Combination of oil preparation of spun fabric cord

A composition and cord technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of poor adhesion between cord fabric and tire, poor compatibility between oil agent and latex, high degree of tar formation, etc., and achieve adhesion performance Excellent, low strength loss, low waste silk rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

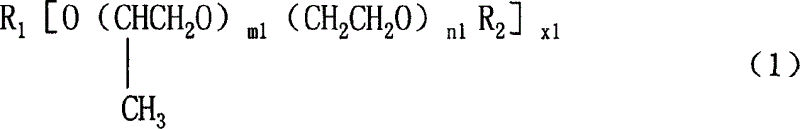

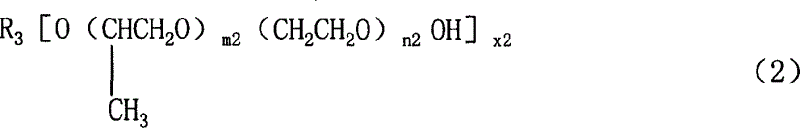

[0028] Get successively 15 gram pentaerythritol tetralaurates, 49 gram polyether A (m1=75, n1=75, R 1 for C 8 straight-chain alkyl, x1=1, R 2 for C 18 straight chain alkyl), 25 grams of polyether B (m2=165, n2=55, R 3 for C 8 straight chain alkyl, x2=1), 5 grams of dodecyl phosphate potassium salt, 3 grams of dodecylamine polyoxyethylene ether, 2.9 grams of butylphenol, 0.1 grams of simethicone in 500ml In the reactor, heat to 80°C, stir for 30 minutes, and then cool to 30°C while stirring.

Embodiment 2

[0030] Get successively 25 gram pentaerythritol tetrastearates, 32 gram polyether A (m1=75, n1=75, R 1 for C 8 straight-chain alkyl, x1=1, R 2 for C 18 straight-chain alkyl), 35 grams of polyether B (m2=165, n2=55, R 3 for C 6 straight chain alkyl, x2=1), 3 grams of dodecyl phosphate potassium salt, 2 grams of dodecylamine polyoxyethylene ether, 2.8 grams of butylphenol, 0.2 grams of simethicone in 500ml reaction In a container, heat to 100°C, stir for 40 minutes, and then cool to 30°C under stirring.

Embodiment 3

[0032] Get successively 56 gram pentaerythritol tetrastearates, 65 gram polyether A (m1=75, n1=75, R 1 for C 8 straight-chain alkyl, x1=1, R 2 for C 18 straight-chain alkyl), 63 grams of polyether B (m2=165, n2=55, R 3 for C 8 straight-chain alkyl, x2=1), 8 grams of dodecyl phosphate potassium salt, 3 grams of dodecylamine polyoxyethylene ether, 4.7 grams of butylphenol, and 0.3 grams of simethicone in 500ml of reaction In a container, heat to 120°C, stir for 40 minutes, and then cool to 25°C under stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com