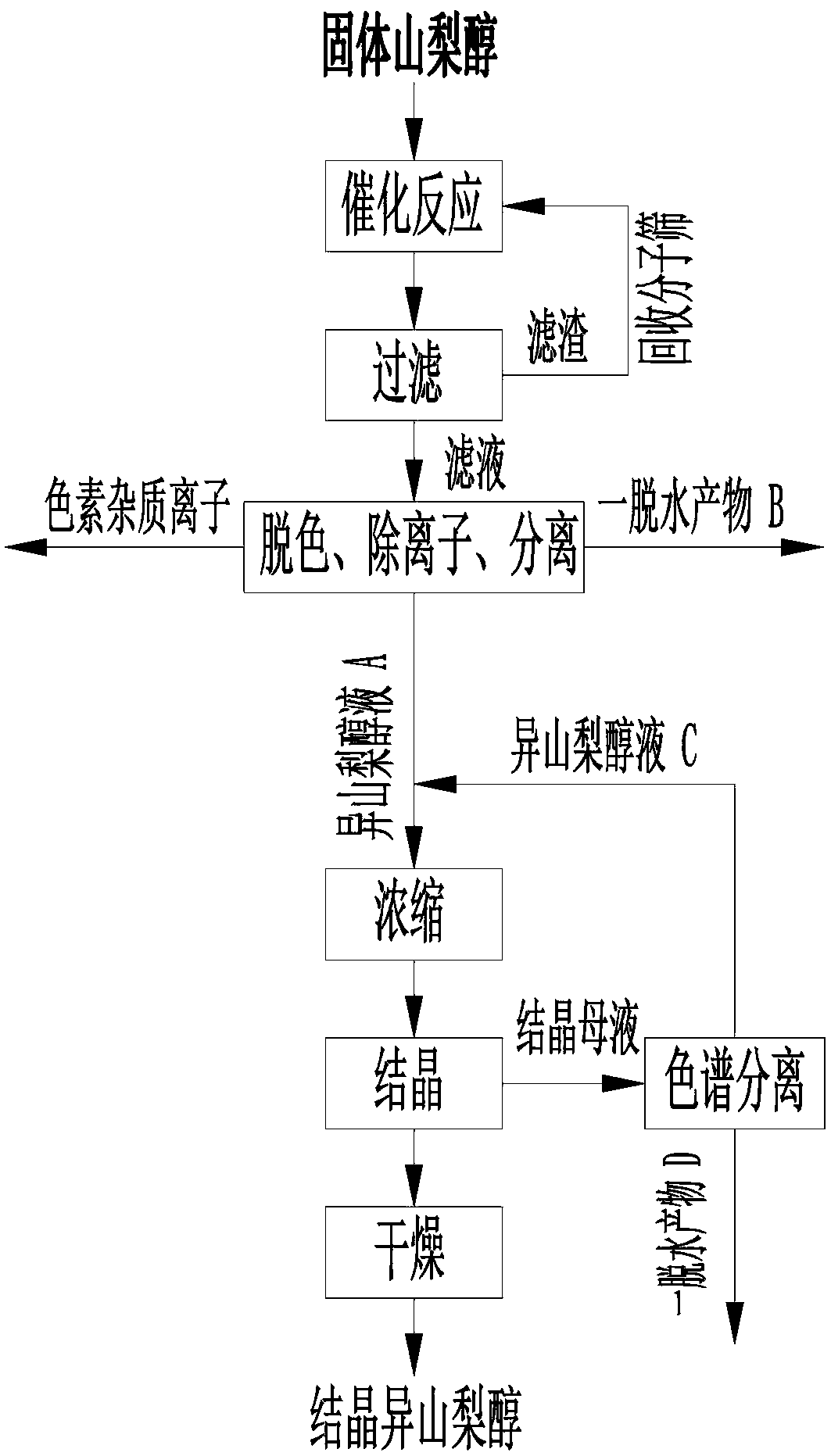

A kind of preparation method of crystalline isosorbide

A technology for isosorbide and sorbitol, applied in the field of preparation of crystalline isosorbide, can solve the problems of high production cost, high pollution and high energy consumption, and achieve the effects of reducing equipment investment and operating costs and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Using solid sorbitol as a raw material and solid acidic molecular sieve as a catalyst, catalyze the reaction for 4 hours at a pressure of -0.02 to -0.06 MPa, a temperature of 180°C, and a molten state to obtain a reaction liquid.

[0046] The catalytic reaction is carried out in a molten state. After the reaction is completed, pure water is added to dilute the reaction solution until the mass percentage concentration is 50-55% to obtain a diluted solution. At this time, the diluted solution has better fluidity.

[0047] The diluted solution was filtered, and the filtrate and filter residue were collected. The filter residue is the molecular sieve used in the reaction, which is recycled. Molecular sieves can be reused 5-8 times.

Embodiment 2

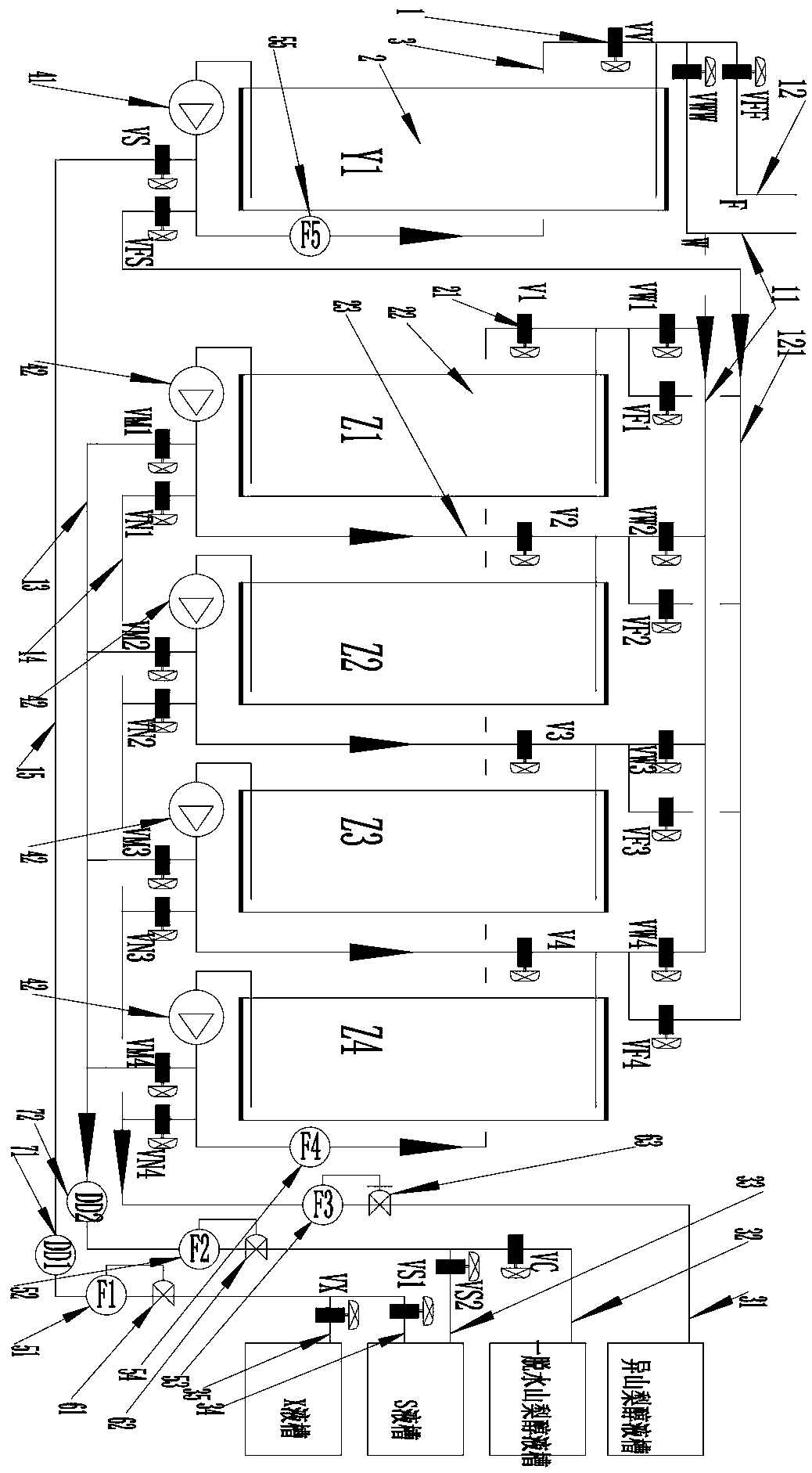

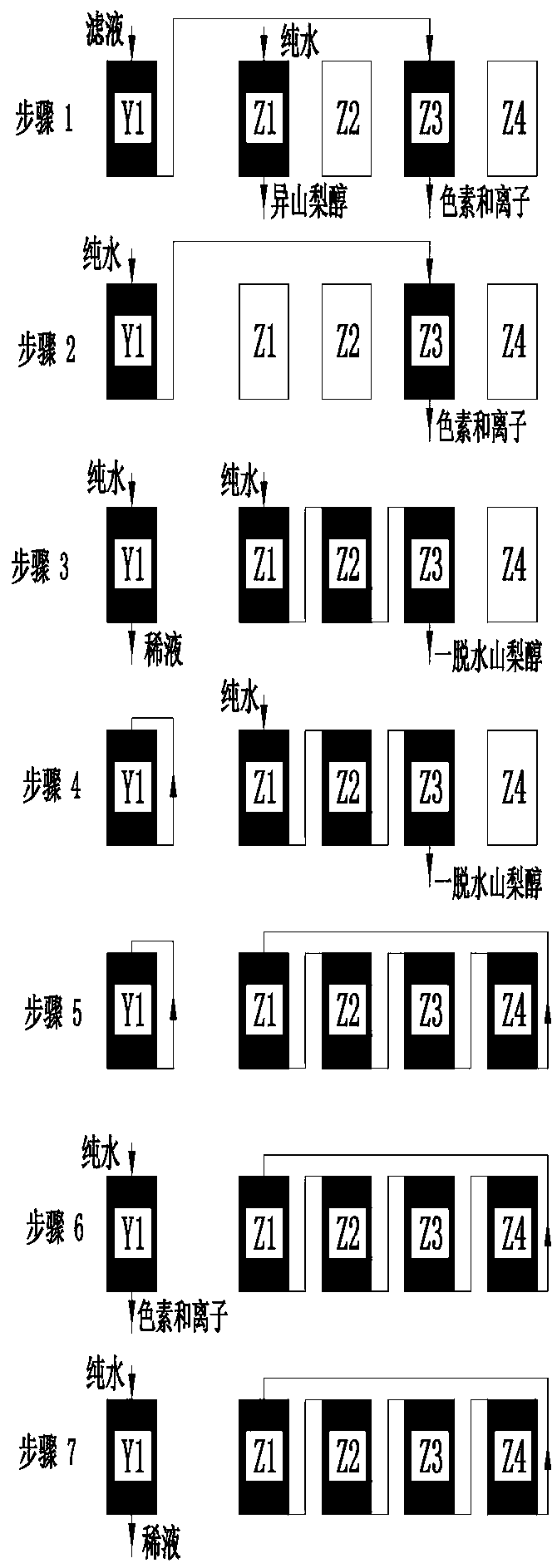

[0049] The filtrate is decolorized, deionized and separated with a decolorization, deionization and separation mixture device. The decolorization, deionization and separation mixture device consists of the first group of chromatographic systems and the second group of chromatographic systems:

[0050] (1) The first group of chromatographic systems is composed of 1 chromatographic column, and the outlet of chromatographic column 2 and the inlet are connected by booster pump 41, isolation valve 1, connecting pipe 3 and flowmeter 4 54; Described chromatographic column-2 inlet is connected with eluent valve-VWW, material valve-VFF; Described eluent valve-VWW and material valve-VFF are connected with eluent main pipe 11 and material main pipe 12 respectively; Described chromatographic column Outlet 1 is connected with impurity valve VS and feed valve VFS; the feed valve VFS is connected to the feed pipe 121, and then connected to the feed valves VF1~VFn of the second group of chrom...

Embodiment 3

[0065] The isosorbide solution A is concentrated to a percentage concentration of 80-85% to obtain a concentrated solution.

[0066] The concentrated solution is naturally cooled and crystallized, the cooling rate is 1~5°C / h, the amount of seed crystals added is 1%, stirred, cooled to 20~25°C, left standing for 8 hours, then dehydrated and dried to obtain crystalline isosorbide The product has a purity of 98.0-99.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com