Polyethylene film for plastic composite flexible packaging and blow molding method thereof

A polyethylene film and flexible packaging technology, which is applied in the field of polymer packaging materials, can solve the problems affecting the labor efficiency of downstream enterprises, poor opening, and affecting aesthetics, etc., achieve excellent heat sealing performance against inclusions, reduce energy consumption, and improve The effect of labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The raw materials and weight percentages of the inner film are: LDPE 59.48%, LLDPE 19.83%, mLLDPE 19.83%, smooth opening agent 4‰, and mold release agent 4.8‰;

[0045] The raw materials of the middle layer film and their weight percentages are: LDPE 59.71%, LLDPE 39.81%, and release agent 4.8‰;

[0046] The raw materials of the outer film and their weight percentages are: LDPE 59.71%, LLDPE 39.81%, and release agent 4.8‰;

[0047] Pour the ingredients of the inner, middle and outer layers into the mixer for each layer, stir for 5 minutes, mix the ingredients evenly, and send them to the hopper; add the evenly mixed raw materials to the temperature that has been heated to the set value and kept for 4 hours Inside the extruder; turn on the main fan, the upper traction roller, the lower traction roller, and the equipment for the film blowing process in turn; after the extruder and die are added, heated to the set value and kept for 4 hours, turn on in turn The main fan, upper t...

Embodiment 2

[0049] The raw materials of the inner layer and their weight percentages are: LDPE 39.65%, LLDPE 39.65%, mLLDPE 19.83%, smooth opening agent 4‰, and mold release agent 4.8‰;

[0050] The raw materials of the middle layer and their weight percentages are: LDPE 39.81%, LLDPE 59.71%, and release agent 4.8‰;

[0051] The raw materials of the outer layer and their weight percentages are: LDPE 29.86%, LLDPE 49.76%, mLLDPE 19.9%, and mold release agent 4.8‰;

[0052] The blow molding method of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0054] The raw materials of the inner layer and their weight percentages are: LDPE7.93%, LLDPE67.40%, mLLDPE23.79%, smooth opening agent 4‰, mold release agent 4.8‰;

[0055] The raw materials of the middle layer and their weight percentages are: LDPE7.96%, LLDPE67.68%, mLLDPE23.88%, release agent 4.8‰

[0056] The raw materials of the outer layer and their weight percentages are: LDPE7.96%, LLDPE67.68%, mLLDPE23.88%, and mold release agent 4.8‰;

[0057] The blow molding method of this embodiment is the same as that of Embodiment 1.

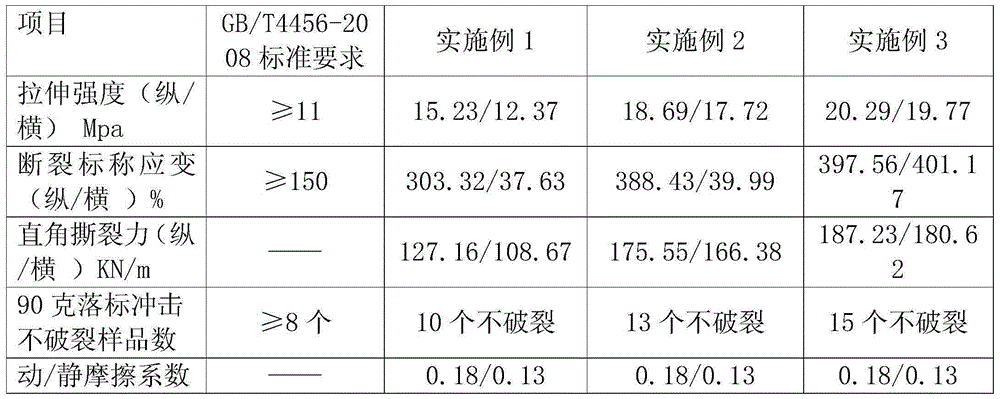

[0058] The polyethylene film for plastic composite flexible packaging prepared with the formulas of the above three embodiments was used for mechanical experiments. The relevant mechanical test data are shown in the following table:

[0059]

[0060] It can be seen from the above table that the tensile strength, nominal strain at break, right-angle tearing force, falling impact impact and other physical and mechanical properties and friction coefficient p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com