A kind of industrial advanced treatment method of vitamin C wastewater

An advanced treatment and vitamin technology, applied in the field of environmental engineering, can solve the problems of poor conversion efficiency, low actual treatment rate, low feasibility of industrialized operation, etc., and achieve the effect of preventing automatic decomposition and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

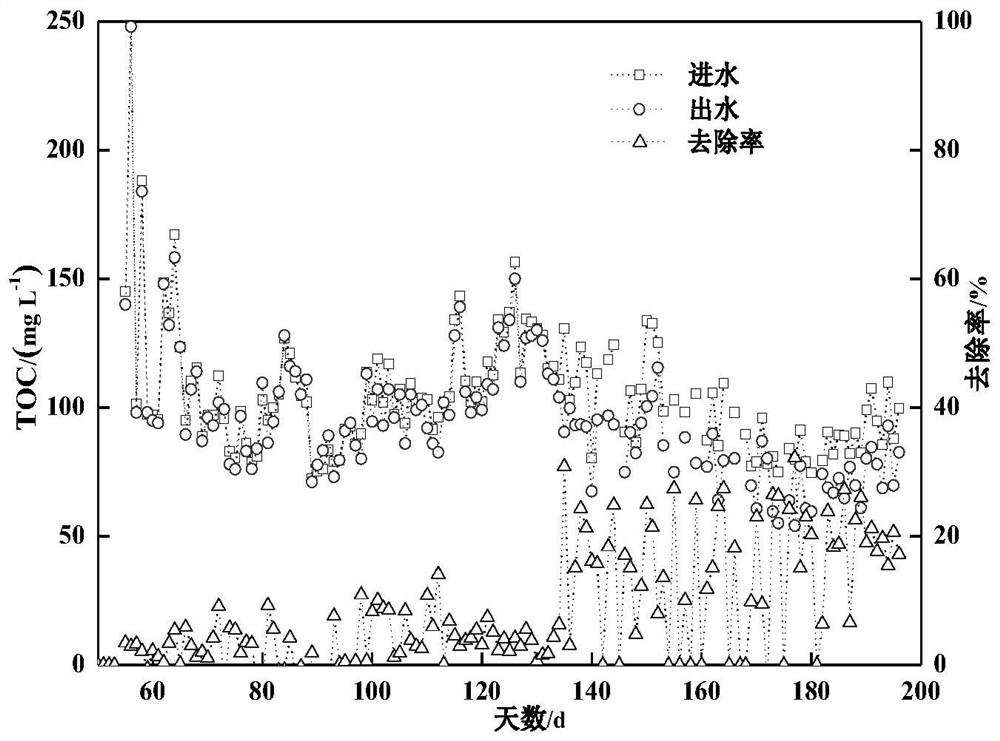

Embodiment 1

[0032] The effluent of the secondary sedimentation tank from the wastewater treatment facility of a vitamin C production enterprise in Hebei was selected as the treatment object. A method for industrialized advanced treatment of vitamin C wastewater, comprising the following steps:

[0033] (1) Wastewater pretreatment: pump the wastewater into the filter device through the submersible pump, after filtering to remove the suspended matter in the water, adjust the pH=3, use the ozone machine to pass ozone into the filtered wastewater, and the ozone flow rate is 1.2m 3 / h, the time is 10min, and in the waste water after filtering, add the ozone slow-release carrier in 3 times, the total dosage of the ozone slow-release carrier is 4g / L, wherein, before the ozone is first passed into the After 3 minutes of the filtered waste water, the ozone slow-release carrier is dropped into in batches while the ozone is introduced, and it is continuously stirred until the ozone is introduced, an...

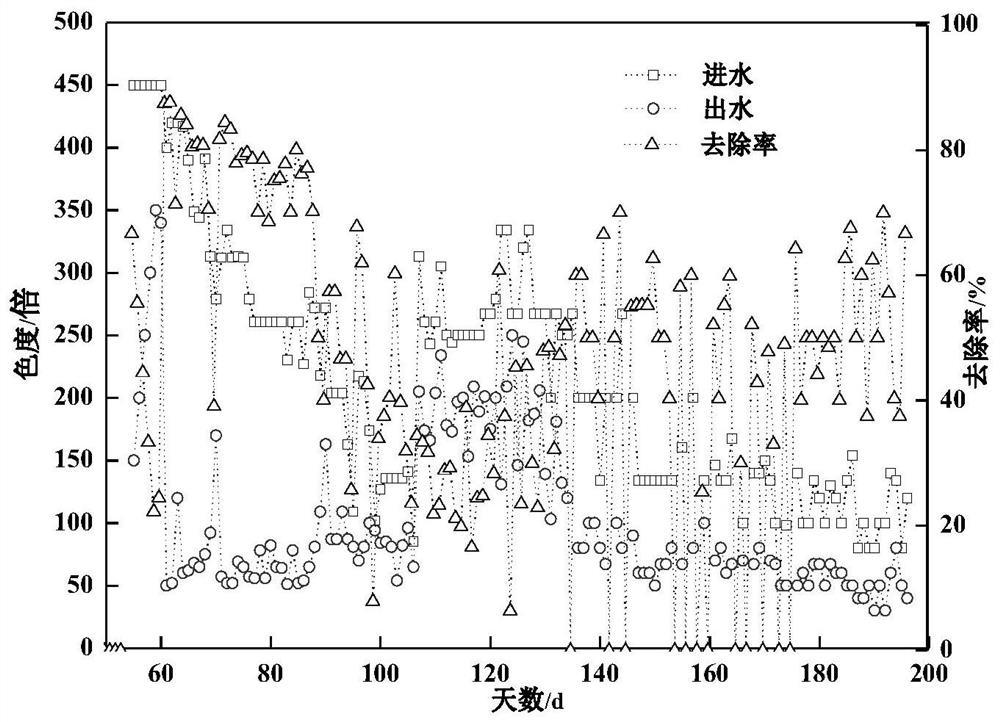

Embodiment 2

[0047] The effluent from the secondary sedimentation tank of a waste water treatment facility of a vitamin C production enterprise in Hebei is selected as the treatment object, and an industrial advanced treatment method for vitamin C waste water includes the following steps:

[0048] (1) Wastewater pretreatment: pump the wastewater into the filter device through the submersible pump, after filtering to remove the suspended matter in the water, adjust the pH=4, use the ozone machine to pass ozone into the filtered wastewater, and the ozone flow rate is 1.7m 3 / h, the time is 15min, and in the waste water after filtering, add the ozone slow-release carrier in 4 equal amounts, the total dosage of the ozone slow-release carrier is 5g / L, wherein, before the ozone is first passed into the After 4 minutes of the filtered waste water, the ozone slow-release carrier is dropped into in batches while the ozone is introduced, and it is constantly stirred until the ozone is introduced, and...

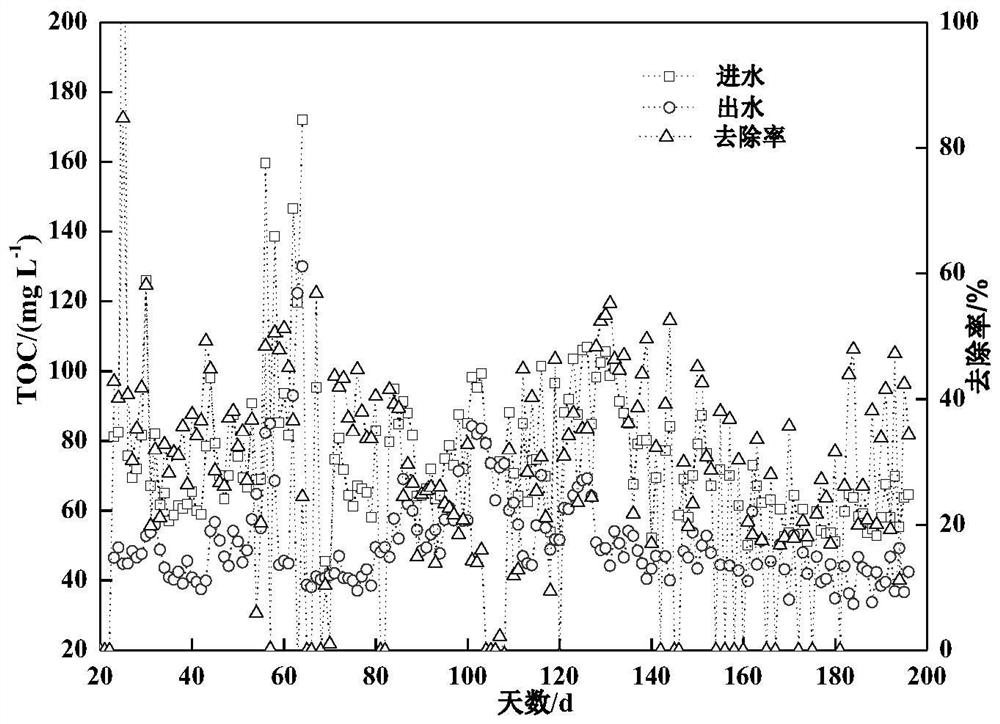

Embodiment 3

[0062] The effluent from the secondary sedimentation tank of a waste water treatment facility of a vitamin C production enterprise in Hebei is selected as the treatment object, and an industrial advanced treatment method for vitamin C waste water includes the following steps:

[0063] (6) Wastewater pretreatment: pump the wastewater into the filter device through the submersible pump, after filtering to remove the suspended matter in the water, adjust the pH=6, use the ozone machine to pass ozone into the filtered wastewater, and the ozone flow rate is 2.0m 3 / h, the time is 20min, and in the waste water after filtering, add the ozone slow-release carrier in 5 times, the total dosage of the ozone slow-release carrier is 6g / L, wherein, before the ozone is passed into the After 5 minutes of the filtered waste water, the ozone slow-release carrier is dropped into in batches while the ozone is introduced, and it is constantly stirred until the ozone is introduced, and the ozone is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com