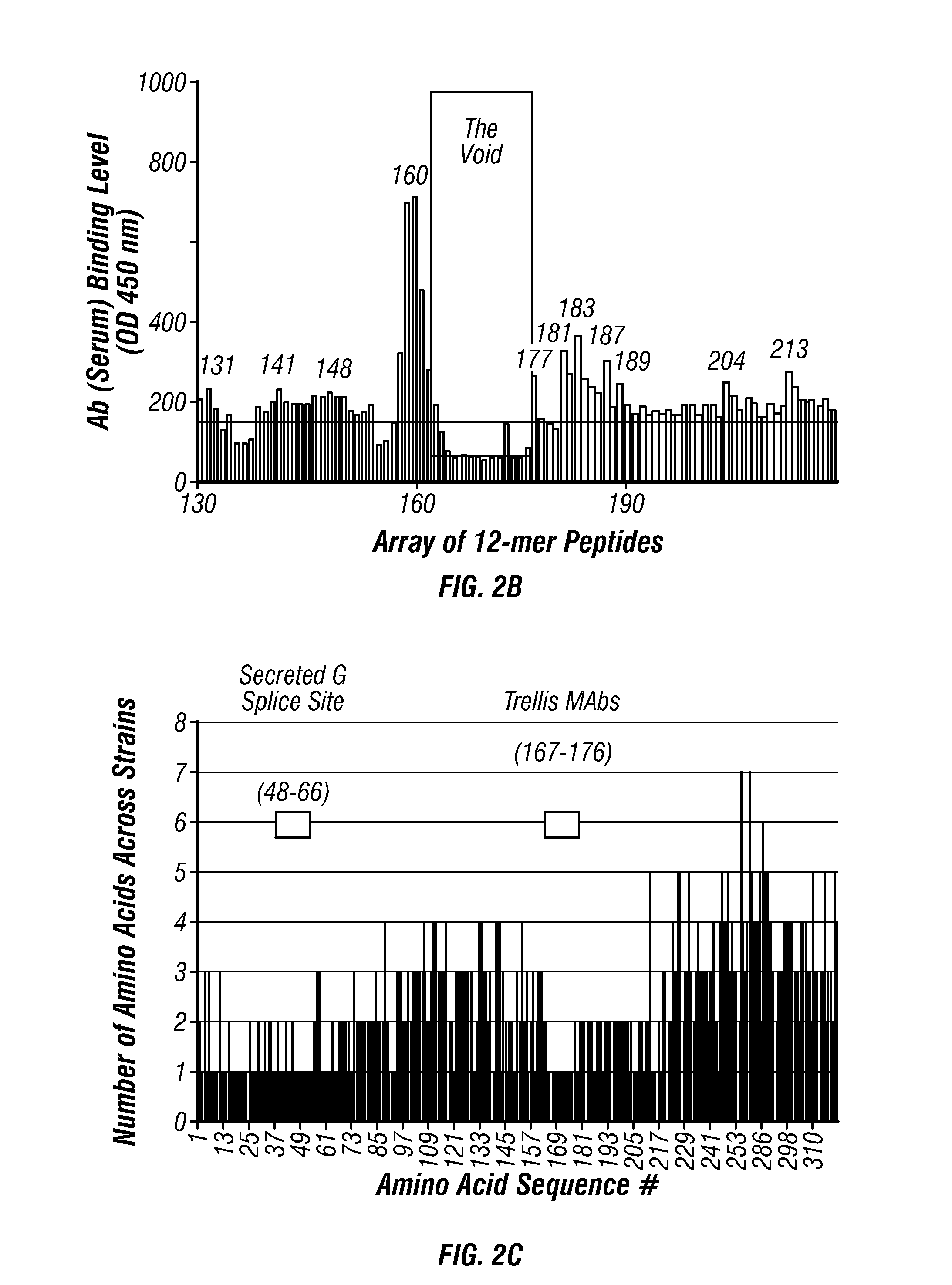

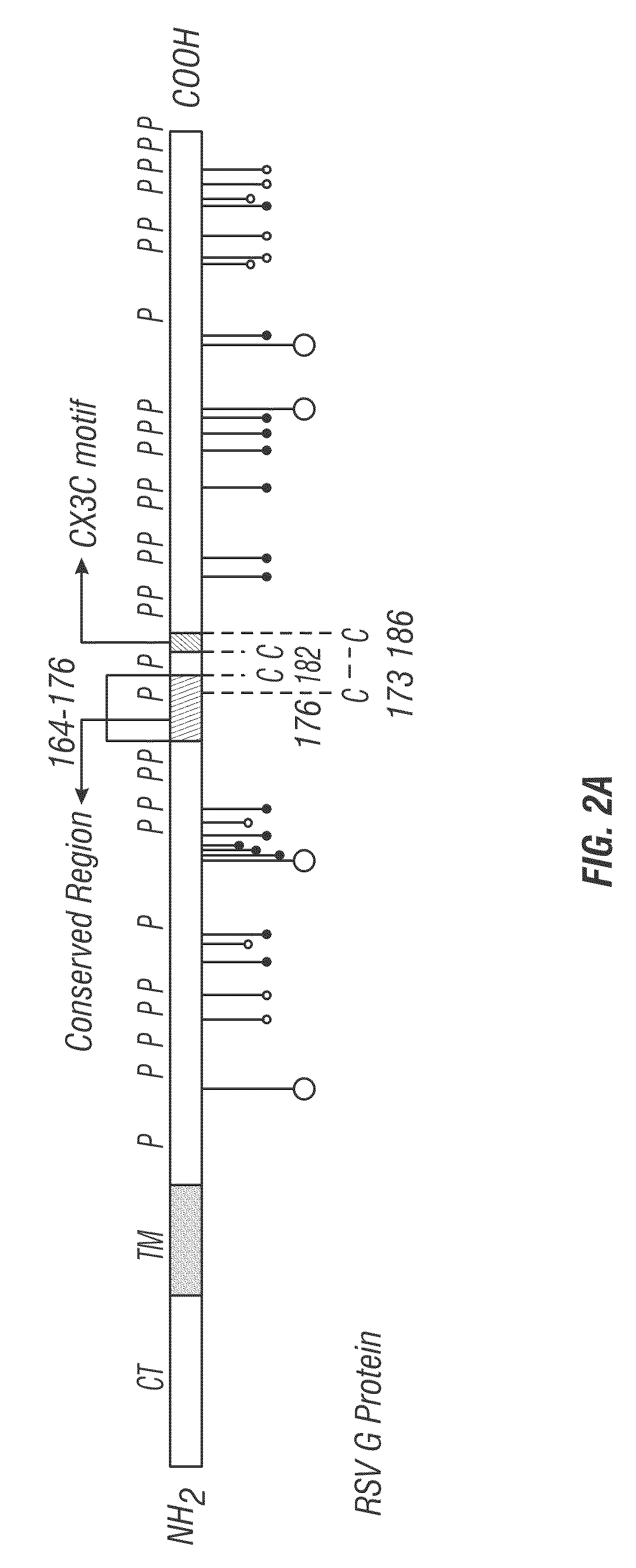

Human antibodies binding to rsv g proteins

ActiveUS20160145322A1High affinityStrong neutralization abilityBacteriaImmunoglobulins against virusesAntigen Binding FragmentAntigen binding

Owner:JANSSEN VACCINES & PREVENTION BV

Human antibodies binding to rsv g protein

ActiveUS20160145321A1High affinityStrong neutralization abilityBacteriaVirus peptidesAntigen Binding FragmentRSV Infections

The disclosure relates to isolated antibodies and antigen-binding fragments that bind to the G protein of RSV and which are capable of neutralizing RSV A and B subtypes, and the use thereof in the diagnosis, prophylaxis, and / or treatment of RSV infections.

Owner:JANSSEN VACCINES & PREVENTION BV

Nano highly effective amendment for sludge dehydration

InactiveCN1621370AHigh floc strengthLow floc strengthSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSulfateSludge

The present invention discloses one kind of Z's nanometer efficient sewage dewatering amendment. The Z's nanometer efficient sewage dewatering amendment consists of polymerized ferric sulfate 85-98 weight portions, polyacrylamide 0.5-6 weight portions, hydroxymethyl cellulose sodium 0.5-6 weight portions and nanometer material 0.5-3 weight portions. The present invention has powerful neutralizing capacity, bridging capacity and permeating capacity and thus has high sewage dewatering effect.

Owner:曾智勇 +1

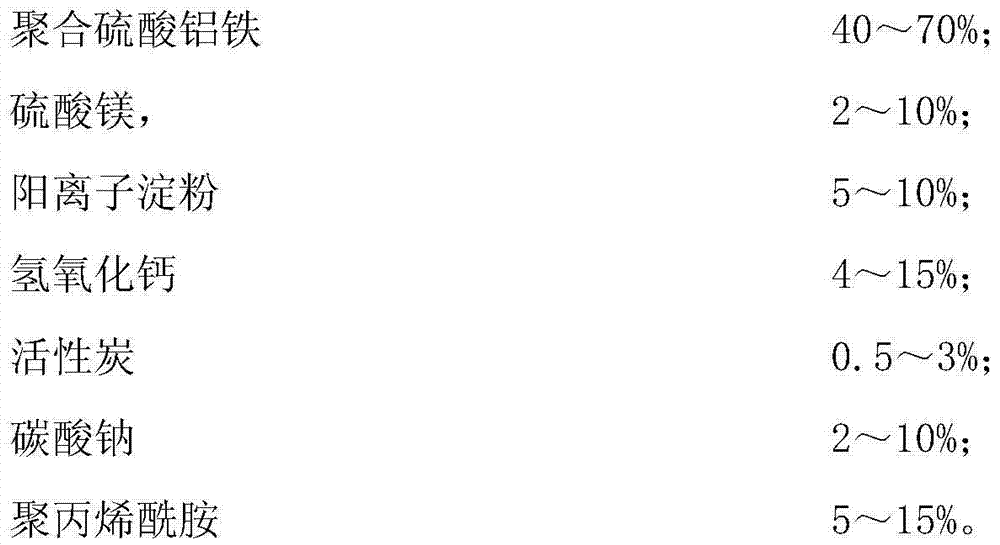

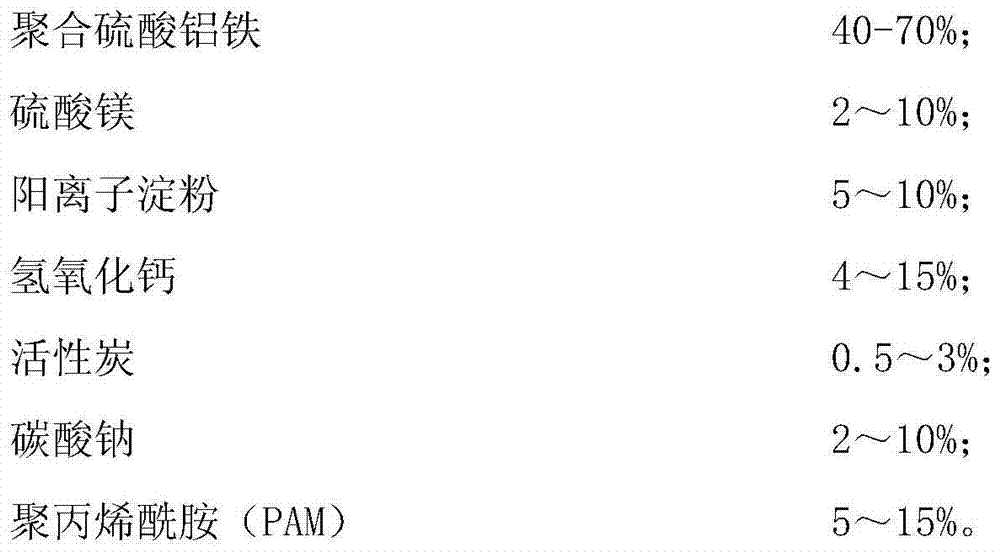

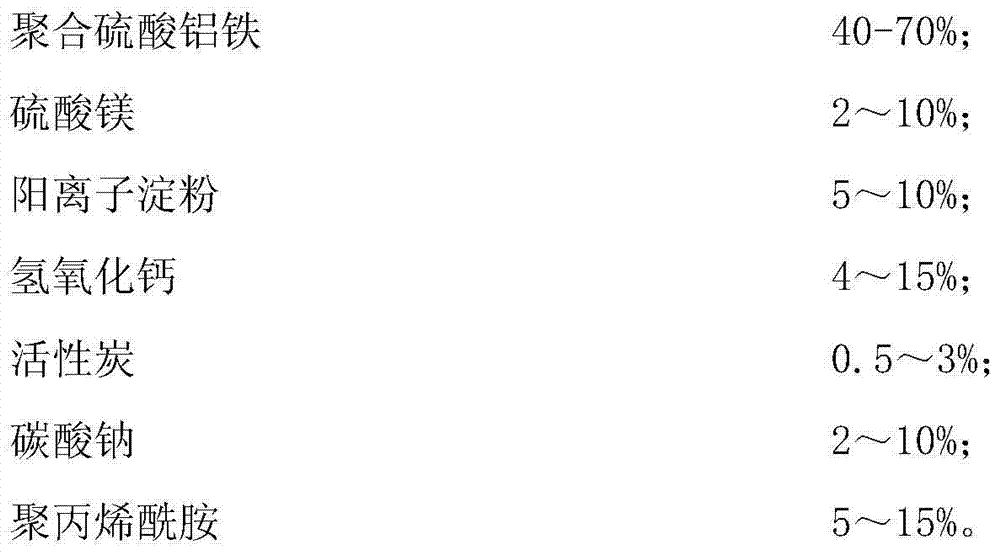

Composite inorganic high-molecular waste water treatment flocculant

ActiveCN104761029ASave raw materialsEasy to handleWater/sewage treatment by flocculation/precipitationIndustrial waste waterSludge

The invention discloses a composite inorganic high-molecular waste water treatment flocculant which is composed of following raw materials, by mass: 40-70% of polyaluminium ferric sulfate, 2-10% of magnesium sulfate, 5-10% of cationic starch, 4-15% of calcium hydroxide, 0.5-3% of activated charcoal, 2-10% of sodium carbonate and 5-15% of polyacrylamide. The flocculant is broad in spectrum, is low-toxic, is low-cost in the raw materials, is good in treatment effects, is simple in operation, is wide in available range, and can form the floc being good in filterability. The flocculant can effectively treats oil-containing waste water, coking wastewater and such industrial waste water, can protect ecologic environment, is less in use amount, can form large alumen ustum, is high in sedimentation speed, is high in removal rate of COD, is less in sludge, is strong in adsorbability on pollutants and is strong in neutralization capacity on micro-acidic waste water.

Owner:陕西绿邦环保科技有限公司

High-flame retardant rubber material in extrusion molding and preparation method thereof

ActiveCN103146081AImprove interface performanceStrong neutralization abilityRubber materialPolymer science

The invention relates to a low-smoke halogen-free high-flame retardant ethylene propylene rubber material in extrusion molding. A preparation method of the rubber material is as follows: uniformly mixing the di-ethylene propylene rubber and ethylene-vinyl acetate copolymer at 100+ / -10 DEG.C by using an open mill or a internal mixer, cooling to the room temperature, orderly adding carbon black, modified mmicron hydroxide, plasticizer, flame retardant synergist, assistant crosslinker and crosslinking agent in proportion, uniformly mixing, adding the rubber compound in a single-screw extruder, controlling the temperature of the extruder body, the screw and the head at 70-90 DEG.C and the revolving speed of the screw within 20-30r / min (revolutions per minute) so that the rubber can be continuously extruded, heating and forming in a direct vulcanizing tank. The retardant ethylene propylene rubber provided by the invention has the advantages of good dynamic performance, low-smoke halogen-free flame retardance and good extrusion performance, and is adapted to a high-flame retardant rubber seal product.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

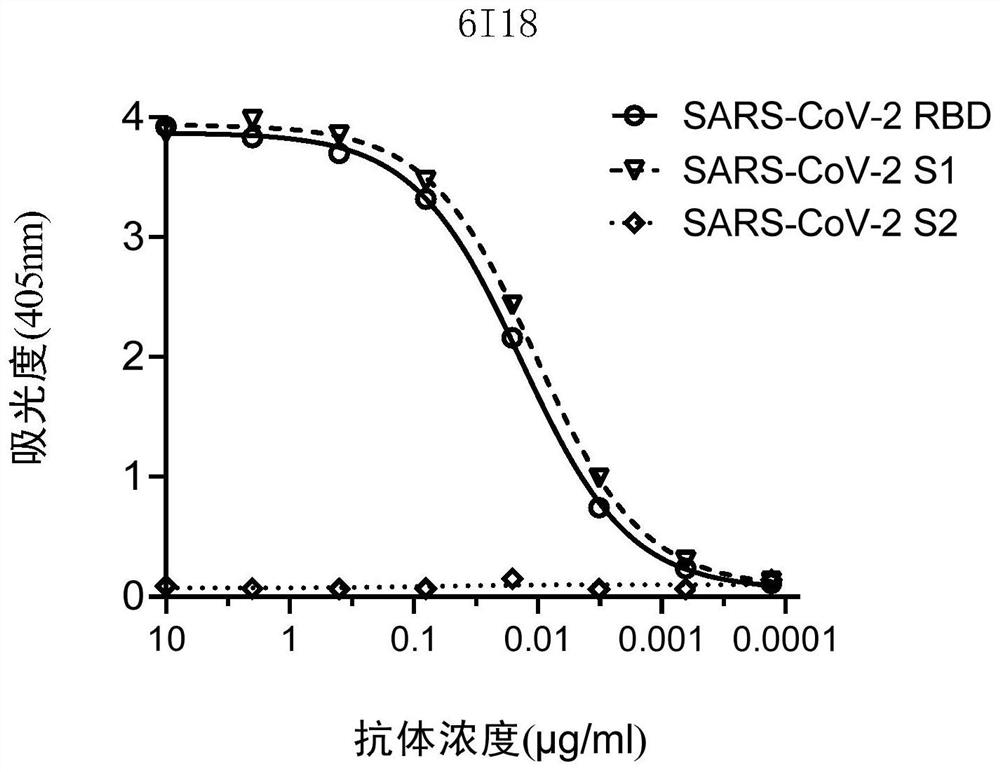

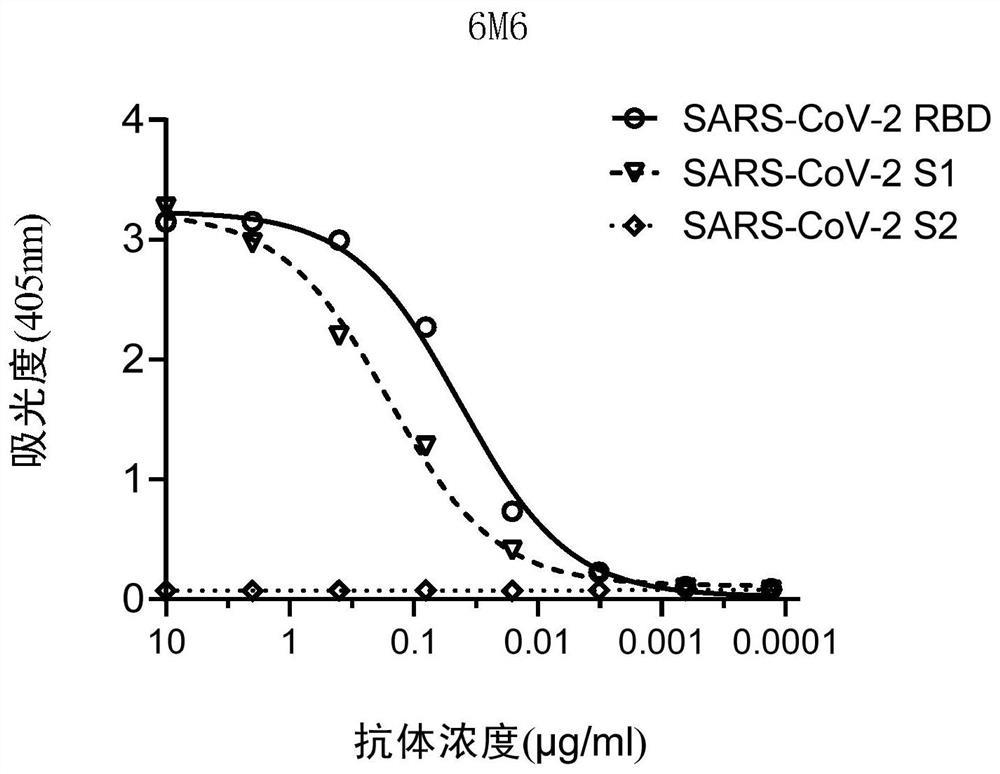

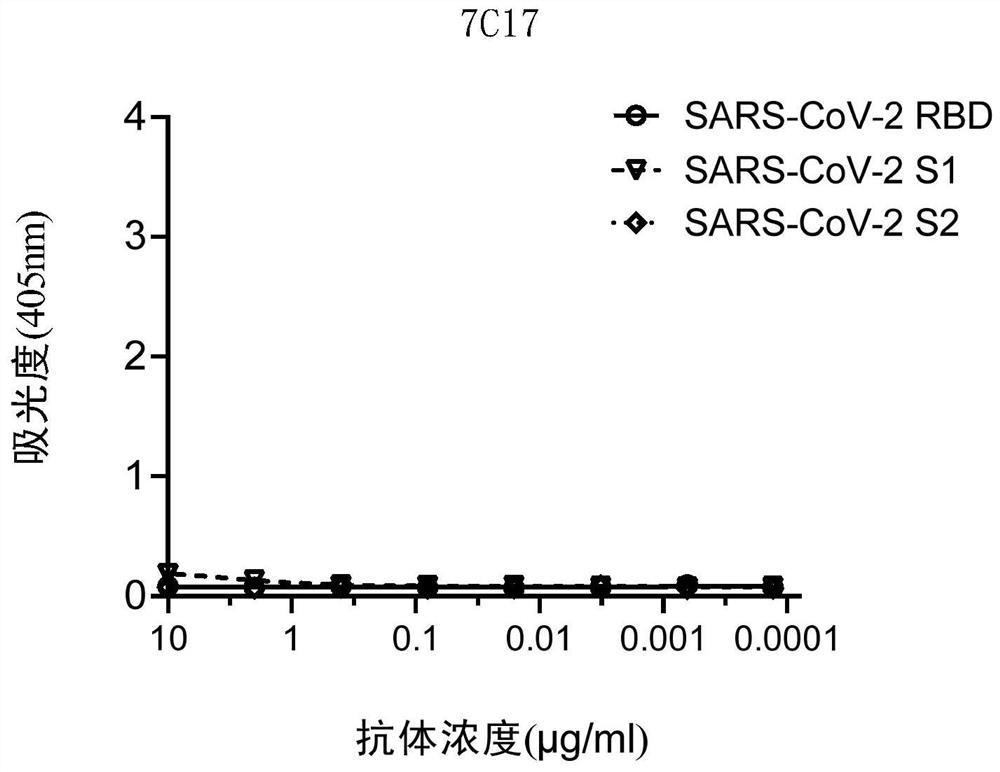

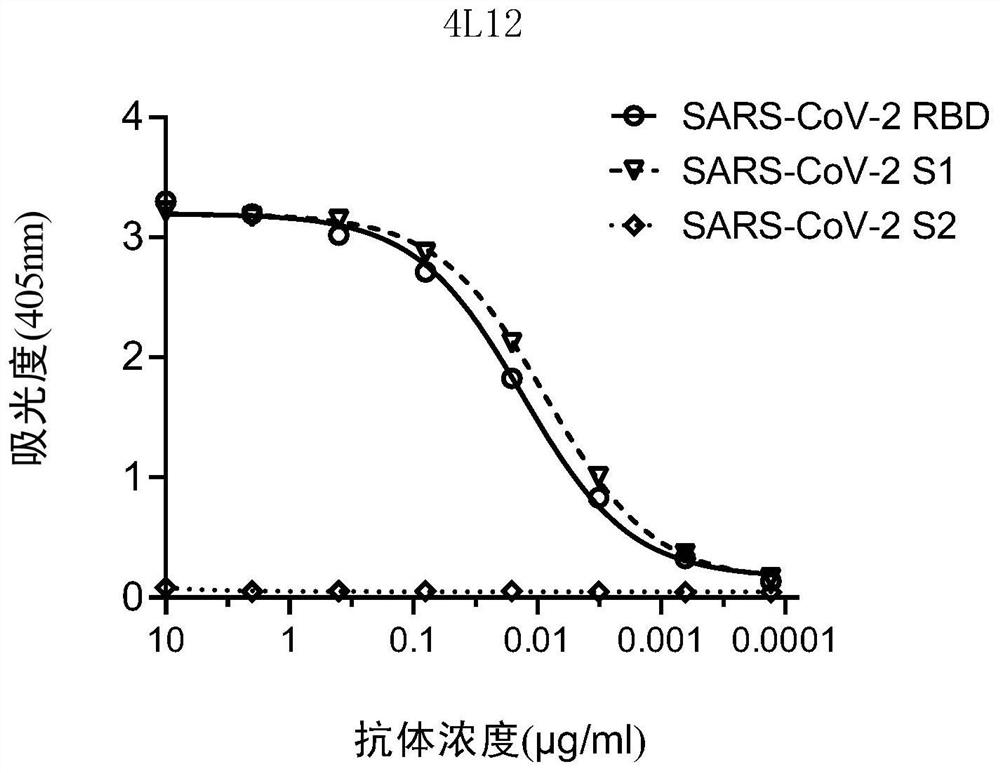

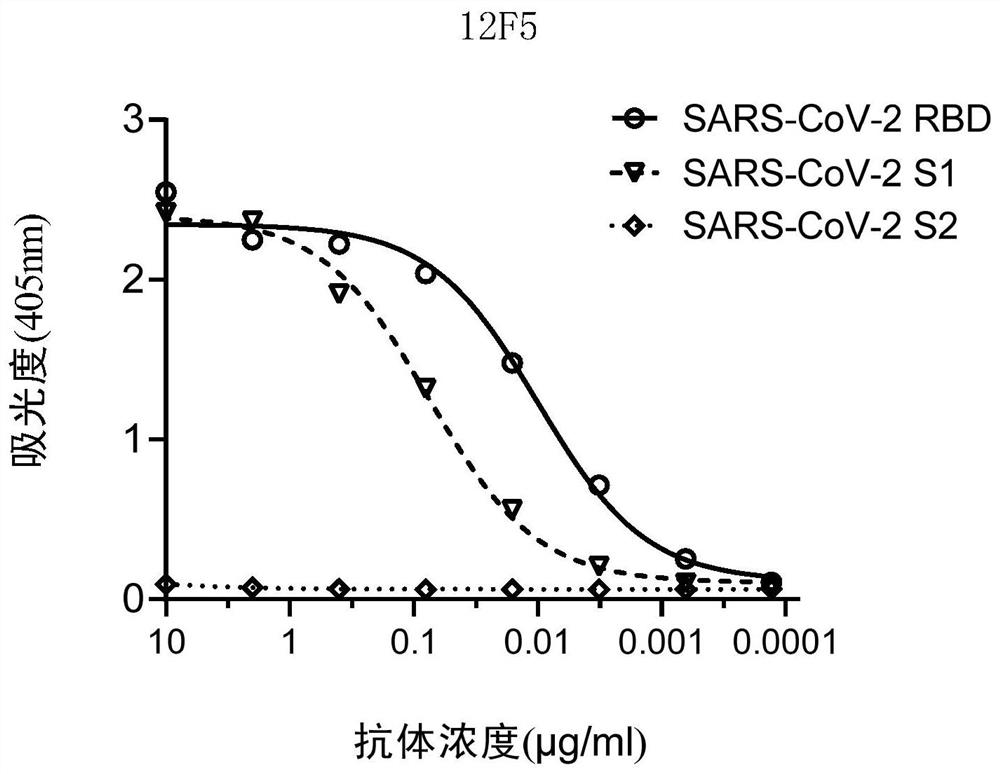

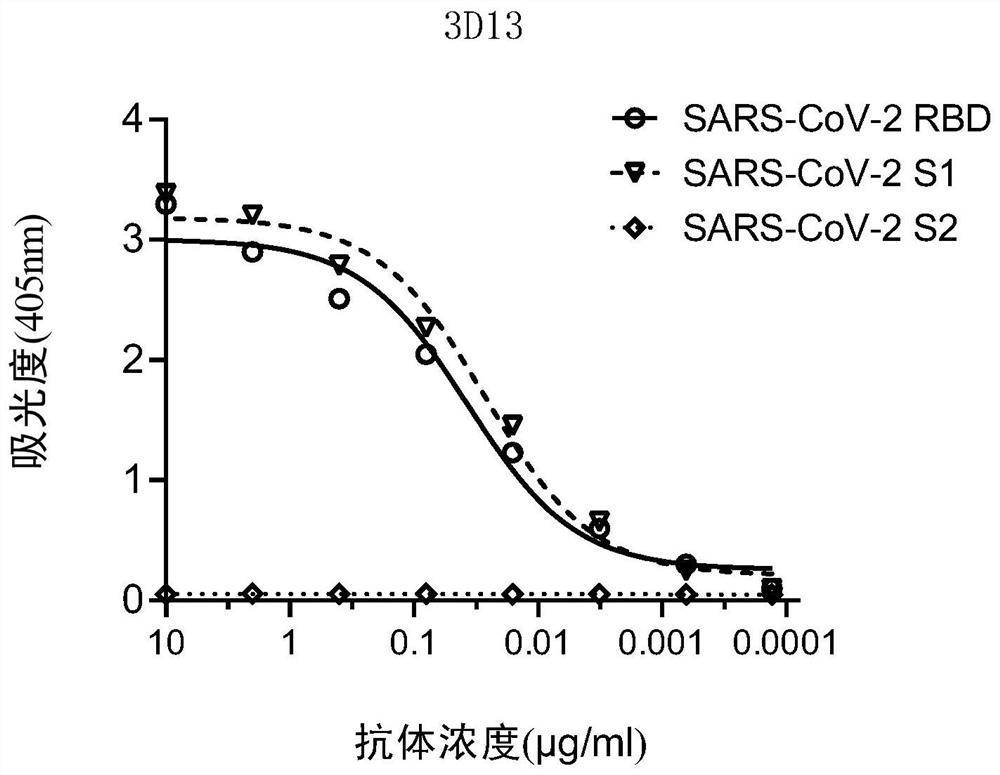

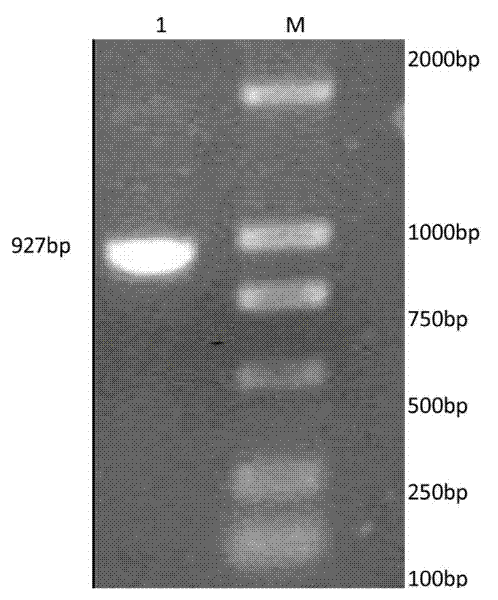

Neutralizing antibody of coronavirus or antigen-binding fragment thereof

ActiveCN112175073AImprove bindingStrong neutralization abilityImmunoglobulins against virusesAntiviralsAntigenDisease

The invention relates to a neutralizing antibody of coronavirus or an antigen-binding fragment thereof, a nucleic acid molecule encoding the antibody or the antigen-binding fragment thereof, a vectorcontaining the nucleic acid molecule, a host cell containing the vector, application of the antibody or the antigen-binding fragment thereof in preparation of drugs for treating or preventing diseasescaused by coronavirus, and application in detection of products. The coronavirus antibody and the antigen-binding fragment thereof have broad-spectrum and strong neutralizing ability for various coronaviruses including SARS-CoV-2, and have good clinical application prospects in the future.

Owner:超非凡(上海)医疗科技有限公司

Antibodies of coronavirus or antigen binding fragments of antibodies

ActiveCN112159469AImprove bindingStrong neutralization abilityImmunoglobulins against virusesAntiviralsAntigen Binding FragmentReceptor

The invention relates to antibodies of a coronavirus or antigen binding fragments of the antibodies, a nucleic acid molecule for encoding the antibodies or the antigen binding fragments thereof, a vector including the nucleic acid molecule, a host cell including the vector, and application of the antibodies or the antigen binding fragments thereof to the aspect of preparation of drugs for treatingor preventing diseases caused by the coronavirus, and the aspect of detection products. The inventors utilize a B cell in-vitro monoclonal culture and high-throughput antibody screening technology toobtain a series of antibodies of the coronavirus and the antigen binding fragments of the antibodies, and the antibodies and the antigen binding fragments thereof have high binding capacity and neutralizing capacity for the SARS-CoV-2 virus, can recognize and bind S1 protein of the SARS-CoV-2 virus and a receptor binding domain (RBD) of the S1 protein, and have very strong affinity, and thus, itcan be speculated that the antibodies and the antigen binding fragments possibly have the binding capacity and neutralizing capacity for other coronaviruses, and coronaviruses possibly appearing in the future, and the antibodies and the antigen binding fragments have good clinical application prospects in the future.

Owner:超非凡(上海)医疗科技有限公司

Electropositive production well treating fluid and method of preparing the same

ActiveUS20040180795A1Enhanced inhibitory effectImprove protectionBiocideFluid removalWater basedWell drilling

The present invention provides an electropositive and water-based production well treating fluid system. The production well treating fluid system can be made to exhibit electropositivity by using a cationic viscosifier meanwhile matched with a cationic fluid loss additive and optionally matched with a mud-building agent, electrical stabilizing agent, colloid-stabilizing agent, lubricant, oil layer protective agent and / or weighting agent. Such kind of electropositive production well treating fluid can solve better the contradiction between "treating fluid stability" and "bore hole stability", and has features in strong ability of inhibiting the dispersion of clay, good effect of protecting oil-gas reservoir, fast drilling speed, regular shape of bore hole and good resistance to salt. The present invention relates further to a method of preparing said production well treating fluid system and use of the drilling fluid and well completion fluid in petroleum drilling and well completion.

Owner:CHINA PETROCHEMICAL CORP +2

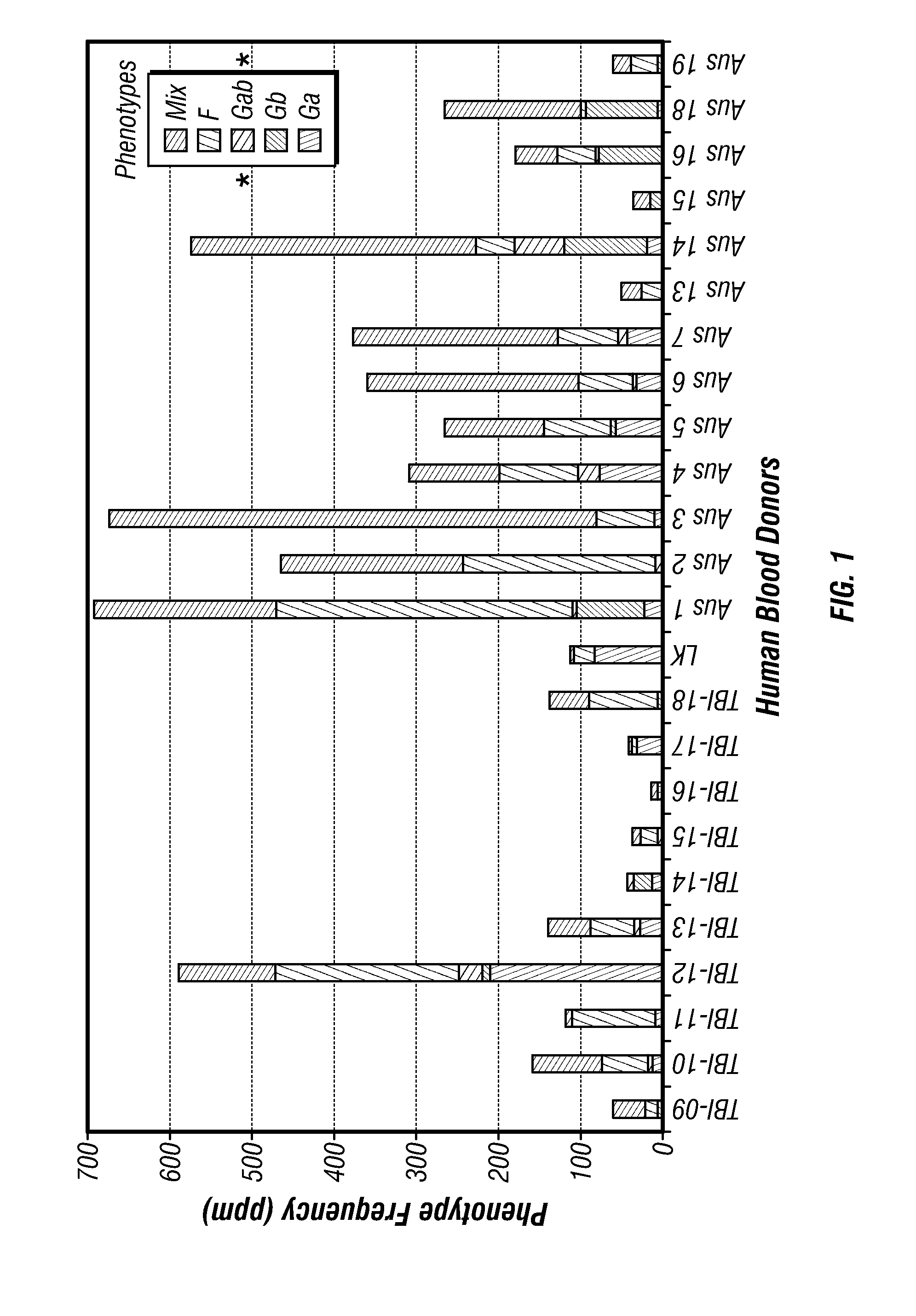

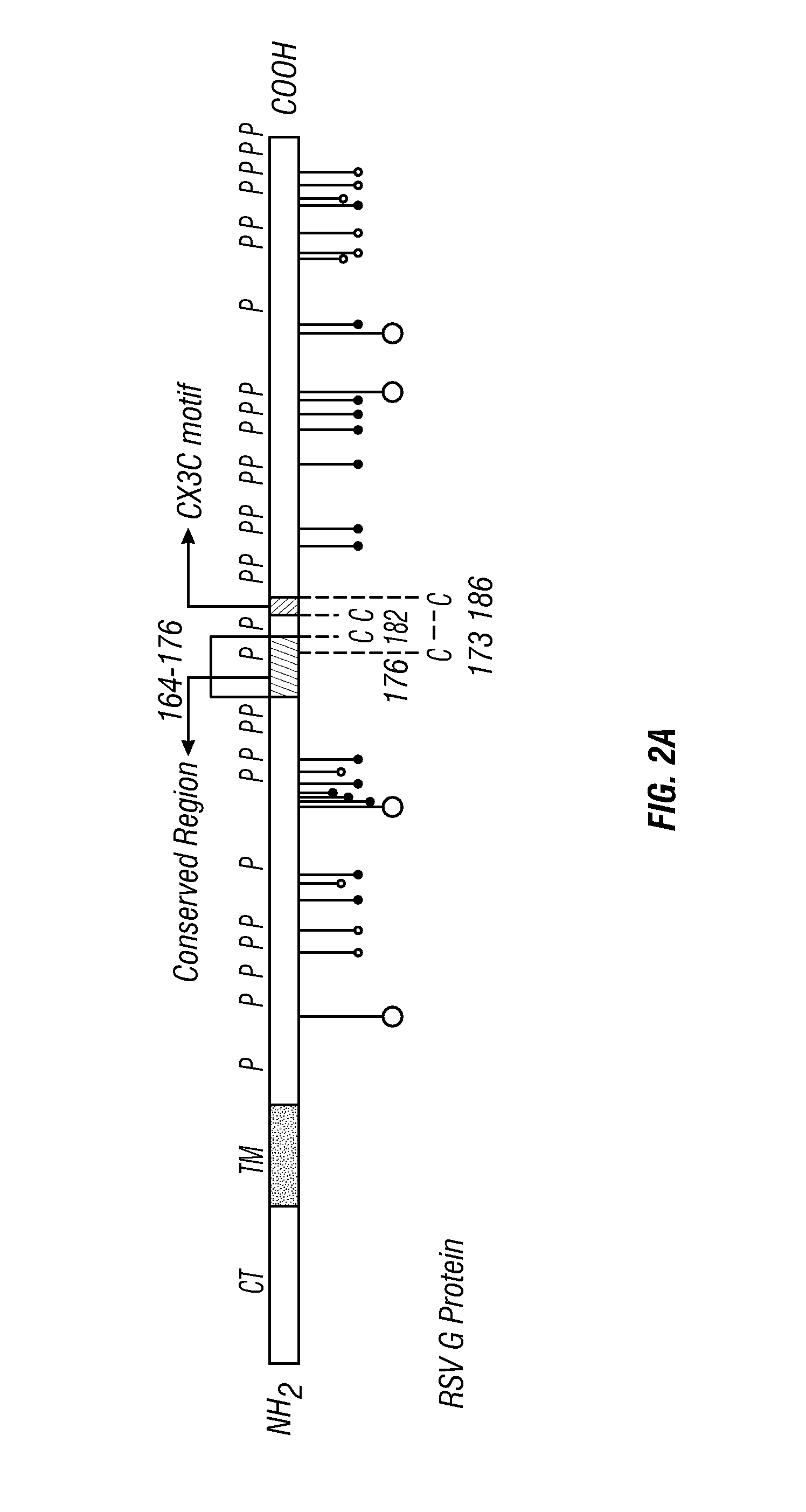

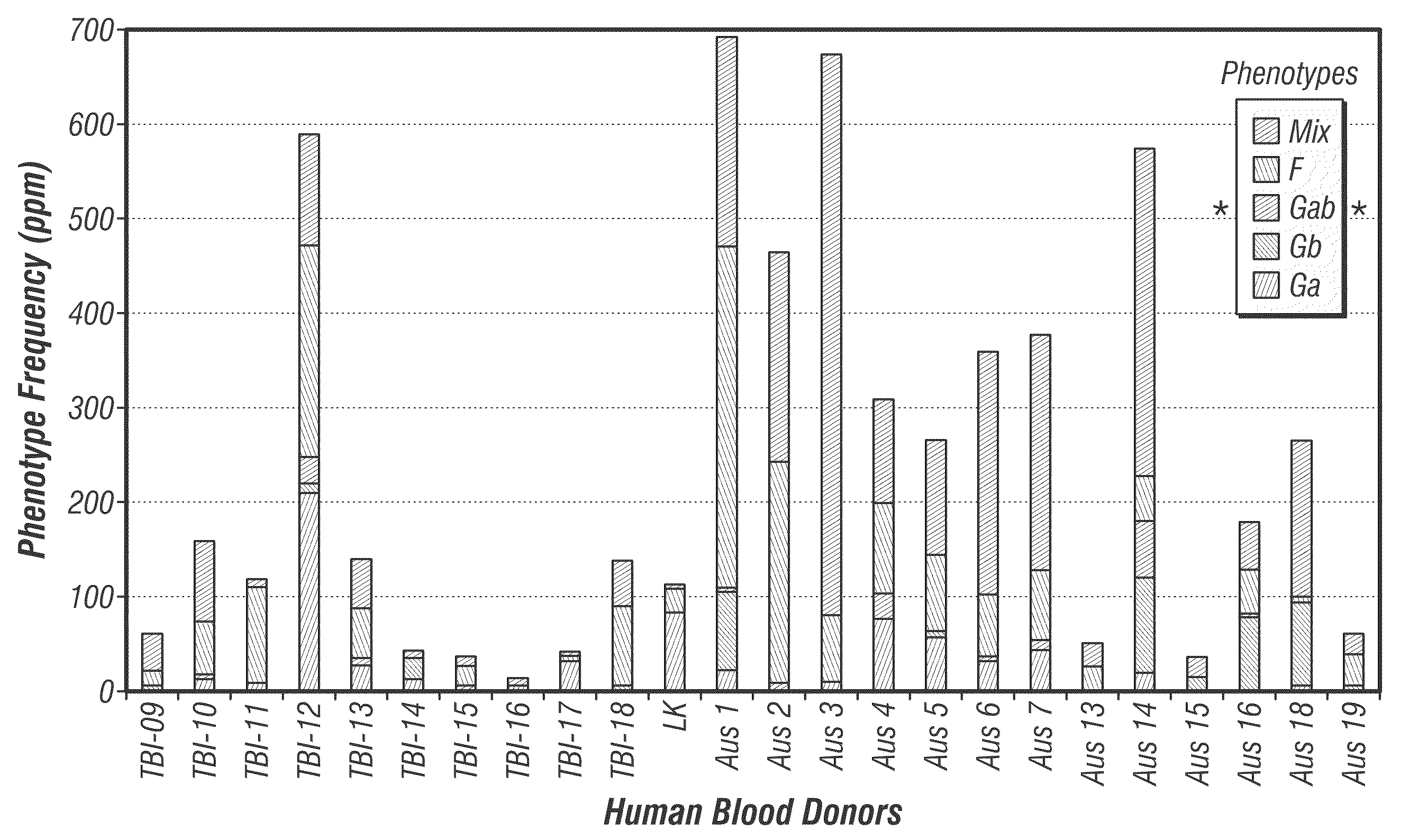

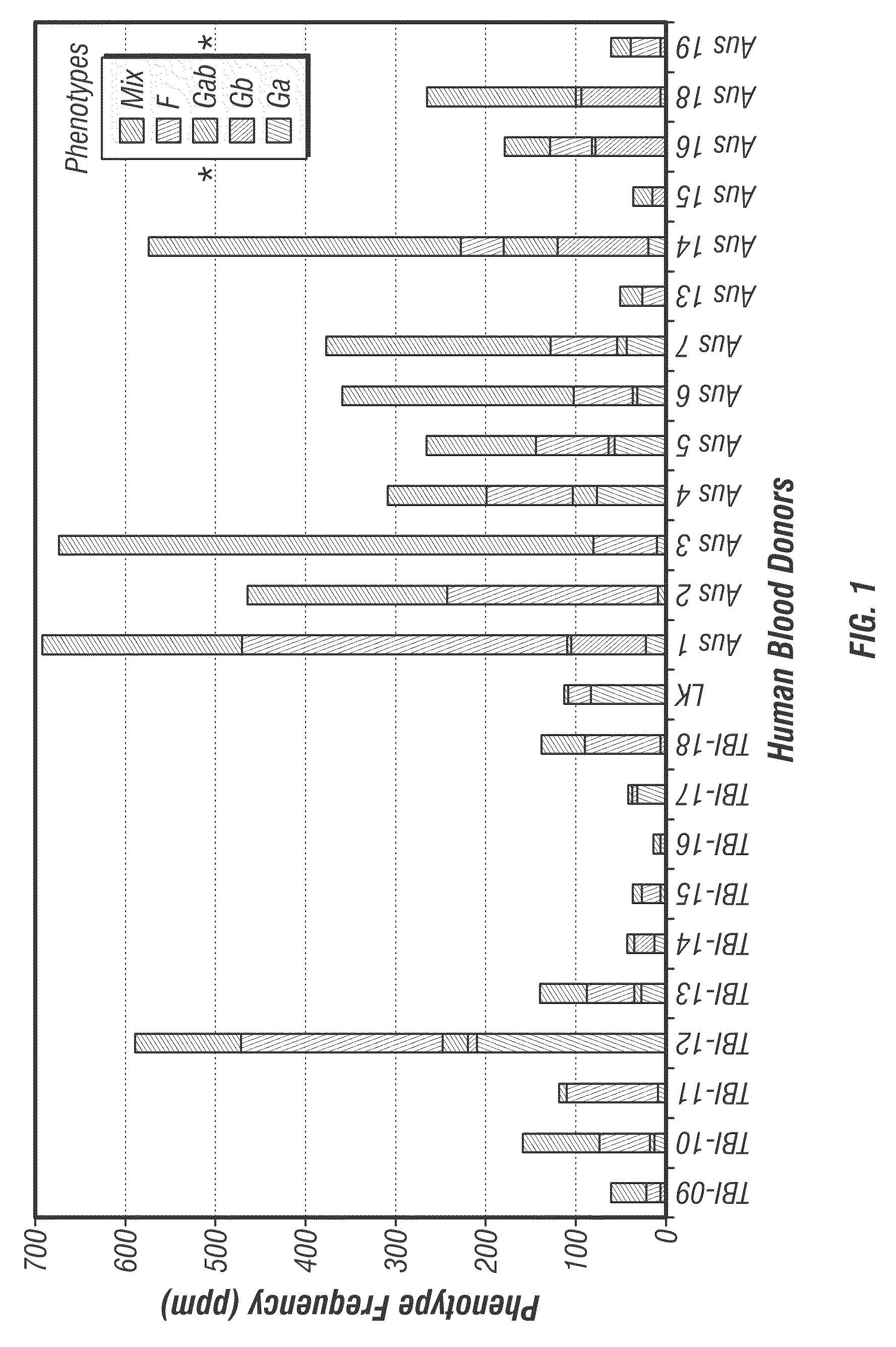

Anti-RSV G protein antibodies

ActiveUS7736648B2High affinityStrong neutralization abilityAntipyreticAnalgesicsEpitopeMonoclonal antibody

Individual monoclonal antibodies and fragments that bind a conserved epitope of the G protein of RSV and which are minimally immunogenic when administered to a human subject, are useful in treating RSV infections.

Owner:TRELLIS RSV HLDG

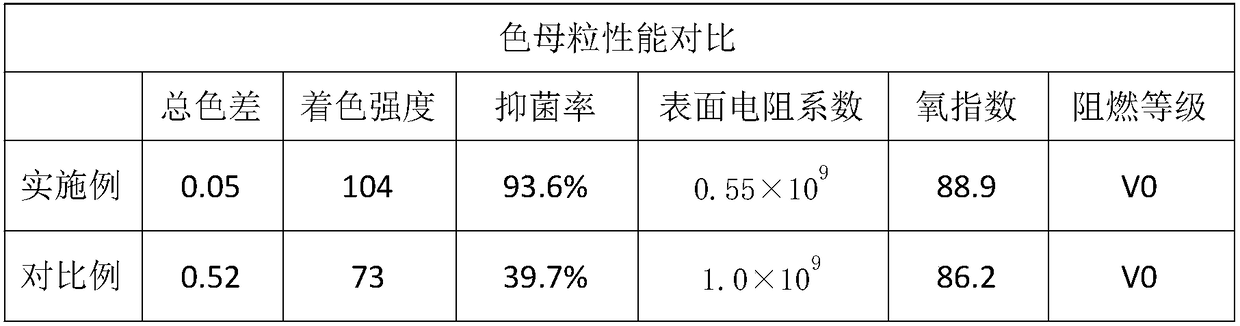

Anti-electrostatic flame-retardant PA (polyamide) color master batch and preparation method thereof

The invention discloses an anti-electrostatic flame-retardant PA (polyamide) color master batch. The anti-electrostatic flame-retardant PA color master batch is prepared from the following raw materials in parts by weight: 50 to 70 parts of PA, 25 to 40 parts of inorganic pigment, 20 to 30 parts of fiber, 4 to 6 parts of composite anti-electrostatic agent, 3 to 5 parts of composite dispersant, 6 to 8 parts of magnesium hydroxide flame-retardant agent, and 1 to 2 parts of compatilizer. The anti-electrostatic flame-retardant PA color master batch has the advantages that the cost is low, the preparation technology is simple, and the anti-electrostatic property and flame-retardant property are excellent; when the anti-electrostatic flame-retardant PA color master batch is used for coloring thePA product, the fire risk of the PA product is reduced, the safety hidden hazards are reduced, and the fire propagation speed is effectively inhibited when a fire accident occurs, so as to provide the valuable time for fire extinguishing, and protect the property safety and body safety of people.

Owner:合肥卡洛塑业科技有限公司

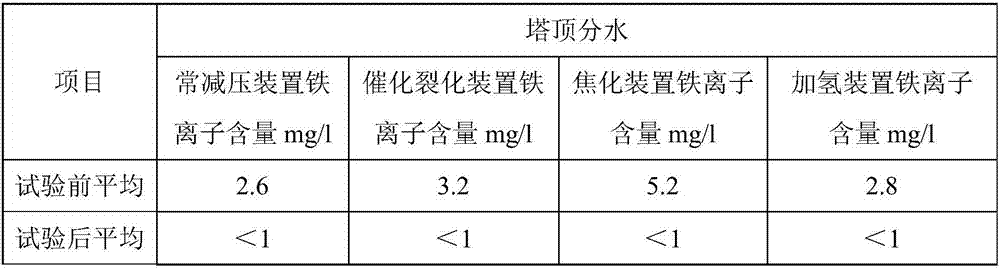

Neutralizing corrosion inhibitor

InactiveCN109518191AImprove lipophilicityBarriers gather with each otherHigh concentrationCarbon dioxide corrosion

The invention discloses a neutralizing corrosion inhibitor. The neutralizing corrosion inhibitor is prepared from the following compositions in percentage by mass: 1-5% of a dispersing agent, 20-25% of neutralizing organic amine, 4-10% of imidazolinecompounds, 1-5% of alkynol compounds, 4-15% of a nitrogenous adsorption-type corrosion inhibitor, 2-10% of a synergistic agent, and the balance of a solvent. According to the neutralizing corrosion inhibitor, high adsorption is achieved on the metal surface to prevent metal from corroding the cathode and anode conjugate process, and thus the effectof corrosion inhibition is effectively enhanced; a continuous and dense protective film can be formed on the metal surface, and corrosion of a high concentration sulfide, chloride and cyanide is inhibited; a mannich base and phosphorothioate are adopted as the synergistic agent, good thermal stabilization and chemical stability are achieved on the two-phase of water and oil, high adsorption is achieved on the metal surface, high inhibiting effect is achieved on corrosion of hydrogen sulfide and carbon dioxide, and meanwhile, good inhibition is achieved on corrosion of hyperthermia naphthenicacid; and the dosage is greatly lowered while it is ensured that the corrosion inhibition rate is greater than 90%.

Owner:JIANGSU KECHUANG PETROCHEM

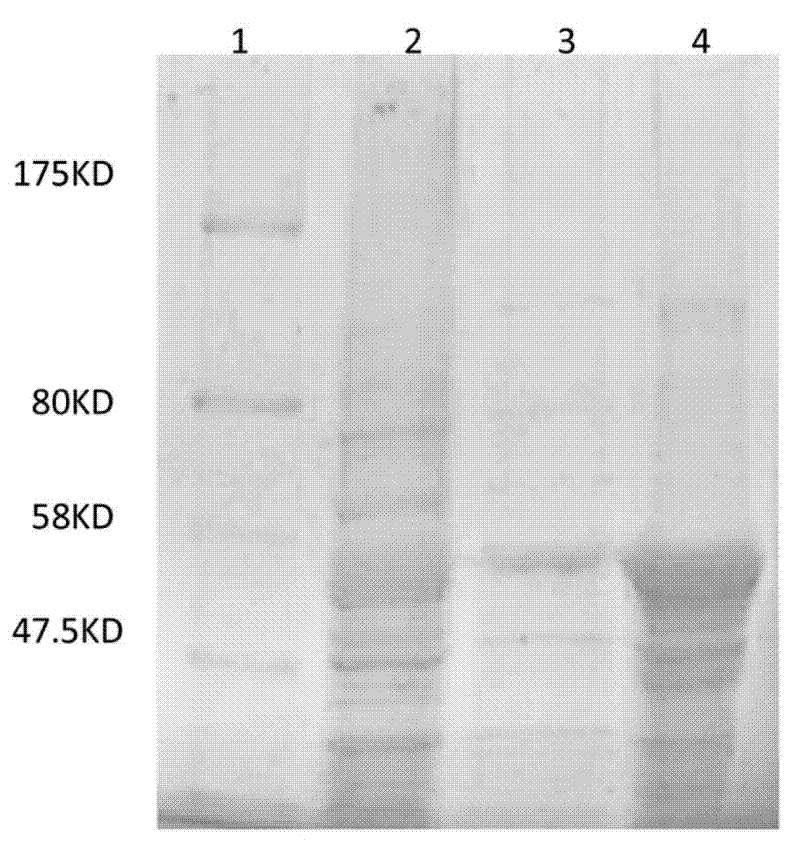

Application of siniperca chuatsi ISKNV (Infectious Spleen and Kidney Necrosis Virus) ORF093 protein

ActiveCN102240399AGood immune preventionGood neutralization effectViral antigen ingredientsAntiviralsRenal necrosisDisease

The invention discloses application of a siniperca chuatsi ISKNV (Infectious Spleen and Kidney Necrosis Virus) ORF093 protein in preparing a vaccine or a medicament for preventing a siniperca chuatsi ISKNV disease. The siniperca chuatsi ISKNV ORF093 protein plays a better immunoprophylaxis role on a siniperca chuatsi iridescent virus disease, has protection ratio exceeding 45 percent and can be developed into a new vaccine or a new medicament for resisting the siniperca chuatsi ISKNV disease.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

Anti-rsv g protein antibodies

ActiveUS20090130120A1High affinityStrong neutralization abilityAntipyreticAnalgesicsEpitopeMonoclonal antibody

Individual monoclonal antibodies and fragments that bind a conserved epitope of the G protein of RSV and which are minimally immunogenic when administered to a human subject, are useful in treating RSV infections.

Owner:TRELLIS RSV HLDG

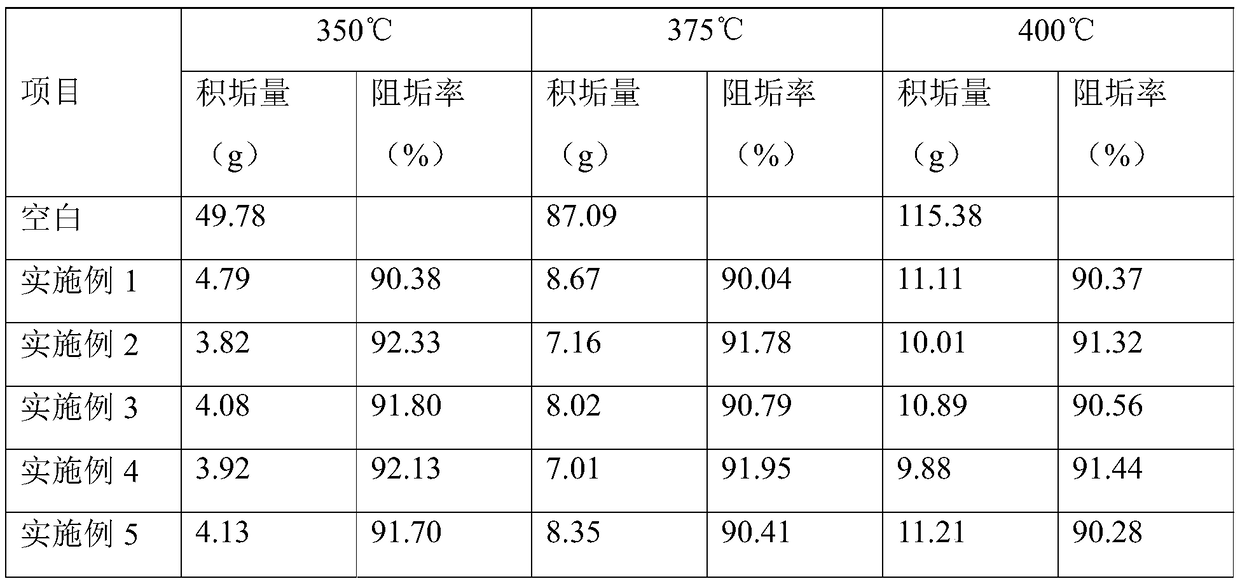

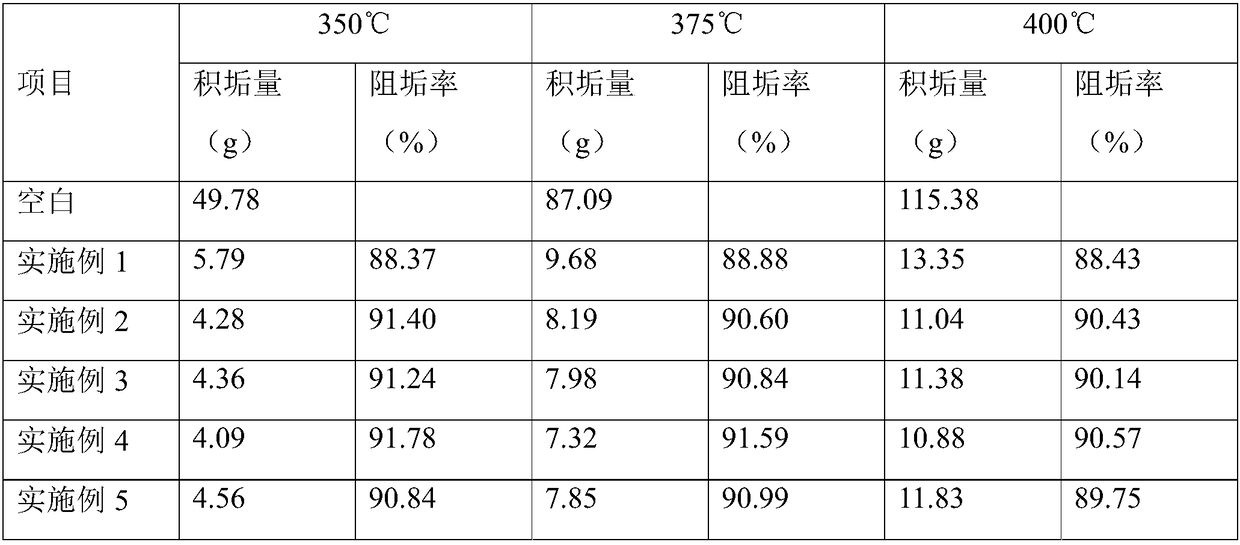

Oil slurry scale inhibitor

InactiveCN109504440ABarriers gather with each otherImprove lipophilicityTreatment apparatus corrosion/fouling inhibitionPhosphateOxidation resistant

The invention discloses an oil slurry scale inhibitor. The oil slurry scale inhibitor is prepared from the following components in percentage by mass: 25 to 40 percent of a detergent dispersant, 6 to12 percent of a phenol-amine type antioxidant, 5 to 10 percent of a corrosion inhibitor, 0.5 to 3 percent of a detergent, 0.4 to 0.5 percent of a metal passivating agent and the balance of a solvent,wherein the detergent dispersant is polyisobutylene succinimide and / or polybutadiene mercaptohexanediol phosphate. The oil slurry scale inhibitor disclosed by the invention has a low freezing point (less than or equal to -15 DEG C), small viscosity (the kinematic viscosity is less than or equal to 50 mm<2> / s at 20 DEG C), a strong anti-oxidization capability and good thermal stability; propertiesand utilization performance of the oil slurry scale inhibitor are not influenced at relatively high temperature of 350 to 400 DEG C and the oil slurry scale inhibitor is suitable for scale inhibitionand descaling in an oil slurry system in a catalytic cracking device; the adding amount of the oil slurry scale inhibitor in oil slurry is 30 to 100 ppm; the oil slurry scale inhibitor can be used foreffectively inhibiting equipment including the oil slurry system, a pipeline, a heat exchanger and the like from being coked; the scale inhibition rate can reach 90 percent and safe and stable operation of a device is ensured.

Owner:JIANGSU KECHUANG PETROCHEM

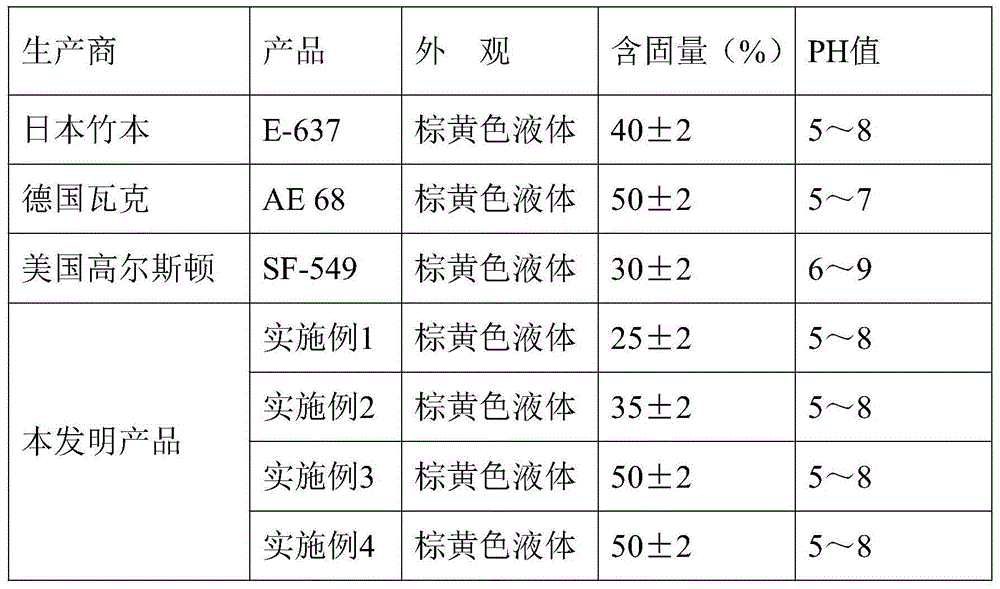

Antistatic agent for polyester fabric

ActiveCN105780466AReduce coefficient of frictionStrong neutralization abilityFibre typesStatic friction coefficientFiber

Provided is an antistatic agent for polyester fabric.The antistatic agent is compounded from, by weight, 6-12 parts of dimethyl octadecyl hydroxy ethyl ammonium nitrate, 2-6 parts of octadecylamine ethyl dimethyl-beta-hydramine dihydric phosphate, 1-4 parts of tri-hydroxyethylmethyl ammnium methosulfate, 1-2 parts of dodecyl trimethyl ammonium bromide and 2-6 parts of Tween 80.On the basis that cationic surfactant is added, an appropriate amount of other components are added, and the polyester antistatic agent which enables the static friction coefficient of fibers to be reduced and has better cohesion collection property is obtained.

Owner:黄山市强力化工有限公司

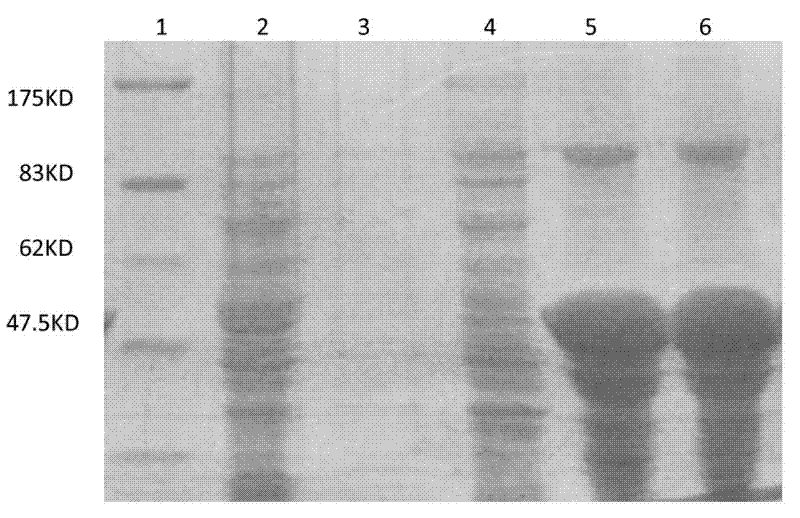

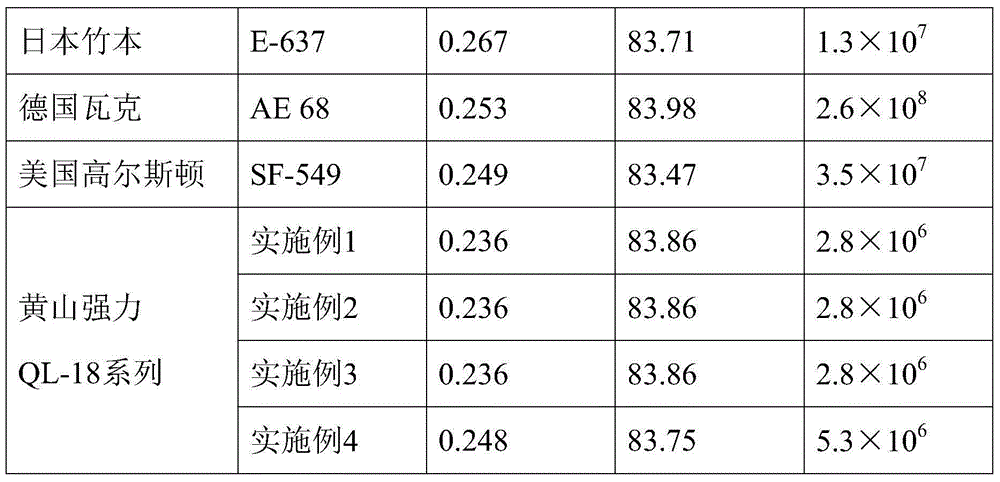

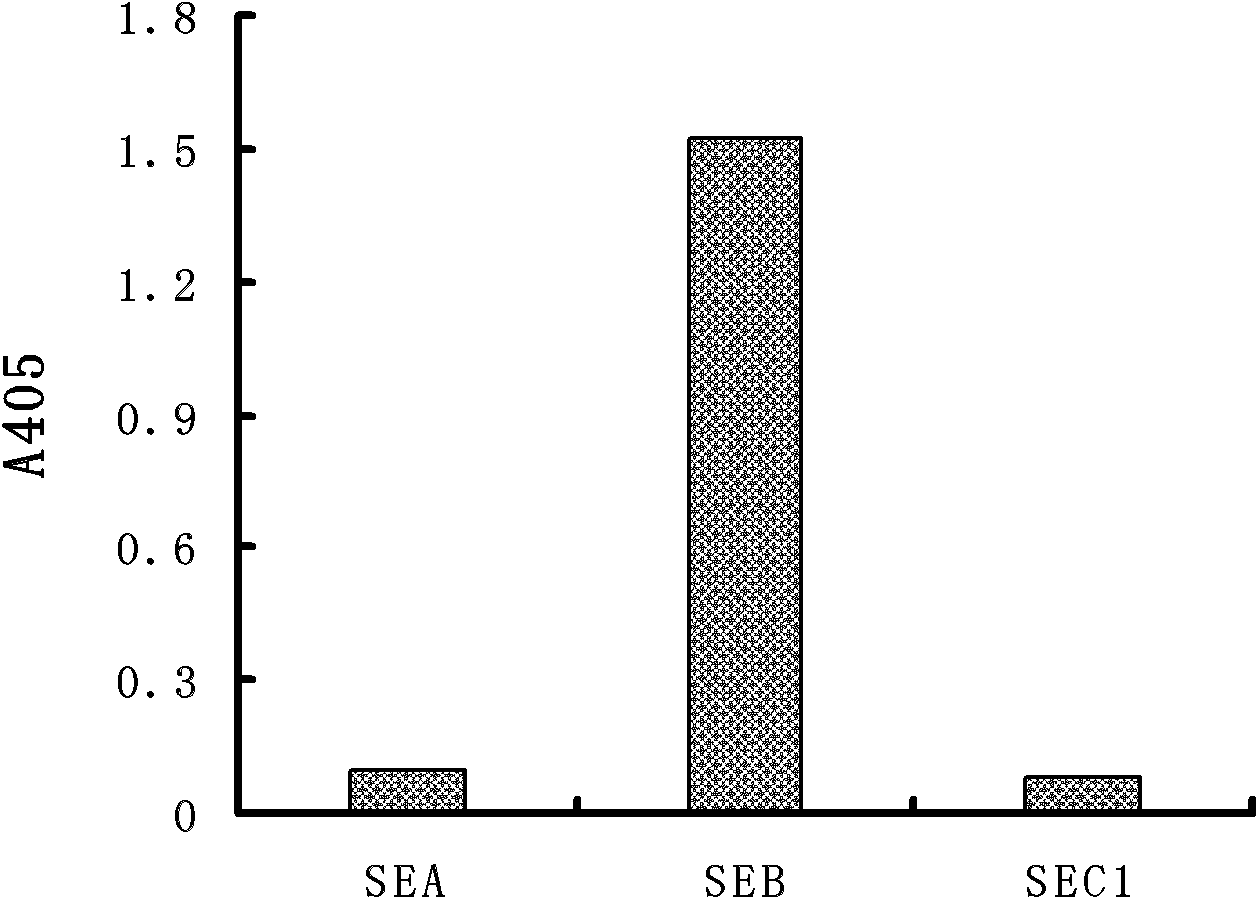

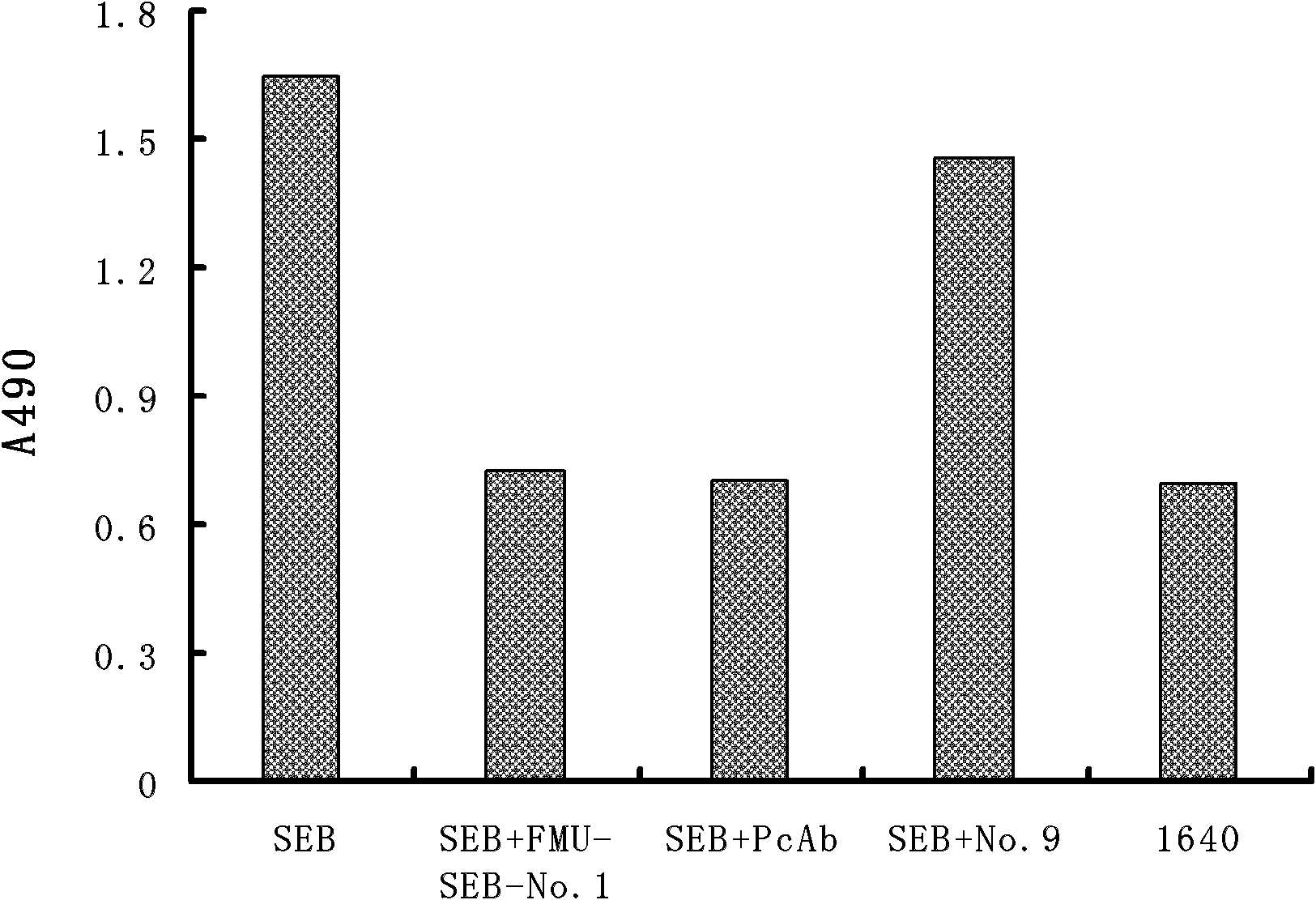

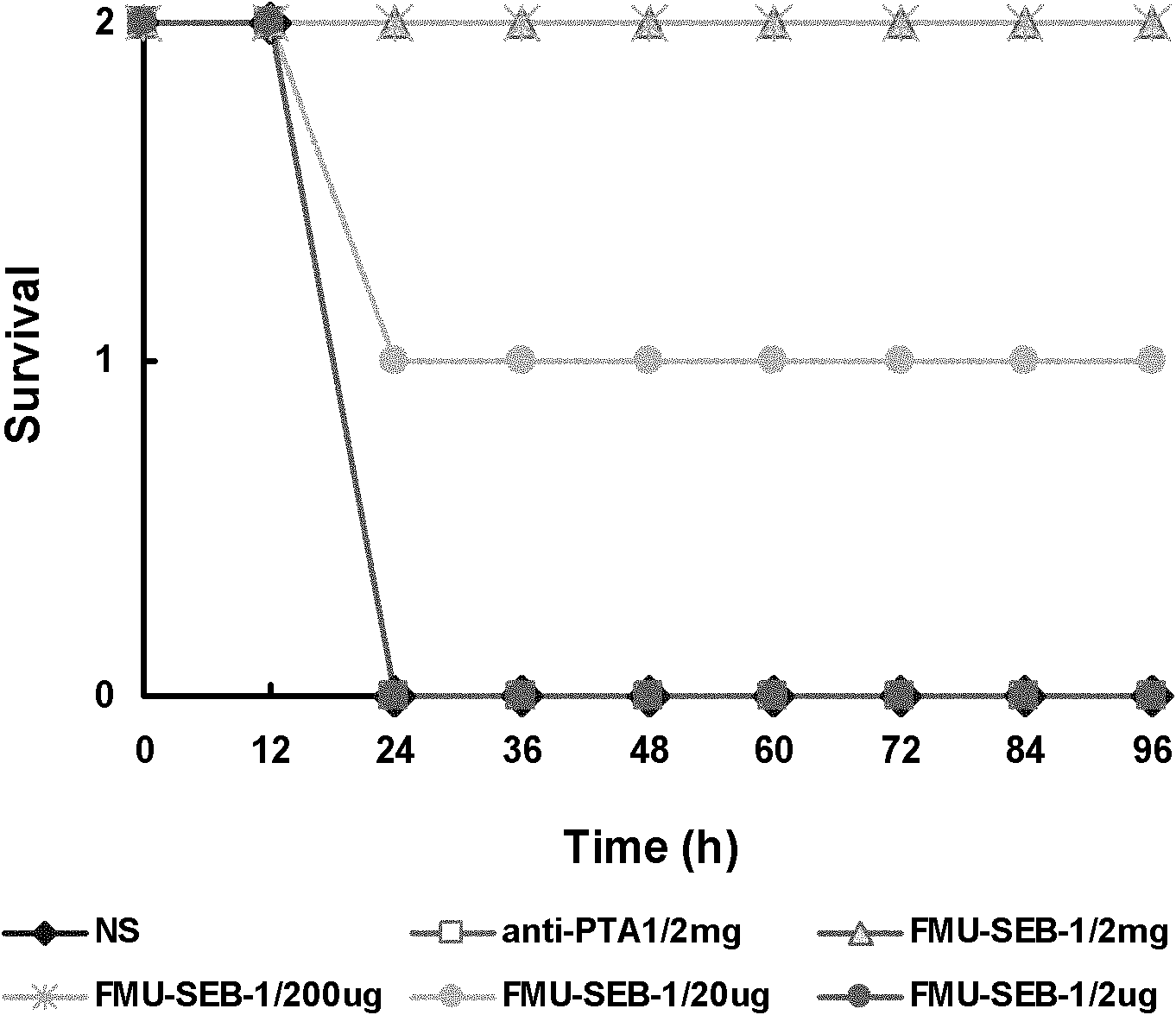

Light chain and heavy chain variable regions of anti-SEB (Staphylococcal Enterotoxin B) monoclonal antibody FMU-SEB-No.1 with high neutralizing activity

ActiveCN101955533AHigh affinityStrong neutralization abilityImmunoglobulins against bacteriaMaterial analysisBALB/cGenetic engineering

The invention discloses light chain and heavy chain variable regions of an anti-SEB (Staphylococcal Enterotoxin B) monoclonal antibody FMU-SEB-No.1 with a high neutralizing activity. The amino acid sequence of an FMU-SEB-No.1 mAb light chain variable region is shown in SEQ.ID.NO.1, and the amino acid sequence of an FMU-SEB-No.1 mAb heavy chain variable region is shown in SEQ.ID.NO.2. A method for the invention comprises the following steps of: preparing a group of mouse anti-SEB mAbs by using a natural SEB immune Balb / c mouse, screening hybridoma cell lines which can stably secrete high-affinity anti-SEB mAb; and preparing ascitic fluid to obtain a high-affinity anti-SEB mAb FMU-SEB-No.1. The invention is beneficial to confirming the uniqueness of a gene sequence and a corresponding protein sequence as well as a CDR sequence thereof, and providing support for researching and developing an anti-SEB mosaic or humanized genetic engineering antibody.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Hydrocracking scale inhibitor

InactiveCN109504439ABarriers gather with each otherImprove lipophilicityTreatment apparatus corrosion/fouling inhibitionSolventChemistry

The invention discloses a hydrocracking scale inhibitor. The hydrocracking scale inhibitor is characterized by being prepared from the following components by mass: 25-40 percent of cleaning dispersant, 6-12 percent of antioxidant, 5-10 percent of corrosion inhibitor, 0.5-3 percent of detergent, 0.2-1 percent of poly alpha-olefin, and the balance of water; the cleaning dispersant is polyisobutylene succinimide. The hydrocracking scale inhibitor disclosed by the invention has the advantages of low freezing point, small viscosity, and mechanical impurity being less than or equal to 2 percent; the hydrocracking scale inhibitor has a good dispersion effect on catalyst powder in slurry oil, prevents the powder from being coagulated and settled, and can effectively inhibit coking of equipment such as a feed heat exchanger; the hydrocracking scale inhibitor is applied to the feed heat exchanger of a catalytic cracking device for scale inhibition and scale removal, the addition quantity in fresh feed slurry oil is 50-100 ppm, and a scale inhibition rate can reach 85 percent or more; after coking phenomenon of the heat exchanger is changed, the efficiency is improved, heat exchange and reaction are more sufficient, the temperature of the slurry oil returning to a tower is decreased, and the amount of steam generation is increased.

Owner:JIANGSU KECHUANG PETROCHEM

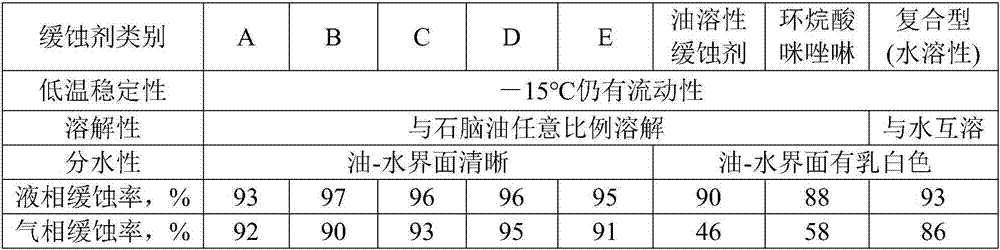

Oil soluble composite corrosion inhibitor

The invention relates to an oil soluble composite corrosion inhibitor, and belongs to the field of petroleum refining. The oil soluble composite corrosion inhibitor is composed of following components including 20-40 wt% of carboxylic acid amine salt, 5-20 wt% of sulfonic acid amine salt, 15-40 wt% of organic amine and 20-40 wt% of an organic solvent. The carboxylic acid amine salt is a mixture formed through combination of two or more of carboxylic acid amine salt prepared through vegetable oleic acid and tertiary alkyl primary amine, carboxylic acid amine salt prepared through animal oleic acid and tertiary alkyl primary amine and carboxylic acid amine salt prepared through naphthenic acid and tertiary alkyl primary amine according to any proportion. The sulfonic acid amine salt is a mixture formed through combination of sulfonic acid amine salt prepared through heavy alkylbenzene sulfonic acid and tertiary alkyl primary amine, sulfonic acid amine salt prepared through nonyl phenol sulfonic acid and tertiary alkyl primary amine and sulfonic acid amine salt prepared through mahogany acid and tertiary alkyl primary amine according to any proportion. The product is stable in performance, good in oil solubility, high in anti-corrosion capability and neutralization ability and good in film forming performance, and when a tower roof system is used, an organic amine neutralizer or ammonium hydroxide does not need to be additionally injected.

Owner:南京万象新材料科技有限责任公司

Enterovirus 71 (EV71) monoclonal antibody and application thereof

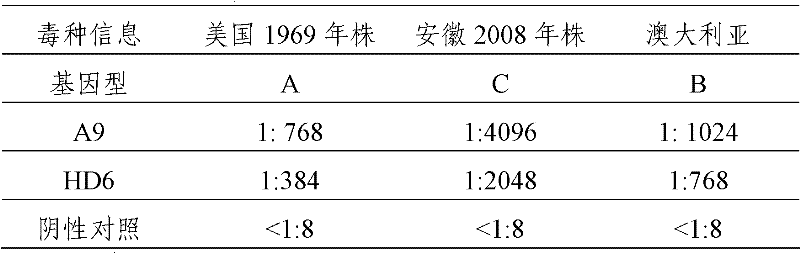

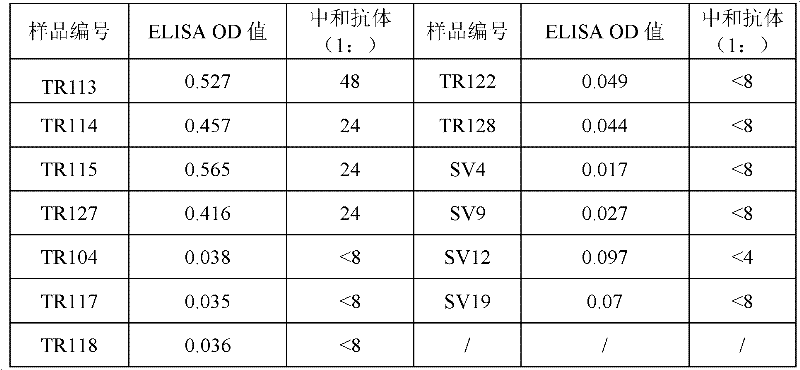

ActiveCN102409028AHigh school and activeStrong guiding significanceImmunoglobulins against virusesMicroorganism based processesLaboratory culturePassive Treatment

The invention provides an enterovirus 71 (EV71) monoclonal antibody and an application thereof. The monoclonal antibody is derived from an EV71 hybrid tumor cell strain, which has a preservation number of CGMCC (China General Microbiological Culture Collection) No.5330. The monoclonal antibody and related reagents thereof have important significance in promoting the treatment and research of severe cases and death cases caused by EV71 in China, and have extremely important value in further promoting clinical research, epidemic development and passive treatment of EV71.

Owner:SINOVAC BIOTECH

Environment-friendly grafted chloroprene rubber plant cleaning agent and preparing method thereof

InactiveCN105602754ASimple manufacturing processThe cleaning process is not pungentOrganic non-surface-active detergent compositionsInorganic non-surface-active detergent compositionsAlkylphenolPhosphoric acid

The invention provides an environment-friendly grafted chloroprene rubber plant cleaning agent and a preparing method thereof. The cleaning agent is prepared from, by weight, 18-22 parts of phosphoric acid, 16-19 parts of glycolic acid, 11-14 parts of ethoxyl ammonium salt of alkylphenol, 11-12 parts of ethylene tetraacetic acid tetrasodium, 11-13 parts of xanthic acid gum, 12-14 parts of methylbenzene, 25-27 parts of methyl ethyl ketone, 10-12 parts of chloroprene rubber DCR-10, 8-9 parts of MMA, 1-3 parts of BPO1, 3-5 parts of BHT, 6-9 parts of phenolic resin, 30-50 parts of water, 4-5 parts of draba, 10-12 parts of cassia twigs, 10-12 parts of radix paeoniae alba, 10-12 parts of dried ginger, 8-10 parts of ephedra herbs, 8-10 parts of pinellia ternate, 5-8 parts of thunberg fritillary bulb, 3-5 parts of asarum sieboldii, 10-15 parts of schisandra chinensis, 8-10 parts of liquorice and 4-5 grains of scented tea. The cleaning agent has the advantages that the preparing technology is simple and convenient, the cleaning agent is not pungent in the cleaning process, plant ingredients in the formula are used for neutralization, and therefore environment-friendly and pollution-free effects are achieved; meanwhile, during application, contamination of petroleum and the like is cleaned mainly; compared with a common cleaning agent, the cleaning agent is good in decontamination effect, high in neutralizing capacity and obvious in use effect.

Owner:ANHUI HAIDE PETROCHEM

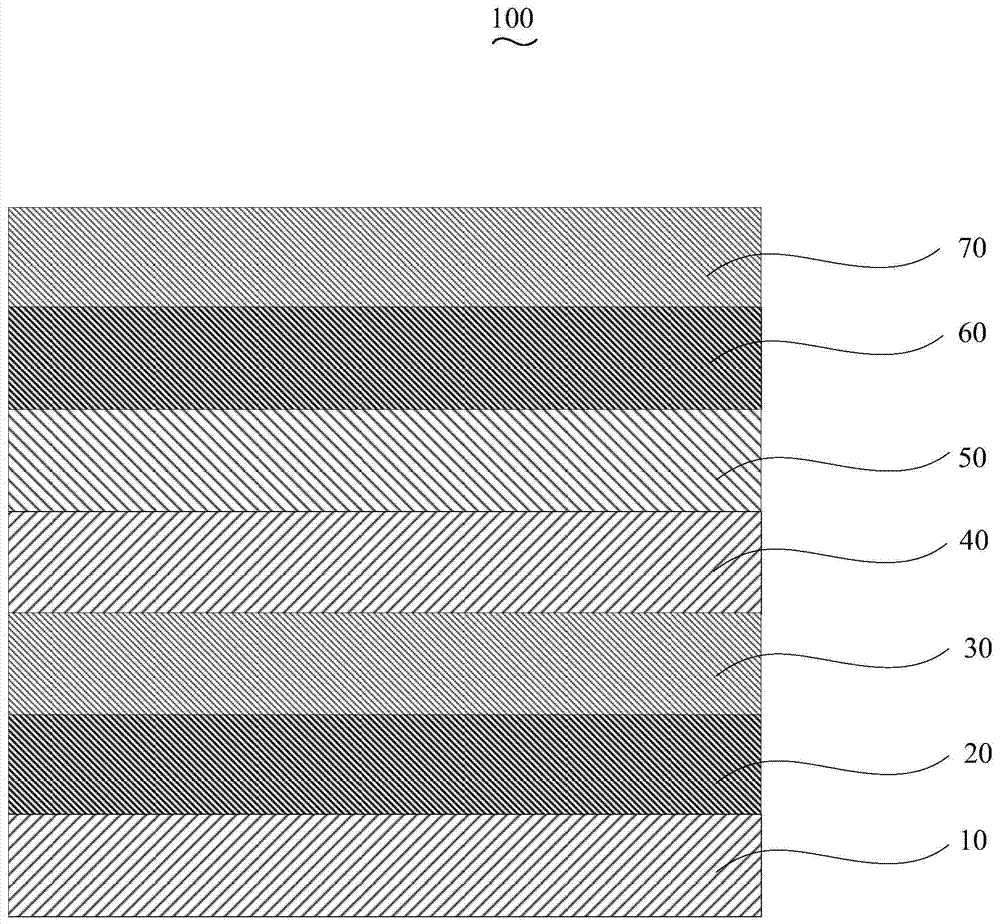

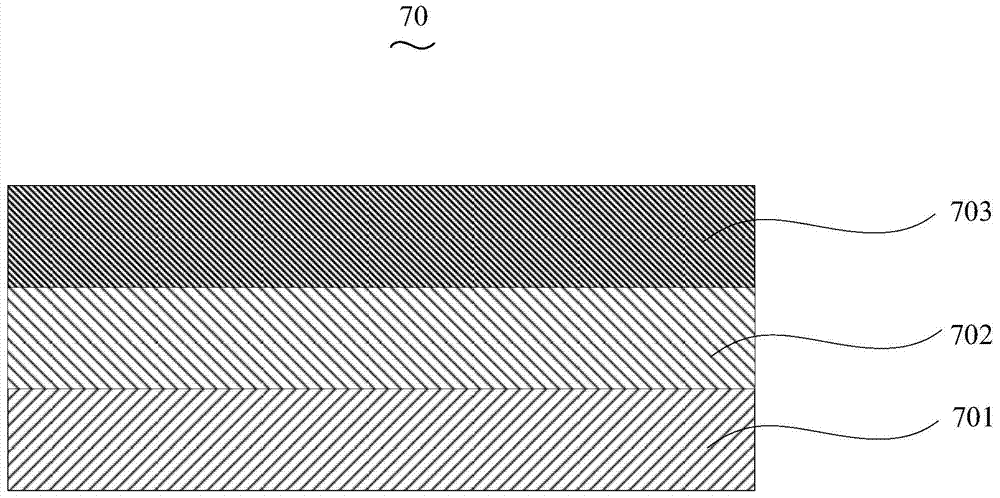

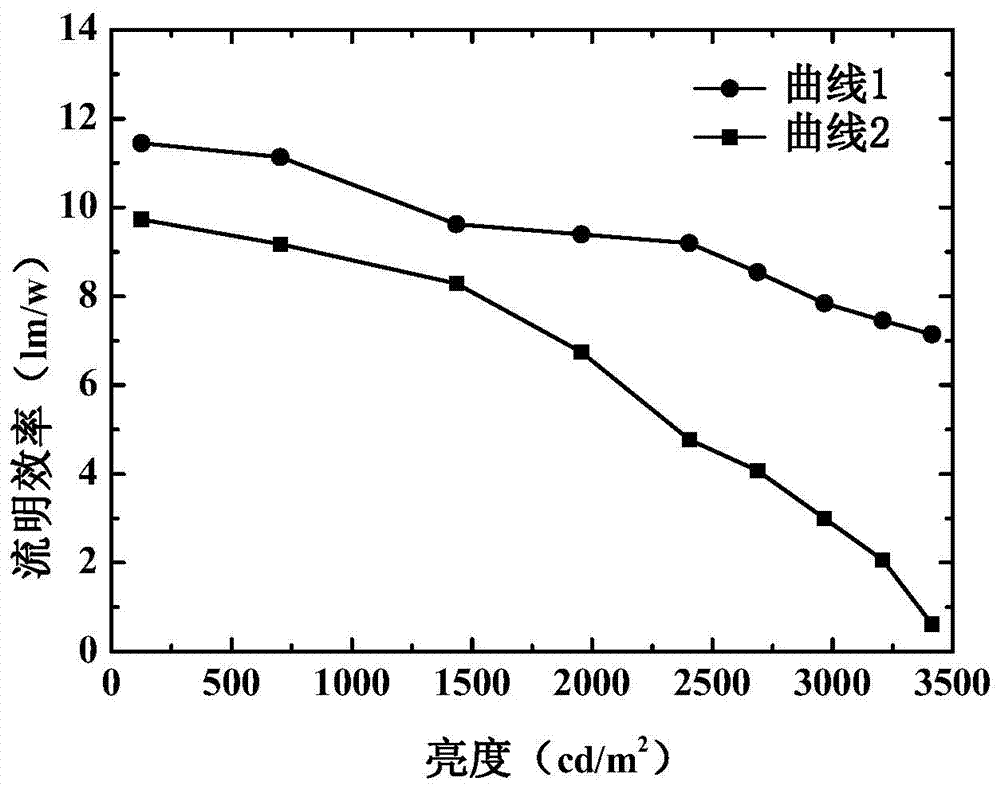

Organic electroluminescent device and method for preparing same

InactiveCN104518148AImprove stabilityImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingMetallic materialsMetallic sulfide

Provided is an organic electroluminescent device, comprising an anode, a hole injection layer, a hole transport layer, a luminous layer, an electron transfer layer, an electron injection layer, and a cathode stacked in sequence. A cathode layer is formed by a sodium salt layer, a metal doping layer, and a metal sulfide layer. The material of the sodium salt layer is selected from at least one of sodium carbonate, sodium chloride, sodium fluoride, and sodium bromide. The metal doping layer material contains a metal material and a passivation material doped in the metal material. The work function of the metal material is -2.0 eV to -3.5 eV. The passivation material is selected from at least one of silica, alumina, nickel oxide, and copper oxide. The material of the metal sulfide layer is selected from at least one of zinc sulfide, cadmium sulfide, magnesium sulfide, and copper sulphide. The luminescence efficiency of the organic electroluminescent device is high. The invention also provides a method for preparing the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

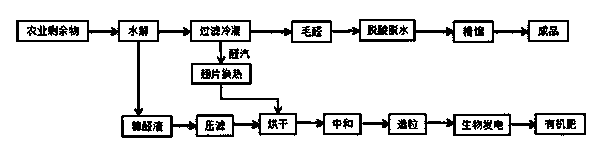

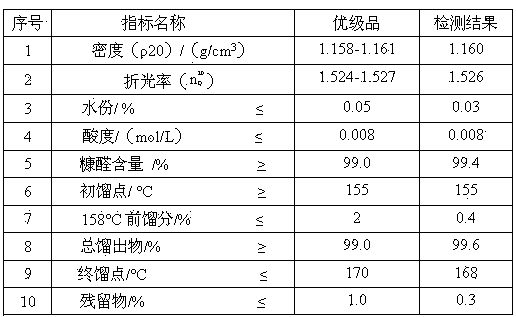

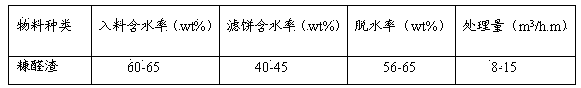

Novel process for comprehensively utilizing agricultural wastes

The invention belongs to the technical field of reutilization of agricultural wastes and particularly relates to a novel process for comprehensively utilizing the agricultural wastes. The novel process comprises the following steps: adding acid into the agricultural wastes and hydrolyzing to obtain aldehyde gas and furfural residues; carrying out filter pressing on the furfural residues and primarily reducing the water content of the furfural residues to be 40%-45%; then drying the furfural residues and further dehydrating the furfural residues; when the water content of the furfural residues is reduced to be 15%-20%, adding fly ash to neutralize; after neutralizing, granulating to obtain biomass fuel; combusting the biomass fuel to be used for biomass power generation; meanwhile, taking solid wastes generated by combustion as raw materials of an organic fertilizer to be reutilized; after filtering and condensing the aldehyde gas, condensing to obtain liquid, namely raw aldehyde; carrying out deacidifying and dehydrating on the raw aldehyde to obtain crude aldehyde; refining the crude aldehyde to obtain finished aldehyde; and carrying out heat exchange on the uncondensed aldehyde gas to replace aldehyde gas heat energy to be used as a heat source for drying the furfural residues, wherein all the percentages are mass percentages.

Owner:濮阳宏业生物质能源有限公司

Fragrant and environment-friendly plant cleaning agent and preparing method thereof

InactiveCN105602743ASimple manufacturing processThe cleaning process is not pungentInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsAdditive ingredientBoron carbide

The invention discloses a fragrant and environment-friendly plant cleaning agent and a preparing method thereof. The fragrant and environment-friendly plant cleaning agent comprises, by weight, 18-22 parts of phosphoric acid, 16-19 parts of glycolic acid, 11-14 parts of alkylphenol oxethyl ammonium salt, 11-12 parts of ethenyl tetraacetic acid tetrasodium, 11-13 parts of xanthic acid gum, 10-12 parts of resol, 10-12 parts of boron carbide, 80-100 parts of deionized water, 4-5 parts of seeds of pepperweed, 10-12 parts of cassia twigs, 10-12 parts of white paeony roots, 10-12 parts of rhizoma zingiberis, 8-10 parts of herba ephedra, 8-10 parts of pinellia ternate, 5-8 parts of thunberg fritillary bulbs, 3-5 parts of herba asari, 10-15 parts of the fruits of Chinese magnoliavine, 8-10 parts of liquorice and 4-5 parts of scented tea. The fragrant and environment-friendly plant cleaning agent has the advantages that the preparing technology is simple and convenient, and pungent smells do not exist in the cleaning process; as neutralizing is carried out through plant ingredients in the formula, the environmental protection effect and the pollution-free effect are achieved; meanwhile, in the application, pollutant such as petroleum is mainly removed; compared with a common cleaning agent, the fragrant and environment-friendly plant cleaning agent is good in decontamination effect, high in neutralizing capacity and obvious in using effect.

Owner:ANHUI HAIDE PETROCHEM

Non-toxic epoxy resin plant cleaning agent and preparation method thereof

InactiveCN105695123ASimple manufacturing processThe cleaning process is not pungentInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEpoxyPhosphoric acid

The invention discloses a non-toxic epoxy resin plant cleaning agent and a preparation method thereof. The non-toxic epoxy resin plant cleaning agent is prepared from, by weight, 18-22 parts of phosphoric acid, 16-19 parts of glycolic acid, 11-14 parts of alkylphenol oxethyl ammonium salt, 11-12 parts of ethenyl tetraacetic acid tetrasodium, 11-13 parts of xanthic acid gum, 89-99 parts of E-42 epoxy resin, 89-99 parts of phenol-nitrile butadiene rubber copolymer, 66-75 parts of acetone, 10-15 parts of quadrol, 4-5 parts of draba nemorosa, 10-12 parts of cassia twigs, 10-12 parts of white paeony roots, 10-12 parts of dried ginger, 8-10 parts of herba ephedra, 8-10 parts of pinellia ternate, 5-8 parts of thunberg fritillary bulb, 3-5 parts of asarum, 10-15 parts of the fruit of Chinese magnoliavine, 8-10 parts of licorice roots and 4-5 scented tea leaves. The cleaning agent prepared through the preparation method has the advantages that preparation technology is simple and convenient, the cleaning process is not pungent, the formula is environmentally friendly and free of pollution due to neutralization of plant ingredients, contamination such as petroleum is removed mainly in the application, and the cleaning agent is good in decontamination effect, high in neutralization ability and obvious in using effect compared with a common cleaning agent.

Owner:ANHUI HAIDE PETROCHEM

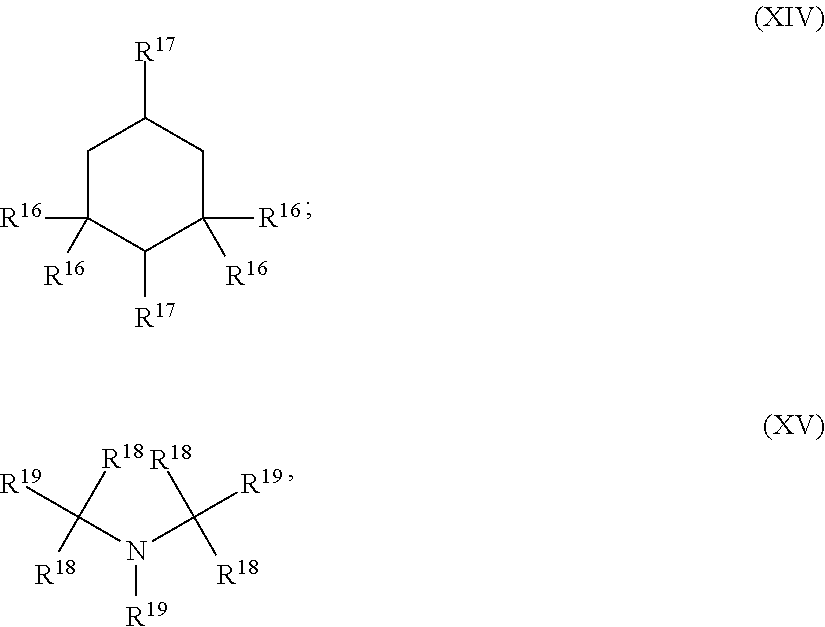

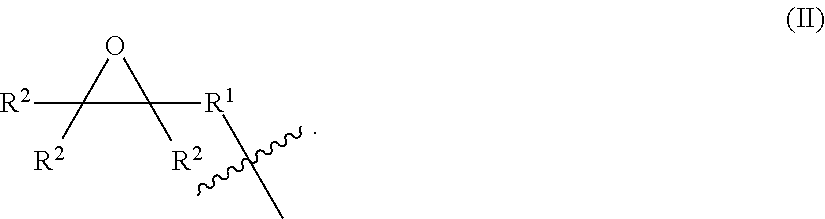

Lubricant Compositions Comprising Epoxide Compounds

InactiveUS20140142010A1Improve sealingStrong neutralization abilityAdditivesTotal Base NumberPolymer science

A lubricant composition including an epoxide compound is disclosed. An additive package including the epoxide compound is also disclosed. The epoxide compound of the lubricant composition acts to improve compatibility of the lubricant composition with a fluoropolymer seal and improve the total base number of the lubricant composition.

Owner:BASF AG

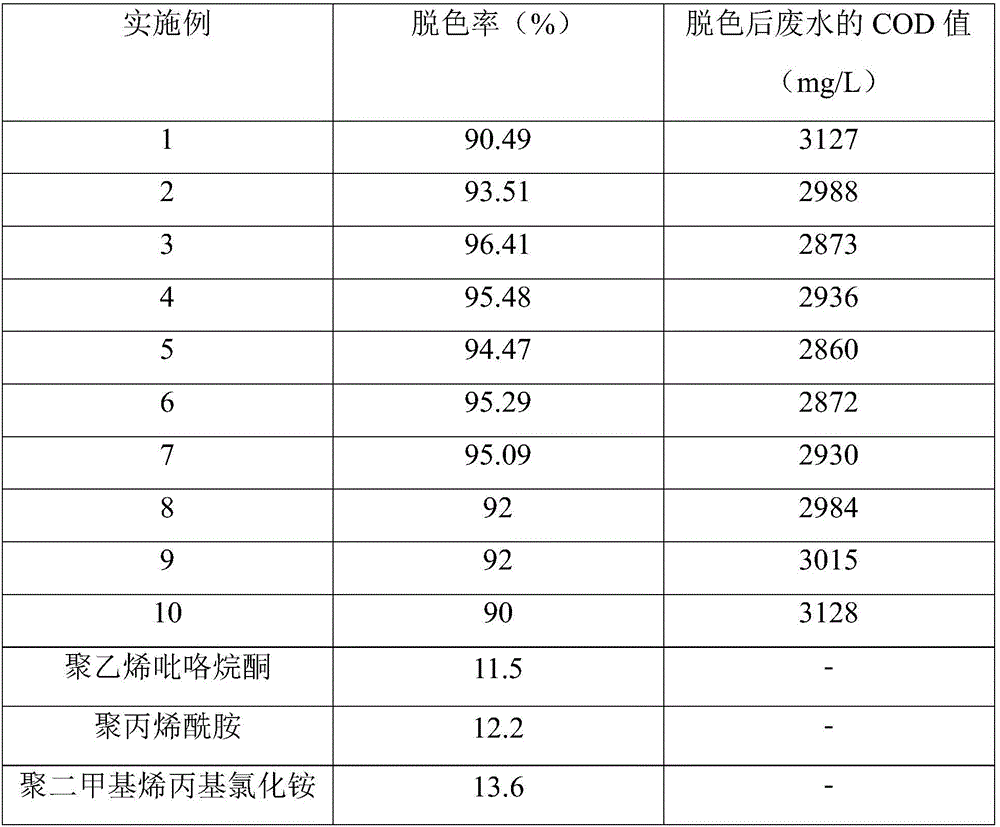

Decolorization method of disperse dye production wastewater

InactiveCN106380023ADecolorization achievedNo secondary pollutionWater treatment parameter controlWater contaminantsDisperse dyeDyeing wastewater

The invention provides a decolorization method of disperse dye production wastewater. A strong-alkali reagent with good stability and high neutralization capability is used for performing high-efficient decolorization on the disperse dye production wastewater with high chromaticity, strong acidity and high chemical oxygen demand. The decolorization method of the disperse dye production wastewater provided by the invention has the advantages that strong alkali is used for regulating production wastewater until the pH is greater than 5.5; redundant raw materials, residual products and few intermediate byproducts in the wastewater are separated out; then, filtering is performed; the dye wastewater decolorization is realized. The method has the advantages of simplicity, convenience, high speed, high efficiency, cleanness, no secondary pollution and the like; the decolorization rate can reach to 90 percent or higher, and can reach to 96.41 percent to the highest degree. The decolorization of the disperse dye production wastewater is realized; organic matters in the dye wastewater are separated out, so that the chemical demand quantity of the dye wastewater is reduced; the quantity of hazardous wastes in the traditional quicklime neutralizing method is reduced; the technological process of subsequent wastewater treatment can also be reduced, so that the wastewater treatment cost is reduced.

Owner:PENGLAI JIAXIN DYES & CHEM +1

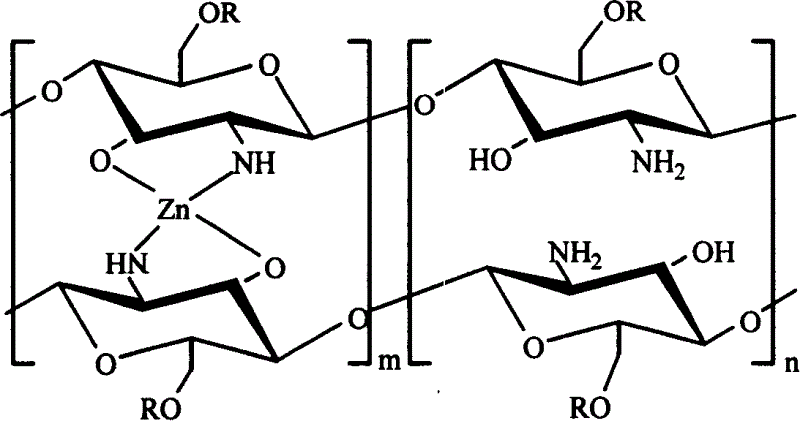

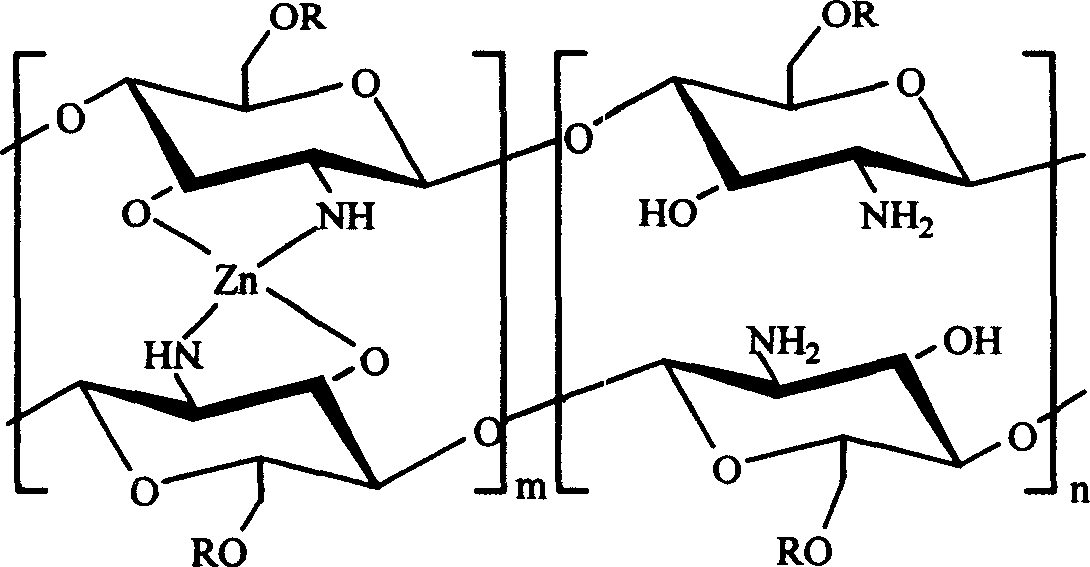

Carboxymethyl chitosan potassium zinc bismuth and preparation process and application thereof

InactiveCN1624003AInsulation erosionIsolation stimulusOrganic active ingredientsAnti ulcerogenicPotassium hydroxide

A compound, carboxymethylchitasan bismuth zink potassium [(C12H16O8N2R2Zn)m(C12H20O8N2R2)n], for treating digestive ulcer, protecting mucosa of stomach and sobering-up is prepared through reaction between chitosan and Zn, carboxymethylation reaction, reacting on potassium hydroxide and bismuth salt, depositing, washing, filtering, baking and pulverizing.

Owner:OCEAN UNIV OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com