Decolorization method of disperse dye production wastewater

A technology for the production of wastewater and disperse dyes, which is applied in chemical instruments and methods, water pollutants, water treatment parameter control, etc., can solve problems such as high technical requirements, difficult operation, and complicated process, and achieve reduction in process flow and safety performance High, clean secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

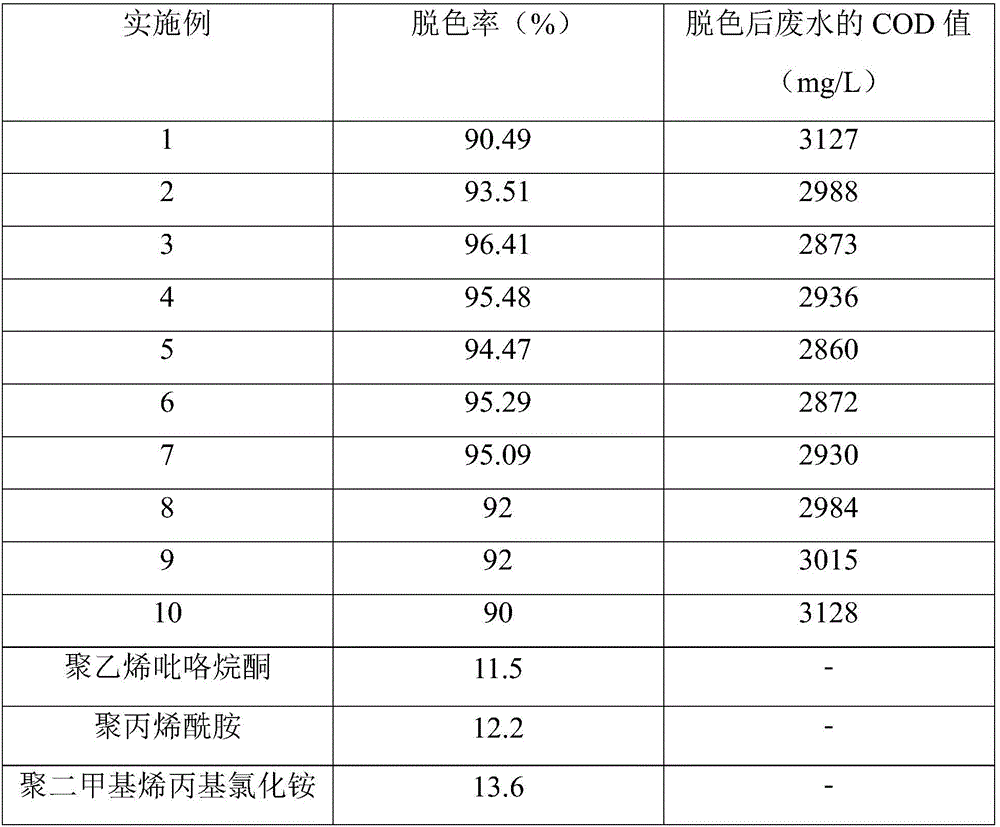

Examples

Embodiment 1

[0035] The decolorization method of the disperse dye production wastewater provided by the present embodiment specifically comprises the following steps:

[0036] Use sodium hydroxide with a mass concentration of 220g / L to adjust the pH of the disperse dye production wastewater to 5.5, stir at a speed of 100rad / min to make the reaction complete, let stand for 0.5 hours, and filter with suction to obtain decolorized wastewater.

Embodiment 2

[0038] The decolorization method of the disperse dye production wastewater provided by the present embodiment specifically comprises the following steps:

[0039] Use sodium hydroxide with a mass concentration of 250g / L to adjust the pH of the disperse dye production wastewater to 6.5, stir at a speed of 500rad / min to make the reaction complete, let stand for 2 hours, and filter with suction to obtain decolorized wastewater.

Embodiment 3

[0041] The decolorization method of the disperse dye production wastewater provided by the present embodiment specifically comprises the following steps:

[0042] Use sodium hydroxide with a mass concentration of 240g / L to adjust the pH of the disperse dye production wastewater to 7.5, stir at a speed of 200rad / min to make the reaction complete, let stand for 1 hour, and filter with suction to obtain decolorized wastewater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com