Polyester terphthalate-sebate resin and preparation method thereof

A technology of polyterephthalate and phthalate, applied in the field of polymer synthesis, can solve the problems of unfavorable development of food packaging films, and achieve low static friction coefficient, high light transmittance, good transparency and The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

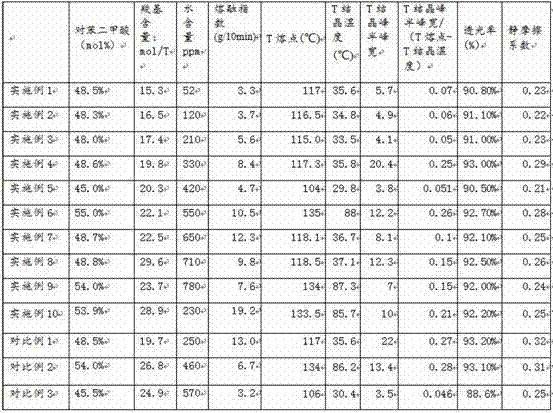

Examples

Embodiment 1

[0026] Example 1: The quality of sebacic acid is 2616.5g, the quality of 1,4-butanediol is 3395.8g, the quality of terephthalic acid is 2024.0g, the quality of tetrakis (2-ethylhexyl) titanate is 6.0g.

Embodiment 2

[0027] Example 2: The quality of sebacic acid is 2625.9g, the quality of 1,4-butanediol is 3394.7g, the quality of terephthalic acid is 2015.1g, and the quality of tetrakis (2-ethylhexyl) titanate is 6.0g.

Embodiment 3

[0028] Example 3: The quality of sebacic acid is 2639.9g, the quality of 1,4-butanediol is 3393.2g, the quality of terephthalic acid is 2001.6g, and the quality of tetrakis (2-ethylhexyl) titanate is 6.0g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com