Antistatic agent for polyester fabric

An antistatic agent, polyester fabric technology, applied in the field of antistatic agent, to achieve the effect of reducing friction coefficient, reducing usage and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

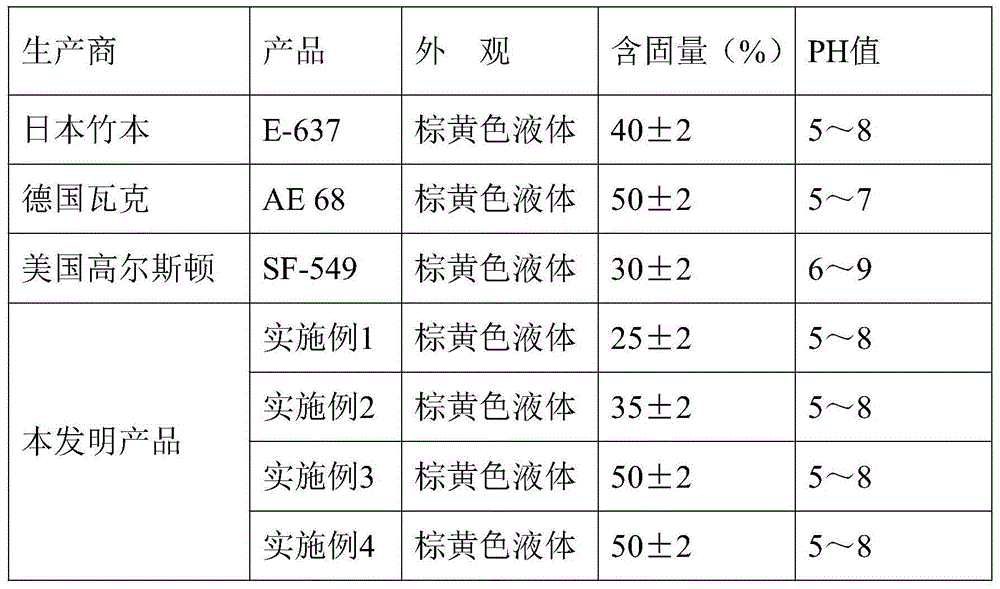

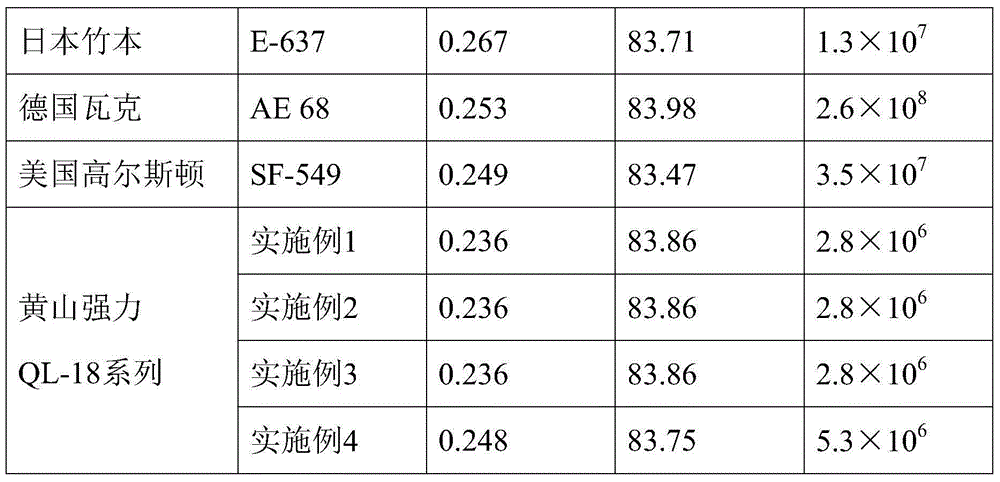

Examples

Embodiment 1

[0033] Embodiment 1, a kind of novel environment-friendly antistatic agent for polyester fabric

[0034] According to parts by weight, it is compounded from the following components:

[0035] Octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate (referred to as antistatic agent SN) 600g

[0036] Dihydrogen phosphate salt of octadecylamine ethyl dimethyl-β-hydroxylamine (referred to as antistatic agent SP) 200g

[0037] Trihydroxyethylmethylamine methyl sulfate salt (referred to as antistatic agent TM) 100g

[0038] Dodecyltrimethylammonium bromide 100g

[0039] Tween-80200g

Embodiment 2

[0040] Embodiment 2, a kind of novel environment-friendly antistatic agent for polyester fabric

[0041] According to parts by weight, it is compounded from the following components:

[0042] Octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate (referred to as antistatic agent SN) 1000g

[0043] Dihydrogen phosphate salt of octadecylamine ethyl dimethyl-β-hydroxylamine (referred to as antistatic agent SP) 600g

[0044] Trihydroxyethylmethylamine methyl sulfate salt (referred to as antistatic agent TM) 400g

[0045] Dodecyltrimethylammonium bromide 100g

[0046] Tween-80200g

Embodiment 3

[0047] Embodiment 3, a kind of novel environment-friendly antistatic agent for polyester fabric

[0048] According to parts by weight, it is compounded from the following components:

[0049] Octadecyl dimethyl hydroxyethyl quaternary ammonium nitrate (referred to as antistatic agent SN) 1000g

[0050] Dihydrogen Phosphate Salt of Octadecylamine Ethyl Dimethyl-β-Hydroxylamine (referred to as antistatic agent SP) 400g

[0051] Trihydroxyethylmethylamine methyl sulfate salt (referred to as antistatic agent TM) 400g

[0052] Dodecyltrimethylammonium bromide 200g

[0053] Tween-80400g

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com