A kind of preparation method of the functional fiber material used for aqueous phase dye decolorization

A technology of fiber materials and functional fibers, applied in the field of preparation of functional fiber materials, to achieve good application prospects, easy reuse, and high decolorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

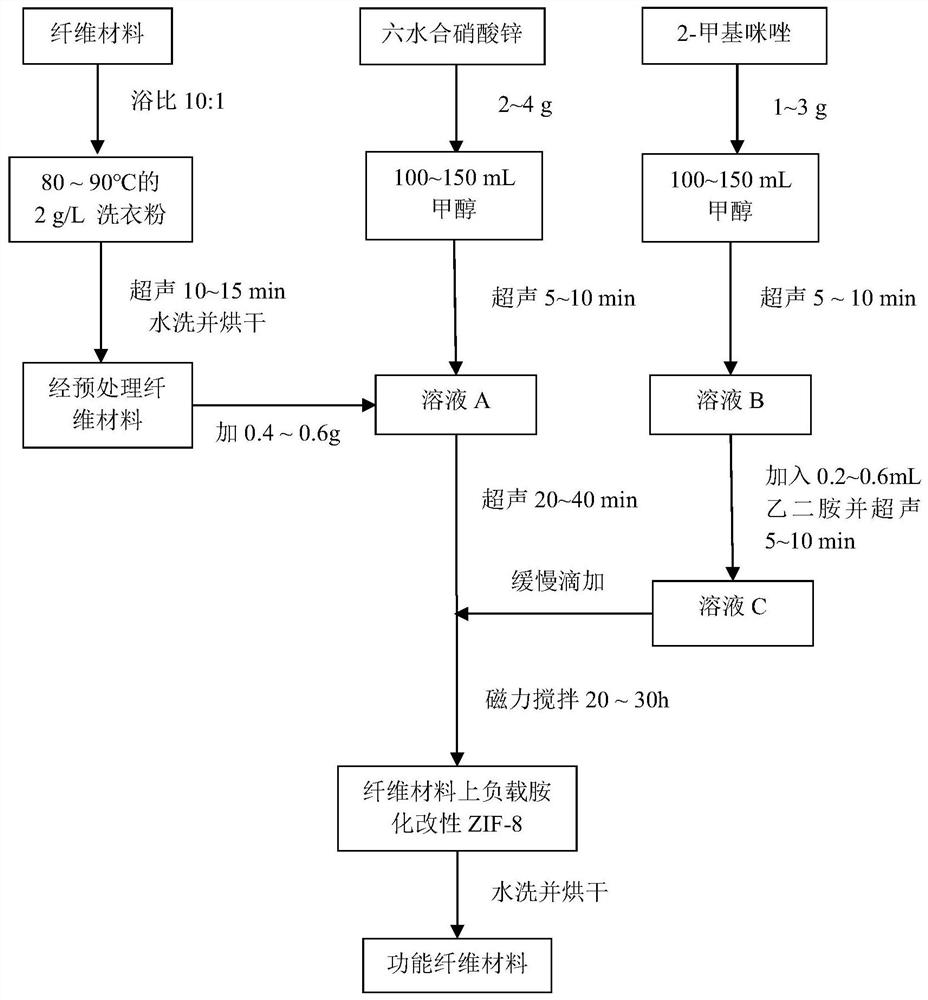

[0025] see figure 1 , the present invention provides a technical solution: a method for preparing a functional fiber material for aqueous dye decolorization, comprising the following steps:

[0026] A. Fiber material pretreatment: the fiber material is subjected to impurity removal pretreatment;

[0027] B. In-situ growth of amination-modified ZIF-8 on the fiber: load the amination-modified ZIF-8 on the pretreated fiber by in-situ growth method, wash with water, and dry to prepare a functional fiber material .

[0028] Specifically, the fiber material is ultrasonically treated at 80-90° C. for 10-15 minutes with 2 g / L washing powder at a bath ratio of 10:1, and the fiber material is pretreated for impurity removal, washed with water, and then dried.

[0029] Weigh 2-4g zinc nitrate hexahydrate and add it to 100-150mL methanol, sonicate for 5-10min, record it as solution A, weigh 1-3g 2-methylimidazole and add it to 100-150mL methanol, sonicate for 5-10min, Denote it as solu...

Embodiment 1

[0030] Example 1, the viscose woven fabric was ultrasonically treated at 90° C. for 15 minutes with 2 g / L washing powder at a bath ratio of 10:1, washed with water and then dried.

[0031] In situ growth of aminated ZIF-8 on the fabric, weigh 2.97g of zinc nitrate hexahydrate and add it to 100mL of methanol, sonicate for 5min, record it as solution A, weigh 1.64g of 2-methylimidazole and add it to 100mL of methanol , sonicated for 5 minutes, and recorded as solution B, 0.2 mL of ethylenediamine was dropped into solution B, ultrasonicated for 5 minutes, and recorded as solution C; 0.4 g of pretreated viscose fabric was immersed in solution A, ultrasonicated for 20 minutes, Under certain conditions, solution C was slowly added dropwise to solution A soaked in the fabric, and reacted at room temperature for 20 hours. After the reaction, the viscose fabric was taken out, washed with water, and dried.

[0032] In order to investigate the decolorization effect of the prepared functi...

Embodiment 2

[0033] Example 2, the viscose woven fabric was ultrasonically treated at 90° C. for 15 minutes with 2 g / L washing powder at a bath ratio of 10:1, washed with water and then dried.

[0034] In situ growth of aminated ZIF-8 on viscose woven fabrics, weigh 2.97g of zinc nitrate hexahydrate and add it to 100mL of methanol, ultrasonic for 5min, record it as solution A, weigh 2.05g of 2-methylimidazole and add it to In 100mL of methanol, sonicate for 5min, and record it as solution B; drop 0.3mL of ethylenediamine into solution B, and sonicate for 10min, and record it as solution C; immerse 0.5g of pretreated viscose fabric in solution A, and sonicate for 30min, Under the condition of magnetic stirring, the solution C was slowly added dropwise to the solution A soaked in the fabric, and reacted at room temperature for 25 hours. After the reaction, the viscose fabric was taken out, washed with water, and dried.

[0035] In order to investigate the decolorization effect of the prepare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com