Preparation process of machine washable spun silk

A preparation process and technology of spun silk, which is applied in the field of preparation process of machine-washable spun silk, can solve the problems of unusable washing machine, easy fluffing on the surface, poor friction resistance, etc., and achieve the reduction of static friction coefficient, improvement of fluff resistance, expansion of development and Applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

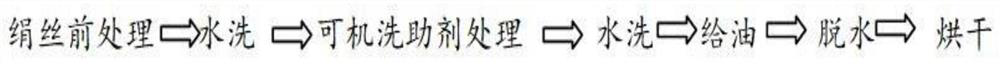

Method used

Image

Examples

Embodiment 1

[0021] Take the treatment of 5 kg of silk as an example, 5 kg of silk needs to be added with 100 kg of demineralized water, and 100 kg of demineralized water is equal to 100L.

[0022] The invention discloses a preparation process of machine-washable spun silk, which comprises the following steps: the first step, spun silk pretreatment; including hanging the spun silk on the hanging rod of the skein dyeing machine, and then adding the spun silk to the water tank of the skein dyeing machine 100kg of demineralized water, 50g of penetration enhancer, 200g of lubricant, 100g of soda ash, mix and stir evenly, then adjust the temperature of the water tank of the hank dyeing machine to 100 degrees Celsius, after the completion, turn on the pump, and the liquid in the water tank of the hank dyeing machine It is drawn out by the pump from multiple round holes on the hanging rod and penetrates into the inside of the silk. After 20 minutes, turn off the pump and drain the liquid in the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com