Novel process for comprehensively utilizing agricultural wastes

A residue and new process technology, applied in the new process field of comprehensive utilization of agricultural residues, can solve the problems of complex operation process, increased cost input, poor dehydration effect, etc., achieve high purity, reduce production and maintenance costs, and save energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

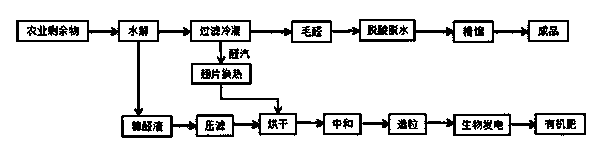

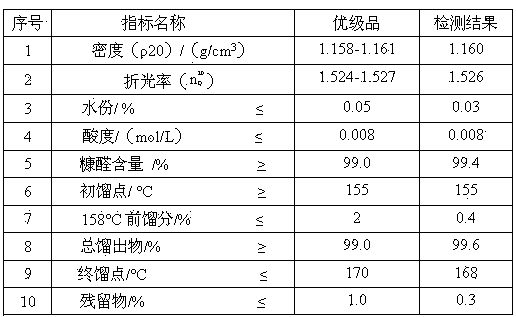

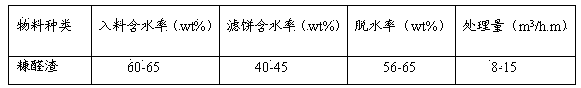

[0032] Such as figure 1 As shown, the new technology for comprehensive utilization of agricultural residues: the agricultural residues (corn cob + straw) are hydrolyzed with acid to obtain aldehyde vapor and furfural residue. The furfural residue is filtered through a belt filter to initially reduce the moisture content of the furfural residue to 40wt%, and then sent to the rotary dryer for further drying and dehydration. When the moisture content of the furfural residue drops to 15wt%, fly ash accounting for 10wt% of the furfural residue mass is added for neutralization, and after neutralization, it is pelletized by briquetting Biomass fuel is produced. After the biomass fuel is burned, it is used for biomass power generation. At the same time, the solid waste generated after the combustion is used as the raw material of organic fertilizer to realize the reuse; after the aldehyde vapor is filtered and condensed, the liquid obtained by condensation is the hair aldehyde. The ald...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com