Patents

Literature

57results about How to "Small coefficient of static friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

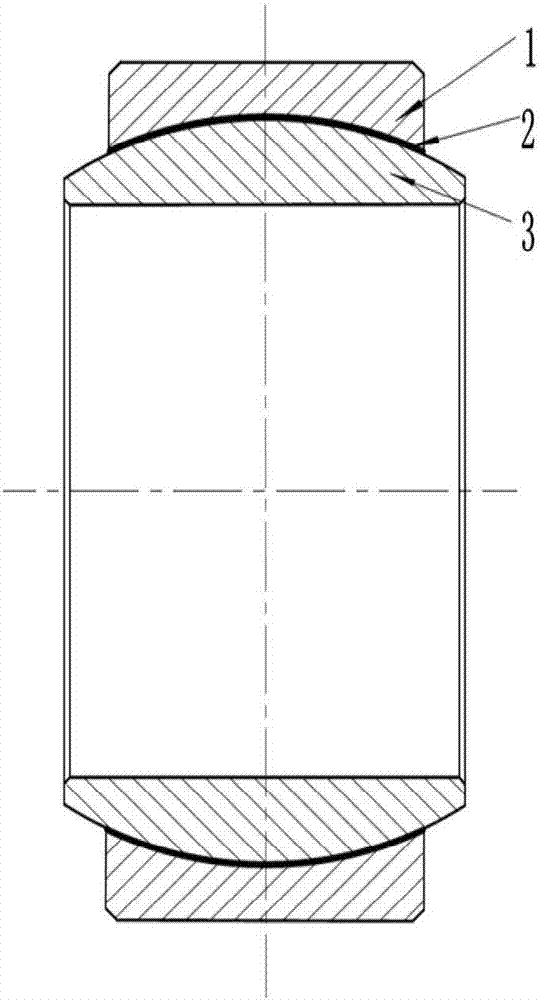

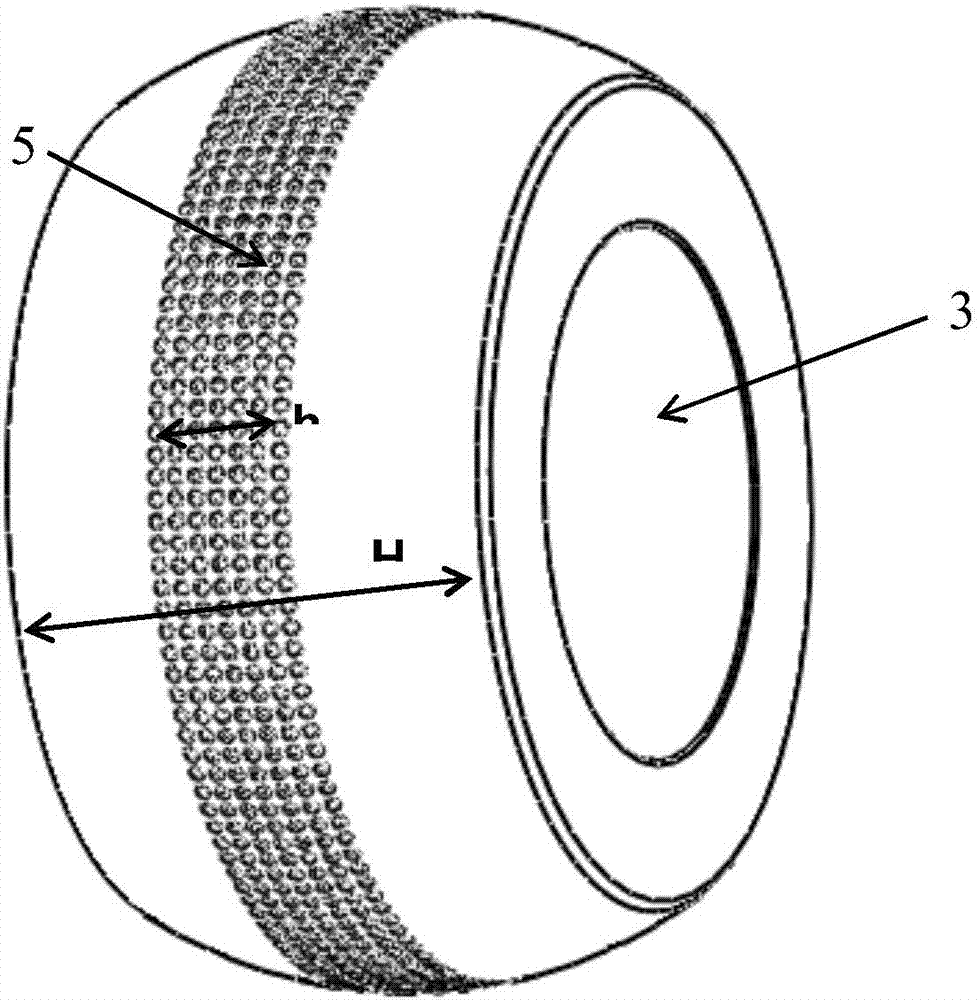

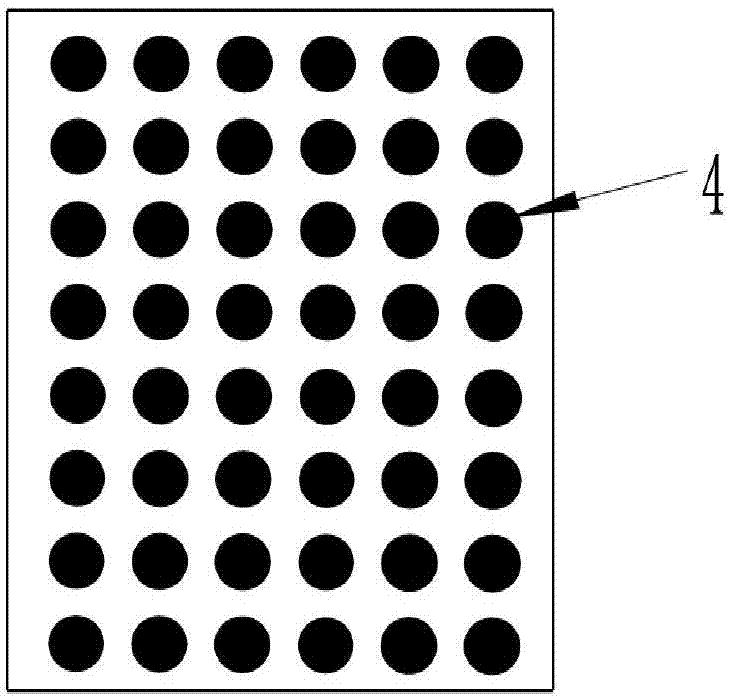

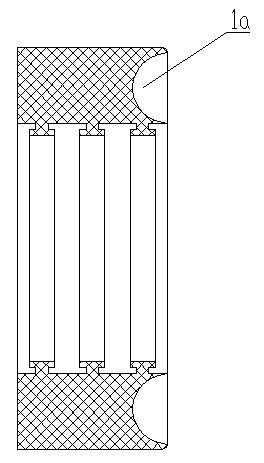

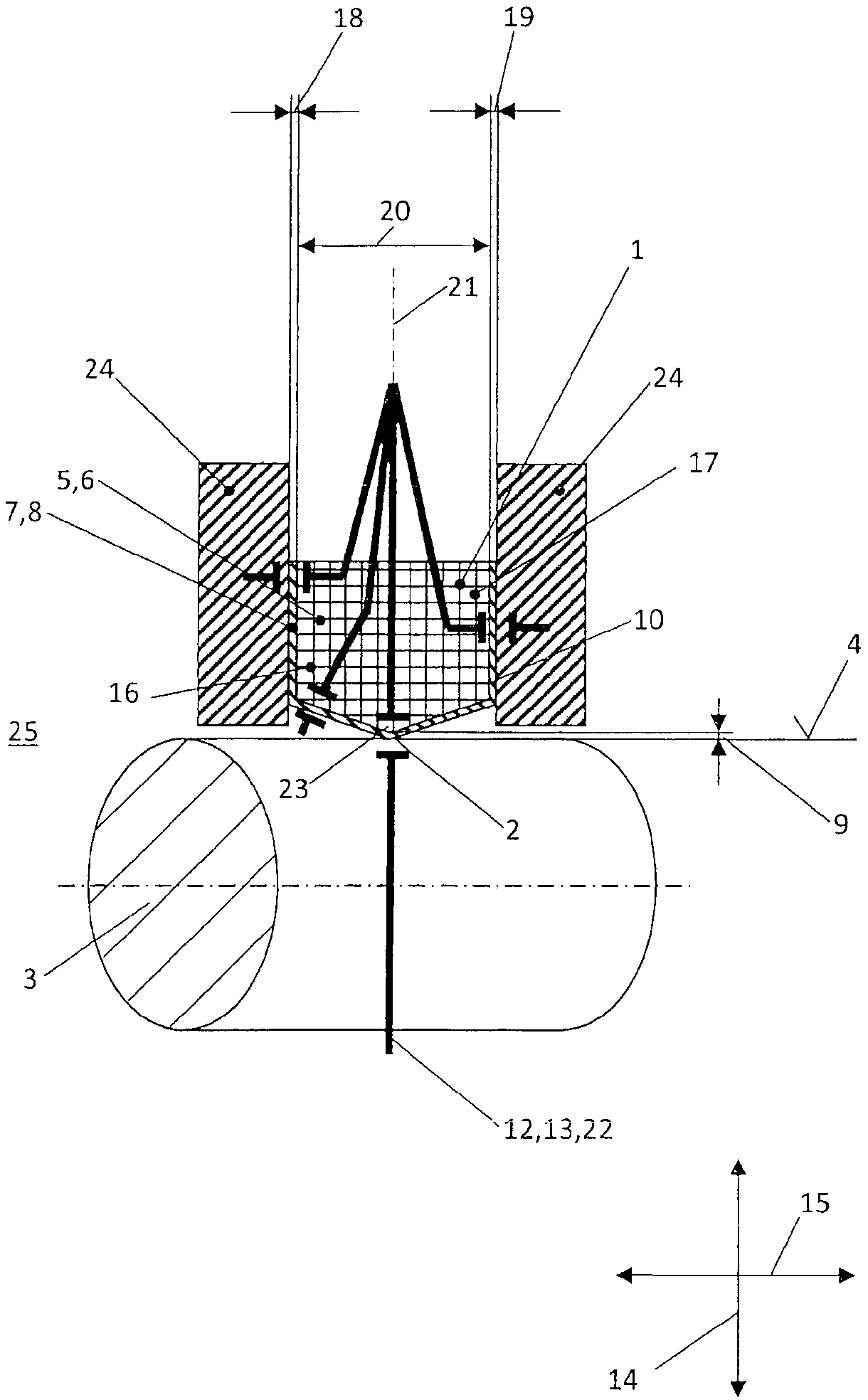

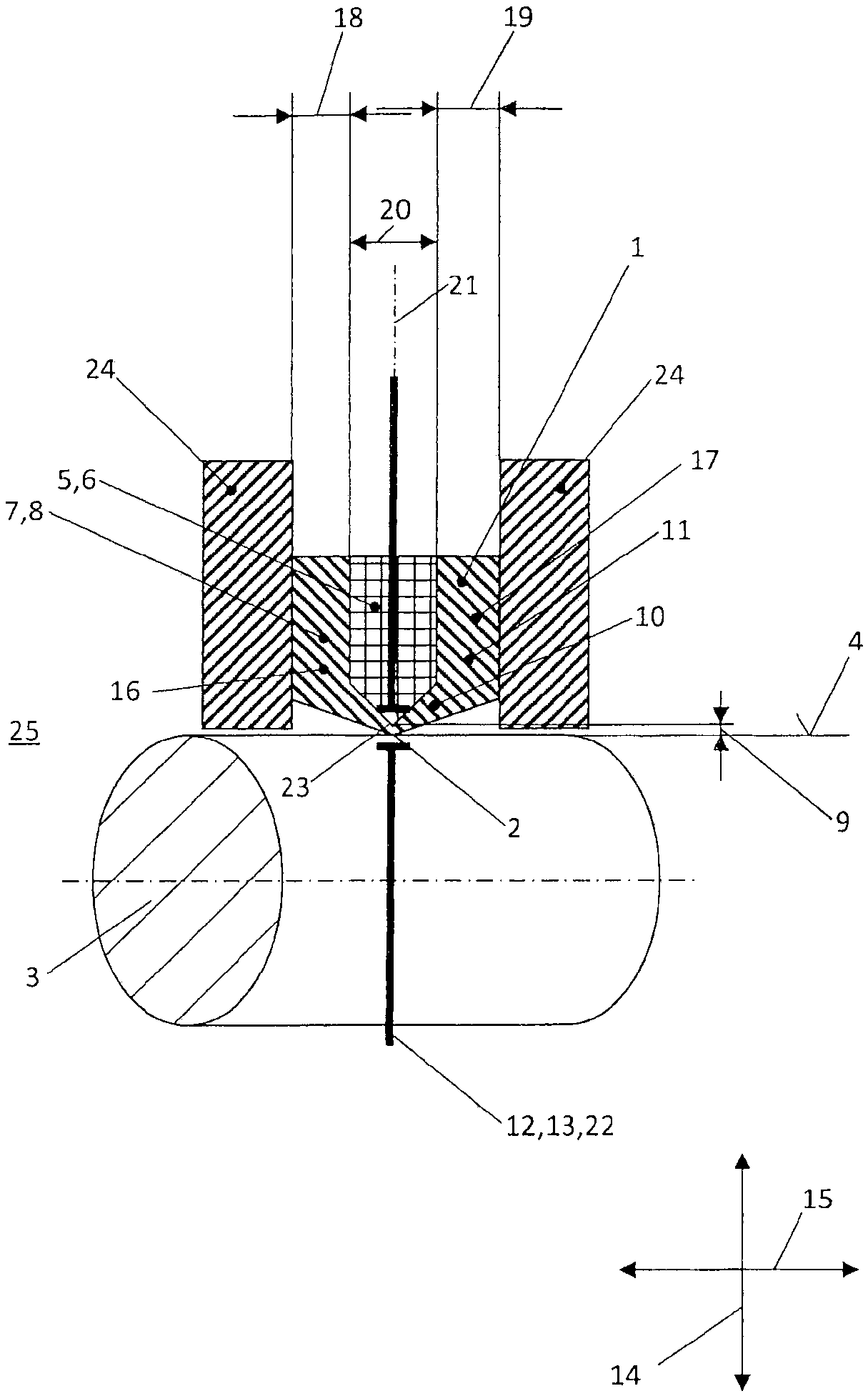

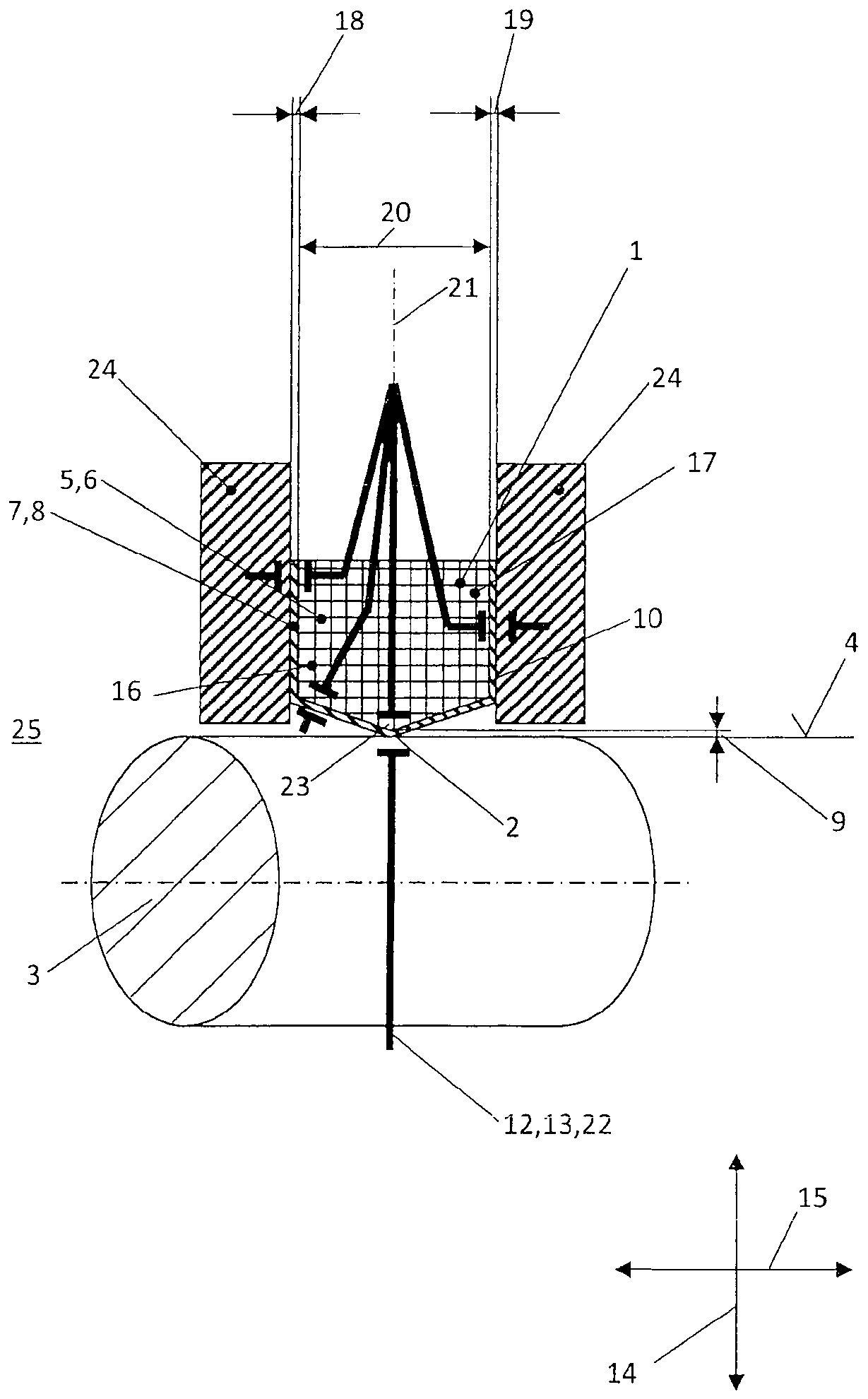

Fabric type surface texture friction pre-filling type self-lubricating knuckle bearing

ActiveCN107387553AExtended service lifePromote generationShaftsBearing componentsStatic friction coefficientEngineering

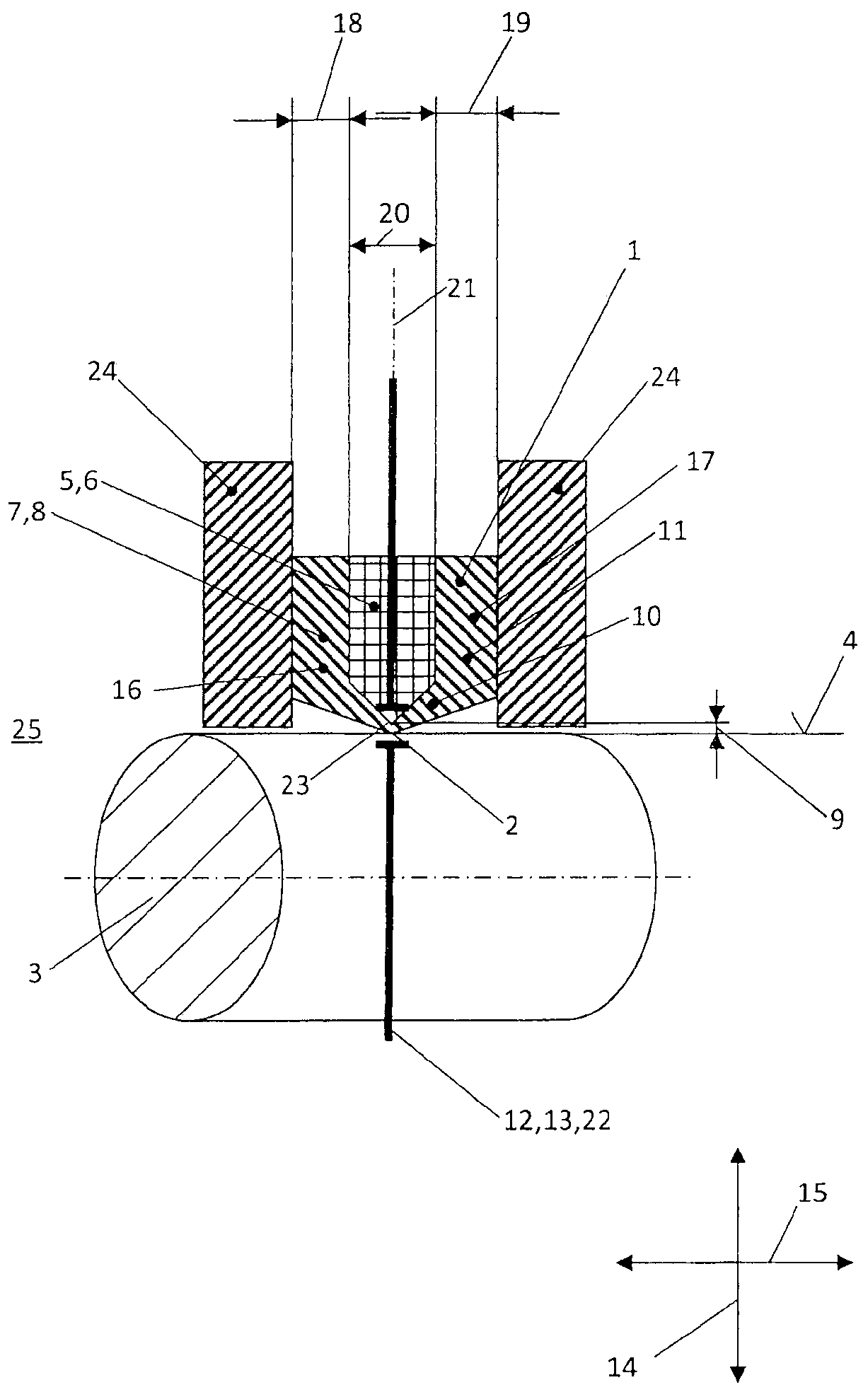

The invention discloses a fabric type surface texture friction pre-filling type self-lubricating knuckle bearing. The fabric type surface texture friction pre-filling type self-lubricating knuckle bearing comprises an inner ring and an outer ring; a surface texture is machined on the outer sphere face of the bearing inner ring (3) and subjected to self-lubricating material friction pre-filling technology treatment to form a self-lubricating material friction pre-filling surface texture structure; and a layer of fabric self-lubricating material liner is pasted on the surface of the inner sphere face of the bearing outer ring (1). Abrasion to the fabric liner by the edge of the surface texture in the initial stage of friction is avoided to a certain degree, the surface texture is easily full of self-lubricating materials in a friction mode, and the process is simple. The self-lubricating materials pre-filling the textured surface optimize the friction interface material configuration, so that a friction surface transfer membrane is easy to generate, the texture edge cutting effect is weakened to a certain degree, the friction interface has lower static friction coefficient and lower dynamic friction coefficient, and accordingly the service life of the self-lubricating knuckle bearing is greatly prolonged.

Owner:YANSHAN UNIV

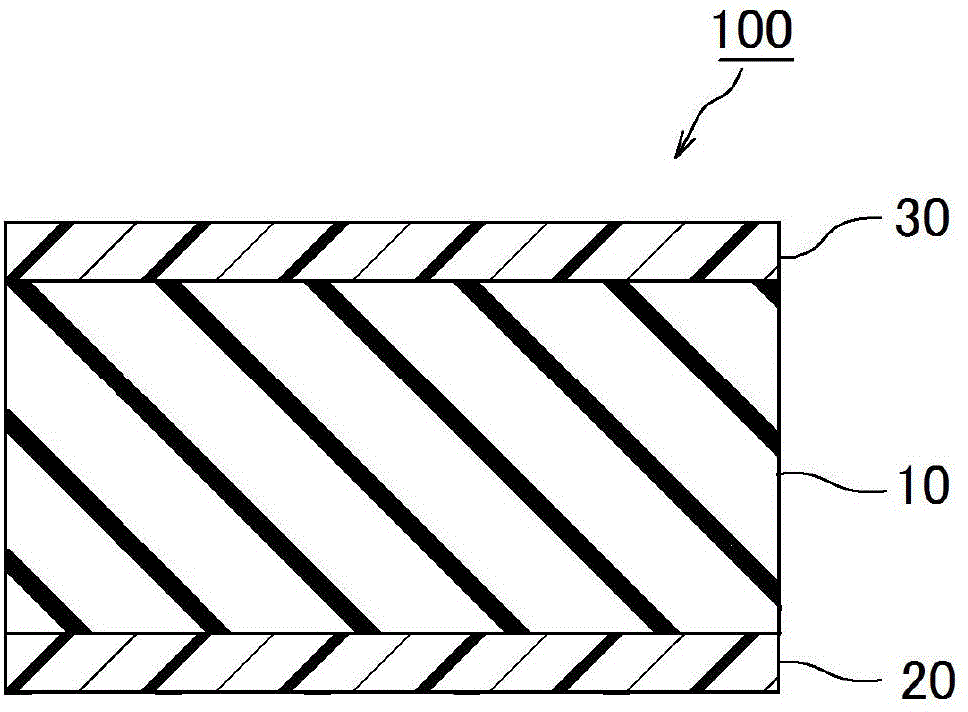

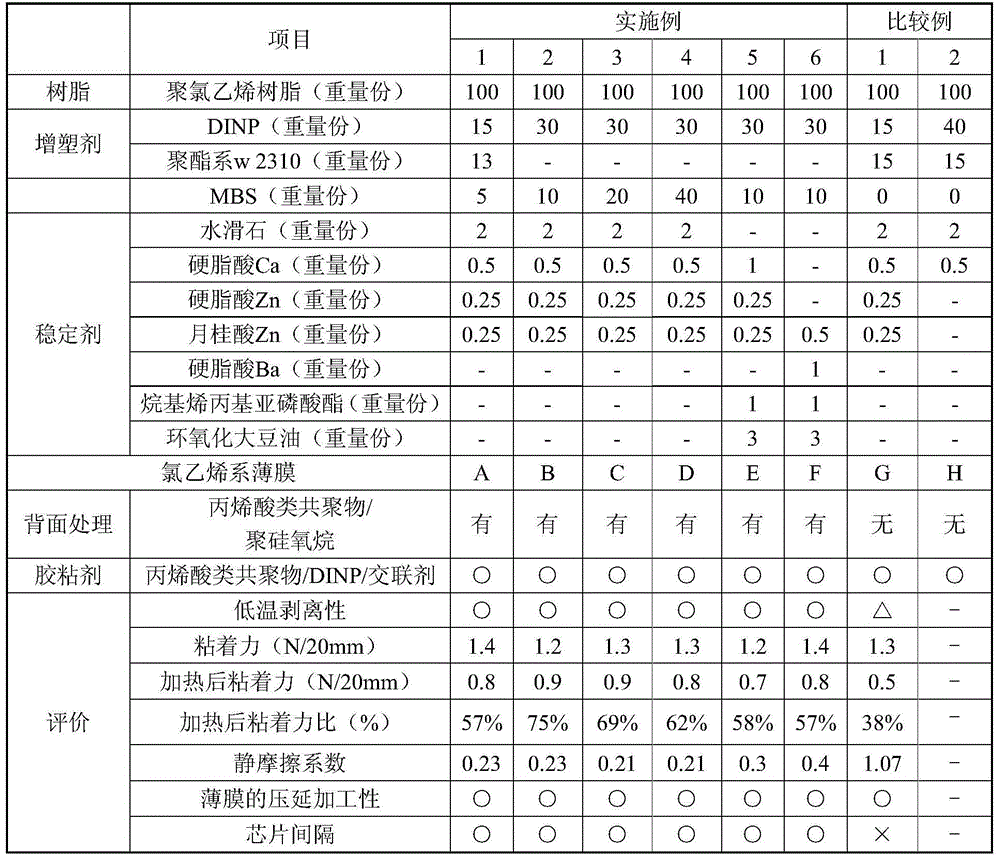

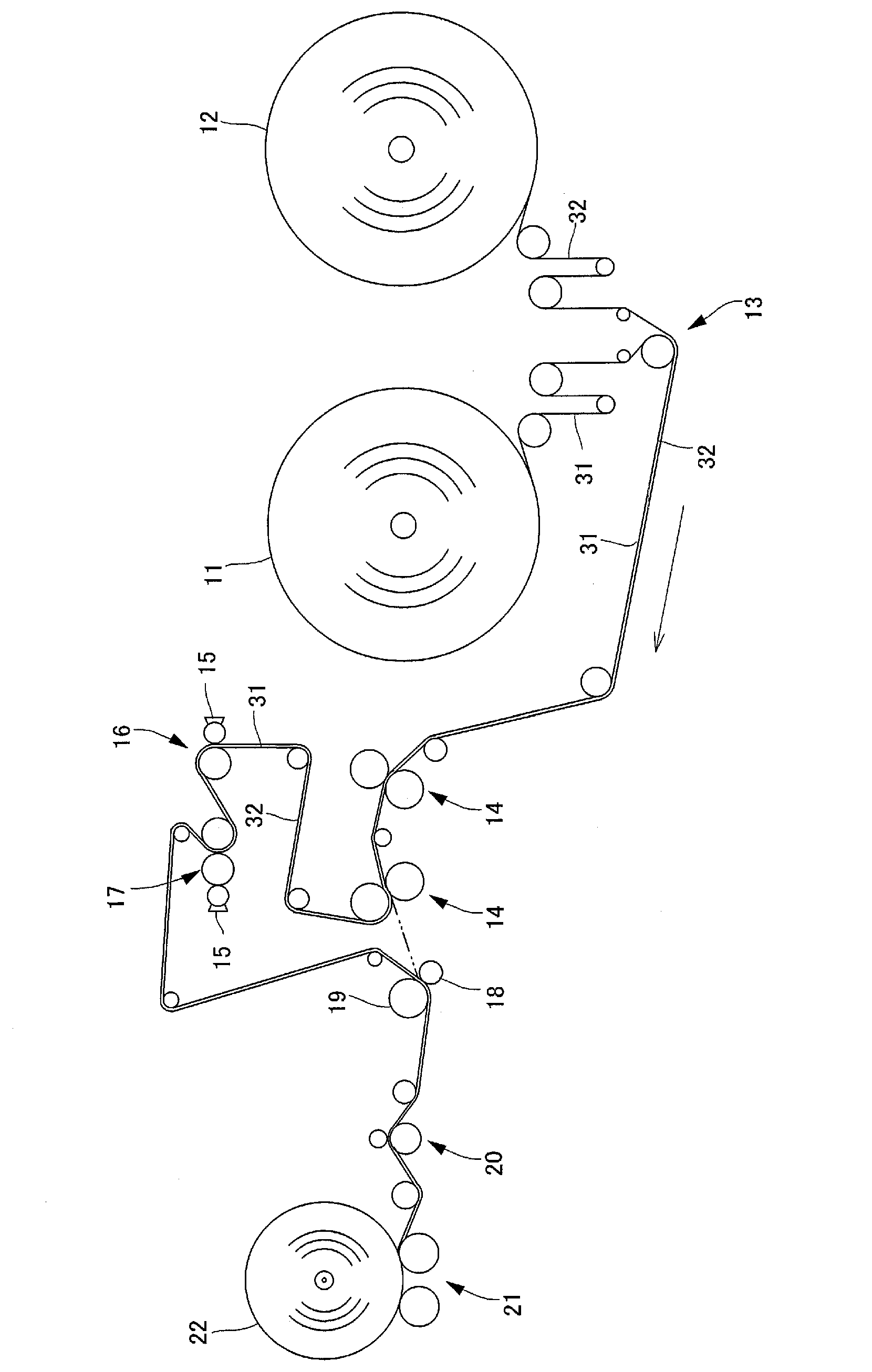

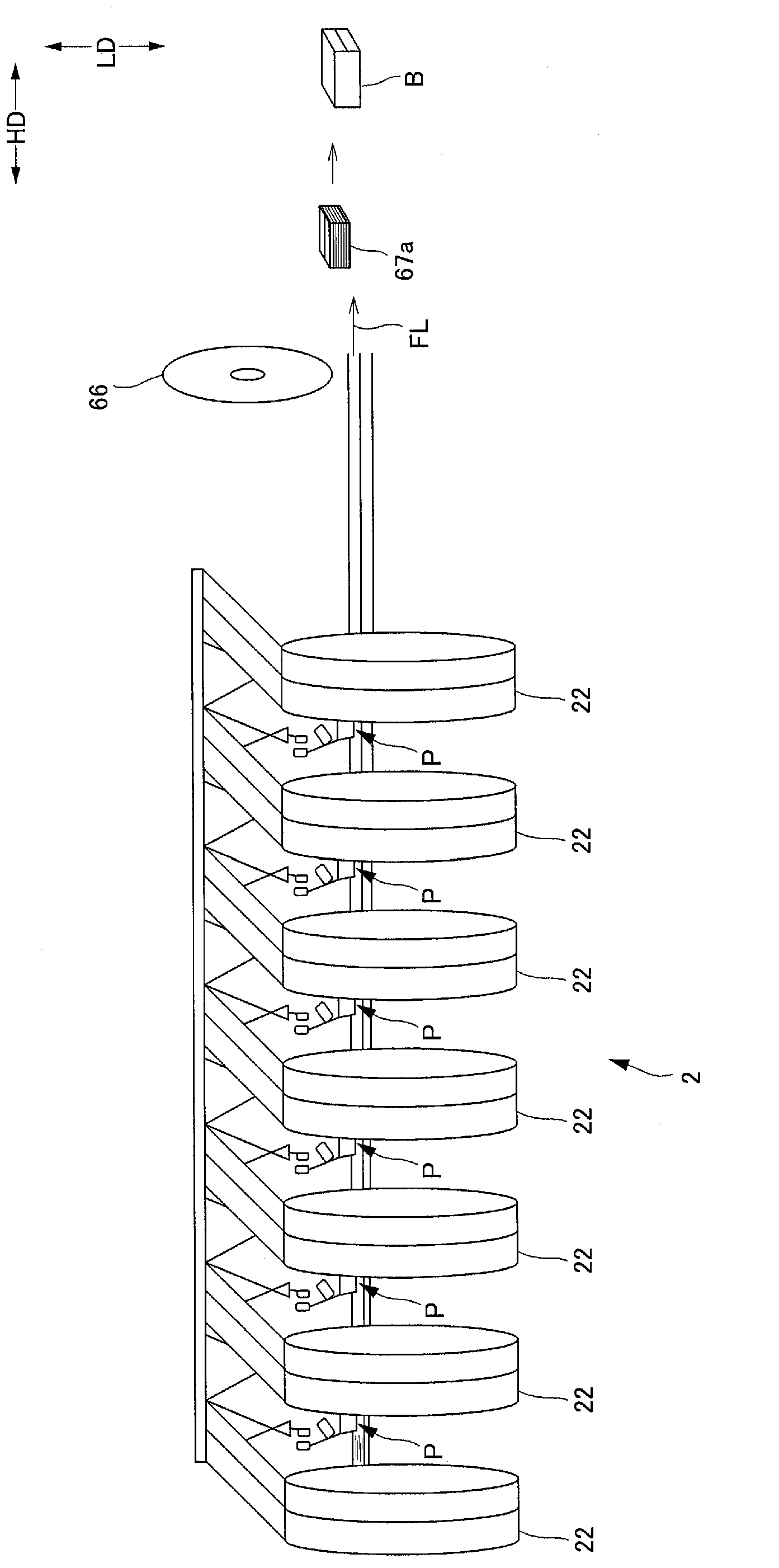

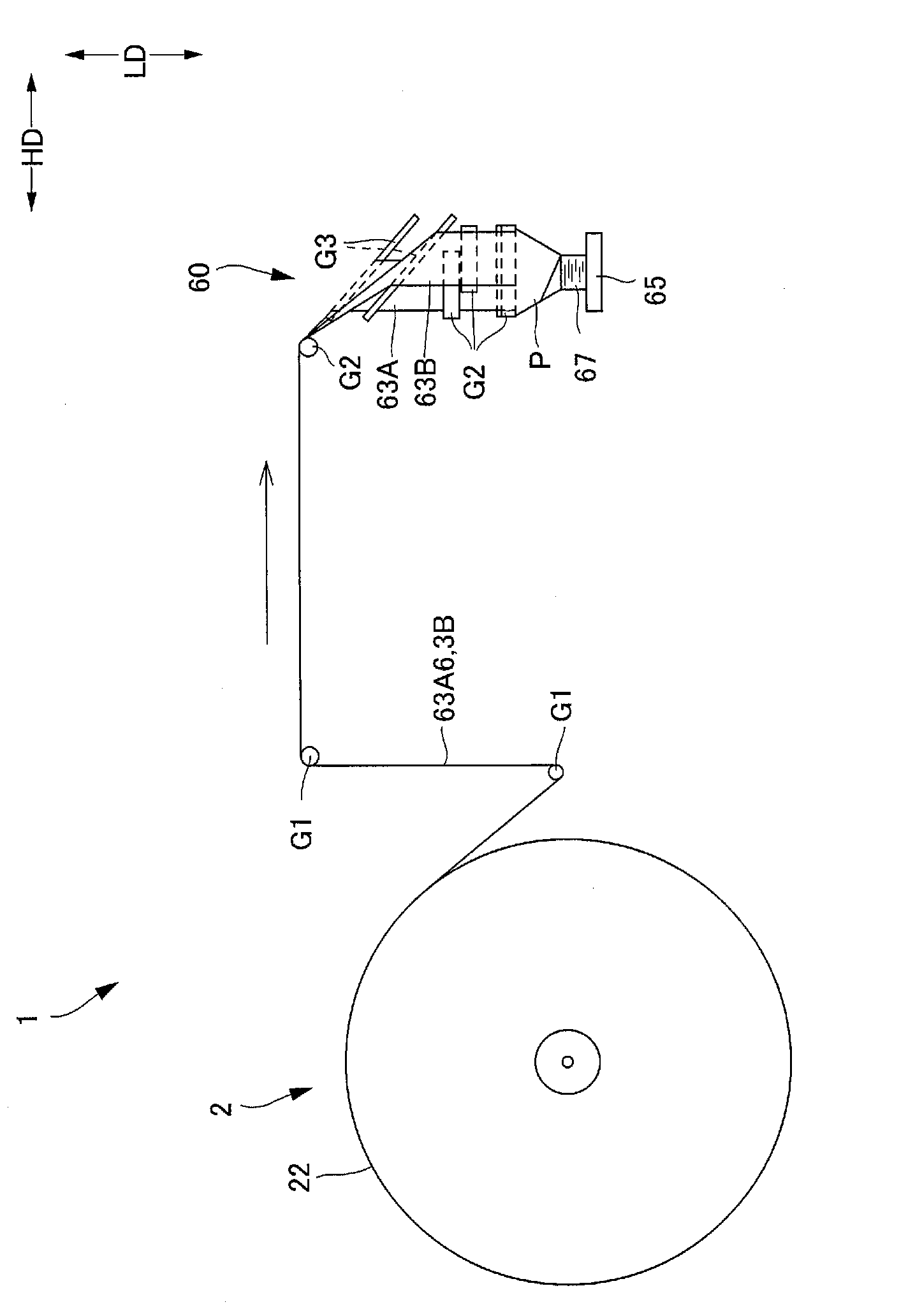

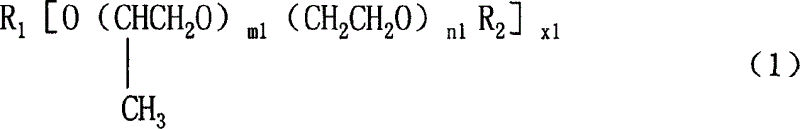

Vinyl chloride series adhesive sheet and adhesive tape

ActiveCN104130724APrevents deterioration of adhesive propertiesSmall coefficient of static frictionFilm/foil adhesivesMethacrylateStatic friction coefficient

The invention provides a vinyl chloride series adhesive sheet and an adhesive tape, which are little influenced by the temperature of a service environment and are prepared by using vinyl chloride series film as a substrate. With the exudation of a non-lead series stabilizing agent and a plasticizer, adhesive performance of the vinyl chloride series adhesive sheet and the adhesive tape is reduced little. The vinyl chloride series adhesive sheet and the adhesive tape are characterized in that one surface of the substrate has an adhesive layer; one surface of the substrate, opposite to the surface with the adhesive layer, has a back processing layer which is a mixed layer of polysiloxane and a (methyl) acrylic polymer; the mass ratio of polysiloxane to the (methyl) acrylic polymer is 1:5-5:1; the substrate contains PVC resin, a copolymer of metacrylic acid ester, styrene and butadiene, a stabilizing agent and a plasticizer; the adhesive layer is a (methyl)acrylic polymer; and in the vinyl chloride series adhesive sheet and the adhesive tape, static friction coefficient of the back processing layer is 0.05-1.0.

Owner:NITTO DENKO SHANGHAI SONGJIANG

Tissue paper and tissue paper products

The invention provides tissue paper having equal or better smoothness and moist feeling than conventional moist tissue paper, and which is less sticky and does not tear as easily when used. To also provide a tissue paper product that does not tear easily when being pulled out. [Solution] With respect to a two-ply chemical solution-applied tissue paper, the chemical solution is applied such that the amount of the chemical solution contained in both surfaces is 1.5 to 5.5 g / m2, and the basis weight per layer of the sheets that constitute the two-ply paper is 10 to 25 g / m2 and the thickness of the two-ply paper is 100 to 140 [mu]m. The web bulk is 0.28 to 0.40 mm per pair and the length of the slit section of the opening in the storage box for pulling out the tissue is 45 to 65% of the length of the web in the longitudinal direction.

Owner:DAIO PAPER CORP

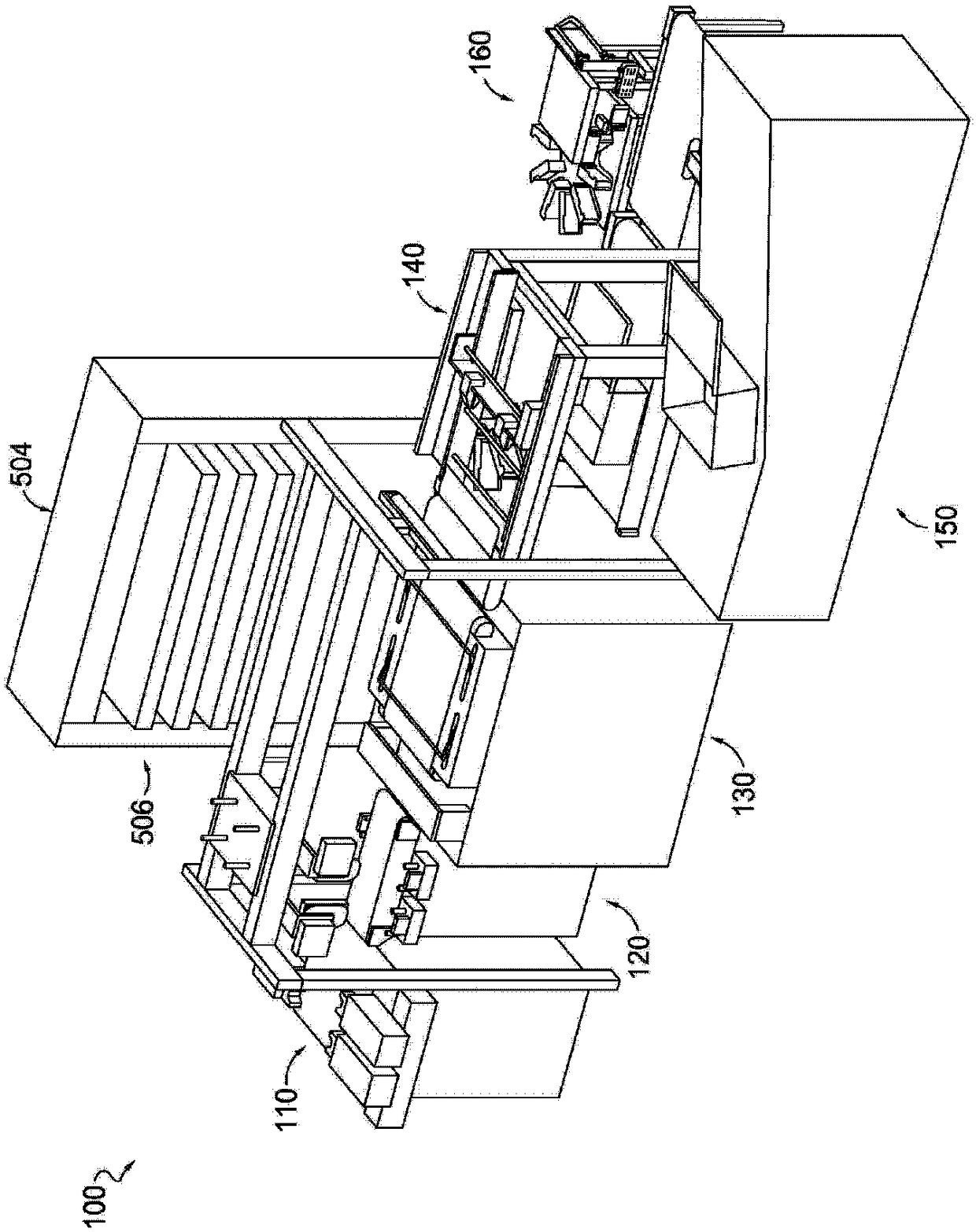

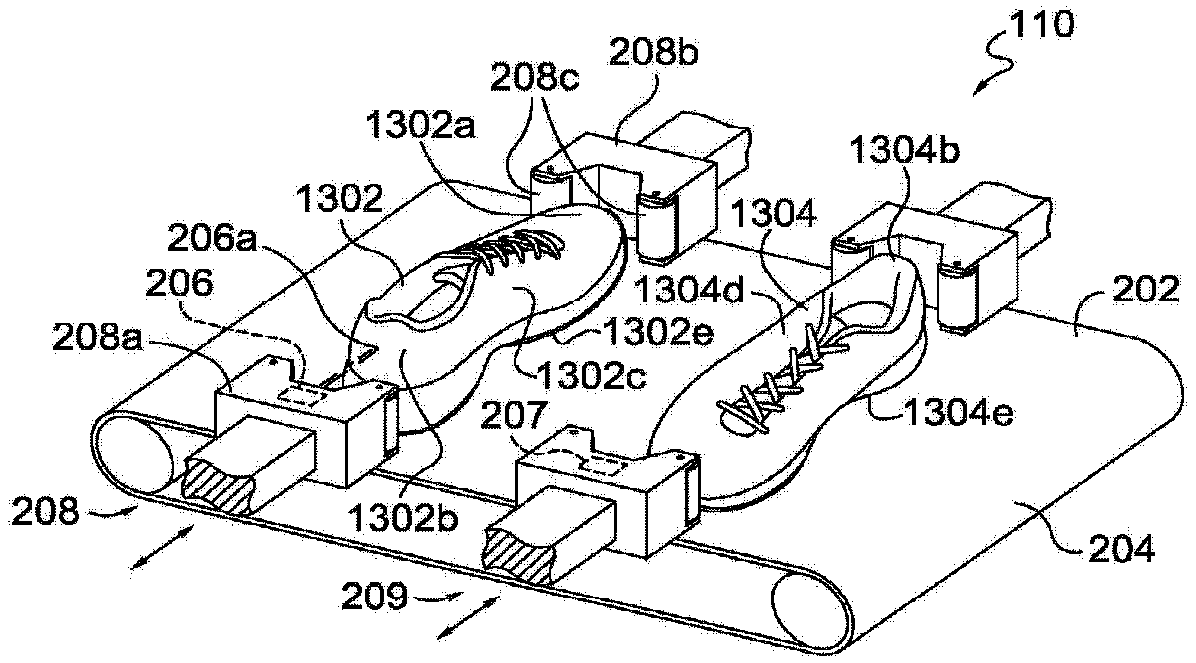

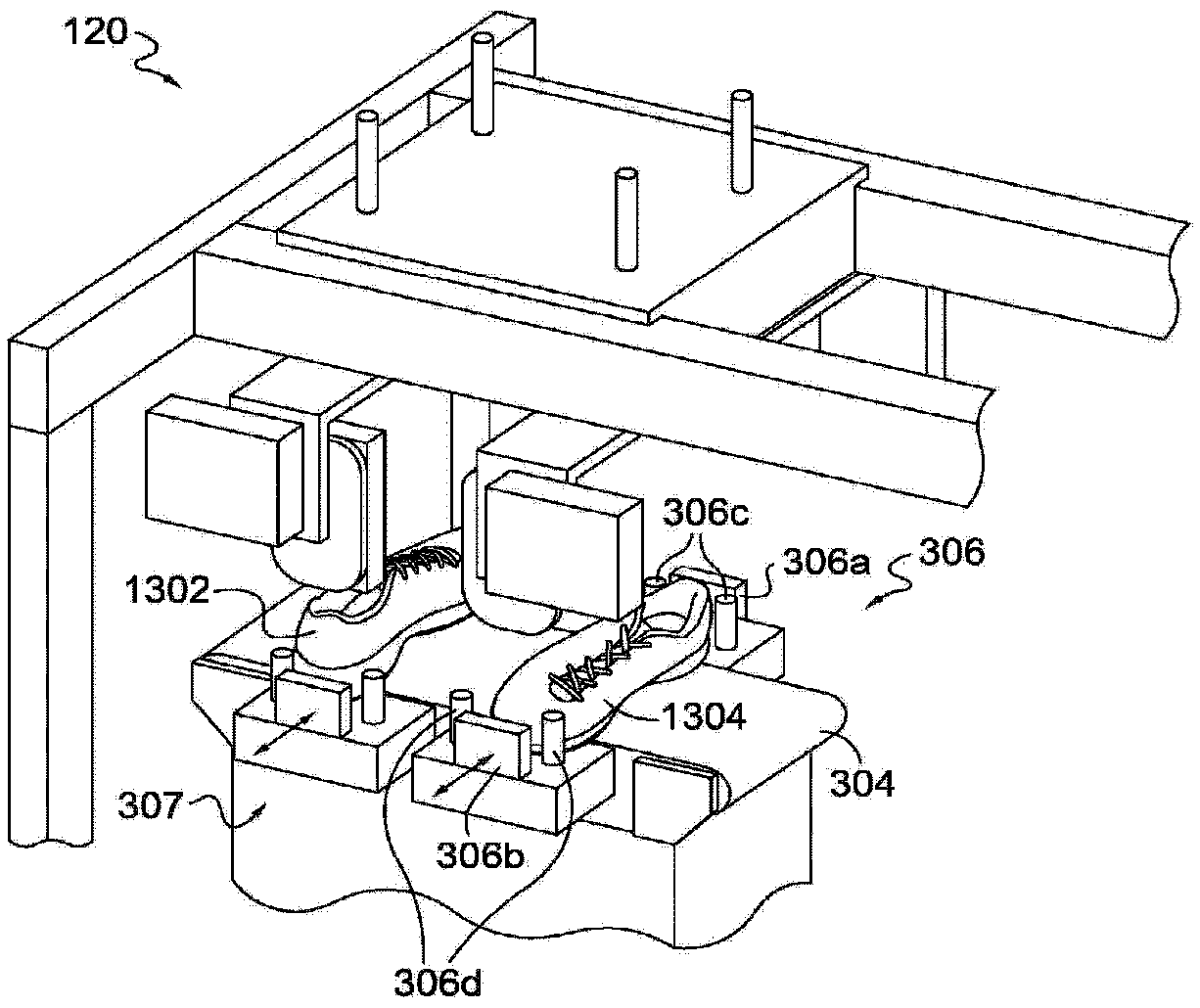

Systems and processes for packing articles of footwear

ActiveCN108974458AImprove efficiencyReduce mistakesWrapping material feeding apparatusWeb rotation wrappingSheet materialMechanical engineering

Systems and processes for packing complementary articles of footwear into a container are disclosed. The processes can include utilizing a reusable packing sheet positioned underneath complementary articles of footwear to transfer the complementary articles of footwear into a container. The processes can also include removing the reusable packing sheet from underneath the complementary articles offootwear while the complementary articles of footwear remain positioned in the container. Additional processes can include aligning and sizing complementary articles of footwear for packing in a container.

Owner:NIKE INNOVATE CV

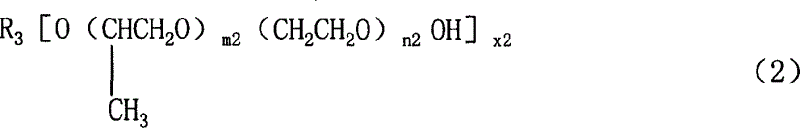

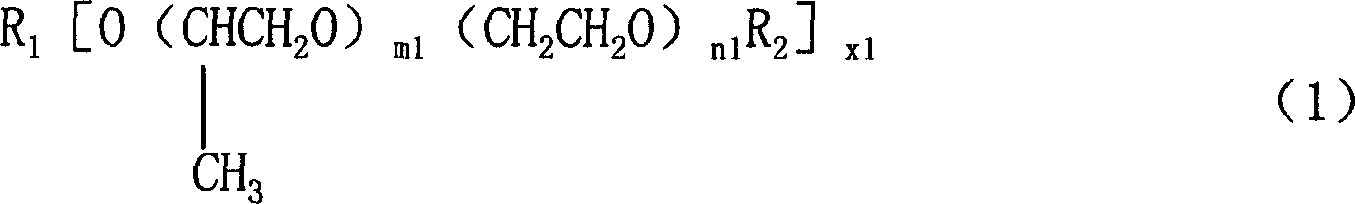

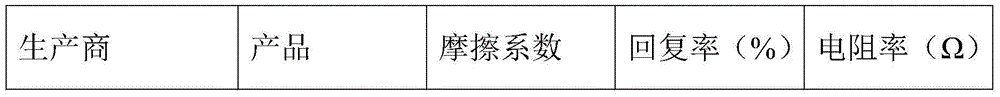

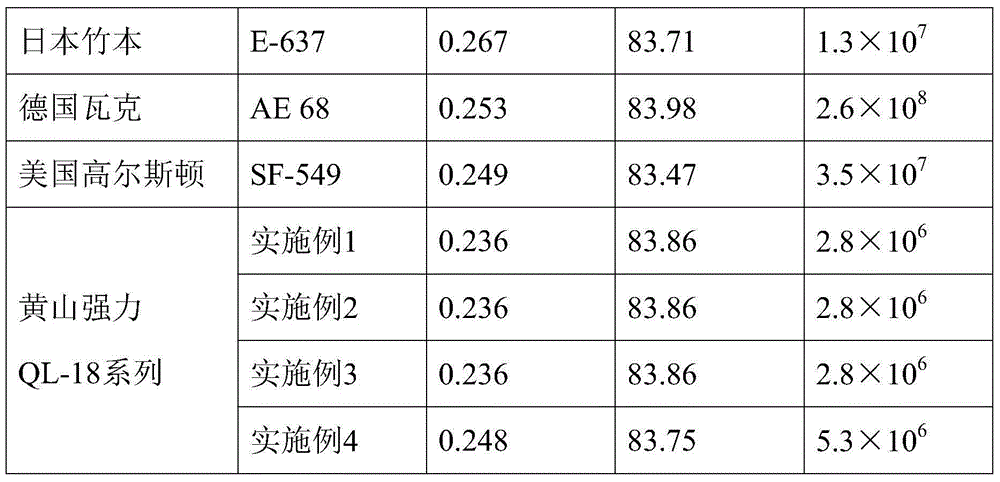

Combination of oil preparation of spun fabric cord

A composite oil for spinning cord yarn contains synthetic ester, polyether A, polyether B, antistatic agent, physical propoerties regulator and viscosity improver. Its advantages are high stability, high temp resistance and smoothness, and high spinnability and less strength loss of raw fibres.

Owner:CHINA PETROCHEMICAL CORP +1

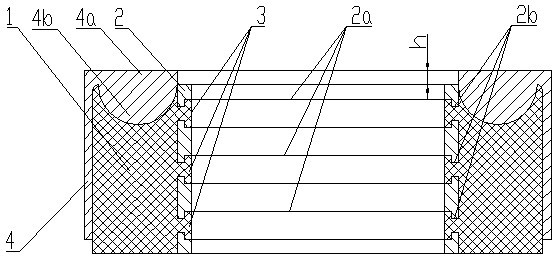

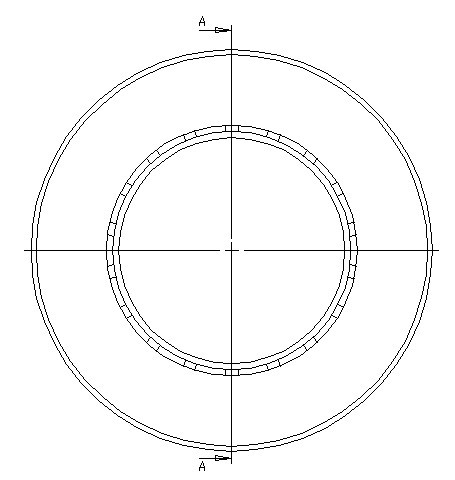

Compressed packer sealing cylinder for oil and gas fields

ActiveCN102041975AMeet job requirementsAvoid damageSealing/packingStatic friction coefficientTemperature resistance

The invention discloses a compressed packer sealing cylinder for oil and gas fields, comprising a rubber cylinder which is sheathed on an inner core of a packer when in use. An outer sleeve made of polytetrafluoroethylene is sleeved outside the rubber cylinder. When the compressed packer sealing cylinder is in use, the rubber cylinder is compressed to radially expand and deform to act on the outer sleeve so that the outer sleeve tightly clings to an outer sleeve of an oil and gas well to form axial sealing; by utilizing the characteristics of the polytetrafluoroethylene, such as high temperature resistance, higher strength in comparison with rubber, low static friction coefficient, corrosion resistance and the like, the contact strength of a sealing surface is improved and the sealing cylinder can satisfy the using requirements on the corrosive working condition that the pressure is 90-105Mpa and the temperature is 160-180DEG C; in addition, axial sealing of the inner core of the packer is formed by the inward expansion of the rubber cylinder so as to meet the operating requirement of the packer. Furthermore, the rubber cylinder is internally provided with a pressure bearing core bar; when the rubber cylinder is compressed for a certain distance, the pressure bearing core bar plays a supporting role to bear continuously increased pressure, thereby preventing the rubber cylinder from being damaged when the deformation of the rubber cylinder is increased continuously, greatly enhancing the pressure bearing capability of the sealing cylinder and prolonging the service life.

Owner:贵州国塑科技管业有限责任公司

Polyamide-imide finish for corona-resistant enameled wire

ActiveCN104778991ASmall coefficient of static frictionImprove wear resistancePlastic/resin/waxes insulatorsInsulated cablesNew energyDrive motor

The invention discloses polyamide-imide finish for a corona-resistant enameled wire. The polyamide-imide finish comprises, in terms of the total weight accounting for 100 parts, components as follows: 1-10 parts of a lubricating abrasion-resistant component, 1-10 parts of a solvent and the balance of base paint, wherein the lubricating abrasion-resistant component is a mixture of molybdenum disulfide, sepiolite powder, polytetrafluoroethylene, polyethylene wax and silicone oil in the ratio of (20-30):(20-30):(15-25):(15-25):(5-15) in terms of the total weight accounting for 100 parts; the solvent is a mixture of N-methylpyrrolidone and xylene in the weight ratio of (1-2):1; the base paint is polyamide-imide paint. The polyamide-imide finish can decrease the static friction coefficient of the corona-resistant enameled wire, is good in improvement effect on the corona resistance of the corona-resistant enameled wire and is applicable to driving motors of new-energy vehicles.

Owner:TONGLING JINGDA SPECIAL MAGNET WIRE CO LTD +1

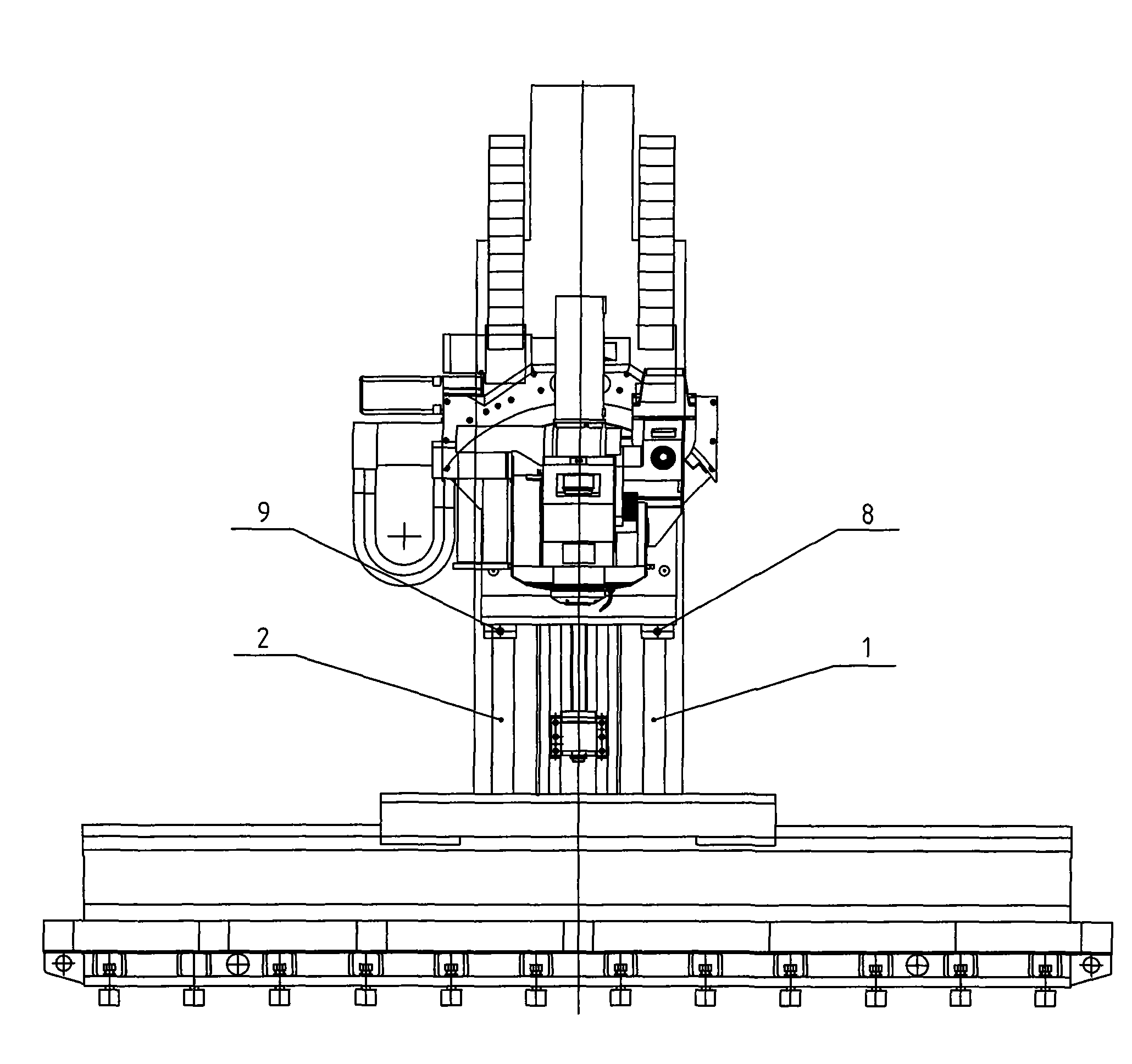

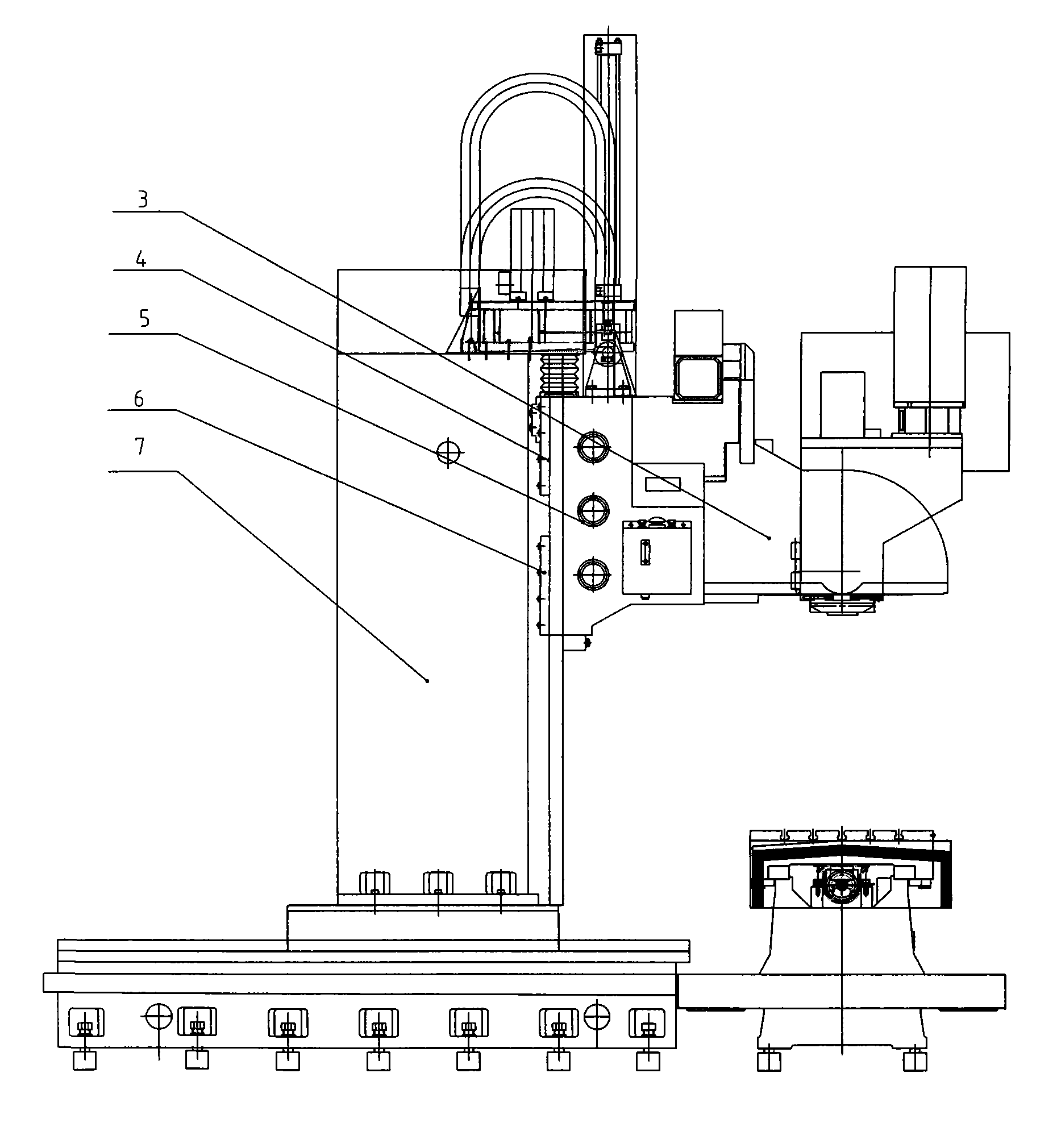

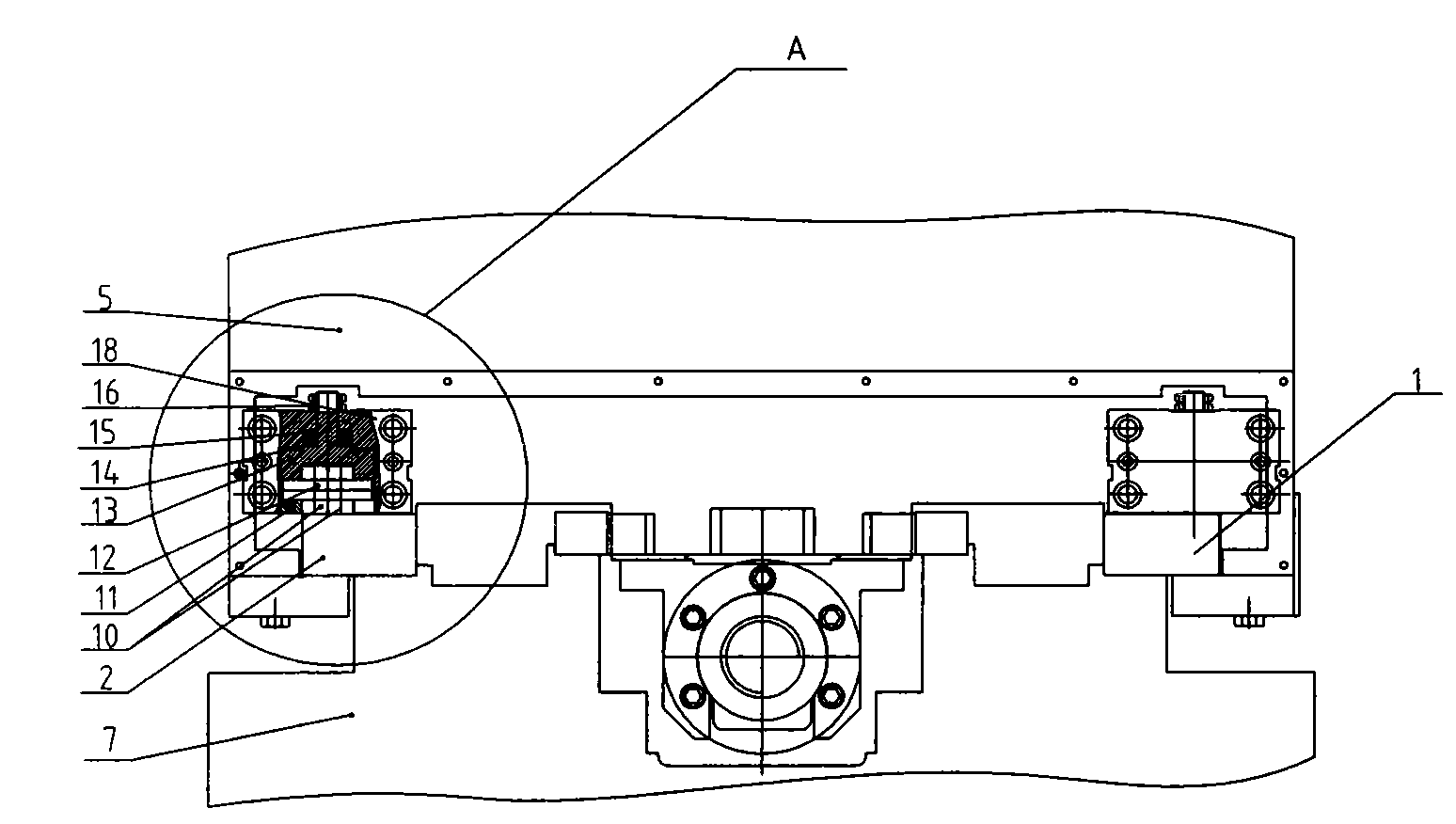

Upright type five-shaft processing center Z-direction vertical guide rail unloading devices and manufacturing method

ActiveCN101633132ASmall coefficient of static frictionImprove wear resistanceMilling machinesMaintainance and safety accessoriesLow speedCutting force

The invention relates to upright type five-shaft processing center Z-direction vertical guide rail unloading devices and a manufacturing method. An upright face at one side of an upright post used for loading is provided with a left / right guide rail, and the double-pendulum milling heads of an A shaft and a B shaft make up-and-down movement in the vertical direction of the front face of a Z-direction guide rail by a sliding plate. The invention is characterized in that the left / right guide rail at the front face is respectively provided with a set of A unloading devices, and the A unloading devices are respectively installed below the sliding plate and are combined with a left guide rail and a right guide rail of the upright post; in addition, two sets of B unloading devices are arranged and are respectively installed on a left upper press plate and a right upper press plate at the back face of the left / right guide rail; a rolling bearing bracket and a rolling bearing in the unloading devices are connected by a pin shaft and are locked by a holding screw; and part of load on the double-pendulum heads of the A shaft and the B shaft is borne by the rolling bearing supported on a guide rail face, and the magnitude of unloading force is regulated in such a way that a regulating nut drives the rolling bearing bracket to regulate the magnitude of butterfly spring force, thus part of the load is unloaded. By adopting a bearing increase unloading guide rail device, part of the load (gravity and cutting force) of the guide rail can be shared, the load supporting the guide rail is lightened, and the static friction coefficient of the guide rail is lowered, thus frictional force is reduced, the wear resistance of the guide rail and the smoothness of low-speed movement are enhanced, and creeping is reduced or prevented.

Owner:通用技术集团沈阳机床有限责任公司

Automatic gearbox oil and preparation method thereof

InactiveCN108728222AGood fluidity at low temperatureAvoid accumulationLubricant compositionAntioxidantOxidation stability

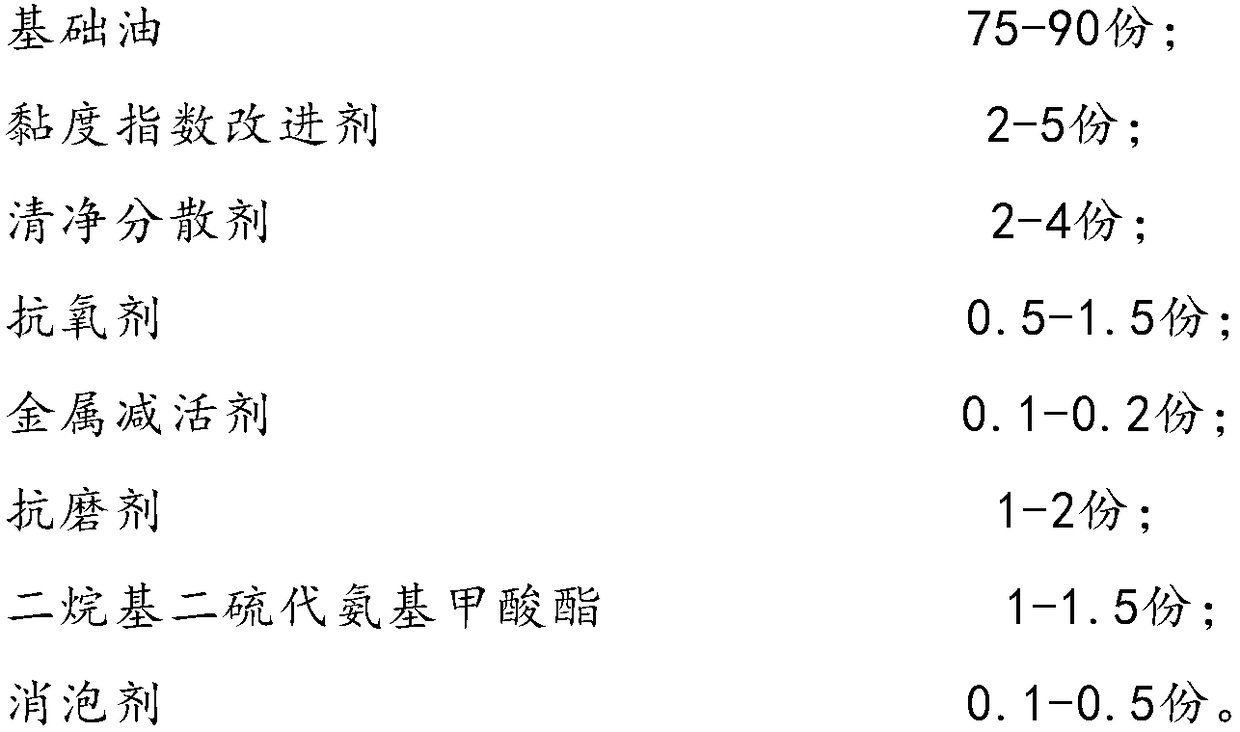

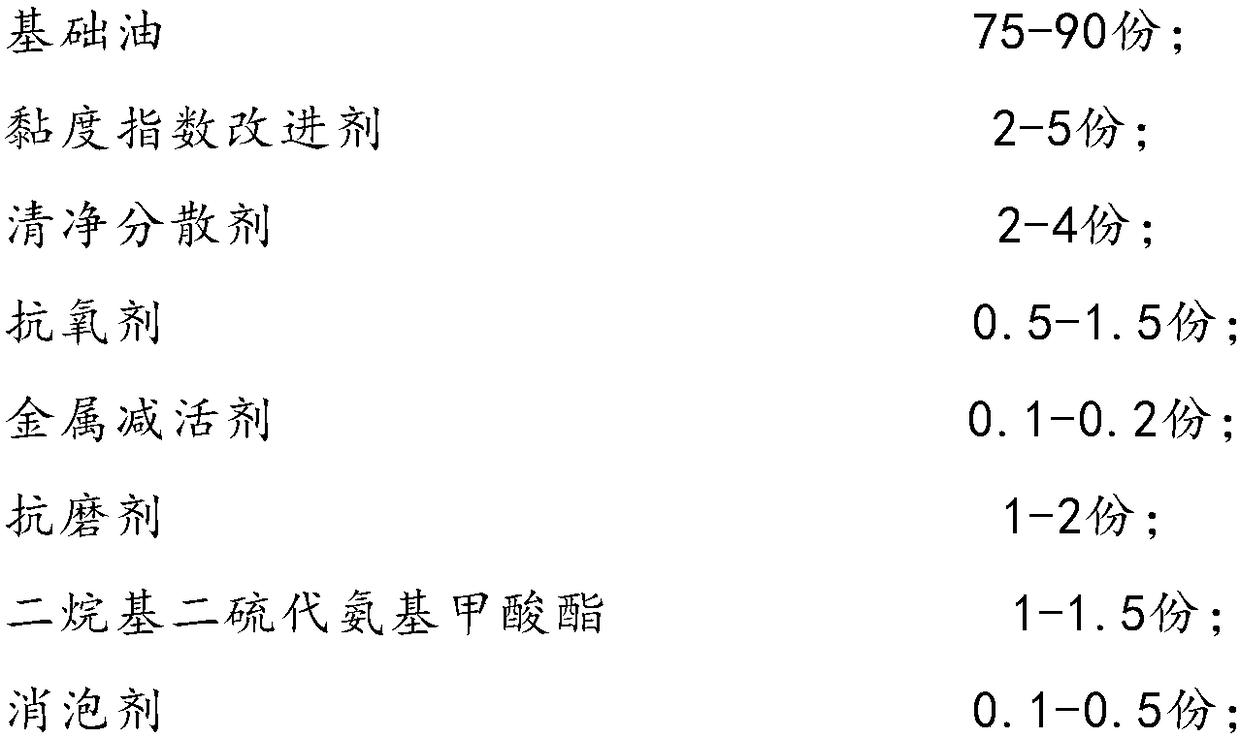

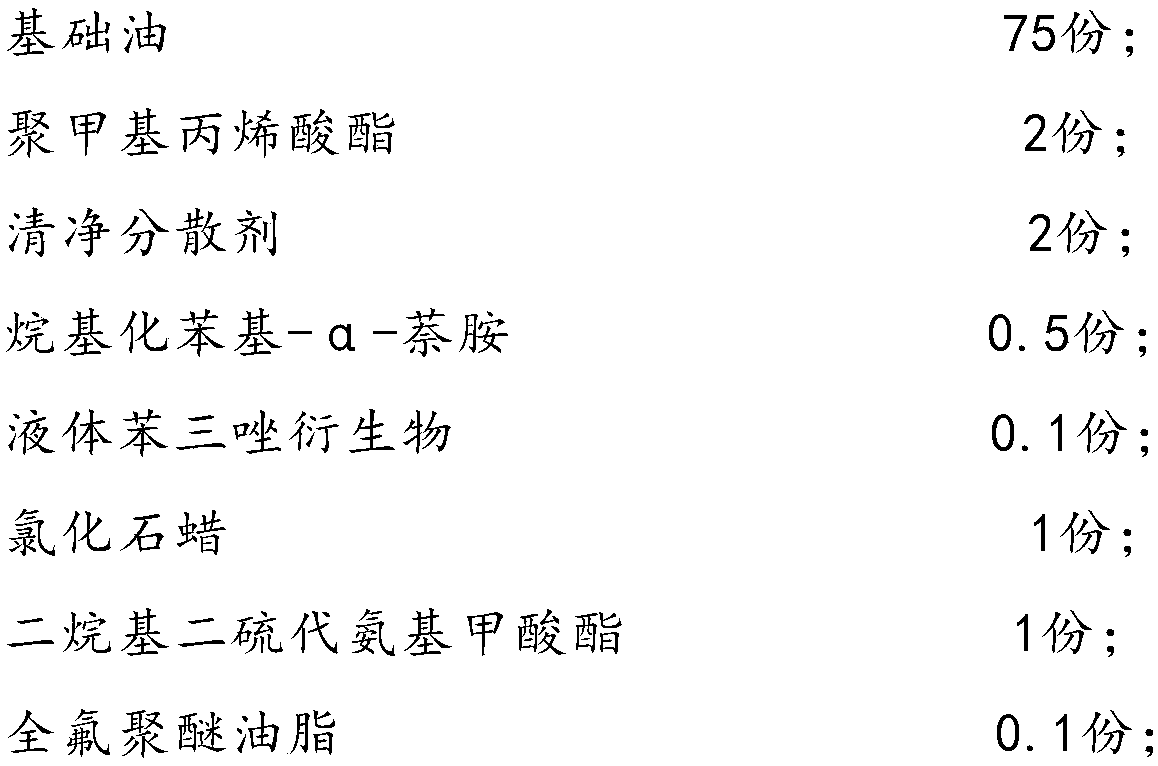

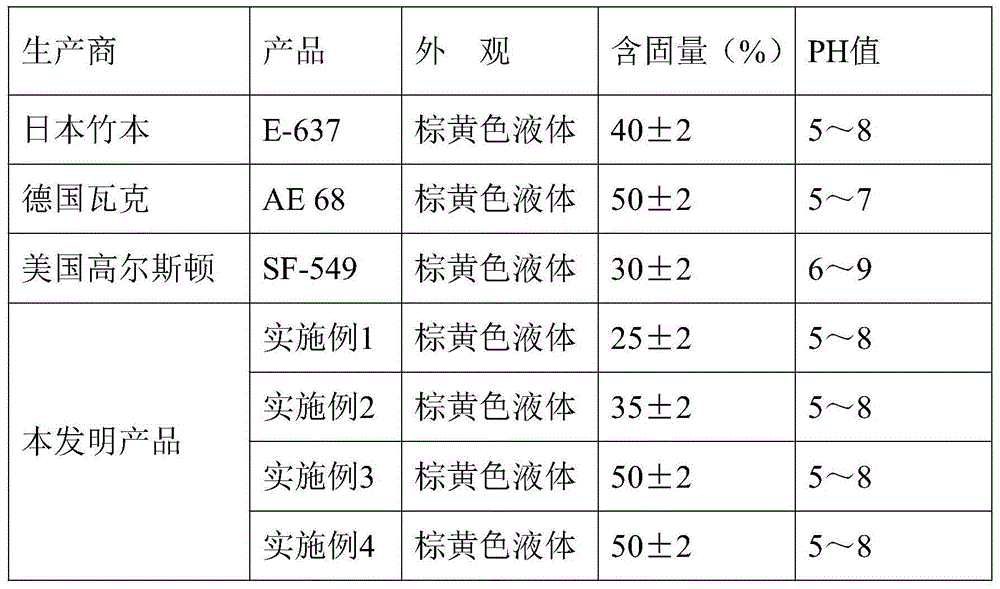

The invention discloses automatic gearbox oil. The automatic gearbox oil comprises the following components in parts by weight: 75-90 parts of base oil, 2-5 parts of a viscosity index improver, 2-4 parts of a detergent dispersant, 0.5-1.5 parts of an antioxidant, 0.1-0.2 part of a metal deactivator, 1-2 parts of an antiwear agent, 1-1.5 parts of dialkyldithiocarbamate, and 0.1-0.5 part of a defoamer. The automatic gearbox oil provided by the invention has excellent lubricating performance, oxidation stability, low-temperature fluidity, high wear resistance and detergent dispersibility, and nofrothing, and the service life is prolonged.

Owner:SHANGHAI DELIAN CHEM

Antistatic agent for polyester fabric

ActiveCN105780466AReduce coefficient of frictionStrong neutralization abilityFibre typesStatic friction coefficientFiber

Provided is an antistatic agent for polyester fabric.The antistatic agent is compounded from, by weight, 6-12 parts of dimethyl octadecyl hydroxy ethyl ammonium nitrate, 2-6 parts of octadecylamine ethyl dimethyl-beta-hydramine dihydric phosphate, 1-4 parts of tri-hydroxyethylmethyl ammnium methosulfate, 1-2 parts of dodecyl trimethyl ammonium bromide and 2-6 parts of Tween 80.On the basis that cationic surfactant is added, an appropriate amount of other components are added, and the polyester antistatic agent which enables the static friction coefficient of fibers to be reduced and has better cohesion collection property is obtained.

Owner:黄山市强力化工有限公司

Non-stick coating layer and coating process thereof

InactiveCN111171682AGood lubricityGood non-stickPretreated surfacesSpecial surfacesPolytetrafluoroethyleneFirming agent

The invention discloses a non-stick coating layer, which is prepared from the following raw materials in parts by weight: 40 to 50 parts of epoxy acrylate, 25 to 32 parts of polyacrylic acid fluorine-containing ester, 25 to 32 parts of poly (vinylidene fluoride-trifluoroethylene), 10 to 15 parts of polytetrafluoroethylene powder, 2.5 to 4 parts of a suspension dispersing agent, 1 to 1.4 parts of aleveling agent and 1.5 to 2 parts of a curing agent. The non-stick coating layer has excellent lubricating performance and excellent non-stick performance, can completely meet the use requirements ofvarious processing molds (such as various plastic demolding, baking molds and papermaking and textile industries), contains no demolding agent (the production efficiency can be improved), and has excellent durability; in addition, no silicone oil is contained, and the product is prevented from being polluted; the adhesive force with a base material is large, the loading capacity is large, the impact resistance is good, the flexibility is good, the comprehensive performance is good, and the service life is long.

Owner:骋润(嘉兴)新材料科技有限公司

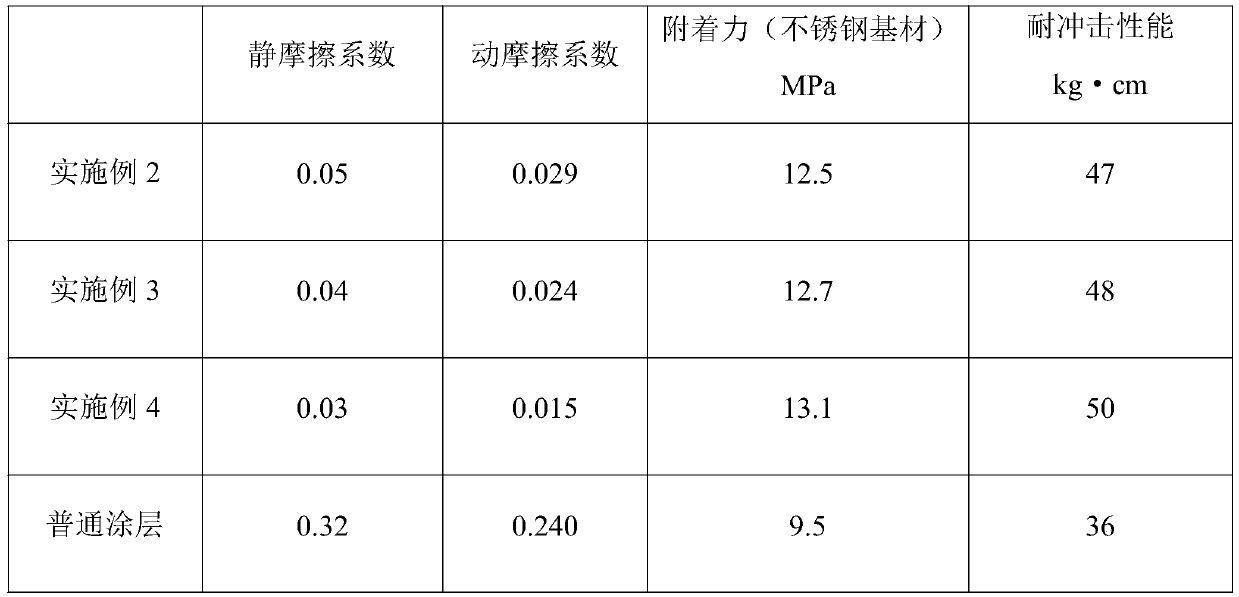

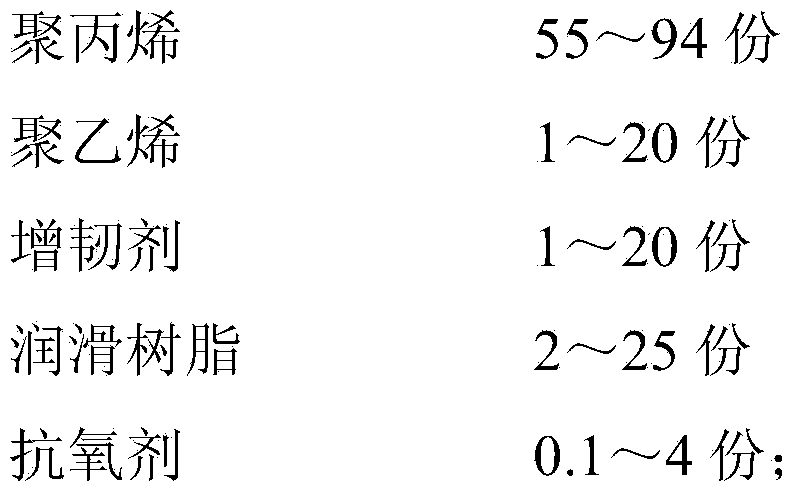

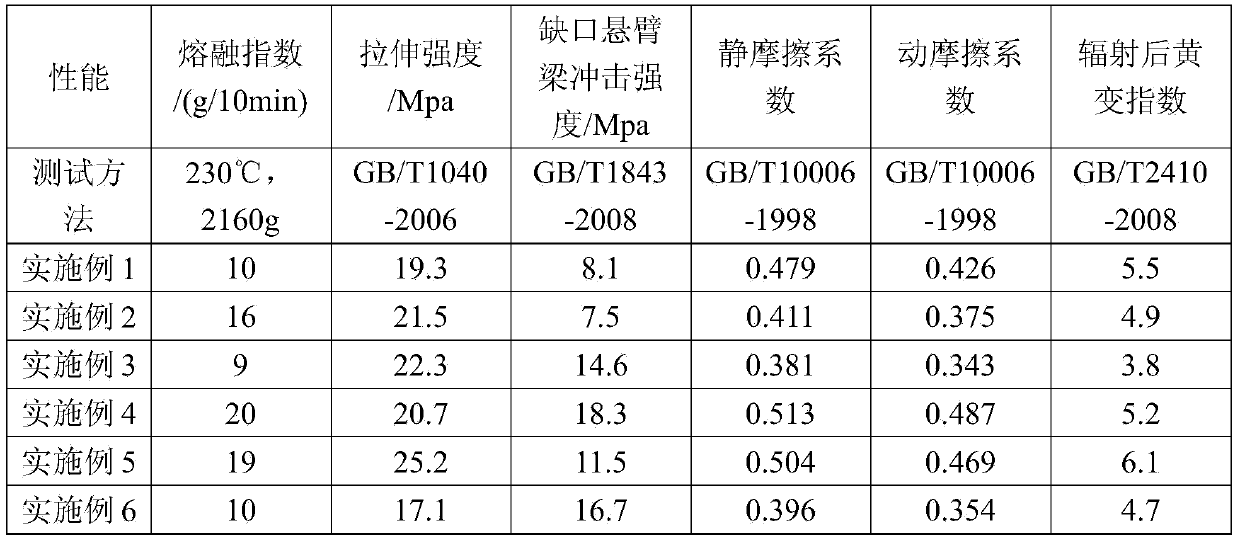

Self-lubrication composite material used for producing easy-folding outer covers of infusion bottles or bags

ActiveCN104212080AGood compatibilityNot easy to precipitatePharmaceutical containersMedical packagingPolypropyleneLubrication

The invention belongs to the technical field of materials for infusion bottles or bags and discloses a self-lubrication composite material used for producing easy-folding outer covers of infusion bottles or bags and the application of the self-lubrication composite material in the medicine packing materials. By weight, the self-lubrication composite material comprises the following components: 55-94 parts of polypropylene, 1-20 parts of polyethylene, 1-20 parts of flexibilizers, 2-25 parts of lubrication resin and 0.1-4 parts of antioxidants. The lubrication resin is composed of at least one of ethylene, norbornene copolymer, 1,1,2,3,3,3-hexafluoropropylene-1-propylene and 1,1-polyvinylidene floride copolymer master batches. Polypropylene is adopted as the main material so that the self-lubrication composite material can ensure the welding intensity. The lubrication resin and the substrate have good compatibility so that the self-lubrication composite material has good temperature resistance, biological fitness, chemical inertness and high lubricity, enables the static friction coefficient to be as low as 0.381, the dynamic friction coefficient to be as low as 0.343, and the yellow color index after 25 kGy doses of 60 Co-gamma ray radiation to be smaller than and equal to 9.

Owner:合诚技术股份有限公司

Self-lubricating polyurethane paint and enameled wire

InactiveCN109627954ASmall coefficient of static frictionLow costInsulated cablesPolyurea/polyurethane coatingsStatic friction coefficientCresol

The invention provides a self-lubricating polyurethane paint and an enameled wire using the same. The polyurethane paint is prepared from, by mass, 30-50% of polyurethane resin, 10-50% of cresol, 5-40% of aromatic solvent oil and 0.1-6% of high-temperature-resistant paraffin; the enameled wire sequentially comprises a conductor wire core, an insulating primer layer and a self-lubricating paint layer from inside to outside, and the self-lubricating paint layer is prepared from the self-lubricating polyurethane paint. According to the polyurethane paint, the high-temperature-resistant paraffin is added into the traditional polyurethane resin, the static friction coefficient of the polyurethane paint can be effectively reduced, and the polyurethane paint has good thermal stability.

Owner:GUANGDONG JINGXUN LIYA SPECIAL WIRE

Preparation method for self-lubricating polyamide-imide enamelled wire insulated paint synthesized by grafting polymerization

The invention relates to a preparation method for a self-lubricating polyamide-imide enamelled wire insulated paint synthesized by grafting polymerization. The method comprises the steps of preparing an aliphatic acid or alcohol with a long chain alkyl into a solution with a concentration of 10% by using N-methyl pyrrolidone as a solvent; adding the solution to hexamethylene diisocyanate with a spraying method; stirring rapidly and heating to a temperature of 100-150 DEG C gradually to obtain an intermediate A; adding the intermediate A and diphenylmethane diisocyanate together into trimellitic anhydride with a molar ratio of free -NCO in the intermediate A to that in diphenylmethane diisocyanate being 1 : 1-1 : 5; controlling the molar ratio of -NCO to two functional groups in trimellitic anhydride being 1 : 1-1 : 1.05; stirring for 2.5 hours slowly at a kettle temperature of 70 DEG C; heating to a temperature of 120 DEG C; fast stirring for 3.5 hours; and adding dimethylbenzene to make the self-lubricating polyamide-imide enamelled wire insulated paint. The self-lubricating polyamide-imide enamelled wire insulated paint has long quality guarantee period, and does not appear layering. The static friction coefficient can be lower than 0.06. Risks that the enamelled wire is scratched during the processes of winding coils, embedding wires and shaping can be decreased.

Owner:上海晟然绝缘材料有限公司

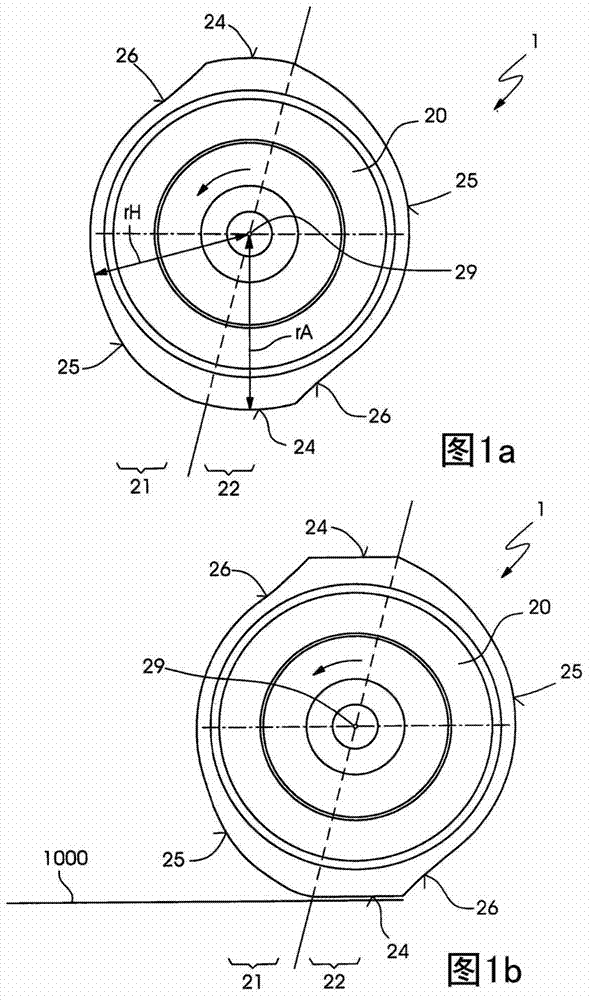

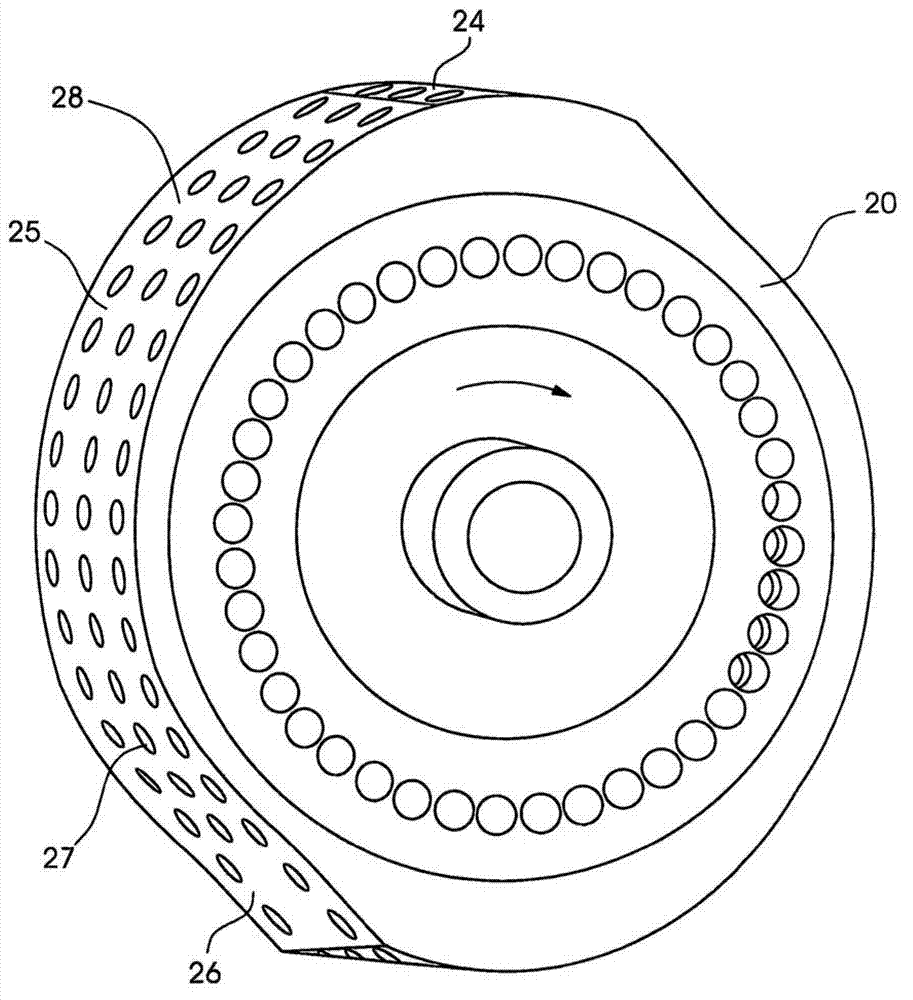

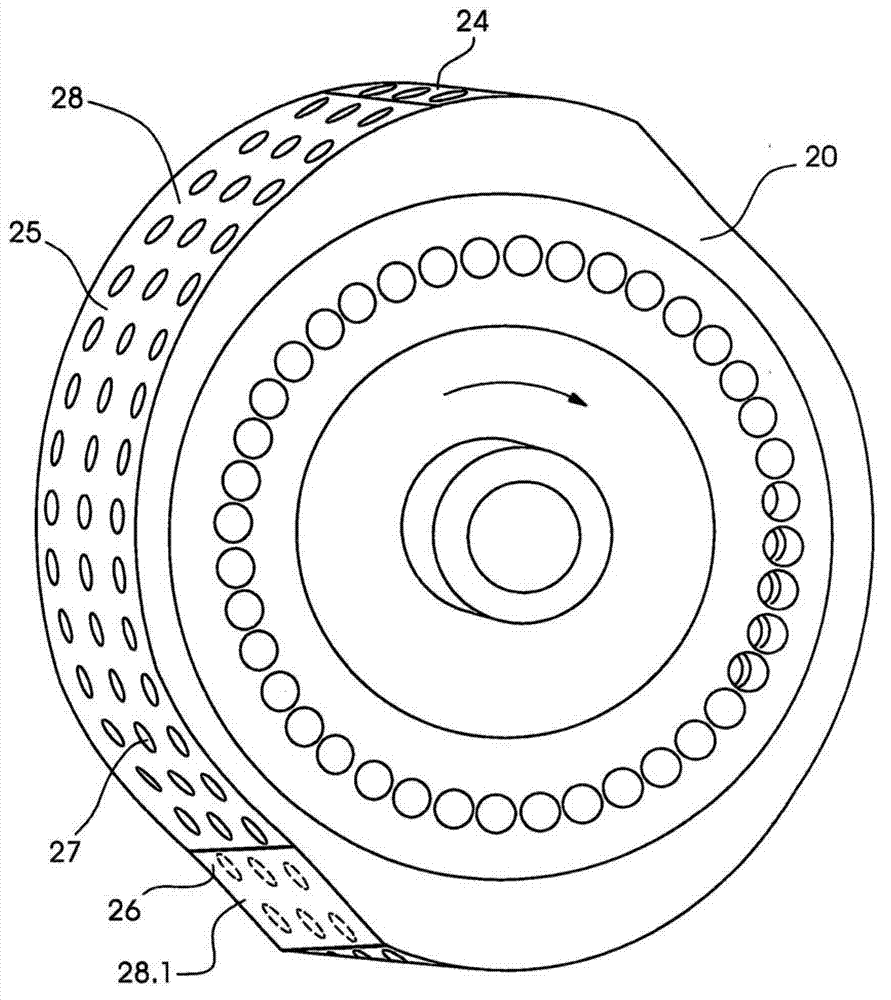

Non-circular suction wheel and sheet feeder

Owner:HEIDELBERGER DRUCKMASCHINEN AG

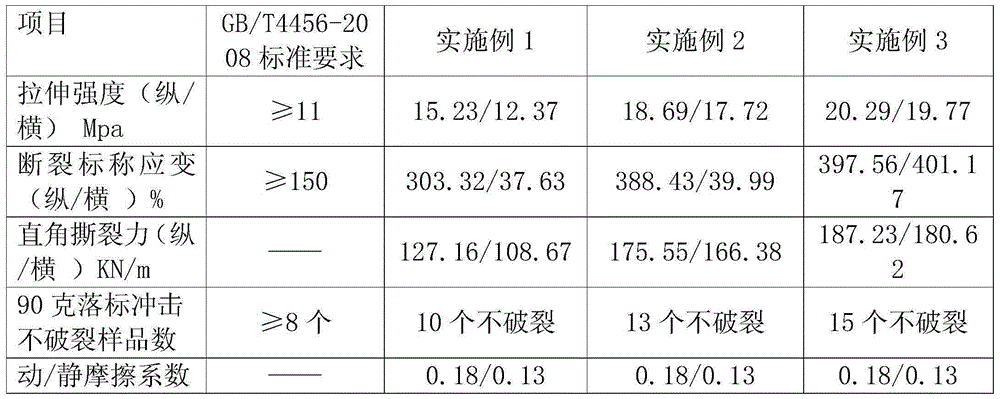

Polyethylene film for plastic composite flexible packaging and blow molding method thereof

ActiveCN103879112BImprove toughnessHigh tensile strengthSynthetic resin layered productsFlat articlesLinear low-density polyethyleneLow-density polyethylene

The invention discloses a polyethylene film for a plastic compound flexible package and a process thereof. The formula of the polyethylene film is as follows: an inner layer of the polyethylene film comprises the following raw materials in percent by weight: 5-60 percent of LDPE (Low-Density Polyethylene), 15-70 percent of LLDPE (Linear Low Density Polyethylene), 10-30 percent of mLLDPE (metallocene Linear Low Density Polyethylene), 0.1-0.5 percent of smooth opening agent, and 0.3-0.5 percent of a demoulding agent; a middle layer of the polyethylene film comprises the following raw materials in percent by weight: 5-60 percent of LDPE, 15-70 percent of LLDPE, 0-30 percent of mLLDPE and 0.3-0.5 percent of demoulding agent; an outer layer of the polyethylene film comprises the following raw materials in percent by weight: 5-60 percent of LDPE, 15-70 percent of LLDPE, 0-30 percent of mLLDPE and 0.3-0.5 percent of demoulding agent. According to the polyethylene film prepared by adopting the formula and the process of the scheme, the flexibility, the tensile strength, the impact resistance and the puncture resistance are greatly improved.

Owner:CHENGDU XINGHENGTAI PRINTING

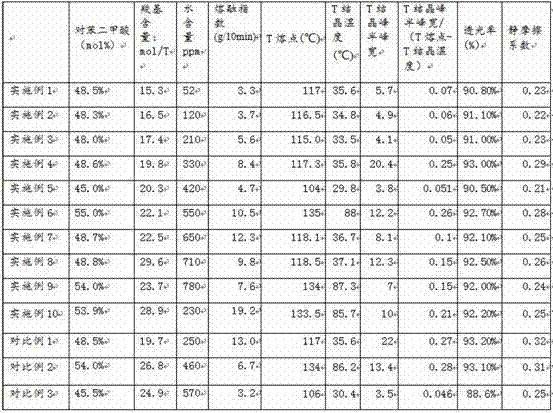

Polyester terphthalate-sebate resin and preparation method thereof

The invention discloses a polyester terphthalate-sebate resin and a preparation method thereof. The polyester terphthalate-sebate resin is formed by polymerization of dibasic acid and diol. By mole percent, the diol is formed by 45-55 mol% of terephthalic acid and 45-55 mol% of sebacic acid. The diol is 1,4-butanediol, thermal performance parameters of the polyester terphthalate-sebate resin meet the following relational expression: T crystal peak width at half height / (T melting point-T crystallization temperature)=0.05-0.26; when the polyester terphthalate-sebate resin is used to manufacture a film with a thickness of 25+ / -1 [mu]m, the static friction coefficient is 0.2-0.3, the light transmittance is 90% or above, the light transmittance and the static friction coefficient of the film are balanced, the film also has a low static friction coefficient while maintaining high light transmittance performance, processing can also be performed smoothly without an opening agent or a compatilizer, and the prepared polyester terphthalate-sebate resin has good transparency and processing performance.

Owner:KINGFA SCI & TECH CO LTD +1

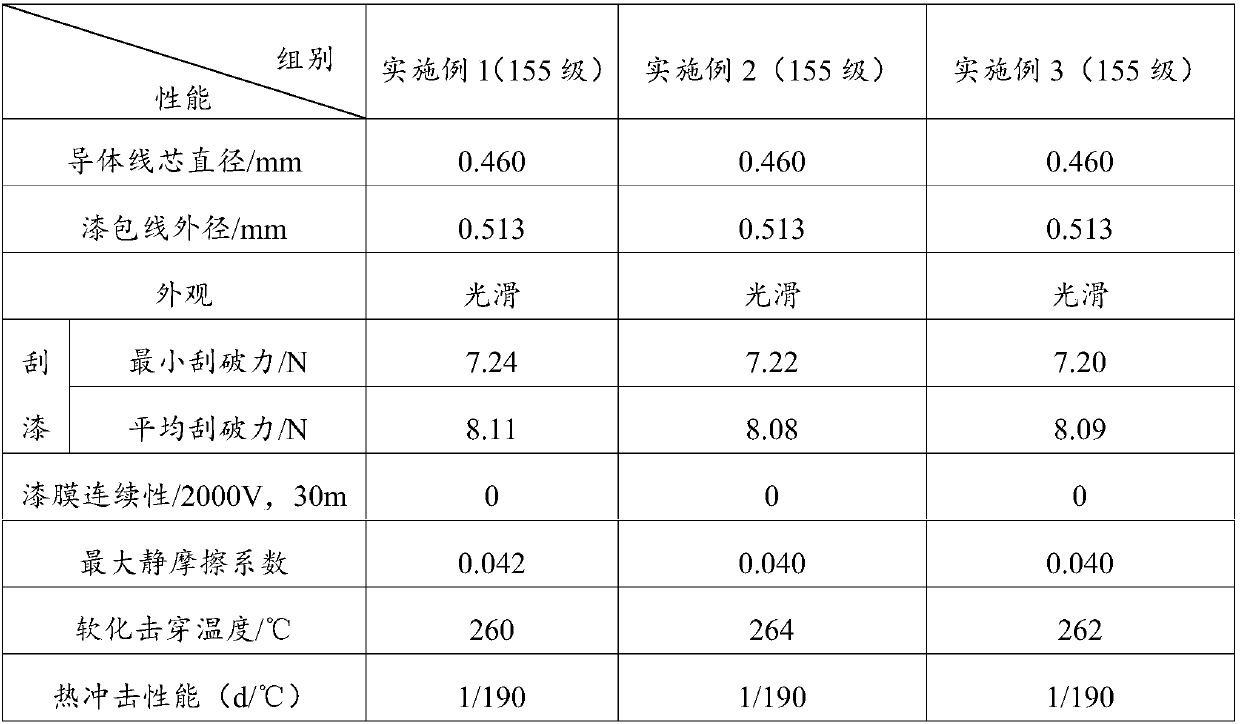

Anti-corona enameled wire applicable to new energy vehicles and manufacturing method thereof

ActiveCN104804503BSmall coefficient of static frictionReduce thicknessInsulated cablesCoatingsElectrical conductorWear resistant

The invention discloses a corona-proof enameled wire for new energy automobiles and a manufacturing method of the corona-proof enameled wire. An insulating layer outside a conductor is coated with three insulating coatings from inside to outside, the outmost coating comprises a lubricating wear-resistant ingredient, a solvent and a base paint, the lubricating wear-resistant ingredient is a mixture of molybdenum disulfide, sea-foam stone powder, polytetrafluoroethylene, polyethylene wax and silicone oil, the solvent is a mixture of N-methyl pyrrolidone and dimethyl benzene, the base paint is a polyamideimide paint, and the thickness proportions of the three coatings are as follows: 15-25% of the inner coating, 60-70% of the intermediate coating and 15-17% of the outer coating. The static friction coefficient of the corona-proof enameled wire can be reduced, the effect in increasing the corona resistance of the corona-proof paint is good, and the corona-proof enameled wire is suitable for driving motors of the new energy automobiles.

Owner:TONGLING JINGDA SPECIAL MAGNET WIRE CO LTD +1

Heat-resistant and low-migrating organic smooth opening agent and master batch prepared from opening agent

The invention discloses a heat-resistant and low-migrating organic smooth opening agent which is obtained by mixing of, by weight, 25-50wt% of component A, 25-50wt% of component B and 25-50wt% of component C. The component B refers to pentaerythritol fatty acid ester, the component B refers to one or two selected from ethylene bis oleamide and stearyl erucic acid amide, and the component C refers to one or two selected from behenamide and polymethyl methacrylate; ethylene bis oleamide and stearyl erucic acid amide are in the mass ratio of 2:1-1:2 when used simultaneously; behenamide and polymethyl methacrylate are in the mass ratio of 2:1-1:2 when used simultaneously. A carrier-free opening-agent master batch obtained with the above formula has the advantages of smoothness, opening, lubricating, demolding and no folding out of the surface in plastics, and the opening agent is resistant to high temperature to 350DEG C, low in migration and uniform in dispersion and is used for preparing the heat-resistant and smooth plastic master batch.

Owner:广州禾工材料科技有限公司

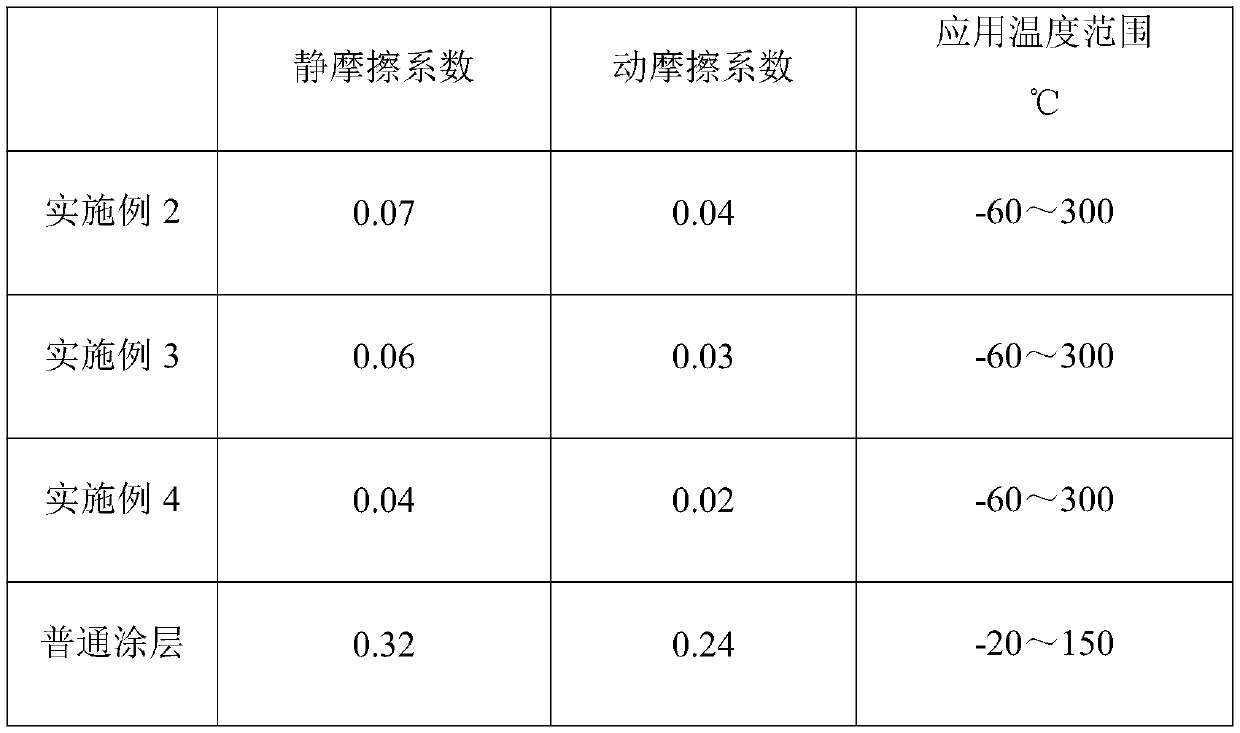

Coating with good lubricating performance and coating process thereof

ActiveCN111234661AImprove the lubrication effectSmall coefficient of static frictionAnti-corrosive paintsSpecial surfacesPolymer scienceFirming agent

The invention discloses a coating with good lubricating performance. The coating comprises the following raw materials in parts by weight: 50-60 parts of epoxy acrylate, 20-27 parts of polyacrylic acid fluorine-containing ester, 12-16 parts of phenolic aldehyde modified epoxy acrylate, 8-11 parts of organosilicon modified epoxy resin, 5-7 parts of a polymer of 2-acrylamide and 1-vinyl-2-pyrrolidone, 10-15 parts of parts of polytetrafluoroethylene powder, 4-6 parts of a mixture of nano-graphite and molybdenum disulfide, 3-5 parts of a suspension dispersant, 1-1.4 parts of a leveling agent and 1.8-2.3 parts of a curing agent. The coating with the good lubricating property has the excellent lubricating property, can completely meet the use requirements of rotating parts (such as pistons, rotors and drill bits) and sliding mechanical parts (such as guide rails), is a primary coating and is permanently used; in addition, the use temperature range is wide, and the coating can be used for a long time within the temperature range of -60 DEG C to 300 DEG C; load capacity is high, comprehensive performance is high, and service life is long.

Owner:骋润(嘉兴)新材料科技有限公司

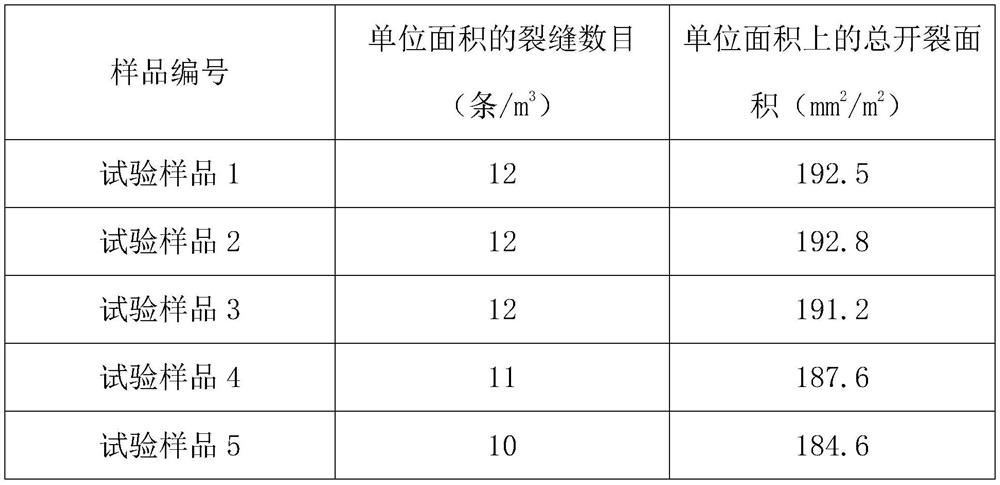

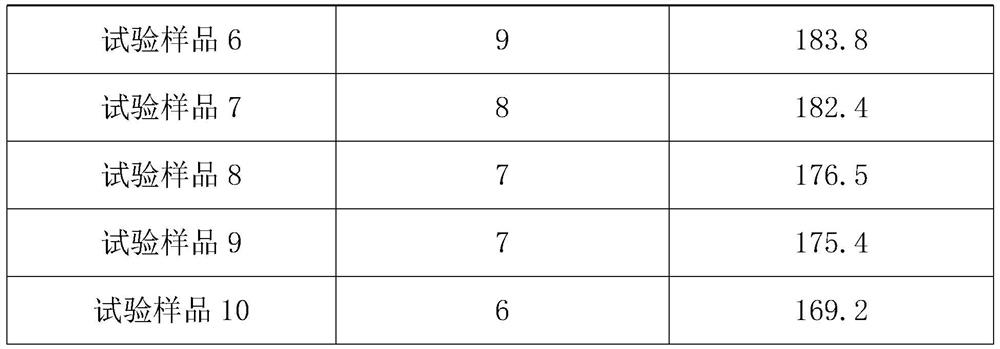

C30 concrete and preparation method thereof

InactiveCN113045274AImprove crack resistanceEasy to separateSolid waste managementKenafWater reducer

The invention relates to the technical field of concrete preparation, and particularly discloses C30 concrete and a preparation method thereof. The C30 concrete is prepared from the following components: cement, fly ash, sand, gravel, water, a water reducing agent, kenaf fibers, a bamboo pulp lignin dispersing agent and rubber powder, wherein the kenaf fibers are subjected to modification treatment; the preparation method comprises the following steps: S1, mixing the cement, the fly ash, the sand, the gravel, the kenaf fiber, the bamboo pulp lignin dispersant, the rubber powder and the water, and stirring for 40-60 seconds to obtain a mixture; and S2, adding water and a water reducing agent into the mixture, and stirring for 60-90 seconds to obtain the C30 concrete. The C30 concrete has the advantage that the anti-cracking performance of the concrete can be enhanced.

Owner:SHAANXI FENGDONG NEW CITY CONCRETE CO LTD

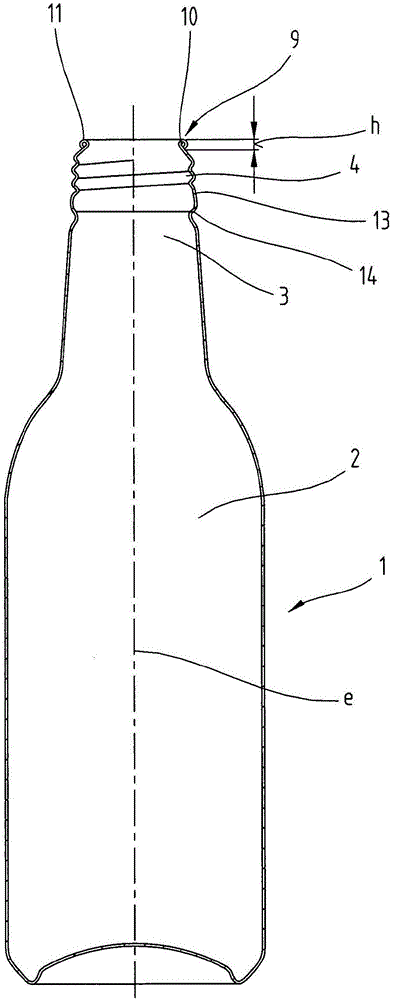

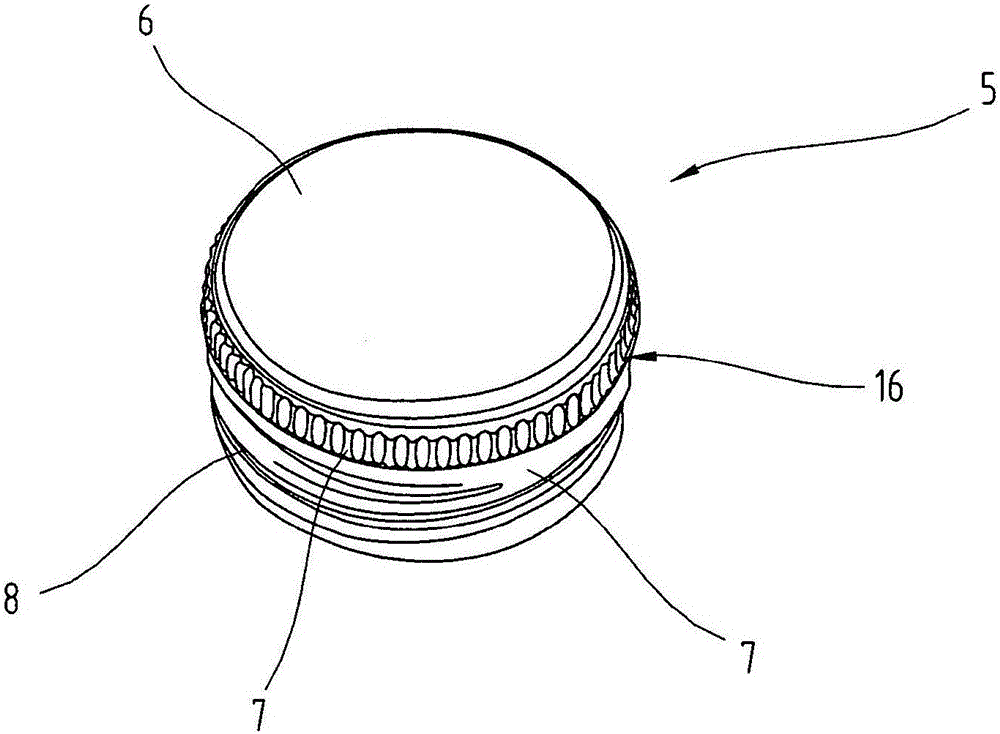

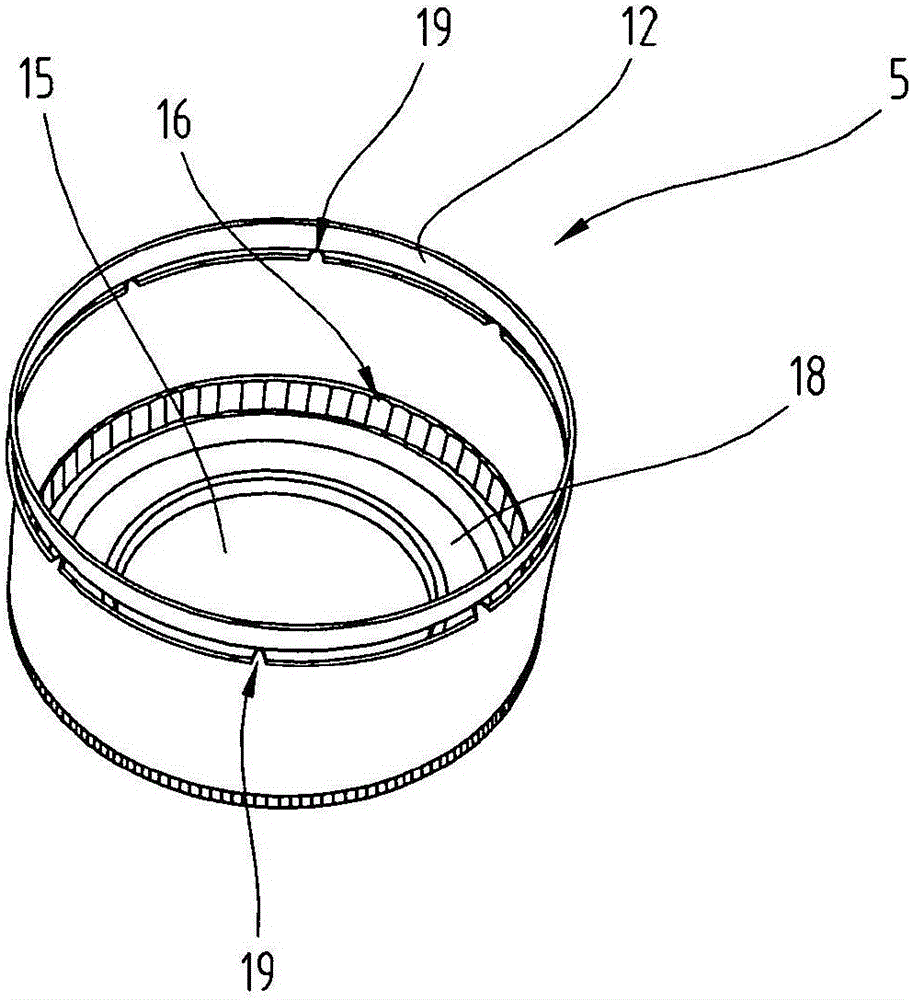

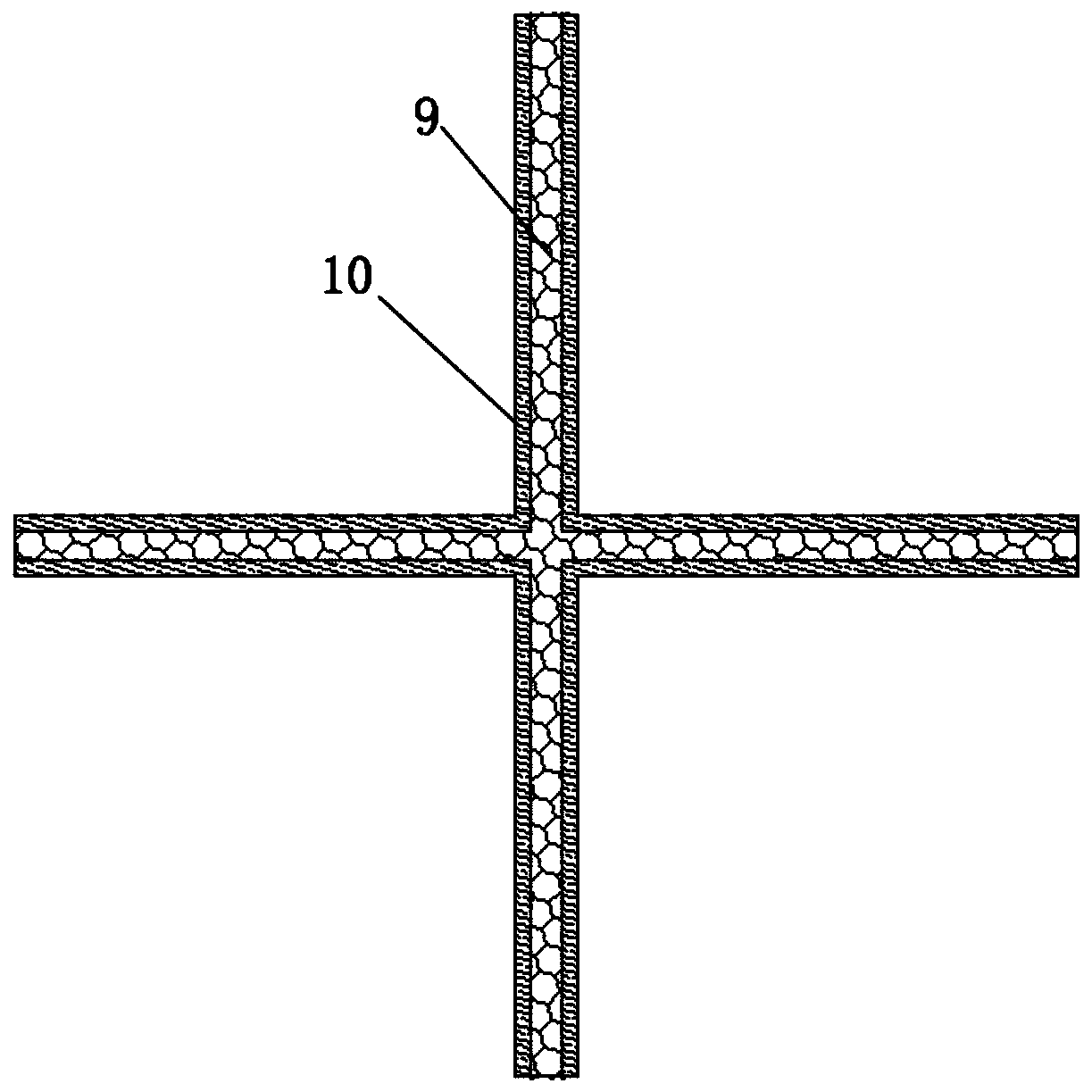

Bottle with closure cap

The invention relates to a bottle having a bottle main body made from light metal and a neck provided with an external thread. The bottle (1) comprises a capsule-type closure cap (5) with a cap (6) closing an opening of the bottle (1) and a skirt (7) adjoining the cap (6) and provided with a thread (8) co-operating with the external thread (4) of the neck (3), the edge (9) of the neck (3) of the bottle (1) being formed by an overturned portion (10) of the neck (3). The overturned portion forms a bead extending circumferentially around an opening of the bottle main body (2). A free end of the over-turned portion (10) points in the direction of an external or internal face of the bottle (1). The overturned portion (10) is of a curved design in the region of an apex (11) of the edge (9) facing the cap (6), and the edge (9) of the bottle (1) has an essentially O-shaped cross-section.

Owner:RED BULL GMBH

Method for producing inwall permanent lubricating layer base materials for optical fiber cable pipe

The invention relates to a process for production of inner wall everlasting lubricating layer masterbatch for optical cable sewing pipe when producing it, the characteristic of which lies in: selecting silicon adjuvant, and adjuvant good for silicon adjuvant dispersing and antistatic agent, anti-oxidant; blending them with carrier resin, then blending homogeneously on a high-speed batch mixer; squeezing and granulating on the twin-screw extruder to get inner wall everlasting lubricating layer masterbatch for optical cable sewing pipe, which takes advantages of the synergic effect of all the adjuvant, in order that even in the low filling range of the adjuvant, the effect is quite good; such masterbatch and base resin lock-in extrusion moldability is sound, and stable processing parameter, good product quality. The coefficient of friction of rest of inner wall everlasting lubricating layer for optical cable sewing pipe produced by such masterbatch is less than 0.165.

Owner:PETROCHINA CO LTD

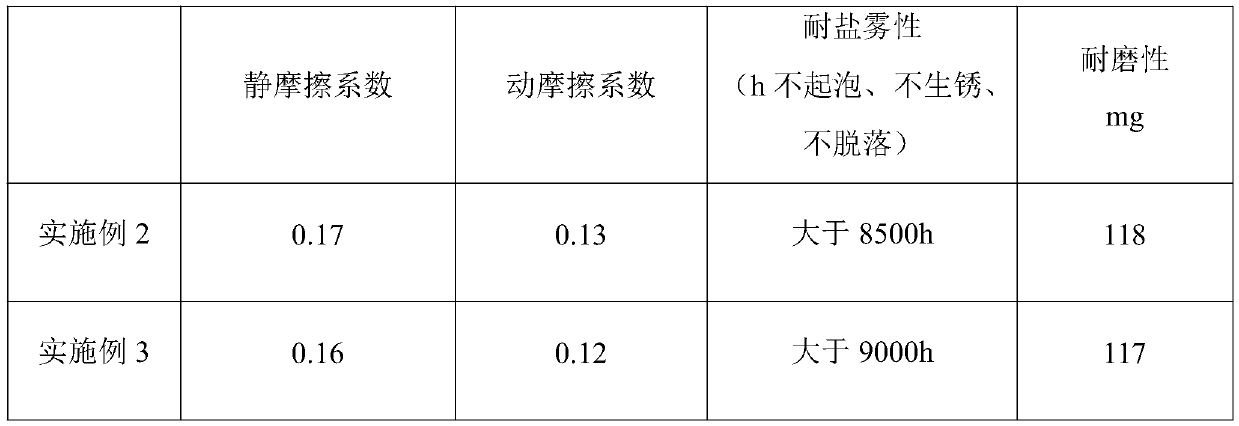

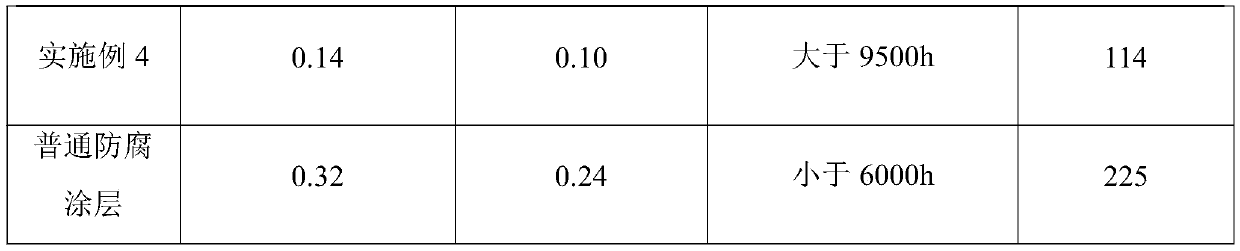

Anticorrosive coating layer with good lubricating property and coating process thereof

ActiveCN111171698AImprove the lubrication effectSmall coefficient of static frictionPretreated surfacesAnti-corrosive paintsPyrrolidinonesMetal particle

The invention discloses an anticorrosive coating layer with good lubricating performance. The anticorrosive coating layer comprises the following raw materials in parts by weight: 75-85 parts of aqueous two-component polyurethane, 18 to 25 parts of 2-acrylamide and 1-vinyl-2-pyrrolidone, 12 to 16 parts of a water-soluble phenolic resin, 4 to 6 parts of nano metal particles, 6 to 8 parts of mixtureof nano graphite and molybdenum disulfide, 2 to 3 parts of nano silicon dioxide, 3 to 5 parts of a dispersing agent, 1 to 1.5 parts of a defoaming agent and 0.8 to 1.3 parts of a leveling agent; wherein the mass ratio of the nano-graphite to the molybdenum disulfide in the mixture of the nano-graphite and the molybdenum disulfide is 1: (0.2-0.4). The static friction coefficient of the anticorrosive coating layer with good lubricating property is as low as 0.14, the dynamic friction coefficient is as low as 0.10, and the anticorrosive coating layer has good lubricating property; in addition, the salt spray test can reach 10,000 hours or above, and the corrosion resistance is excellent; the wear resistance is excellent; in addition, the comprehensive performance is excellent.

Owner:骋润(嘉兴)新材料科技有限公司

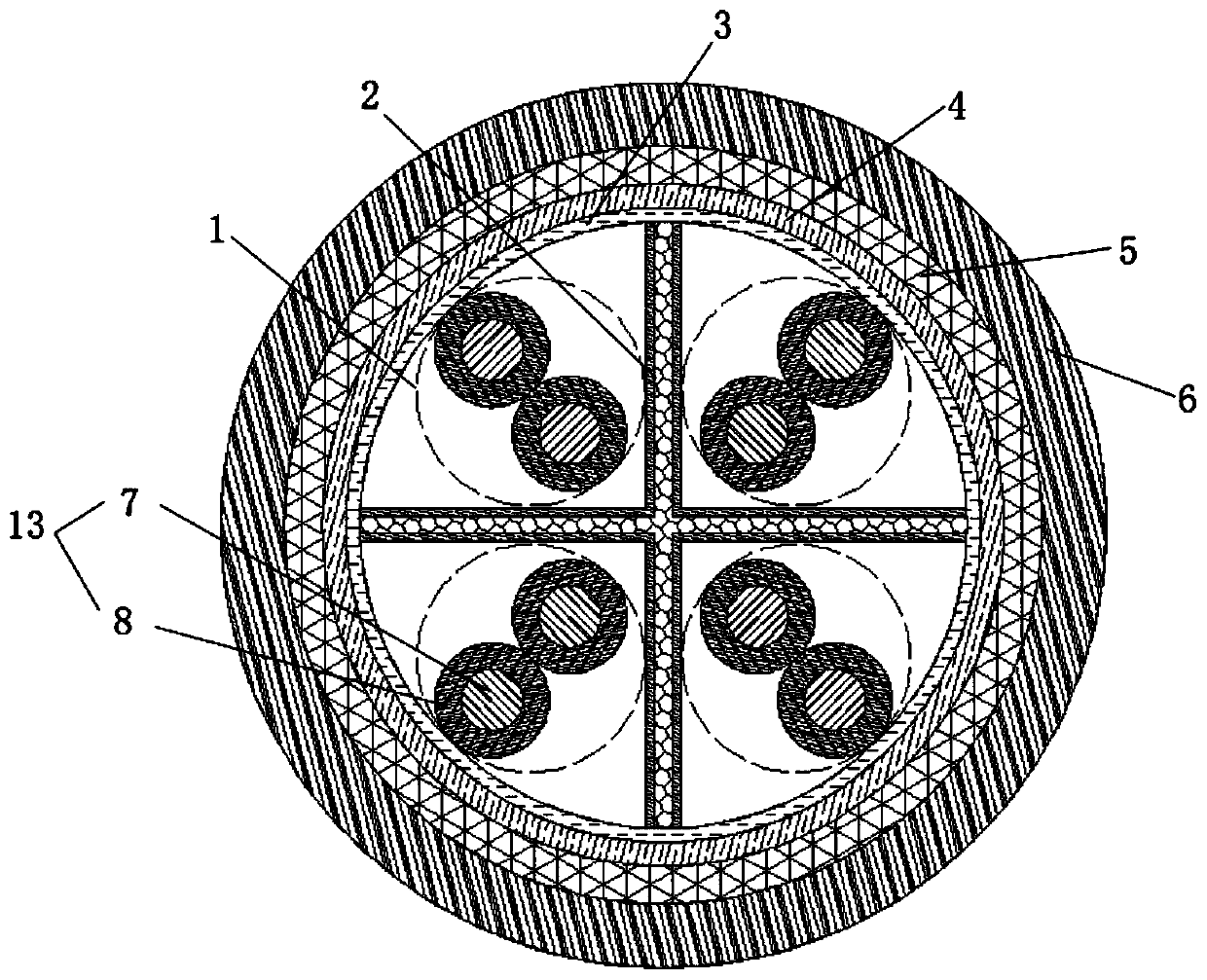

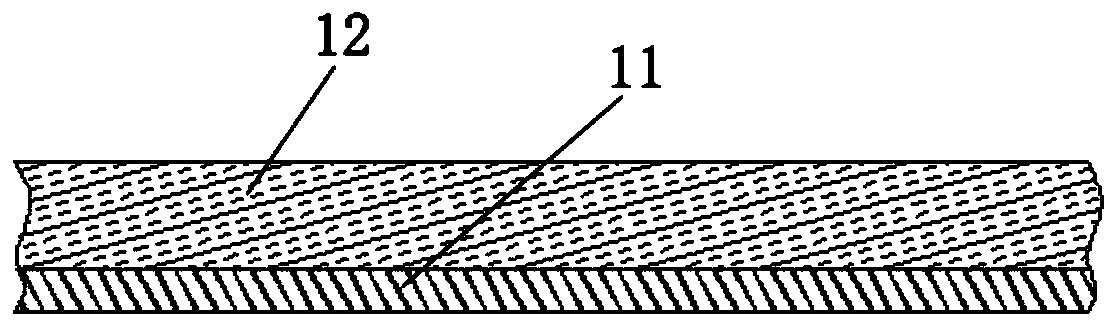

Sealing arrangement and sealing ring consisting thereof

ActiveCN109424746AImpact on test resultsEasy to manufactureEngine sealsMachine sealing rings testingMechanical componentsMachine

Sealing arrangement, comprising a sealing ring (1) having at least one dynamically loaded sealing lip (2), and a machine element (3) to be sealed that has a surface (4) to be sealed, which surface iselectrically conductive and surrounded by the sealing lip (2) in a radially prestressingly sealing manner, the sealing ring (1) comprising a core (5) made of an electrically conductive material (6) and a casing (7) made of an electrically insulating material (8), the casing (7) having a material thickness (9, 10, 11), surrounding the core (5) at least in part and comprising the sealing lip (2), said sealing arrangement comprising a wear detector (12), which has an electric measurement device (13) for detecting the state of wear of the sealing ring (1), wherein, when viewed in section, the material thickness (9) of the sealing lip (2) is smaller in the radial direction (14) than the material thickness (10, 11) of the remainder of the casing (7).

Owner:CARL FREUDENBERG KG

Flexible anti-aging shielding twisted pair cable and preparation method thereof

PendingCN110853827ASuppress interferenceContainment leakNon-insulated conductorsFlexible cablesElectrical conductorHigh density

The invention discloses a flexible anti-aging shielding twisted pair cable and a preparation method thereof. The cable is characterized in that four twisted-pair wire cores and a cross-shaped fillingcore material are twisted together to form a cable core, the exterior of the cable core is coated with a fluororesin wrapping tape layer, an aluminum-plastic composite tape wrapping layer, a copper wire shielding winding layer and a silane grafted crosslinked high-density polyethylene insulating layer, the pair-twisted wire core is formed by pair twisting of two insulating wire cores, each insulating wire core comprises an inner conductor and a silane grafted crosslinked low-density polyethylene insulating layer, a nickel copper damage prevention coating and a zinc oxide barrier layer are sequentially sprayed outside the inner conductor and the copper wire shielding winding layer, the cross-shaped filling core material comprises a cross-shaped resin matrix and an aluminum foil layer, an aluminum-plastic composite belt wrapping layer is of an aluminum-plastic composite belt gap wrapping structure, and the aluminum-plastic composite belt comprises an aluminum foil belt outer layer and aPET resin belt inner layer. The cable is advantaged in that the cable effectively suppresses signal interference caused by crosstalk between the pair-twisted wire cores, can effectively suppress a copper damage phenomenon of an insulating layer, and has better mechanical strength, flexibility and electrical characteristics.

Owner:浙江元通线缆制造有限公司

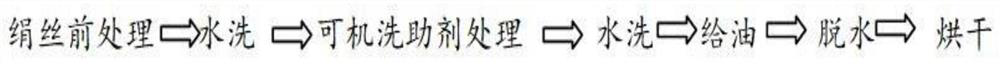

Preparation process of machine washable spun silk

InactiveCN113265798ASimple preparation processSmall coefficient of static frictionTextile treatment machine arrangementsLiquid/gas/vapor removal by centrifugal forcePolymer chemistryDyeing

The invention discloses a preparation process of machine washable spun silk. The preparation process of the machine washable spun silk comprises the following steps of 1, pre-treating of spun silk; 2, washing with water; 3, treating with a machine washable auxiliary agent; 4, washing with water; 5, oil feeding; 6, dewatering; and 7, drying. The step of treating with the machine washable auxiliary agent comprises the substeps that softened water with the bath ratio of 1: 20 is added into a water tank of a skein dyeing machine, and then 10% of the machine washable auxiliary agent is added. The preparation process is simple; and after the spun silk is treated with the process, a uniform and breathable coating layer can be formed on the surface of the spun silk, so that the static friction coefficient and the dynamic friction coefficient of the spun silk are greatly reduced, the anti-fuzzing and anti-pilling performance of the spun silk is effectively improved, the characteristics of the spun silk are brought into full play, machine washing is achieved, and development and application of the spun silk in the textile and garment aspect are further expanded.

Owner:JIANGSU SPCC SILK

Weighing paper

ActiveCN104266736AAntistaticEasy transferWeighing apparatus detailsStatic friction coefficientSurface roughness

The invention discloses a piece of weighing paper. The surface resistivity of at least one surface of the weighing paper is not greater than 1010 ohms, the quantity of the paper is 25-45 g / m<2>, and the static friction coefficient of the surface for weighing is not greater than 0.25. The surface resistivity can be further reduced by increasing antistatic components, and due to reduction of the surface resistivity, the possibility of powder flying can be effectively reduced when nano-powder is weighed. Meanwhile, substances like nano-powder can be transferred from the surfaces of the weighing paper smoothly by controlling the surface roughness and the static friction coefficient of the weighing paper.

Owner:廖张洁

A kind of low-viscosity capsule release agent and preparation method thereof

The invention discloses a low-viscosity capsule mold release agent and a preparation method thereof. The low-viscosity capsule mold release agent consists of the following components in parts by weight: 80-99 parts of white oil, 0.5-20 parts of soybean lecithin, 0.1-0.5 part of stearic acid and 0.5-16 parts of soybean oil. The viscosity of the mold release agent disclosed by the invention is 50-90mPa.s, the static friction coefficient is 0.15-0.45 and is only less than a half of that of a general capsule mold release agent, and the mold release agent is excellent in lubricating effect and relatively high in capsule product mold release rate. The preparation method of the low-viscosity capsule mold release agent disclosed by the invention has the advantages of simple and convenient process, short preparation period, high production efficiency and the like, and the produced mold release agent has the advantages of small surface tensile force, wide oil film distribution area, less dosage, uniform coating and the like, and is easy to realize low-cost large-scale production.

Owner:JIANGSU LEFAN CAPSULE

Sealing assembly and sealing ring therein

ActiveCN109424746BImpact on test resultsReliable detectionEngine sealsMachine sealing rings testingMechanical componentsMechanical engineering

The invention relates to a sealing assembly comprising: a sealing ring (1) with at least one sealing lip (2) subjected to dynamic loads; a mechanical part (3) to be sealed with a surface (4) to be sealed, said The sealing surface is electrically conductive and is tightly surrounded by the sealing lip (2) with radial pretension, wherein the sealing ring (1) has a core (5) of electrically conductive material (6) and an electrical a cladding (7) of insulating material (8) having a material thickness (9, 10, 11), at least partially surrounding the core (5) and including said sealing lip; and a wear detector ( 12) The wear detector comprises an electrical measuring device (13) for detecting the wear condition of the sealing ring, wherein, viewed in section, the material thickness (9) of the sealing lip along the radial direction (14) is smaller than that of the packing The material thickness of the rest of the layer (10, 11). The invention also relates to a sealing ring.

Owner:CARL FREUDENBERG KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com